Superglue revives punky oak

With milling over 1,000 pieces for this month-long workshop I expected a lot of the usual waste, but, surprisingly, there was very little beyond the planer shavings and sawdust; perhaps much less than 5% and not the accepted 25% allowed for in most such milling.

This piece of white oak was really a piece of junk with some soft, spongy punky areas around the knot when I bandsawed the 3” wide section down the middle.

I did this to show my students exactly what book-matching was, but then I decided to glue up the piece and see how far I got and to redeem the work. I used super-thin superglue which soaks readily into the punky areas and also the many voids and fissures that typically occur around areas such as this. This is not new to me and I have done this for many years.

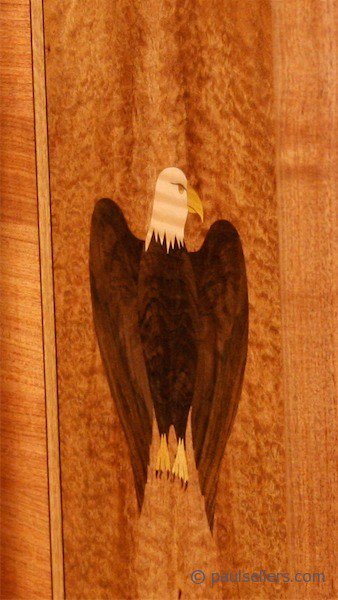

Here is a closer view of the crotch area and you can see how you can make various configured book matches with a little imagination and a mirror. The picture with the ebony dots are the segments of the clock face and I will have only a mechanism behind the wood to move the fingers.