Questions Answered – On Brace and Bits

For more information on brace and bit, see our beginner site Common Woodworking.

Question:

Hi Paul,

I did a quick search on your blog and can’t find any information on brace and bits. I wonder if you have any thoughts on what to look for/brands to pick/avoid when choosing a second hand brace and bit. It might make a good idea for a future blog post?

thanks,

Matt

Answer:

Thanks for this question Matt. Brace and bits don’t take the limelight too often any more because of the power drivers everyone reaches for so readily. There is a silent strength to the brace and bit that quietly takes it’s place in the hand tool shop that so readily does the work steadily and without the buzz of Dewalt, Makita or Milwaukee. Most of the time the brace and bit will create cleaner work than the power tools will simply because they are cutting and slicing more readily and without the excesses you get with power equipment.

A good brace is virtually indestructible. I have owned one of mine for 50 years and it will go for another 50 I am sure. There are things to look for that are necessary for them to work well.

The parts to the brace need light, periodic oiling. Often this is neglected in finding a secondhand brace. The centre handle works well if oiled and a drop in the gap will ensure it stays moveable.

The pad here has an oiling hole and two or three drops works fine there too to keep the race of ball bearings free.

About the bits

The bits need to be in good shape and so below are some pictures to show flawed bits and what to look for when you buy.

Bits have two key cutting aspects that bore into the wood. The first cutting aspect of the bit cuts the circumference of the hole with two spur cutters that extend each side of the business end of the bit. On most bits there are two spurs, but sometimes there is just one. Slicing a circular line cuts across the fibres in advance of a second or later cut that comes from two inclined bevels inside the two spurs and on either side of the snail. As the bit rotates to form the opening cut with the spurs, the cutting inclines slice in a paring cut and at the same time lift out the then severed waste. Each rotation of the brace pulls the bit deeper into the forming hole. Combining hand and arm pressure with the pull of the snail at the tip the bit readily removes the waste in most woods.

The spurs on the bit above stand [rode of the bevelled area inside the spurs so that they cut beforehand. After much use and neglectful filing, these spurs can get too low and when level no longer sever the rim fibres to the entrance of the hole. This results in torn fibres, so watch out for this when buying as they can be extremely difficult if not impossible to restore.

Hardwoods such as ebony and rosewood, boxwood and so on are much harder to bore.

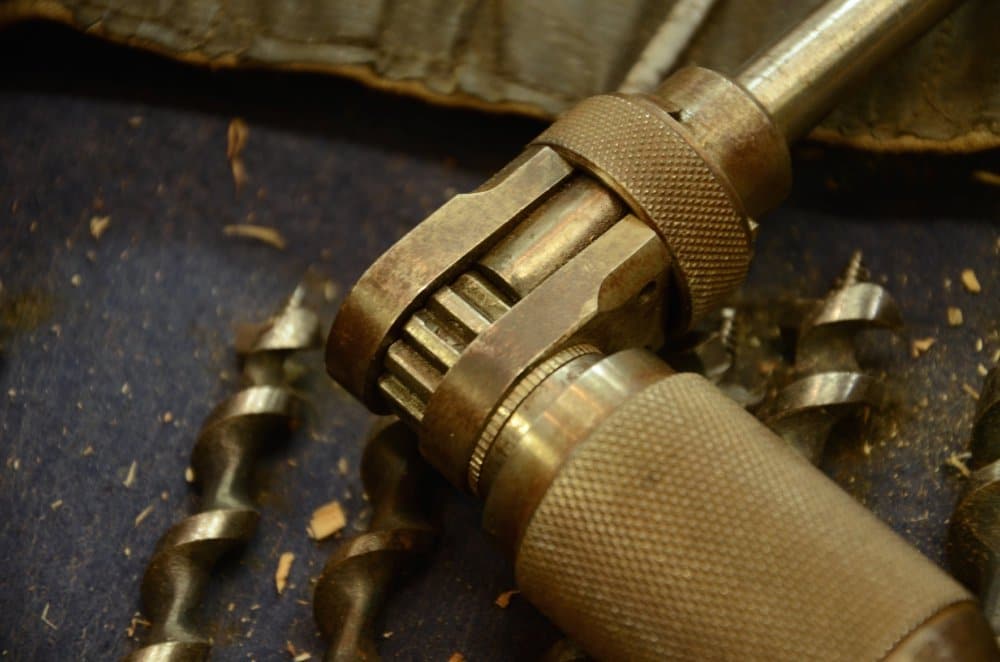

Here the ratchet needs regular oiling too.

Inside the chuck are two jaws held with a spring that opens up the jaws to receive the square bits.

