A Bevy O’ Octagonal Chisels

For more information on chisels, see our beginner site Common Woodworking.

More Thoughts About Chisels.

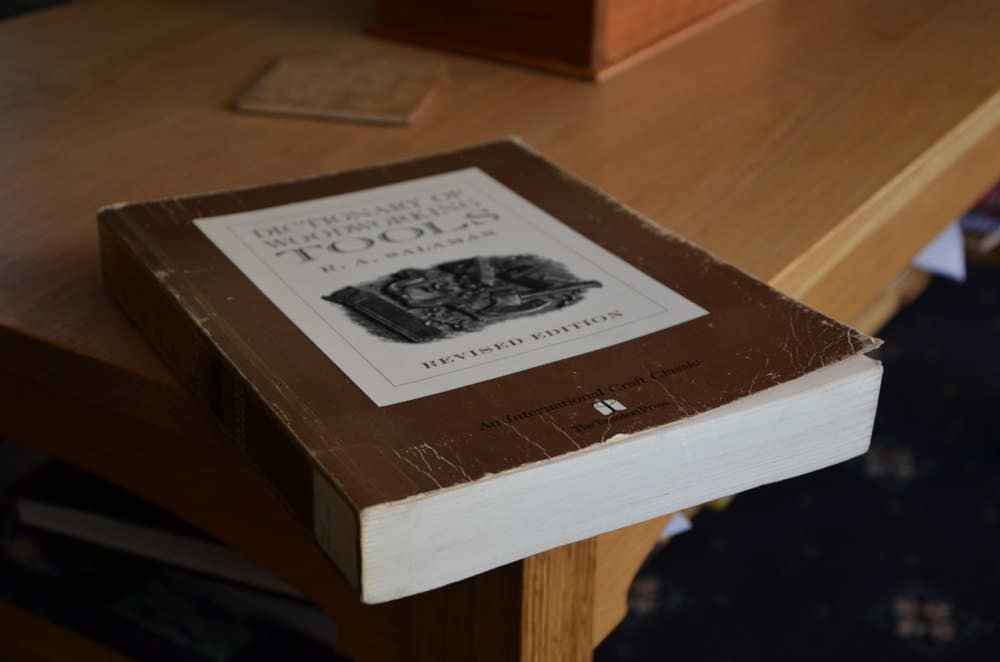

Someone asked me if dovetail chisels sold in pairs for left and right hand use are worth owning. A few years ago I bought some new old stock 3/8” bevel edged chisels with London-pattern boxwood handles from a jobber friend of mine for $2 each at a US woodworking show. I realised that I could make two dovetail chisels without any loss and I did. Then I realised that I had just complicated the whole process of dovetailing without really thinking through the issues. I now had two more chisels of very, very limited use to take care of and I inevitably picked up the left one instead of the right or vice versa almost every time. The benefit over what existed before was barely, ever so barely, discernible, which makes me look at other issues surrounding bevel-edged chisels and fineness. Always remember that tool makers are naturally inclined towards looking for something new to make. First create the illusion of a perceived need and lack and you create the demand. I doubt whether it was a craftsman going to the chisel maker declaring some lack that brought these tools about because you don’t really find them in pre World War II tool catalogs or indeed R A Salaman’s Dictionary of Woodworking Tools. That said, there is of course always entrepreneurialism that shouls always welcome new ideas. Nothing wrong with that at all. Better mousetraps and all of that.

When I cut dovetails my normal bevel edged chisels are close to hand on the benchtop. I use every size from 1/8” to 1 1/4” routinely throughout most days and especially when cutting any type of dovetail. I keep them in a tray in the well of the bench. I use chisels appropriate to width for chopping out the waste and then, if and only if I need to, I pull out a narrower chisel to reach into the inside corners of say a half-lap dovetail innards. A 3/8″ chisel works best for most of this aspect of the work but 1/4″ and even 1/8″ are called for at times. I angle the chisel so that the very corner of the chisel slide-slices right into the corner and slice-cuts a pristine inside corner perfectly.

