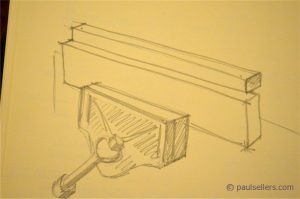

Saw rabbeting

Rabbeting without a rabbet plane – rebate UK

Someone wrote me and asked me if there was a way he could run a rebate to stock without a machine and special planes. There is a way I use quite often that works fine. It may take a couple of practice pieces but you soon get the hang of it. I will probably complicate what is really dead simple and practical, but here goes.

By way of introduction

As a boy there were after-construction retrofits on projects that sometimes needed a rebate, groove or inset along the length of a board in an existing, installed section of wood or indeed on the site work at someone’s house where a rebate was needed and no fancy routers then or we couldn’t make the mess in someones living room or we just needed a quick and effective way to do it. Sometimes a piece of wood is too short for a hand held router and so we continued as we always did with a hand saw or a chisel and mallet.

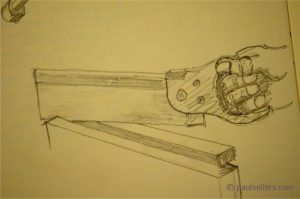

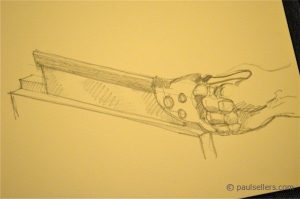

You can also superglue a second fence parallel to the first, with the saw in place to minimize slack, this minimizes slopping around if dead accuracy is essential.

Using a ripcut saw gets you there fastest and use a tooth count of fifteen or less. You can use a panel saw or a tenon saw. Both work equally well as long as not too long. No more than 22”.

Check this guy out, he is pretty amazing! 😉 especially around 4:17 and then again at 5:10 or so…. (actually the whole video is amazing but these times address the question.)

http://www.youtube.com/watch?v=vujxY99pprA

Paul,

This is very interesting. Would you use the same basic technique in cutting the sidewalls of a dado? Also, do you go over your saw cuts with a chisel to smooth things out or leave them as they are from the saw?

Thanks,

Josh