Turning the handle tightens jaws.

The pointed snail shown above has a spiral that pulls the bit into the wood. When it’s broken and blunt it usually will not pull into the wood. When it’s gone it chews away the wood and wont centre.

Above the spurs are broken off or filed away as you can see. They do not score and cut the entrance to the hole or the wall and the surface on the outside is always fractured and torn.

Here is a larger bit with the same problem.

Compare the two holes here. On the one hand the 1/4” bit has no spurs and the hole is spewed out. The same sized bit with spurs cuts a clean wall and clean rim.

Here is an auger bit made for a power driver.

These bits work well in a swing (hand) brace too and although they have a a single spur they do cut a clean walled hole with a clean rim. Another thing is that they are readily available, cut as well and give good results. Rather than not have bits I think it is better to have one or two of these around to work with.

These two traditional pattern bits are both patterns commonly made. One is referred to as a jennings pattern, that’s the one with a steady and even twist, and the fast cut or Irwin pattern. Some say that the Jennings pattern works best and stays more steady in the hole as you bore. I find that that’s true, but the other still works fine.

here is how we generally use the brace and bit. There are other holds too.

Hi, I found this YouTube video very helpful. I learned a lot.

https://www.youtube.com/watch?v=dnjtGKIksXs&list=PLPwaeGpyHo40DNPRyCfOn829-cDsw3HU4

Very thorough and helpful overview.

Text is easy to understand, but the wealth of pictures makes it even easier.

Thanks,

Ron

Irwin still make bits for a hand brace of which I have a couple and they are as good as my original bits. Not available everywhere but they are still in production (made in Brazil). Their cost varies massively from place to place though. I think I paid just under $20 per bit for mine.

I have read many negative comments on amazon about those bits made in Brazil. I’ve even written to Irwin about it and they said they will look into I never heard from them since.

I can’t comment on amazon reviews but my experience with them has been very positive.

I have some Prager – Made in Japan bits that work well. They have a different shaped shaft not tapered but they fit braces or drill chucks. I found them at the local hardware. I might buy a few more to add to my collection. I will be selling all my brand new Stanley scotch pattern bits. If anyone’s interested let me know.

I have a Millers Falls 10″ bit brace I bought off eBay. Unbeknownst to me, the pad is somewhat loose and I can see the bearings underneath which are coated with rust. Can the pad be removed to access the bearings, and if so should I replace them and repack with grease or try and salvage the existing ones? Thank you.

Have a cheaper, made in Japan 8″ sweep brace. Metal holding the knob in place was just fractured pot metal. Got the old knob off, ground the end to recieve a vintage white door knob. Intention is to use a magnetic tip holder in the ratcheting chuck. It would then give a bit more torque than my Yankee screwdrivers. Knob does not even need to turn, and is glass smooth. Part of a group of six braces I have. From a 12″ Pexto to a few 8″ ones.

Hey Paul, it it practical to recut the snail and spurs on a bit that gas been abused…or more effort than its worth? What are your thoughts on the older spoon bits and spur bits? I find them easier to use to get good bored holes than the auger styles.

John

The spurs are a continuous thread and they can be filed to repair a broken thread but it’s not so easy to get to the original condition. Spoon bits are excellent for some work like chair making because the can be angled more easily mid cut in the hole to redirect the course or angle of the hole. The spur bits you speak of are the old blacksmithed bits. They do bore OK but not as well as the auger bits.

I got my first brace earlier this year and was amazed how well it works. I wouldn’t hesitate to say it works as well or better than a power drill. I spent a few weeks on eBay building up a full set of bits in good condition, and had a good time making a nice box to store them in. http://www.keithpeters.org/?p=1117

I have boxes of brand new Stanley Bits still in individual packets. They were made in Australia probably 30 years old now. Great quality but they are horrible to use even when sharp straight out of the packet. They have no spurs and are called scotch pattern bits. I now have boxes of useless bits and had to go out and buy more with spurs. I wouldn’t recommend anyone bother with the spurless ones. I don’t even understand why Stanley even bothered to make them. Horrible!

I want to sell them all but I don’t even know who would use them. Maybe good for barb wire fencing but that’s about it. Hopefully a collector will snap them up.

There are bits made without spurs that cut cruder holes for work such as telegraph poles, boring wiring holes through joists that will be hidden and so are indeed fit for purpose but not finer woodworking.

Hi Paul. From your experience, what do you do to a second-hand brace to bring it back to working condition? I’m specifically referring to cleaning. I want to wire brush the heck out of mine to remove the rust and gunk, but since I don’t really understand the ratcheting mechanism I worry that stuff might get in there and damage something. Then again, I also considered soaking the head in citric acid overnight and rinse with water, repeat a few times, and then dunk the head in engine oil for good measure! But I don’t know. Any advice? Thanks, and happy holidays.