My personal chisels are old chisels mostly, which I have bought through the years as secondhand tools. Most of them are wooden handled Ward, I Sorby or Marples from between the mid 1800s to the pre 1940s, but I have others made in more recent decades too. The old chisels are refined. Very refined. When I say refined I don’t mean snobby refined but craftsman defined. I think there was a reason for the highly f]developed models and that it wasn’t some pretence of refinement for appearances sake but an exactness demanded by working men for efficiency combined with effectiveness. I think that the steel works as well if not better than many modern chisels I have tested and used over recent decades and that they are not only equal to the task but they have all proven themselves to, one, be readily sharpenable (not to soft and not too hard), two, take a keen edge and, three, equally if not more importantly, hold the edge for a goodly amount of work, which is many hours in a day for the more general work.

The refined tangs of old are still lovely to see as compared to the ugly ones of modern makers…

…I ground the tang to a point for good measure and installation into the new handle.

The thing I like about them the most is that they were designed for fine woodworking, yes, but that they are strong yet lightweight with good balance in the hand and that’s what makes them efficient. On a more recent level, most modern-day chisels are made to thicker dimensions with narrower bevels and thicker sides to them. They look and feel clunkier and though they undoubtedly are more robust for heavy work, they often project the wrong impression. If you look at chisels made with a steel cap and stem passing into or through the plastic handle of a chisel it somehow conveys a message to the user, “Go on, beat me with a waffle head hammer. I won’t break.” In times past, when we only had wood for handles, a craftsman would never have even thought in those realms and would never have stressed a wooden handle in any way. Why do we not think that way any more? The men I worked with all had beautiful wooden handled chisels and had used the same chisels for fifty years and more with nothing done to degrade them. The chisel, saw and plane handles on their tools reflected their sensitivity and care in the use of tools and work. I think we should return to this even if chisel handles are made from unbreakable plastic.

I made a chisel handle for a video on making replacement London-pattern chisel handles yesterday. I fitted it to a refined Aldi 3/4” chisel to show how we can take a £2 chisel and make it into a £30 in about half an hour or so. It is much simpler to do than it looks and the handle made the chisel one that I would like to own and use.

Here is how it looked when done.

The wood is Indian Laurel cut on the bandsaw from the inside of some birdhouses I made using the outer circumference of a 6” diameter limb. I got four chisel blanks from the 9” length, so from one innard I got a £15 birdhouse and four chisel handles. The Laurel feels about as hard as Boxwood and turns just as beautifully and readily. It looks very similar and works the same with hand planes to form the octagon.

For some weird and very daft reason, after over a century of making fine boxwood chisels with hexagonal handles and a single ferrule with no hoop, Robert Sorby decided to add a silly and flimsy hoop to the the top of their chisels. These hoops come off after a while because the handles always shrink unless you live in Houston, Texas. I chucked mine back in the lathe and refined the shape more like their former counterparts for comfort and shape.

It takes just a few minutes to restore the tool to the former glory of the company father’s standards.

A bevy octagonal chisel handles is about as lovely as it gets.

Are they hexagonal or octogonal?

Looking at the pictures (and some og my tools), it seems that they are octogoal.

Can you explain how you managed to have such a regular shape with a hand plane?

Regards

Jean-Luc

Sorry, Octagonal!

Just corrected it. I will do a blog before the video is up. Easier to show than tell but pictures will show the method.

Looking forward to it! It’s just what I needed. Thank you Paul and team.

Jason

I bought a set of 4 chisels for £5 from a car boot a couple of months back and have been a lot more pleased with these than with the new ones I’d bough the year before.

Trouble is, the handle keeps coming off one of them. It looks like quite a short tang that goes into the handle. Short of glueing it in, how can I fix that so the steel doesn’t keep coming away in my hand when I’m trying to pare away some waste?

Also the top is flat rather than rounded over which is a bit awkward if I want to pop it with the heel of my hand. Presumably just rounding it over with a file should do the trick do you think?

thanks

I usually pop the handles off and chuck in the lathe to reshape but a file or rasp will work fine too.

Re the loose handle, sometimes I drill out the hole to make it round and symmetrical and make a dowel to fit the hole. Drill a hole through a piece of steel and then drive a square section of appropriately sized wood with the corners removed through the steel plate and you will have the size dowel you need. Glue this in the hole and leave over night. Then you can step the hole for the tang of your chisel. On the other hand you can use a two part epoxy and glue it in place and that works fine too.

