Poor man-s Dog for Dog-loving Woodworkers

Benchtop insertion dogs

Round or dowel dogs work best in the bench top if you insist on having dogs at all. Metal dogs tend to mar the wood, especially on softer woods, so wooden dowels absorb some of the pressure and reduce this risk.

I made some dogs at the show because I felt that I needed to balance out my anti-dog opinions. First of all I found a piece of dowel slightly under the 3/4” auger bit I used for boring the holes in the benchtop.

Here are the steps:

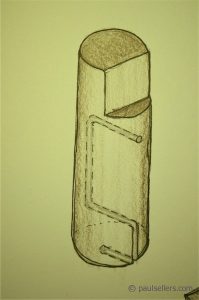

Measure down 18mm (3/4”) from the end. Cut the dowel to 75mm (3”) long and square across.

Saw down from the end to the 18mm (3/4”) depth line about 1/3rd the way in from the outer face of the dowel.

Saw into the dowel on the 18mm (3/4”) line to remove the section.

Pare down the face to smooth the face and remove the saw kerf marks.

Bore a 2mm (1/16”) dia hole 90-degrees to the sawn face you just created and 1/2” from the bottom edge of the dowel.

Draw a line from the hole to the bottom edge of the dowel…

….and onto the end.

Using the same 2mm (1/16”) drill and also using a block of wood, drill from the ned toward the other hole to form a channel that will receive the wire spring we are making.

Run a pencil line on the opposite side of the dowel in line with the hole.

Use a saw to cut a channel along the dowel the depth of the thickness of the wire.

Drill a second hole through the dowel about 12mm (1/2”) from the recessed section of the dowel.

Bend a piece of wire (I used a found surveyor’s flag a marker) to 90-degrees.

Slide it into the hole and sit the pliers against the end of the dowel to get the position of the second bend.

Withdraw the wire and, using a second pair of pliers, bend the second bend as shown.

Cut off the excess, leaving about 10mm (3/8”).

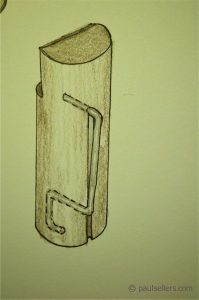

This how it should look now.

Slide the wire back in place…

…press the wire into the groove and press home with pliers.

Bend the wire on the opposite side along the groove toward the top of the dog.

Cut the wire about 1/2” longer than the second hole height.

Bend the wire in line with the hole at 90-degrees.

Press the wire into the hole.

Use pliers to seat, but leave spring in the wire so that the wire springs out at the knuckle you just bent.

Press into the bench dog hole.

Lower to just below the bench surface.

Clamp boards when needed.

Never thought of that one, thanks Jim. A lot less work.

Now I’m intrigued… any idea what the original comment said (as it doesn’t show up now?) I like the sound of less work!