I think this can be too harsh. A brass wire brush will be fine but steel wire brushes are more often a no no. Degreaser will remove gunk from threads and the internal jaws to the chuck are simple enough to dismantle and reinstall. fine abrasive will usually remove rust. Just surface coating with light machine oil like 3-in-One is all that’s really needed.

I use cutting compound the same you use on strops to clean and sharpen the threaded screw. I rub some compound on the thread then with the bit in the chuck I drive the screw in and out of the timber a few times. This thoroughly cleans the thread and sharpens at the same time. Works really well.

Paul – thank you for another timely and insightful post. Did you or will you do post or video for sharpening auger bits?

Oops, found it!

Not sure why I missed it before?

https://woodworkingmasterclasses.com/2013/10/sharpening-auger-bit/

I really enjoy using mt Brace and Bit’s as opposed to the “battery” or corded type. I have both but when I can I usually just get my brace and Bits out, I have mostly North Brother’s and Stanley 2100 series from 8″ to 12″ and ( 1 ) I think it it is a Pexco 14″. I also have Jennings and Irwin bits and like both. I am looking for a 6″ Brace to complete my collection.

Steve

I’ve caught this bug, too. I have all of the sizes, pounds of them (literally!), but not one complete set of Irwins or Russel Jennings/Russel Jennings Pattern bits! Estate sales and antique stores are fantastic places to find these and the bits to go with them, estate sales more for the augers.

There are so many types out there it’s almost impossible to settle on a favorite brand or style, but I would suggest a 10″ ratcheting brace, of almost any make, for someone’s first.

Irwin does make new sets of square-taper bits. I have not tried them as they’re still somewhat expensive for me, which is also the same reason why I won’t be buying the newly-made Russel Jennings bits available online ($35-$60 EACH?!? Are you mad?!?). The old bits are plentiful, but one definitely needs to learn what to look for in a used bit so one doesn’t get… bitten.

Here’s what I look for, but I bet Paul would rather a blog post! I can remove rust on my own so that’s not a worry. I like to make sure that the screw tip is clean and still sharp, not broken. The shank should not be bent, but a small amount is not a worry as small amounts of crook can be bent back out fairly easily, because augers are not hardened! I don’t worry about dull, because thanks to Paul’s video and a couple of others I found online, I find them easy to sharpen up. The biggest thing for me is the spurs. Spur augers need to be able to make one full revolution’s worth of cut before the lip engages if single-spur, and double-spur augers need to engage at least one half turn in the wood before the chisel lips do. If the spurs are too short, usually at LEAST 1/3 the length of the screw, I pass on them. I have enough badly sharpened bits to get rid of to bother spending money on more useless things!

Paul, I have seen conflicting advice about how to chuck the square shanks on bits in the chuck. One company advises pushing the square into the deepest part of the chuck, where the is a detent for this. Another advises having the square part of the shank just back of the jaws. What is the proper way to chuck the bit? Appreciate any advise. Thanks very much.

Open the jaws whilst at the same time pressing the tang of the bit against the protruding jaw ends. As the jaws retreat inside they will be further allowed to open as you hold the shell (chuck) and the bit in the one hand and turn the sweep clockwise with the other. When the jaws are opened wide enough the tang suddenly seems to drop in place. To tighten so that the jaws clamp continue holding the bit and the shell as you turn counterclockwise and at the same time centring the stem of the bit in between the two jaws as best you can. Use the thumb and forefinger to rotate the bit back and forth and feel for it settling into the jaws so that that two opposite corner aspects of the tang engage in the counterpoised reveal inside the jaws. Once engaged lock the shell tight and that should be the conclusion.

Hi Paul, have you ever done a video showing how you sharpen your auger bits? I’ve watched you sharpen just about everything else so informatively. Thanks Matt

Actually we filmed it for the three DVD series that complement the new book Essential Woodworking Hand Tools but I don’t recall videoing it as a freebie as yet. Bit by bit we are getting there gradually though

hello, I have owned 2 braces bought in the early 70’s. They were new at the time and both from being carried in large tool boxes on a truck have came apart and I lost the parts to them. Anyway, I am getting back into doing things the old way and I bought a very good quality brace on ebay. It is old, better than the Stanleys I bought in the early 70’s. My problem though is some of my tools do not fit in the chuck. All of my drills fit though. I have some old hollow augers and cone augers that the tang is to large to fit into the chuck. Can you tell me what braces have larger chucks to accept these. I am only interested in older American made tools. Thank you, Joseph Nunn

Hi Paul,

If I need to bore a hole which is 40mm in diameter with a brace, what will be the bit for the job?

