Buying good tools cheap #2 – The combination square

For more information on the square, see our beginner site Common Woodworking.

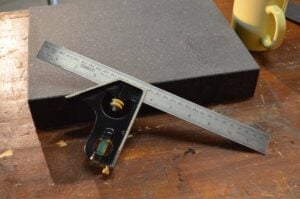

The engineer’s combination square

Today I begin with talking about my square. I have more than one for practical reasons, but the one I reach for the most is a standard engineer’s combination square. As the name implies, this tools was designed for the high demands of the engineer.You will likely add more types and sizes as you grow your collection so patiently wait for them and buy at the right price.

My old Rabone combination square

I have owned a Rabone since I was around 15 years old. Almost fifty years. It was indeed the first square that I ever bought or owned. I also own a large roofing square for the occasional need on say sheet goods like plywood and laying out projects on story boards.

I buy the traditional squares, the ones with wood and metal (brass) stocks and wide, flat plates too, if I see them and also good ones like this Rabone square made in the 1940-50s, because they are useful too.

Convenient to hold

The main advantage of the combination square for woodworkers over many others is that it’s a one size fits all hands which gives the convenience of holding the square against the workpiece without overextending the hand. The holes in the stock casting allow for excellent grip, an essential ingredient for small-handed people and convenient for all.

Accurate squares

It stands to reason that the square must be exactly what its name says, dead square. There can be no compromise on the accuracy of a square and so you must pursue this ruthlessly if you want fine and accurate work. Any compromise here will telegraph throughout your work and make it impossible for you to produce the impeccable standards you must strive for in joinery and so on. You can read more on this in an earlier blogpost and if you are looking to restore one you have or find here is another blog.

Cheap square may not be so cheap

In my experience, low cost alluminium squares are surprisingly accurate when you first buy them. In a matter of a few days of constant use at the bench however, they can and do go out of square. At first this is not so evident and you find yourself working without realising the shoulder lines of joints are not lining up all the way around. The problem worsens and then you discover several areas where your work has been compromised with inaccuracies. Alluminium squares are also quite lightweight, too light in weight actually. Here I like the extra weight of cast iron for the stock. Cast iron wears well and adds the extra weight and heft I like. It feels balanced in the hand too.

Our everyday squares

We have used new squares at the school in the UK for three years. We use a Stanley Rabone square that has a cast iron stock and hardened steel beam. Their reference number is: Stanley Rabone Combination Square 12″ – 300mm Professional Cast Iron 0-46-151. This one I bought brand new online on eBay for £12.99 plus £1.50 shipping. There are many other suppliers selling for under the £20 mark but many selling at regular retail, which is still good value for money at £28.

In our USA New Legacy New York school we went with the Sears Craftsman 12” square. Sears offers a no-nonsense lifetime warranty on all of their hand tools regardless of how damage occurs and have done so for decades. It makes sense to use their squares, which though aluminum stocks, are heavier stock than average and so have extra weight. These are fairly new to the school, but we have needed to return only one and that was a manufacturing failure and not through deterioration or use.

Problems buying secondhand on eBay

Issues are wear mostly. The beam can be worn on the corners and this isn’t good because we use the knife and pencil so much along the beam and this can compromise our crisp clean edges.

The best squares

I think Starrett combination squares are the very best made. For the quality and engineering standards they tick every box. Price wise they represent good value for money, but they are more expensive at three to five times the price of all others.

In closing

This combination square expands the functionality of the tool from the simple square of conventional try squares to include forty-five degree capabiity for marking and cutting as well as test checks for both square and angle. This then at least doubles the value and purpose of the tool. The sliding beam (blade or plate) makes the tool versatile too in that you can slide the beam to suit specific applications.

My now old Rabone square mentioned above did cost me a week’s wages. A hefty price back then. But having used the craftsman’s I worked under for several months the time came when I saw the need to buy my own and I then saw the absolute need for accuracy. Back then there were cheap alternatives but they were so bad no one would buy them so that made my choice a simple thing. My general advise on this particular tool is that you buy the best you can. The less expensive ones may not last as long but they must not only last, they must retain

I never really trusted combination squares and mine’s nothing special, probably bought it at Canadian Tire about 40 years ago. Yet it has held its “squareness”, better than a couple of try squares – so it’s the one I reach for.

