Busy Past, Busy Future Too!

We are about done with the Shaker Deacon’s bench seat and so we are going to release the new series on picture frame making using methods unknown in the last 150 years or so. I mentioned them recently. We’ll use scratch stocks and moulding planes and other methods too. I am so glad we have been able to transition dome of the teaching to video because it saves so much of my writing time. Today we have been working through a series on replicating a table following methods we are unlocking by dismantling the past in the piece itself piece by piece.

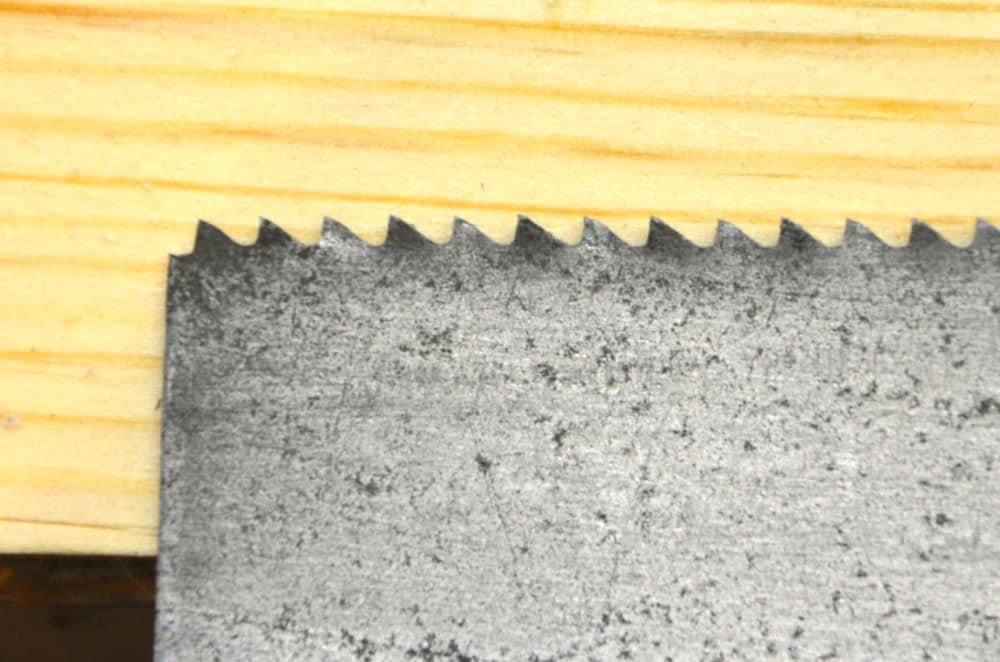

A lot of what we do in woodworking masterclasses is very unique to us. I am glad for this because that’s what is making our training so unique and refreshing to do. I often think that you might think everything I teach is old stuff I learned as an apprentice and whereas there is a lot in that, much of what we are teaching is new and innovative too. We might take a 100 year old tenon saw and file off all the teeth. We have a brand new video we just worked on that shows how you, not just me, can remove the teeth of any traditional hand or tenon saw that has bad or wrongly sized teeth – and I mean file off every single one of them – and recut and file them sharp in only a few minutes.

The results are stunning and all you need is two or three small and inexpensive tools to do it. So looking forward to sharing this with everyone. Look out everyone with woodworking masterclasses for another new and free video you’ve never seen before. It was a blast to see this come together.

I often think I would prefer a firmer chisel for mortices, and re-reading your related post on chisel choices, i still have not decided, will have to find some to try I guess. Please keep on doing what you do, soaking it up like a sponge ! Its amazing we can take a100 year old tool and sharpen it on diamond dust bonded to metal plates.

I don’t think I have seen anything about building picture frames using hand methods anywhere. That makes it even more exciting to me.

“A good two hours work” ok maybe, if your a master craftsman, probably more like two week for me and the other members ,i for one appreciate being taught the ways you were taught as an apprentice after all it is the right way and with your innovative spin on things we are lucky enough to have the best of both worlds and we thank you for it .

Anxious for the picture frame series as well. I don’t own any moulding planes though will need to find some, somewhere.

Steve

Wow!

Paul.

First of all many thanks to you and John for taking the time to show me some of the good works that you are doing, I really enjoyed my visit.

Sorry about all the woodturning, I could come down and help!

Great idea the jig to make legs.

If you are going to make some London pattern handles it would be easy to make a jig given that all the octagonal sides are at 45 degrees.

Best Wishes

Fred Sutton.

Yeah, thats what well do for some of them at least. It will be good practice for John.

Best for now and thanks!

Awesome! I have a Disston 12″ hand saw with several chipped teeth. I’d love to learn how I can file it down and restore all the teeth back to good working order.