Use an expansive bit. Where you can “dial” the radius you need.

Most bits are in 16ths of an inch….the biggest one I has is a 22/16″

I have a Clark that will go out a wee bit farther. There are some that can reach up to 3″ diameter.

Cheers mate.

Living in Taiwan and can hardly find expansive bits. There’s even no proper name for it in Chinese. That’s the thing, it’s tricky to find decent handtools in Taiwan, I mean the proper ones, not those made in China toys. Handsaws, bevel edged chisels, planes…all despairing finding journey are concluded with long sighs.

Found something called hole cutter though:

http://youtu.be/pw4bQ4Jw92Q

Anyone tried such a stuff before?

If these are sharpened properly and fully supported with a backer board they work well. Notice in this video that the plastic pops up after pressure. This can ruin a pice of thin wood. Best to clamp it with cauls to prevent this. Otherwise there are luthiers who I know use them for sound holes on guitars and such. Bit scary but with the right precautions you will be fine. Oh, you can also do the inlay recess for the rosettes too using one of these. `Still a bit scary though it does work well.

Sweet! Nice to hear that. I’ll give it a go. Thanks a lot mate! All the best.

Hi Paul I have both your books and first set of DVDs because I love to listen and read what you have to say it’s like having my granddad out in the shop with me I hope to get your new DVDs soon lee valley has your new book but not the DVDs so I will get elsewhere. But I do have a question that bothers me because I have yet found a valid solution to my issue I have my grandpa’s brace and bits miller falls ratchet head 732 10in. And a breast drill miller falls no.12 I have notecard when loading my bit in either my Russell Jennings no100 set or Irwin bits that I see a substantial run out in the bit I have tried to move jaws down and up or quarter turns on the bit in jaws and can never seem to get it to run true like my spofford brace I just picked up a month ago it has bothered me for some time that I can’t find a reason as to why this issue can’t be adjusted accurately every time. Have you ran into this issue with your Stanley brace you mentioned in the new book. I like my setemental attachment to my grandfathers tools and don’t want 5 drills around my shop because I only want what I use and need as long as it works the way I think it should or do I have lofty expectations gotmy brace chuck to run dead true.

I got a brace (and several other nice hand tools) from a widow who invited me to go through her late husband’s tools. I notice that the brace may be a bit large for me. I’m a bit short on one end, so it’s hard to put much pressure on if I’m aiming the brace downward. I wonder if I should be on the lookout for a smaller brace?

I tried using a power auger bit to drill 3/4″ dog holes with the brace. It really tore the wood up; maybe I should have sharpened the spur, but I returned it to the store instead. These things are not cheap.

Then, two days ago I noticed that the 13-piece Irwin auger bit set (with square shanks, i.e. bits for the brace) was on sale on Amazon for a much lower price than usual. I ordered them and they arrived today.

The machining on the cutting parts is deplorable. The spurs and cutting edges are just a total blunt mess. There is so much resistance that they cause the pilot screw to strip in the wood. I doubt these things would cut through Mom’s famous jellied salad she serves at church luncheons. Now I have to skedaddle down to Lee Valley and buy an auger bit file and diamond hone. Disappointing, but hopefully I can rescue them with a bit of sharpening work.

I am simultaneously embarrassed and thrilled. I have complained to anyone that would listen (and some that wouldn’t) about the Irwin auger bits I ordered online. Today I decided to spend the money on a new brace from Lee Valley, one with a three-jaw chuck that will grab round or hex shanks more securely. Fifteen minutes ago I threw a bit in and tried it, and instantly noticed something important: the bit wasn’t wobbling. My old brace is apparently bent, or out of whack anyway. With the point in the work, the shank end of the bit wobbles like crazy in a one inch (or bigger) circle. It turns out that this just totally prevents the bit from cutting properly, and prevents clearing the waste. With my new, very expensive brace all of my bits drill beautiful holes with very little effort. Lesson: pay attention to this when buying an otherwise ok used flea-market brace. Why didn’t I notice the wobble before? Inexperience. I didn’t know it wasn’t supposed to do that!

Many people don’t realise many things due to inexperience and that’s all part of the learning curve. If you didn’t buy an antique and if you didn’t buy a new one you probably still wouldn’t know. Education is most expensive.

Here’s an alternative – I already used it and it’s a good auger bit file: https://www.fine-tools.com/schlangenbohrerfeile.html

hi Paul, am new to all this – having just picked up an old C. Whitehouse & Sons 1 1/2″ bullnose auger bit from a local toolmart I was excited to give it a whirl but now I’ve come to load it in, I realise it has a 1/2″ square tang which won’t fit into the opening of my brace drill chuck, am I missing something?