Would love to have a Starrett – just for the feel of the superb machining and finish.

– Miles

I have starrett for sale for cheap.

I wholeheartedly agree. A good square is vital to success. If you’ve got the money, I would suggest plopping down the US$80 or so for a new Starrett combo square.

If you don’t, then I’ve had success at garage sales–picked up a vintage starrett rule and protractor for $2.00 and at a flea market–picked up a vintage Union Tool company combination square for US$9.50–and I REALLY use this one a lot. I also purchased a steel 4″ machinists square from Lee Valley, which I also use a lot.

I’ve bought the vintage wooden/brass squares because they’re beautiful, but had to rehab them to true the edges. Not a good record, and unless you’re prepared to do this (it’s not hard) I wouldn’t bother.

Paul is also correct about buying used sight unseen. You’re better off rolling the dice at your local casino. I just won’t do it.

Thanks Brad,

I think that Starretts might be more readily found secondhand stateside than here in the UK.

I recently purchased a 12″ starrett with centering heads for $25 from http://www.brasscityrecords.com, the guy who runs the shop is great and you never have to worry about surprises. I think he ships internationally too.

Since this comments section is relatively timeless, I thought I’d note that, unfortunately, Walt has closed Brass City Records and Old Tools.

I just got my WWII era Starrett combination square from Ebay. That’s not just a tool, it’s a piece of ART. It’s almost intimidating to take it out to my work area as it seems to be setting a pretty high bar for my work to meet.

Thanks for the recommendation.

I just took delivery of one of the ‘Stanley Rabone Combination Square 12″ – 300mm Professional Cast Iron 0-46-151’ mentioned in this blog. I managed to get hold of it for £16 including delivery so was pretty pleased with the deal I got (just used Amazon). I’ve been pleasantly surprised at just how good this tool is. It has a nice weight to it and the markings on the rule are really easy to read (I’m nearly 48 and now have to wear varifocal specs so this was really important to me). Best of all though it came out of the box 100% dead square – I’ve never had that from a combo square before. It’s a joy to use. I’m really glad I got one.

I just bought a starrett combination square and I want to keep it safe apart from using it at work. How do you keep your square safe? Perhaps is there a nice little box or something like that? I often read that a drop on the floor isn’t good for the accuracy.

Why don’t you make a box for it? Not rocket science – ply and glue, thin foan interior optional. 🙂

I’d love to see a few more of your thoughts here Paul. Looking at the Starrett assortment of squares presents significantly more options than I expected to see. What length do you suggest for the bar? What about the options for the center head and the protractor? Are they at all worth having? And what about the graduations?

Tim, I can’t speak for Paul, but am willing to offer my experience. First buy a 12″ square. If you take care to plane your stock square on 4 sides, the “12 can be pressed into service on any stock 0″- 21″ wide by marking from both edges. Just be sure your edges are parrallel. It can also be used on edges that are less than 3/4″ if you’re careful. 12″ is the best all-around size for most work. For what I would expect is a rare case when you will have something larger than 21″ in width, this can be initially marked with a 12″ square and a longer straight edge can be used to continue the line. Depending on whether you do large furniture routinely, a 12″ is all you really NEED. Having said that, I find my 4″ double square and 6″ combo square great for marking edges and miters on small workpieces, but to be sure, this is pure convenience. Someone on a budget is much better served buying 1 high-quality 12″ square than various sizes of lesser quality. It’s often said that the square is THE most important tool for a woodworker and I emphatically agree. Even a great craftsman can have work ruined by a poor square. I echo that Starrett is the absolute best if you can find one that fits your budget. Even a full priced Starrett is well worth the money IMHO. Another source I have used often is the $24 12” squares from Harry Epstein. He sells squares that have minor blemishes, but which are otherwise very well made from thick steel and cast iron heads ala Starrett. They have deeply-etched markings rather than printed markings. He has metric, 4R (which have imperial markings in 64ths, 32nds, 16ths, and 8ths), and 16R (which have a combination of the above and 10ths and 100ths). Depending on whether you use metric or imperial, I recommend either the metric or 4R unless you already work in 100ths. In my experience, 100ths are not typically used by woodworkers except for some engineers. On his site, you can search for “combination squares” and find them. Just be careful to get the 12″ one that is about $24 and that has the right measurement scales for your methods. The others below this price point look too cheap to be a smart investment. I have 4 of these squares 4″ double, 6″ combination, 12″ combination, and 18″ combination” and they have remained accurate for years alongside my Starrett’s. Having this many is a true luxury and I use them when teaching. Also, I would choose a Starrett if my budget allowed, but I didn’t have another $400 to spend on extra squares. I hope this helps.

