Some Thoughts for Christmas Gifts

Of course you all know about the knife I use and like over all others. The Stanley folding pocket knife here, the 10-598, is about the very best of woodworking knives and I cannot fault it at all. It’s exceptionally good for knifewalls and the blades resharpen readily too. Just what woodworkers need to keep the edge in their work. Indeed, the blades take and hold a good edge and a blade is of course replaceable if you would rather not resharpen. Again it’s pretty much a lifetime tool that wears well and lasts because it really has little to breakdown unless you fold it throughout the day. I never fold mine because I like it ready for use. This tool is inexpensive and a great gift for any woodworkers.

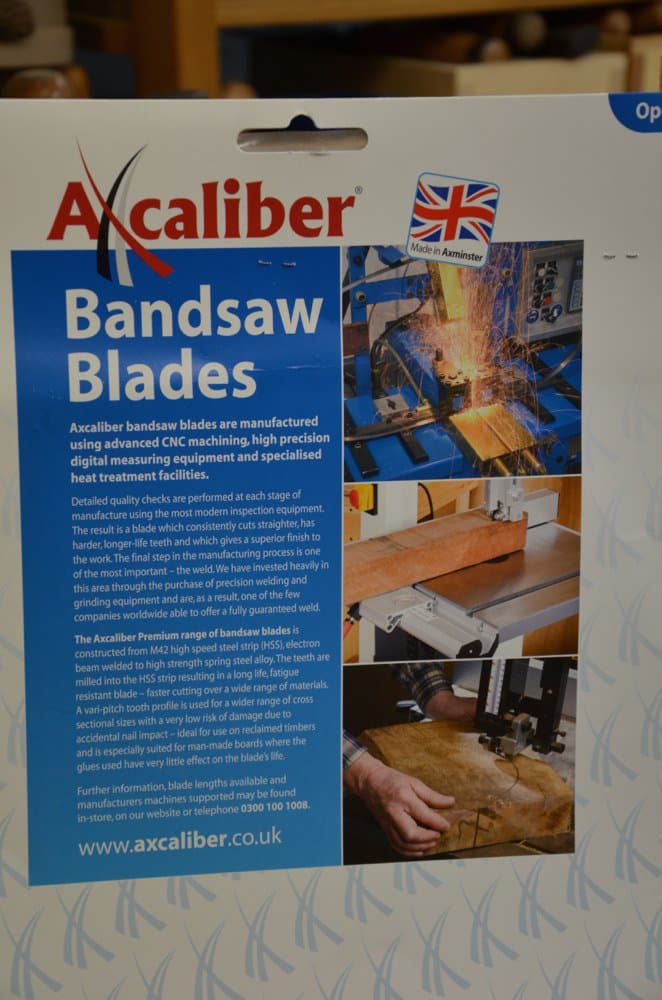

Since I have been in the UK I have tried out many bandsaw blades but the best blade I have ever used is the one made by Axminster they call Axcaliber. I put one in the bandsaw about three months ago and changed it out only yesterday.

A 1/2” blade gives me the wide and rigid beam I need for resawing thicker stock and also the best longevity on my smaller bandsaw because the 1/2″ width gives a good weld area, which is where most bandsaw blades snap. I have to say it never ever drifts with these blades and I can set a fence and the saw cuts perfectly parallel through 4” oak or mahogany for continuous hours if needed.

Of course my need is limited but I do find it very convenient and I kept waiting for the blade to need replacement but only yesterday did I feel the need at all and I have to say that was after cutting lengthwise down an hardened nail embedded in the wood I was cutting.

Gouges of course are much needed for spoon making work and carving bowls. We’ve tested two out over a long enough period to be able to make good recommendation if you can’t find secondhand old ones and the very best is still in my mind the highly polished and well finished Hirsch #7 sweep 35mm from Highland Woodworking.

There are choices for chisel hammers but this one still gives instant access to a real chisel hammer. The Thorex 712 with interchangeable heads for hard and soft and the wooden ash shaft has proven itself the best for me and in the school work we do. These are good tools for assembly work too and also for tap adjusting on the bodies of the wooden planes. I use them for dismantling plane irons in all of these planes when they arrive in poor condition.

