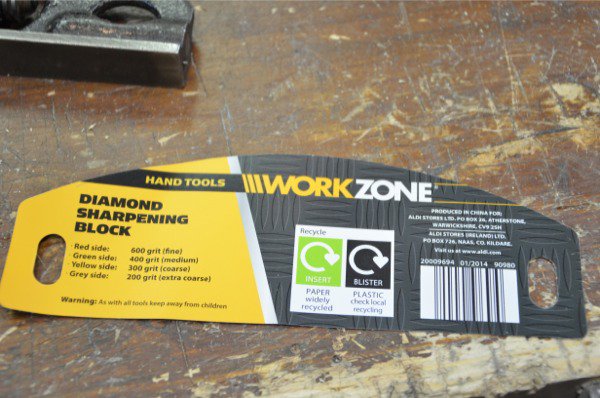

Aldi Sharpening Block

Some of you asked me about these, whether they worked for sharpening.

I bought one to try it out and I was surprised that it works quite well as a simple system for sharpening or abrading tools. I have seen similar flip-face systems for several years and they seem quite practical if not a little cumbersome. Aldi had this one made under their Workzone brand name. It works for coarse cutting quite well. I don’t know that they would work close enough to get to a fully developed edge because they stop at 600-grit, which would be a general carpentry level so for finer tools you’ll need some additional plates or stones.

You can keep 10mm of water in the bath itself and rotate the block to remove swarf and expose fresh particulate during the sharpening steps. I found it best to spray the surface I was on with my preferred auto-glass cleaner from PoundStretcher. This is the best lapping or honing fluid I have found so far so I keep using it.

Conclusion

I felt this would be a useful abrasive around the shop for some things such as sharpening an axe, roughing work on bevels, rough carpentry tools, garden shears and kitchen knives I think that they are fine. Restoring the chisel did work and I did get an acceptably good edge and flattened the back face fine. I cannot tell what it’s longevity will be. Rather than not have a sharpening stone I would definitely use one of these. They will make a stepping stone to more refined work and longer lasting plates. For plane irons too they will get you there quite effectively, but once you have refined your back face and bevel you might question whether the coarser plate is what you really want to go to. A real flaw I found was that the size of the elliptical holes. They were too big for small chisels as they tended to rock as I moved the tool edge back and forth. 3/4″ and 1″ were OK and I am sure I could have made it work for smaller ones, but unlike the more expensive perforated plates with plastic support, the plastic on these plates is not flush with the diamond surface.

I will keep this around to see how I feel after a week or so. I definitely don’t get the same confidence I had with the Aldi chisels so I cannot say go for it.

thanks Paul for a true and honest review, it is a breath of fresh air to get an unbiased opinion /review on the web these days

This very closely resembles the Harbor Freight diamond stone. I have the harbor freight stone and it works fine. For the price of around 10 dollars you are not going to find anything better. I have used it for rough sharpening of my chisels and plane irons then I go to my water or arkansas stone. If you’re starting out this is a good stone to get you going.

I suspect they are all made in one Chinese factory somewhere, but that shouldn’t hold any new woodworker back if it gets him and her started.

Hi Paul.

I’m glad you gave an opinion on these cheap diamond plate blocks from Aldi. I have bought one myself, to see if it is any better than the three plates I got some years ago from either Aldi or Lidl, and never much liked.

These three plates are very similar indeed to the four on the Aldi block, although separately mounted on coloured plastic boards slightly larger than the plate. The colours are to quickly indicate which cut they are, coarse, medium or fine. However, after a few years sitting around in the garage, the plates have come detached from the plastic, once the rubbery glue perished. The plastic boards themselves had perished and slightly curved over time, taking the plates with them. The plates are 0.33mm thick, and easily bent.

I’m quite happy to keep using them loose, as I only use the edges to get into tight spaces, as when honing a flat bit or the edge of a router bit. If necessary, I’ll cut a bit off to make a hone of the right size/shape.

Perhaps the square block is to avoid the distortion of the plastic from shedding the plates, but I suspect the glue will fail anyway in due course, and there will remain the danger of the plates not being flat in the long term. After reading all the posts on here about giving the diamond plates a real go before going back to my old oil stones, I’ve now bought the three 4mm plates offered on eBay by uk-t00ls-direct at £14.49 plus £2.99 delivery. These are possibly from the same Chinese factory, but are superior in having a solid 4mm steel base that doesn’t show any sign of bending. They seem dead flat, although I have no engineering tools to prove that. Also there are no holes to get in the way or catch a corner. The fine plate is claimed to be 1200 grit, but I have my doubts as I can’t tell the surface apart from the 600 grit on the Aldi block, other than the lack of holes. The overall width/length are identical to the cheaper plates.

I’m preparing to mount mine in a Π configuration on a 19mm MDF block, with one edge and one corner of each plate flush to the edge of the block so I can get to an edge or corner with blades other than flat ones, e.g. scissors etc. I’ve also bought a bottle of Astonish auto glass cleaner, in a shiny black spray, from my local supermarket at £1.35. I looked at Poundstretcher, but it seems they have changed theirs to a bright blue liquid in a clear bottle, and I wasn’t sure if that would be the same stuff inside. Have I bought the right brand?

Thanks for all your hard work, and your efforts to de-mystify the processes.

Yes, that’s fluid is fine too. I have seen the plates offered and thought of trying them out to see if they get people started for a little less money. Plates actually don’t need to be flat unless you plan on flattening the back face of the tools. I usually do most of this on the granite block with initial flattening using abrasive paper. This seems to work after than diamonds for some reason. Once the flat faces are done they need not be done again.