Paul

I burn mine on drill pilot 2 holes tight to the tang, heat the tang near cherry red (this is too far from the working end to cause problems with temper etc) tap it on and off repeat the process and tap it down to the ferrule.

Some say but it is charred wood and will not hold,, fine try getting it off!

I think the old Sheffield little mesters used this method

Fred Sutton

Burning the tang in was the method I was taught.

Thank you for all the useful tips.

I’ll round it over with a file as I don’t have a lathe (yet).

I also think this time I’ll glue it in. I don’t have the equipment either to drill out the handle perfectly straight, or burn the tang.

What’s the science behind burning the tang? I would have thought that heating it up would make the steal swell up, and then once cooled down wouldn’t it just shrink back? It obviously doesn’t or people wouldn’t do it, but I don’t understand how or why it works.

Paul I love the London Pattern Chisel Handles and looking forward to your video, however I do not own a lathe ( well I do,a Shopsmith ) and don’t know how to turn nor can I afford those expensive chucks. Hopefully your video and blog will shed some light as you normally give alternatives to do something.

Steve

No chucks needed for retrofitting handles.

Paul, I wanted to share an experience I’ve had with fine older steel and was initially afraid I would risk creating scarcity in the market place as happens each time you make a recommendation. Then i realized I’m not Paul Sellers so few will flock to follow my advice. 🙂 I got the deal if a lifetime on a mixed set of 11 carving gouges for just $3 each from a woodworker who developed arthritis and could no longer perform much hand work. I tried to offer him a fairer price, but he said it was enough that they were going to someone who would cherish them the way he had for 60 years. They were made by the S.J. Addis company and from my research it seems they were formed in the 19th century from the finest tool steel I’ve ever encountered. They sharpen readily, take a keen edge, and hold it just as you describe. I had no idea that steel could perform like this and have been looking for bench chisels from this maker ever since. They have the Masonic Square and Compass as their logo, along with the words Addis and either “9 prize steel” or “10 prize steel” indicating that even in the 1800’s they were recognized as being made from exceptional quality tool steel. I would recommend this brand over all others and will purchase them even if I don’t need them because they are incomparably superior in my meager 12 years of experience.

Hi Paul,

Has the video been made yet please? I am quite capable of putting the facets on the London pattern, handles, but it’s the sizing that bothers me. I have a 1-1/2 inch paring chisel with a lovely boxwood London Pattern handle. It’s quite a short handle, but it is a lovely balanced old tool, and the grey, forged blade is a delight to sharpen and to see. (And to use of course) I have four or five chisels that need new handles, including my late Uncle’s 2″ wide straight turning chisel. (I think it’s a turner’s chisel ‘cos Uncle was a turner, in the Dockyard at Portsmouth. I think it will make a nice firmer chisel. I can get by on the lathe bus mostly with scrapers and gouges. So these handles will probably be in my skills range; after a few softwood tries!

Sorry, John, We never pursued it because of time constraints and it has so little interest.

Paul, uneducated question from this side of the pond!

How many chisel handle patterns are ‘named’? Is it a matter of each original maker naming products according to place of production or something else?

In the same vein, what were the ‘preferred woods’ for handles back in the day? I’ve seen boxwood, you mention Indian Laurel above, I believe I’ve also seen maple elsewhere. Were these handles made by the chisel manufacturers or by ‘chisel handles makers’ and sold to the manufacturers?

I keep reading, learning and putting some of that to use. Thanks. Noel

Chisel handles were predominantly made from ash and beech, with boxwood being accepted as premium quality handles. That’s here in England and its attached neighbouring countries too. Hornbeam makes one of the best chisel handles and I like that well enough as it is well proven. Some people beat their chisel handles with steel hammers and this is an uncouth man that does such a thing. A brute beast. That’s my view. when chisel handles are used with dull cutting edges there is a tendency to increase force to effect a cut. This too is idleness and dull witted. Again, that’s my view.

Thanks for the quick reply, Paul and for the education!

I’m with you on the steel hammer and brute force; unneeded if the cutting edge is up to par.