Paul Sellers palm gauge-cum-beading tool #3

OK, last one on the Paul Sellers palm gauge-cum-beading tool.

As a boy I was shown the screw in the block of wood method for making side beads quickly with no fuss and no tearout that can typically occur with moulding planes run against the grain. This method is highly efficient use of time and materials and I use it more than any other.

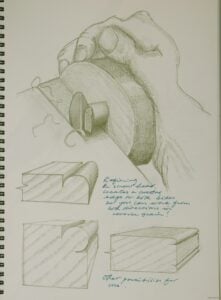

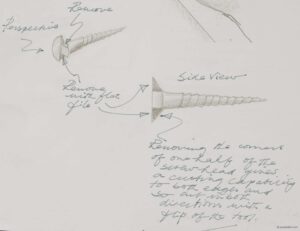

I use a regular slotted steel, countersunk screw…

… and refine the screw head a little as shown in the drawings and the picture.

There is too much to list here for the use of this tool and the use of beads like this, but this was one of the most used of all the beads and was used around cabinet drawers and doors to form a break-free edge. It was highly innovative and was used a lot in high-wear areas such as workshops, offices and kitchens in the 18-19th centuries.

All drawings are copyrighted from my Journal: A Woodworkers Journal by Paul Sellers and used with permission of Paul Sellers and the New Legacy Foundation

Great stuff. Thank you.

Very nice! I’m going to have to make a quick stack of these so I can leave them at different settings while working on a task. One for the left mortise walls, one for the rights, one for the bead, etc.

I love this idea. I tried makig a scratcher to to this but your idea is much better.

Paul,

I use the poor-man’s marking gauge with gusto, perhaps more often than my regular marking gauges, so when I read about the beading-tool variant I thought it was a great idea.

In practice however, I have not been able to obtain any proper results.

This problem I encounter when trying to make a cut with “half moon” of the refined screw head is that after half a stroke the screw head will rotate a quarter of a turn, and the bead I am trying to create is now uneven in depth but more worrisome not really straight, as the cutting surface of the screw is pulled a little bit towards/or away from the fence as a result of the rotation.

Do you have any comments or advice on how to solve this?

Cesar

Hi Paul, I was wondering if this tool will work in Hardwoods such as Birch and walnut as well as the softer Woods. Thanks, Roy

I have used it on hardwoods more than soft woods. Oak, ash cherry walnut and even cocobolo and birch is quite soft so yes!