Just ordered a PEC 4R combination square from Harry Epstein. Thanks for the tip DJ!

You can also get the PEC (Precision Engineering) “blemish” combo squares from Taylor Tools on ebay for about the same total price as Harry Epstein w/shipping. The PEC trademark is removed just as they are from Epstein. It’s interesting that Taylor Tools, Harry Epstein and Precision Engineering are all located in the same area which probably explains the sourcing for these “blemished” tools. These are definitely quality tools! The weight alone is impressive and the SS blades are hardened and satin finished (Made in USA). Accuracy (straightness and angle) is .001 over 6″ or .002 over 12″ which is about as good as can be had for an adjustable square. The Starret 12″ squares now go for well over $100, PEC (Precision Engineering) branded go for about $80-$85 and the PEC blemishes go for about $32 delivered so they are a heck of a good buy. Parts for PEC squares are readily available just as they are for Starret. As you can tell I am impressed with mine.

I was wondering if anyone knew of an accurate square that had cm / mm instead of inches?

Starrett?

It seems the ones I was looking at were from the USA.

Have found this one on amazon https://www.amazon.co.uk/Starrett-33MH-300-Graduated-Adjustable-Square/dp/B003XU795I/ref=sr_1_6?ie=UTF8&qid=1464035541&sr=8-6&keywords=starrett+square (apologies for the link) Would it need some tinkering to get it square or should I expect it to come true?

Thanks 🙂

sorry for my questioning but what do the letters mean with regards to starrett combination squares? For example what is the difference between the Starrett C33MEH-300 300 mm and the Starrett 33MH-300.

In October 2014 I bought a cheap Faithfull Combination Square 150mm/6 inch.

Actually the little notch of the adjustment screw running in the groove of the beam snapped off last week. That’s what you get for little money when you’re poor. It looked nice and shiny all in brass but in fact the groove of the beam is 2,6 mm wide while the notch had only 1,8 mm. So it wore off in no time. They could have left a little more material ! (What makes thinking and goodwill so difficult ?)

What I wanted to say, dear Paul, is that thanks to your teaching I feel confident enough to repair my tools at any time now. This one took me half an hour with a 6 mm bolt a metal saw and a file. Everything’s square and working fine again.

Kind regards to you and the whole crew!

I literally bought a new combination square a couple days ago.Before finding this blog and reading this article of course. I bought a Pittsburgh square because I couldn’t read the measures on my hand me down combo square. I’ll need to check but I’m pretty sure it’s cast iron. It was the second hand tools I bought after my chisels and sandpaper to sharpen them. Thanks for the advice. First chance I get, I’m getting a Starrett.

As a retired engineering pattern maker I bought a starret combination set in1946 as an app I have two sentre finders the set is in good condition after 70 years I would like too sell would I get a fair price all what you have said about it is correct

Yes, I think you would. Give a little history on ebay and people will bid.

heyho folks!

Since it was recommended here, I just got my new stanley combination square today, but unfortunately it is NOT square at all… deviating by half a mm on a length if 20 cm… the main body is not quite 90degrees… more 89.somerhing…

too bad…I guess it is useless this way… dors anybody know a good way to make it square ?

thanks for any help 🙂

cheers!