Paul,

Once again a timely column. I went looking for a square Awl yesterday and couldn’t find one I liked. I had some trouble finding the awl you mentioned on the manufacturer’s website so I’m including a link to the page it’s on. You may have been using it for years but it’s still a “new tool” for them:

http://www.djarv.se/djarvenglish/newtools.asp

An interesting small company that makes a lot of specialized tools. Do you think we ought to warn them what’s about to happen to their on hand stock of awls?

The price is 180 SEK which is $25.11 in American dollars according to google. For those who don’t know you can type in something like “180 SEK to dollars” or “500 lbs to Kilograms” into a google search box and it will convert it for you. Handy trick.

And the Thorex 712 Hammer is apparently the Vaughan 584-12 NT150 Nylon Face Hammer with 1-1/2-Inch Face Diameter in America.

I have the Hirsch Gouge and look forward to using it soon. I also have a Hirsch Bevel Edge Chisel, also from Highland woodworking, and REALLY like it. They have a hexagonal handle that fits my hand much better than any other chisel handle I’ve tried. I also like the weight and balance. And Highland Woodworking went you one better on customer service. When a handle to a Narex Chisel popped off (quite possibly my fault) they didn’t hesitate at all in sending out a new one without asking for the old one to be returned. They can count me as a loyal customer.

Thank you for the tips. It’s nice to get some news about the good things in life that are just a little better than they have to be.

John Purser

I did let them know that their buttons don’t work well but they didn’t reply. I suspect that he’s a maker not a business man.

Hey Paul. It isn’t even Halloween yet.

More an Americanism than British

Not sure what this means??

I believe he is humorously implying that it might (might) be a little early to be looking for Christmas gifts. It’s a standard complaint in the US – the stores always put out the merchandise very early in hopes of getting the early shopper.

Ah! Thanks for that. Never really understood the Halloween thing it was never part of my culture before I left the UK and in the USA I never really understood it either, then when I came back to the UK it was part of UK culture here but I never tied Halloween to Christmas shopping. In the USA I tied thanksgiving to Christmas as the start shopping date.

For about ten years or more, I’ve been using a Crown Tools square-section bradawl, made in Sheffield. Mine is the ‘deluxe’ (as they call it) with a rosewood handle, which is more bulbous than most bradawl handles, and is very comfortable to use – it nestles nicely in the palm of the hand, and doesn’t concentrate pressure uncomfortably on one point of your palm. It holds it’s edge nicely, too. There’s also a choice of three blade lengths, and the cost is about £10. Highly recommended.

My favorite tool, and one I’d give as a gift to other woodworkers, is a 4″ double square, like the Starrett. It is agile for squaring across edges and narrow widths, it is small enough to to test for humps in dovetails and other joints, and it can be used as a depth gauge to see if a mortise bottom is deep enough even on the edges and corners. It is light, so it slides easily up to a knife without bumping or nudging the knife, and small hands can use it. The square stock for the handle shows me when shoulders are good or where they need to be tuned. When the double square is too big to test for bumps in a joint, I use an inexpensive depth gauge, which is slimmer, to get into the joint, one like this, http://www.amazon.com/General-Tools-Instruments-Depth-Angle/dp/B00004T7TD . Using the square and depth gauge to test for humps really improved my joinery and made it easier for me. They helped me see things I didn’t know to look for and was overlooking. Great gifts.

When I saw the title of this blog article, I thought it was going to go in a different direction…things we could be making in wood to give as gifts in a few months.

Paul,

This is slightly off topic, but how was the surface in the first and second pictures finished? It looks like it would age very well and it is very nice.

I don’t see what the question refers to..perhaps try rephrasing.

I’m sorry – I realise my question was not clear at all.

The awl in the first few pictures (and the gouges later in your post) is resting on a wood surface with some kind of black finish.

I know it isn’t the subject of the photos, but I was wondering how it was finished. Is it black milk paint over a coat of lacquer? Is there something more?

Thank you for taking the time to share your knowledge and wisdom.

Milk paint under shellac and wax furniture polish to finish. Thanks for checking back.