Saw files–lasting qualities

For more information on Saw Files, see our beginner site Common Woodworking.

I use saw and flat files of different types considerably because we have fifty student saws that need sharpening regularly and of course if a saw file barely sharpens a single saw nowadays that makes DIY saw sharpening prohibitively expensive. I bought three of Nicholson’s files two weeks ago to make sure they were still consistently bad and nothing’s changed. They are still made in Mexico not the USA and quality is still substandard. I only managed to get down two thirds of the length of a 22″ panel saw with 10 PPI before having to rotate to a fresh corner of the file to do the rest. They are £8 a pop here in the UK so that makes them three times the USA price for a 6” extra slim taper. Anyway, I did this to make sure I wasn’t misinforming you as to the the demise of quality in the Nicholson files and I am not. So my thoughts on files are that as far as a decent file goes I have found other makers of saw files for saw sharpening that work well and I have tested three types out that work well. Here `i want to talk about the Bahco saw files and also their flat files which I use for sharpening scrapers and topping saw teeth.

Here in the UK Workshop Heaven carries the fullest range of Bahco saw files and flat files. There are many US suppliers too

Understanding the dynamic of saw files is important and many file makers like Nicholson seem to have lost their way if not their moral obligation to the USA as a US company once providing good value, quality product. Losing their connection to past working knowledge of what their forefathers worked hard to establish is a sad thing because a good reputation is hard earned and second to none. Many distributors also isolate themselves from accountability via eBay and other online sales outlets. If they choose to be non accountable that’s up to them. I am sure many sales outlets actually like the fact that the Nicholson company producing inferior files instead of the superior ones they were once known for. Radically shortening the working life of their files means customers will return all the sooner as there is no longer a generation that understands that at one time a Nicholson saw file would sharpen a saw 30 times or thereabouts depending on the hardness of the steel in the saw plate being sharpened. Nowadays that has been reduced to possibly two or three but more likely one or two.

Six-sided files with six cutting faces

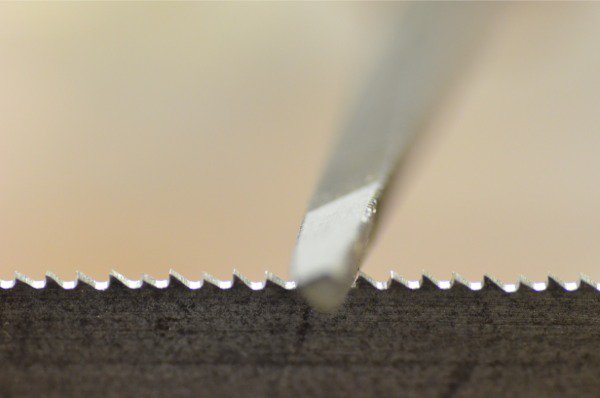

Putting the files under magnifying lens does help to see what’s happening at the cutting edge on the files and in the past I talked about there being six sides or facets to a triangular or three-sided saw file and not three as it seems — three large facets and three small or, actually, narrow ones at the corners. Without these as working edges the files would not work because the edge is too narrow and fragile to retain viable cutting edges. In other words you cannot just take the three flat faces and make a saw file that way. You must have six. These files are different than three-square or three-sided files used in engineering. Some of these files have what we call a safe edge; a corner that’s made specifically not to cut internal corners but cuts into the faces forming the internal corners for refinement of some kind.

File tooth profile of files

Files are made with a series traversing the face of the file with parallel teeth. Each of these teeth are formed with two bevels to them. One is the steep and deep cut that creates the main gullet by forming a vee groove across the working face of the file at a 60-65-degree angle. The second cut refines the back of each file tooth with a secondary bevel that then creates a back relief cut to first strengthen what would otherwise be a weak cutting edge and then provide a relief at the back of the cutting edge. Whereas the back bevel resolves one problem of a weak edge, it also creates it’s own problem if the back bevel is level with the long axis if the file. This back bevel of a few degrees allows the file to cut the steel without riding the work. Without this back relief the file would not work.

The problem I have found with many files is that the narrower edge forming the corner edge-fractures during use, often this happens on the first few strokes in the saw sharpening process because of the stress placed on so narrow an edge. A file is a high-demand piece of equipment. If the edge is too soft then it won’t cut and because it dulls or turns immediately. If on the other hand it’s too hard then it will edge fracture on the tips or the whole tooth will simply break away. Either way, the file is rendered useless for saw filing because the bottom of the gullet where the front and back of the teeth interconnect must also be filed and that’s the reason that the saw file facets are interconnected by the narrow flat face.