Patrick

Stanley recently changed its manufacturing to China. Check the package and let me know.

this one is indeed made in China (printed on the square itself)

maybe quality control is not 100% and I had bad luck and got a bad out of many good ones… the question is if I can fix that? 🙂 have a great day!! Patrick

I recently bought a Stanley combination square, ( the yellow one) from Screwfix at £9.99. Knowing Stanley’s good reputation for planes I had high hopes that it would be true and enable me to test flatness, mark square and 45 degree angles. No such luck! Using the rule part I drew a line then flipped it over to compare with the drawn line. It was 2mm out in the centre! It’s going back for refund. Very disappointing from Stanley.

Great blog, Paul. I much appreciate all the knowledge you are sharing with us. My super sharp planes are now a dream to use!

Nigel, I’ve tried a number of different squares and have a collection of Stanley’s and other brands (mass produced, big-box store quality) I’ve purchased over the years, and all of them are off at least a little. A while ago I took a deep breath and bought the Starrett 11H-12-4R and I am totally pleased with it. Dead on accurate and solidly built.

To: DJ King on 23 September 2015 at 6:52 pm said check out Harry Epstein’s tools. Thanks DJ. I did it and purchased a decent sqaure from them.

JohnnyB

another great source for cheap combination squares is taylor toolworks on ebay. they sell “cosmetic second” slightly blemished squares from PEC, who seem to manufacture squares for several other high end brands. I got a 12″ 4R set with ruler, standard head, center head, and protractor head for about $66. The intended brand has been scratched off, but I can tell that it would have said Mitutoyo.

The blemishes that made it unsellable at full price are 1 or 2 barely perceptible pits from the casting that would never affect the functionality, and could easily be filled in if i cared. a fantastic bargain on a great tool. I also picked up a 4″ double square from them which i’m similarly pleased with.

a few people have commented on buying combo squares that were slightly out of square. this is easy to remedy, and they seem to be designed with a feature that enables adjustment. in each of the heads, the slot that the ruler nests in has a raised ridge (or possible smaller raised “islands” of metal on cheaper squares). the adjustment screw pulls the ruler against this ridge, and that is what registers it. to adjust the angle of the square, simply shave down the ridge very slightly one side or the other (depending on which way the square is out of alignment). the simplest way to do this is to just run the corner of the hardened steel ruler itself along the ridge, which is made of softer iron or (cringe) aluminum. you can also use a needle file or fine sandpaper wrapped around a ruler edge or some other backing. a little adjustment goes a long way so go gently and test it again. repeat if needed. this will very easily and casually square up your tool in a few passes. it is easy to fine instructions for this on youtube too.

I’ve purchased 3 PEC combo squares from eBay all cosmetic blemishes and there all nice and square. There solid heavy squares and are guaranteed to the same standards as starret

Just taken delivery of the Stanley Rabone above but it’s a long way off square. Made in China – you would think Stanley would have a better grip on their quality control. They state “Class 1 accuracy”??! I’ll attempt to adjust it myself…

Likewise, a few months ago I bought the Stanley Rabone recommended here on eBay and it’s way out of square. Nearly 2mm out at full length of the rule. Wish I had taken the time to read the comments, 35 euros that could’ve gotten me halfway to the economy Starrett.

O don’t know why you were out of pocket at all, you just let ebay know it was not fit for purpose and they take up the case with the seller.

Hi Paul, unfortunately I used it for a couple months before realizing it was so out of square (beginner here), so my recourse to return is limited, I think.

I’m going to try and modify it as per one of the comments here. It seems there are couple little steel nubs in the groove of the cast part on either side that are likely ground at manufacturing to adjust squareness. If I can tweak the relative levels of these nubs I may be able to salvage it, will report back when I try.

Well this seems to have done the trick. Only removed a tiny amount from one side and it is now reasonably square. Not “dead square” as some might say, but as square as I’m able to verify for now, which was by drawing lines from either side of the square referenced to a factory edge of a plywood sheet. I also cut a knife line all the way around a small S4S machined board (27x37mm) and it came out perfectly, where before it was 1mm out.

Here’s a photo showing the two nubs inside the groove that I sanded for anyone else with this problem.

https://imgur.com/a/ajwSh82

Not sure why my previous reply didn’t nest correctly. Oops.

Hi, constantly i used to check blog posts here in the

early hours in the daylight, since i enjoy to learn more

and more.