I thought I might leave an update on my experience with the Aldi block of four diamond plates, and the thicker plates from uk-t00ls-direct.

I’ve been using the Aldi block for sharpening the coarser tools, such as the hedge clipper shears and such things. There is a distinct advantage to the block being raised up off the bench for items like this, but the box holder, with the rubber ribs underneath at each end, tends to rock about too much on the bench. It’s better to use some anti-slip matting and just put the block on that. The holder also collects the sharpening fluid, and needs emptying after use. Don’t put this off, or the removed metal collected in the fluid stains everything with rust. The plates are starting to peel off the plastic block, but so far have not become totally detached, and could easily be glued back on.

The diamond plates have so far stood up very well to some severe use, and I can’t fault them for that. I wouldn’t use them myself for chisels or such, but I have no doubt that if you avoid catching corners in the oval holes they will work fine, if it’s all you have. At the price, they are worth using until you can afford better.

If you can afford better, but not the EZE-lap ones, then the 4mm plates I bought from uk-t00ls-direct are the ones to get. They are flat, do not warp and get the job done. I bought the set of three. My only problem is that I’ve used double sided tape to hold them down on a varnished block of faced mdf, and the tape goes rubbery with the sharpening fluid (screen cleaner). I don’t want to set them in to the block, as I like them mounted at the very edge, so I can sharpen things with an obstruction at one end, and at a corner to let me give small items access. I’ve not yet solved this, but I’m otherwise delighted with these plates. Mounting them on a thicker block may be worth while, to raise them up like the Aldi block, which makes them handy for large items, like those shears . . .

Paul thanks for your reply and advice. As a beginner on a budget, I’m not not currently able to afford the eze-lap solution and this should get me off to a start at least as you say. Thanks again for taking the time to review.

I use the Harbor Freight version followed by 1200 and 2000 grit paper with glass cleaner, and I can shave the hairs on my arms with the results, even with my $8 set of HF bench chisels. I still dream of fine tools, but I thank you, Paul, for letting me know I did not have to let a small budget stop me from learning wood working.

Interesting, I’d gotten one of these from Harbor Freight myself a while back. At under $10 it seemed worth trying out. Even after going to the 600 though, I had some pretty deep scratch patterns, so I haven’t really used it much since then. I might pull it out again to condition some plough plane irons that are badly chipped on the edge. It might be good to quickly get the edge down to good metal. My set of 3 EZE Lap plates will be arriving in a few days to finish off the job.

Hi my name is Wladimir I would really like to get one of this story Ne to sharp my knifes I need to know where I can find them can you let me know I’m in Brisbane Australia thank if you can help me ….

I have had the Harbor Freight version of this sharpening block for, let us say, about eight sharpenings, and so far it’s been amazingly good. By holding the blade so that it’s skewed during the stroke I have managed to sharpen a Stanley #4 plane iron on it. And, to my utter astonishment, I have also managed to sharpen a 1/4″ chisel— the oval recesses are not lined up with each other the length of the plate but are staggered and I have yet to run the corner of the 1/4″ chisel into one of the ovals.

But, I’m writing about a small and trivial innovation of mine that obviates the need to use a vise to hold the sharpening block AND cures the problem that I was having of not-so-hot edges due to my not being able to emulate Paul Sellers and hold the blade at exactly 30 degrees at the start each time.

My innovation is simple a gauge block, about 3 or 3 1/2 inches long and 1″ wide, which is cut into a wedge shape so that one long edge has a thickness of zero and the other will turn out to be something like, say, 5/8″, depending upon exactly how wide you make the thing.

So if you’re right-handed you control this wedge in your left hand. You put it down on the near edge of the sharpening block and press down a little— not a great deal of pressure is needed. You then of course start your blade out pressed flat against the slope of the wedge, so the it’s initally EXACTLY 30 degrees (that cures my operator deficiency problem right there).

You then complete the stroke just as Paul Sellers does, putting a camber on the bevel because you lower that angle to below 30 degrees as the blade is being pushed away from you. And then, you can keep the blade down on the surface and sharpen on the backstroke too. Just make sure that you slap it gently and with some care back onto the slope of the wedge for angle registration.

I found that I could quickly relocate the wedge forward on the plate, which might be a concern for some, about wearing out the plate too much in one place. I can also easily skew the orientation and alternate from skewed to non-skewed so as to put revealing scratch patterns on the bevel of the tool. Since I’m a novice, that’s how I know when to flip the block to a finer grit.

I put the block down on a paper towel. Of course a shelf liner sheet might be better. Either way, there’s no problem with the steadiness when you are putting light pressure down on the gauge block.

I don’t have a finer diamond plate, so after the 600 grit on this sharpening block I go to 1000 and 5000 on the synthetic Japanese waterstone that I had acquired prior to finding Paul Seller’s videos on how to sharpen. I then finish off on the strop, exactly as Paul demonstrated.

About flattening. I would have no concerns about whether or not you can get things flat with this system. My chisels have backs that are like dental mirrors. I can see the reflection of the curly-light bulb on the other side of my shop and move it along the cutting edge, observing no distortion whatsoever of the image.

Yes – I saw these here in Australia, and they were only $7 Australian. I bought one to try, and the next time they came along I bought three more. You can’t argue with value such as this! I use them for general sharpening (in vice – they rock otherwise as you say) and they save a huge amount of wear and tear on my more expensive stones. They do wear more quickly than others I have tried, and yes, any irregularities in the surface disappear after the first use, IME. When worn in a little, I find that I can easily put a decent edge on chisel or plane iron provided stropping with Brown (Tripoli) and Blue (Smurf pooh) follows. Seriously, for the price, these should find useful work to do in any shop.