The trestle table design

The goal in making the table as with all we do on woodworkingmasterclasses.com is training, apprenticing, preserving seeds, planting them and ensuring that all we know is living in the lives of woodworkers around the world. There are two levels of membership, free subscription and paid. The paid is £10 per month.

We showed how to hand plane rough-sawn, wide boards with waney edges. Boards that would have at one time been common to people like me. You know something, it’s not so bad knowing how to do such a thing with hand planes, some winding sticks and such. Actually, dare I say it, it’s an enjoyable task. Even for an older man like me it’s still enjoyable. So for a young person and anyone in between it should be seriously enjoyable too.

The recessed tenons through the apron mortises are intentional to transfer most of the pressure from the tenons alone to the housing dadoes. The stability this adds is remarkable. These prevent any twisting under pressure. Why would there be pressure. Well, the table can be upended to sweep or clean under the table. It’s quite easy and light to do because it cantilevers at a certain point. It works.

The positions of the columns are set to allow comfort to the end occupancy and so too the first seater to each of the corners. The table seats 8 people by the way. I placed the uprights close to one another to ensure accuracy to the shoulder lines of all of the tenons. Any slight deviation telegraphs through the work and shows flowed workmanship instantly. It’s an exam if you will.

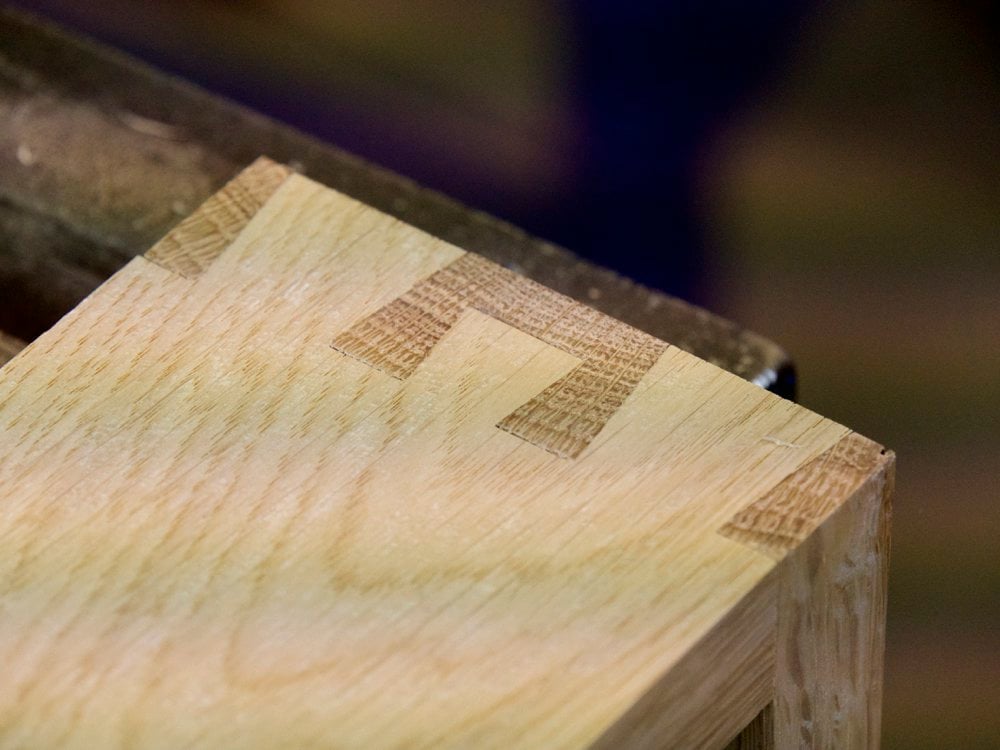

When it comes to the cross bearers at the top of the column uprights we also have close joinery where accuracy is of paramount importance. So we have a version of the hounds-tooth dovetail to the corners and cross bearers a little way away. Synchrony is what this project is all about. I’m glad we did it.

At the moment we are working on a project with sliding dovetails. Cherry is a premium wood to work in.

The table is very nice and an enjoyable project to observe coming together. I have a very nice, modest, cherry antique Ethan & Allen dinette set that my wife loves. But she saw the table project and instantly suggested that should I just happen to want to make her one she would wholeheartedly support it. Ha!

Can’t wait to see what you have cooking with sliding dovetails.

Beautiful table, Paul

Lovely design. It looks elegant without being pretentious and solid without being chunky.

Quite remarkable.

So the table seats 8 total? 3 on each side and 1 on each end?