It depends on whether the bit and the brace are compatible. In most cases they are interchangeable but every so often they are not. have you opened up the chuck far enough to receive the tapered square end of the bit to fully receive it inside and then tightened it so that the chock closes over the entire square taper?

Dear Mr. Sellers,

Can I use hex-shank bits in a two-jaws chuck brace? I tried it and it works but I don’t want to break my nice brace.

Thanks in advance.

Yes, you can. Just make sure it seats nicely in the jaws and cinch it nice and tight so that it has a firm grip. That way it won’t slip whilst turning under pressure.

Paul – I have read that the Jennings twin screw with a finer snail is better for dry and hardwood and that the Irwin single screw coarser thread is better for wet and soft wood, what is your opinion

I can’t say I even knew of the difference though surely I will have used both without noticing because I own both types.

hi paul

I got a 6mm bit for my brace but when i’m drilling it slips in the chuck even if I tighten it firmly. Do you or somebody else a solution for this?

Does that mean the stem is perfectly round with no tapered shank or flats to the sides? I’m guessing thats the case. If so you could possibly grind the stem and put four flats to create sides but with it being so small consider three flats and make them narrow.

Does your bit have that tapered end that enters the square hole in the chuck’s bottom? It could be to small to stay snug in that hole, and you may need an adapter. Fortunately, it’s available at Dieter Schmid, an you can get it for under one Euro (plus the shipping cost, of course). I already have one and it was really useful. Check here https://www.fine-tools.com/bohr1.html for “Adapter for small conical square Shafts”. You will find here some other useful adapters, as well.

You said “A good brace is virtually indestructible”.

Not if, like me, you overestimate the steel’s resistance.

I tried to use an old Stanley four-jaws hand drill for drilling some 25 mm holes in a well dried piece of firewood that a friend gave me, planning to make a mallet.

It went well, but at some point the chuck started to rotate on it’s own, not being able to transmit the rotation to the auger bit. The bit’s tapered end is still intact, so is the chuck’s central square hole. But that internal part that holds the four jaws is rotating looser and looser, independent from the threaded exterior part. Anybody could tell me how to replace it, find out what’s wrong and fix it?

The other day I bought a 5/16. Irwin bit to replace a worn out Jennings bit ( the bit has been resharpened till the spurs are gone ). I chucked in my brace to bore holes for some dowels and found that it would not fit in the insert in my doweling jig. I measured the bit and found that it is 1/32 over size and therefore useless to me. I hate the thought of buying a full set ( about $180 ) to get the one bit I need to replace.

I’ve read several bad reviews on the new set Irwin offers. Just hunt for a vintage one you need.

I have boxes of bits to sell. Stanley. Made in Australia. Still sealed brand new in heatshrink packets with yellow cardboard back.

Problem is most are scotch pattern and useless. Maybe if you have a barbed wire fence that needs new post holes? Not much good for fine woodworking but maybe a collector will want them.

Hi, in their booklet they say the bits are “ground approximately 1/64th oversize. This is done so that holes bored for bolts, pipe, cable, etc. can be bored with the same size bit.” There Dowel bits are made to actual size. So the general ones are a No. 62T and the dowel ones are a No. 61T. I’ve never seen the dowel bits in the wild though.

Hello– I am the grandson of a standard oil blacksmith, My name is Dennis Carlson. Granddad

was Peter Johnson, he passed in the late forties. I have seen his work and have many of his

tools, I have been told by many who knew him of his wood and iron abilities and the quality of

the man and of his craft. I am approaching my mid seventies now and have many family heirlooms, to include granddad Pete’s tools, with regret I feel it is time to make a decision.

Would it be appropriate to ask your advice in this?

I was a builder and as much as I loved my tools they are nothing when compared to grandpa.

I look forward to hearing your stand. Sure money is nice but it is not my purpose in this.

Thank you

You could send them to Australia, I will look after them for you. 🙂

Would you happen to know if Ridgway auger bits are quality bits, or ones to avoid?

no doubt excellent. I’m still using mine from 1966! Before you buy check the cutting spurs and the rakers are in good shape.

Thank you. I just ordered a nice set of 10. (Well, 9 Ridgway and one unknown), going up to 1 and 1/2 inches. They seem to be in good shape, the tips are still ‘new’ don’t look ‘reshaped’, and the rakers and spurs look in good shape.

(None of the cuts into the metal of the point by incorrectly sharpening.)

I think they will serve me well.

Hello,nice share.