Inconsistent hardness is another problem affecting the files. This results in localised and intermittent fracturing along this narrow edge of the saw file too, which then causes difficulty through jerkiness in the strokes. Because you can’t necessarily see the narrow edge, you can’t understand why it’s happening and it’s this edge that Nicholson files are now best known for in terms of fracturing and breaking off of teeth. Occasionally, even on good files, a corner will have all the teeth fractured during manufacture and end up being sold. This is just hard luck for you, but usually the other two corners will be fine. On the Bahco files the corner teeth are usually clearly defined and well shaped with a good flat, chisel-type cut over the narrow width. Other files seem quite random and this means that the small corner can be less than useless.

I recently had to advise people not to buy the Bahco sliding bevel if they were looking for a tool that worked. The beam didn’t lock at all in the stock and slipped all over the place on the 20 or so I tried out. Bahco were quick to respond but offering me another sliding bevel didn’t resolve the issue for me. With their saw files however I have found them to be consistent through the years. Here are my choices for the four saw files I generally find take care of all my working needs for saw sharpening. I also have a couple of 10” single cut flat files for sharpening scrapers and topping (jointing) teeth and other metal working needs. I do like Bahco Oberg single cut files and I use a couple for my sharpening needs. As far as files go I do enjoy the Bahco files. Here are the ones I use most:

Saw Files

Bahco 4-187-07-2-0 — X Slim 175mm (7″)

Bahco 4-188-06-2-0 — XX Slim 150mm (6″)

Bahco 4-190-07-2-0 — XX Slim 150mm (6″) Double ended

Bahco 4-188-05-2-0 — XX Slim 125mm (5″)

Flat Files

Bahco Oberg 143-10-1-0 250mm (10″) Millsaw Bastard Single-cut flat file

Bahco Oberg 138-10-1-0 250mm (10″) Millsaw Single-cut flat file

Bahco Oberg 1-100-12-2-0 300mm (12″) Hand Hand Second-cut flat file

I am just starting to sharpen my own Saw’s so I have followed your advice and bought the bahco saw files.

Thanks for the recommendation Paul, and the list of the files you use. I’ve found when shopping for files that the description or listing tends to be inconsistent, and then I’m never sure what it is I’m thinking of buying. For instance, the Bahco Oberg 143-10-1-0 250mm (10″) Millsaw Bastard Single-cut flat file might just be listed as a Bahco Bastard 10″, and I can’t be sure that’s the one I’m aiming to get. It’s useful to have the numbers you give.

Incidentally, Axminster tools had a £1 delivery offer which attracted me to look at their saw files. They have the Nicholson ones, which I knew to avoid, but also Swiss Vallorbe Precision Swiss Saw Files. I bought a Double Extra Slim 125mm(5″) and a Slim 125mm(5″) for £3.76 each, plus postage plus VAT. I haven’t tried them yet – have you ever used that brand?

@momist: The ‘Oberg Cut’ is more a type of file than a particular cut. So you get a normal hand file with a ‘bastard’ cut and then an Oberg file with a ‘bastard’ cut. It’s always safe to refer to the Bahco catalogue to make sure you are referencing the correct part number.

Ah – never mind Paul. A quick search of your blog turned up this, referring to your post about Grobet in the USA:

26 October 2012 at 10:04 am

Stephan Nardone says:

This files are also known under the brand Vallorbe. They are both manufactured by the same company in Switzerland. http://www.vallorbe.com/Standard.php?p=500&m=4&l=3

I am hoping this company is holding the standard. We are testing out different file and rasp makers currently and will be posting on them soon and this includes Vallorbe/Grobet as we have heard conflicting reports since I blogged on them a couple of years ago.

Paul, I see the link to 18, October 2012 post on “Grobet answers this saw filer’s quest”

Your conclusion was “Love the Grobet saw file. Lets see how it does over the next year or so. That will be the real test.”

so it will be interesting to hear your 2015 opinion…

Mr. Sellers, I recently grew brave enough to sharpen my first saw – a Veritas dovetail saw – based on your videos. I used an appropriately sized Bahco file and the job went well.

