Plane Retrofits Improve Design and Comfort

Stanley too has a minor flaw in that on their #4 planes they have no set screw to the fore part of the tote. This means that the tote can slip and the screw often loosens as a result. I add a piece of silicone shelf liner between the tote and the cast iron sole, which totally resolves the screw from coming loose

The trick with the shelf liner is really neat. I think I have to try that. I have a No 4 at home that has the same problem.

Thanks for the solution

Brgds

Jonas

Paul, try a small fiber washer just under the brass nut to take up the slack, works really well. BTW thanks for sharing your insights and knowledge. You are an inspiration.

The problem with the Veritas small router plane is well known as the cutter rotates if you push the plane hard at an angle while the Lie-Nielsen’s (with a square shank) does not have that problem. However, this is the first time I heard of a tightening problem with the large Veritas plane (square shank cutters), a problem I never experience. My large router plane from Veritas has worked fine without any concerns all these years.

Simon

I’ve seen the main problem has been pulling the blade downwards and further out from the plane. Especially was this so in hardwoods such as oak. You may not have a problem if you have strong hands, but many woodworkers not working with their hands and or with smaller hands do have this problem. Now it’s solved. The same is true of the depth stop on the plow plane and the fence on the same. I’m working on one for this too.

Thanks, Paul, for clarifying that. I also heard people complain about the fence on the plow plane, though I have had problem with that either. I did rough up the posts a little bit with coarse sandpaper. I am sure your modified knob approach will work for the plow planes for those who have experienced that problem. Thanks for sharing your solution.

Simon

Re twisting cutter. I resolved this by filing a flat on the round cutter bar and now there is no twisting from task.

“I can’t manufacture that but innovators could.”

Instead Paul, you innovated an elegant solution that is easily repeatable (manufacture-able) by anyone with the materials and tools they have at hand. Particularly innovative to me was using a piece of wood with a kerf in it as a guide, something which I would not have considered.

I’ve had this problem on an inerited #4 plane, and couldn’t figue out why. Thanks for the tip.

I too have a loose handle on my #4…. drives me bananas. I’ve tried everything to fix it…. except shelf liner. Huzzah!

Paul …….. Thanks for the tip I have the same problem with a couple of my #4’s so this will get fixed very shortly. Another great tip on the knurled knob, I don’t have either one of those tools but have been considering them in the future.

I do how ever have Veritas small router where the blade does twist and I did grind a falt in it after I tried roughing up with course sandpaper which did not help. Mr. Robin Lee also mentioned a few weeks ago on one of the Wood Working forums they were coming out with collar stops for the small router which I am anxiously waiting for.

Have you tried talking to Mr. Robin Lee he seems very responsive when questions are asked on the Forum when something about Lee Valley come up.

Steve

Paul, I heard a presenter at a woodworking say he broke the brass screw mechanism on a veritas plough trying to get it tight. Sounds like they really need to rethink it.

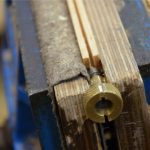

I have never heard of that and I am surprised because Veritas tools are always well made.. After I made my keyway toggle I thought it might have been easier to drill 3mm (1/8) holes and use a tommy-bar approach using an appropriate allen wrench. I might try that on the plough plane.