However, my next sharpening job was to take a 26 inch, 8 PPI Disston D-8 (pre-1917) and file it rip. I was told by the ebay seller that it was a crosscut saw, and perhaps it was, but the previous sharpener had filed it pretty nearly as a rip. Because I wanted a rip saw anyway, I decided to go ahead and convert it over to rip. I again used a new, appropriately sized Bahco file, but on this job, the file edge was lost a number of edge teeth and was screeching horribly before I had finished one pass down the saw. I did notice that during the jointing filing it seemed to be hard to get flats on the teeth. Perhaps the teeth were very hard? Did I damage the file by being too aggressive? I’d sure appreciate some advice.

I have had this too with Disston saws in the past. Occasionally you can come across one where the teeth were not tempered at all or they were unevenly tempered, which results in teeth that snap during setting and damage to the files used. It’s not likely to be over aggressive filing. Also,most people selling saws on eBay state them to be crosscut saws for some reason. Most of them are not crosscut saws and most people selling them can’t tell if they are or not. Most of the carpenters and joiners I’ve met can’t tell the difference either so I am not surprised people just list them as crosscuts because most people are thinking crosscut not rip when they are looking for handsaw buyers.

Hi Paul,

my grandfather was a foreman in a steel mill and so I learned a little about steel.

Obviously the Nicholson saw files ran through a faulty annealing process. So the steel is still hard and briddle as glass. Perhaps it is worth trying to temper them at 250°C in the baking oven aiming on releasing the stresses in the crystal-structure.

I would be curious if that corrects the flaws of the Nicholson files.

Nevertheless it is a shame that Nicholson sells such bad quality.

Here in Germany I buy the saw files from fine-tools Dieter Schmid which are DICK files.

They work well and stay long. I also used some files from PFERD (translation = horse).

They stay long and cut well but they sell saw files as three sided files. The small side of the file isn’t clearly formed and therefore that side cuts but not as good as it could.

So thank you for another interesting blog. And let us know if you try to anneal those Nicholson

files in the oven. I think I am not the only one who would be curious about the results.

Best regards from Germany

Dominik

Yeah, BACHO is a real hard to quantify these days, some of their stuff is world class, and yet others are the typical crap found in most department stores now. As a Swede I have the great fortune to be able to find a lot of old tools from when Swedish steel made it’s name, E A Berg stuff that was bought up by BACHO in the 50-60 made some amazing chisels, planing irons and so on and there is a lot of great vintage BACHO stuff out there too..

Sadly, as many big companies the lure of selling cheap(ish) “crap” at inflated prices are making it’s way into their stuff also :(… So as a buyer you need to be aware, their files are still great, but I’m always looking to make sure that they are made in Portugal, as suddenly they will move it to china or some other place, and the quality will drop without any notice and of course no change in price 🙁

Sir;

I’m wondering if the newer Nicholson, files are simply using cheaper steel and have eliminated the de-scaling operation.

While I wouldn’t recommend this technique normally when using a file, I have had some luck with cheap files by running the edges over something soft like a chunk of brass first (then carding it clean,) setting the saw as low in the vise as possible and using a lighter stroke and even running a crayon across the face (to lubricate and cut down a bit of the chatter.) Again, usually one never lubricates a file but needs must sometimes.

CG

Under the magnifying lens the teeth are mostly gone, i.e fractured off.

Sir;

Sure, once the teeth are gone they’re gone. What I was getting at was with a new file -albeit cheap, or no I like to run them over a bit of brass a few strokes.

I’ve seen numerous toolmakers do this in shops. The explanation I always got was that this is the proper way to break in a file. With new files it seems to eliminate broken teeth and in the case of the cheapo files, cut down on broken teeth. Can’t tell you exactly why beyond vagaries about new teeth being so sharp they are brittle, etc. and I haven’t really studied it myself -sorry.

Bedding the work deeper is pretty much to cut down on chatter and the heaviness (or lightness,) of cut is more related to the temper of the workpiece. With a saw file, the angle is pretty much determined ahead of time, so you can’t find a sweet spot in the stroke -hence the faster wear. The crayon is just something I tried and found it seemed to work on saw teeth, but I’m still not convinced it’s a good idea.

I’m getting through my small files and so am following your posts on the subject closely as there are so many brands out there. Thank you for thinking to do it.

On a different note, I read you don’t use the paddle shaped auger files, but I kind of like them and they have really gotten hard to find and dear when you do. I guess a little diamond stick works on the scoring ears and a saw file on the chip lifter but the old style are just handy to me. Any suggestions for sourcing them on this side of the pond?

Thanks.

CG.

Dear all,

I found them auger files At Dieter Smid fine tools in Berlin may be this is helpfull, I don’t know from where you are but for Europe this might be helpfull. I am also going to use the brass infiling trick foe my Groblets. I found them till now not very lasting but of a better design then the Baco’s I once filed an old sanvik hardpoint saw succesfully with an old file this means a not so sharp file. A guy in the USA, George Dyson, always got his files from Boeing, there scrap yard. So it might be an good working method to break a file in with someting soft like alluminium or brass. Also Pauls retooting a saw with the start of with a junior hacksaw could prolong the live of your files.

Hi Master Sellers,

I did not know that Portugal makes, good, saw files.

Thanks for the review.

Yes, Portugal makes all of Bahco files and there is also Tome Feteira too. Great work comes from Portugal!!!

It is a shame that customers are increasingly victims of corporate greed fueled by a lack of pride in quality and a ready global access to manufacturing countries where labor costs are low and environmental restrictions are non-existent. Your blog is a valuable resource to all of us who want to circumvent this downward trend!

Hi Paul.

Could you tell us, for what kinds of saws use each file?.

Thank you and have a nice day.

“Twelve perfect files in every dozen”, that’s the Nicholson logo. Maybe, it should be their old logo, replaced by “make ’em a cheap as possible and live on your reputation”!

I don’t want Paul to see this, cause it would make him sick, but here’s the link for the “snow job” that Nicholson has put on youtube: https://www.youtube.com/watch?v=p7RruvJjCTU

It truly is a shame that businesses are looking for the quick buck, rather than building a tradition of quality. Take Schwinn Bicycles as an example. Long the standard of quality, the company finally couldn’t resist closing their American factory and putting their name on foreign made bicycles. They made the money but no longer have a quality product.

Another company, Aladdin Industries, did the same thing. I moved to Tennessee about 20 years ago and was delighted to see the Aladdin factory. As a kid I had an Aladdin metal lunch box, and over the road truckers swore by Aladdin’s stainless steel thermos. Within a year the company sold out. They couldn’t resist. An insulated thermos, the kind they sell with sports teams logos, could be made in China for 30 cents, instead of the $3.00 it would cost if they made them in the states. Many of the workers had worked for Aladdin their whole life, but the company didn’t owe them a job, and the owner wanted to retire (rich) and play with his grandchildren. Sadly, this scenario has been repeated, until there are only a few companies that have resisted the temptation.

Watched it and they couldn’t even use real working men to demo the product. Never saw a chain saw file look so pathetic. When I heard the macho-man voice I knew it would be downhill from there. They should be ashamed of themselves.

I have some old Swedish saws that covers from 5-10 tpi and a Veritas dovetail saw 14 tpi. Could I manage sharpening those using only two of those Bahco files you’ve mentioned, and which ones would that be? Or do I need several? It’s mos likely you’ve already explained this somewhere in this very informative blog, I couldn’t find it though.

Hello Jonas:

Bahco 4-187-07-2-0 — X Slim 175mm (7″) will do the 5-10 tpi

Bahco 4-190-07-2-0 — XX Slim 150mm (6″) Double ended will give you two files in one and take care of your 14 tpi.

Thank you!

Oh, one more question. The second file of the two has a “7” in its number and I believe that indicates the length in inches, whereas you write 6 inches. What is correct?

The 7 inch file will give you more use, so probably ignore the ‘six’ and replace it with ‘seven’.

They are two different files really, or should I say three. The six inch is two files in one as it has a file at each end.

This is a double ended saw file with a file at each end. The files are 3″ files each. The 7″ file has less teeth to the inch and is bigger across the flat faces.

What I really meant was that the “Bahco 4-190-07-2-0” is 7 inches, not 6 as you listed in your blog. There is one with the referens number “4-190-06-2-0” that is 6 inches, I just wonder if that’s the one you mean? The 7 inch version also claims to be double ended so do you think the lenght is the only difference or if there’s a difference in thickness too?

Both the six inch (4-190-06-2-0) and seven inch (4-190-07-2-0) are 6mm wide and have 24 teeth per cm. The eight inch *4-190-08-2-0) is wider, has less TPI and is obviously heavier.

Thank you Hilton!

Another smple question with a potentially difficult answer. The question is, “Was the drop in Nicholson file quality concurrent with moving production of the files overseas?” Your first post on this subject was after 2010, as far as I can tell.

The reason is simple: if a new old-stock (NOS) Nicholson file, one that was verifiably made then in the USA, is found, could a buyer reasonably hope that the file has the good, old-fashioned quality of yesteryear (I sound like a “Lone Ranger” voice-over to the radio and TV introductions)?

And, yes, I am old enough to have listened to the Lone Ranger on the radio. Somehow, his horse “Silver” looked so much bigger on the radio!

And if I find such a source of NOS (New-Old-Stock), I’ll let you know.

It was. Old stock made in the US was fine, made in Mexico showed the demise era started. I did test out new ones here in the UK to make certain standards were still diminished and they were.

For anyone with access to a Snap-On tool dealer, they have excellent files. The best part is they warranty them no questions asked when you wear them out. For $14 I have a lifetime of high quality saw files.

Interesting. Looking in the UK catalogue online, they do not have Saw Files listed. They do sell “Three Square” files in 10″ and 6″ lengths, which may be pressed into use for larger toothed saws, but no saw files.

Now that I have become more and more informed about saw files and associated tools, I am more and more confused. I di see “Snap-On” tool trucks out on the city streets making deliveries. Perhaps I’m going to wave one of these trucks down and ask the driver what he or she has on board.

How long does a decent saw file last? Do you have to keep buying them over and over?

It’s a good question. In my view a decent saw file should last about 30 sharpenings when it is a single stroke to each gullet to renew the edge. That means discerning the saw needs sharpening on time. In my experience, because people are intimidated by filing saws, people leave it too long, often until the saw binds in the cut or stops cutting.I have steered people away from companies like Nicholson in the past because their files were filing only one or even half a saw. At one time they too would touch up the teeth of 30 saws but when they decided to export their file making from the USA they lost the quality Nicholson was internationally famed for. I have enjoyed consistent quality from Tome Feteira in Portugal and you can order direct from them no matter where you are in the world. Bahco are good files too. Some of the mainland European makers seem to be unable to keep consistency of availability for some reason, or you don’t get choices so I don’t know any longer other than the two mentioned above whether I should recommend others.

Oh, I should have said too that if a saw has been neglected it can take its toll on the file used. Even so, a good file will restore several bad saws.

I’m very unlikely to guy a Nicholson saw file; they’ve been reviewed here sufficiently. Does this also go for other Nicholson files? For instance, if I have to joint a saw (and have a couple that could use it) common instructions call for an 8″ mill file.

A what? I boiled that down to 8″ of file face, single cut, flat, and don’t bother with a handle because there’s a jig or two to keep the angle consistent.

To the hardware store and there’s the file, under $10, made by Nicholson. Do I keep looking, because I think I have decent saw files to sharpen the teeth. This is only to joint them evenly, ranging from 4 1/5 tpi to 12 tpi.

Is the Nicholson no-no still applicable with this mill file?

‘Fraid it has been for me. Once they sold out to their USA loyaly and roots the robbed themselves of US loyalty in return. We none of us have to put up with it unless we want to. Sometimes we have no choice and if the same product was indeed being hecho en Mexico it would be fine to keep going there as few if any files are made stateside so there may well be no option as is the case here in the UK.

For those of us on the left side of the pond, I found Tome Feteira saw files sold by Anglo American Tools at http://shop.angloamericantools.com/c/files-rasps_taper-files. I have no experience with this seller, just sharing my information.

By the way, are all of you familiar with the site ResellerRatings.com? I urge any of you who buy online to contribute to it. Sadly, there is no mention of Anglo American on it.

Thanks!

Hi Paul,

After using a file I experienced the magic of it. Can just sit alone, use it and let the time flies. But still not sure about a fine rasp and a fine file. Can a #3 file replace a #3 rasp? And what’s the point of a #5 rasp?

Rasps and files are very much two different animals, Danny, and should never be confused. You can occasionally use them interchangeably on wood but rasps are NOT used on steel. Look closely at the faces of them and you will see just how different they are.

Thanks Paul. Was just thinking about wood when asking the question. Now it’s more clear. And just found that Bahco files are also available in Taiwan, can’t be happier. Have a nice day.

Hi Paul!

I recently followed your technique for recutting and filing saw teeth in order to make my own bow-saw blade (because I didn’t quite like the Gramercy blades or the bandsaw blades that I tried), and I tried a Nicholson file — I had heard that they were good again, and nolonger made in Mexico. When I got home, cut the notches for my teeth with my hacksaw, and then finally went to filing, I noticed that the file was warped near the tip. I tried it any way, and before I could get 1/3 of the way along, I had worn out all the faces of the file. I found an old saw file that I had bought years ago (as a kid, before I knew anything about woodworking or what the file was for — I just used it to file notches for crude bows that I made!) and I did the rest of the blade without any issues!

My saw, by the way, works great and out performs even my antique western rip saw, and my Ryoba when it comes to ripping! I mounted it on turning pins so that I could do long rips with it, because I didn’t have a rip saw that I really liked.

I do not understand why so many companies insist on making imitations — things that look like tools, but do not in fact function as tools. As a novice, I was almost entirely dissuaded from hand tools because I believed that those things on the shelf that look like a plane or a saw were, in fact, decent functioning tools, and not hunks of metal merely shaped to look like a tool and cause frustration to anyone who picks it up and actually tries to use it!

I have found that my best functioning tools are the ones that I make myself, and the ones that I find at flea markets or on ebay and restore. Your videos really encouraged me to do just these things, and I wanted to thank you for sharing your knowledge and pointing me in the right direction! My relationship with my tools has gone from one of frustration to one of joy and confidence, and has really changed my experience of woodworking. I feel bad for all of the young people like myself who have were turned off from hand tools because they bought something at a big box store, and that shaped their impression of a saw, plane, or chisel.

I won’t be buying another Nicholson file — I’ll be trying some of the saw files you’ve recommended in your blog in the future! And enjoying a sharp bow saw blade that I made myself!

Edit/Correction:

The blade that I tried and didn’t like was the Highland Woodworking one, not Gramercy, unless they make/sell the same thing. It’s the 1.5″, very thick blade that I think you used in one of your bow saw builds. It is good, but it was too thick, wide, and long for my purpose, which was to make a smaller all purpose saw. I went with a 1″ wide, thin (about 0.02″, definitely on the thin side, I know, but it’s tensioned so it works fine!) strip of 1075 spring steel. I wanted to go finer, but I cut my teeth at 9TPI as going smaller proved difficult for my very first go at recutting teeth. It’s still quite functional for joinery and dovetails, at least on stock 3/4″ and up, though! And I have to say, I like the thinness of the blade, but my next blades will be 0.025″ I think.

Watched your you tube video on sharpening scissors. You mentioned using a “3 corner saw file”. Is that the term you used? And where might I purchase one? I am totally new at trying to sharpen anything, but would love to be able to sharpen my scissors.

Thank you.

Actually, any fine file will work, triangular of just plain flat; even a nail file/board-can be abrasive card or the diamond type.

Just a quick note for my comment above ……”i have placed” not “plave”

Sorry Paul

Reply

Hello Paul,

Always grateful for your work and spread of knowledge.

I would be very interested to hear your reviews/comments on hardened files such as Pferd CORINOX series and the Pferd brand in general. I live off grid and I don’t always have access to new files so carrying the best quality possible with me is my highest priority.

Kind regards from Chile

Dear Paul,

I am buying the files you suggest and had a question about the 138-10-1-0. The product data said that one edge is round on this file – Is there a reason for that edge being round? Also, both the 143-10-1 and the 138-10-1 are bastard cut I believe so I’m wondering why the 138 series? Finally, the 104-10-2 is a 10″ single cut second cut so wouldn’t that be a good file to use for a little finer finish?

Thank You!

stephen

Newfoundland

Yow! Here I am getting ready to sharpen some saws, and I really don’t understand that post. What brand, scale, nomenclature are you using?

Hello Paul, thanks for the information provided, I’m following your process to restore my first Stanley plane. I was wondering what type of file you were using in the video to take off the edges? Will any file do, or should I look for a particular type of file. There are so many choices, bastard cut, single cut, second cut etc. Thank you and keep up the good work!

Hello. After looking up the flat files recommended i noticed the two 10” millsaw flat files are very alike. As far as i can tell they have very similar cut and length. They differ only in shape with one having a slight taper and the other one rounded edge. I was wondering if these were listed as more or less interchangeable general purpose files or if you actually use them for different tasks?

I think files seem to have their own dark side and can be hard to differentiate the differences. I have rarely found one to be different to another as far task appropriateness goes.

So what are some good to very good files one can purchase today a list as such as one might find online to purchase like Amazon.com or Ebay!