Blades for my bow saw

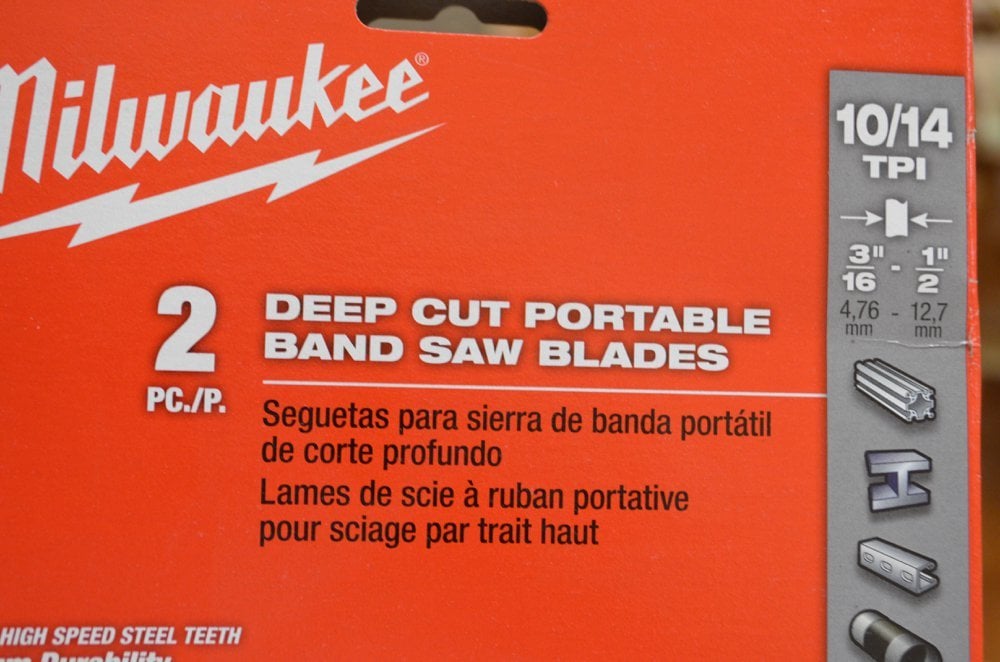

I found these in The Home Depot store but I am sure you can get them online too. This type doesn’t have the wavy corrugated edge as other metal-cutting bandsaws do.

These are dovetails cut with the 14 TPI blades straight from the pack with no alterations except cutting them to length and boring the holes each end.

How about us UKers? 🙂

Axminster Axcaliber metal cutting bandsaw here

Paul,

Thank you for your you tube channel and your teaching abilities. This is the first I have been to your blog site, which instantly gave me the most intelligent and economical solution.

Again thank you and please don’t stop teaching and posting.

Sincerely,

Dale Little

Paul, I believe that you could cut perfect Dovetails with one of those wooden spoons you make. I couldn’t cut dovetails that nice with any saw or machine, lol

I hope you know I’m just teasing you. But I bet you could cut them with a butter knife. I’ve improved so much in just one year because of you but I still have a long way to go. Thanks for the information. I made a saw but it’s a turn saw I had the pins and blades already that I purchased from tools for working wood about a year ago. It turned out pretty nice and it works great.

I just bought a #12 12 tpi 19″ and a D8 16″ 10 tpi that came from the Richard” Dick” Lee collection. Did you know Him? Just curious who he was that’s all. Thanks Paul

Chris

Hi Paul – Do you simply break the bandsaw blades into 3 sections, and drill holes at each end?

Yes, they snap readily if you cowboy-cutter them. I found that they drilled readily too.

Roy, I don’t know what Paul does, but for my turning saw I used 1/4″ bandsaw blade and after snapping the blade to length I softened each end by heating to near red in a butane flame and allowing to cool slowly. That way, they drilled easily. Hold with heavy pliers or similar to stop the heat travelling up the blade to where the teeth will be used.

Thanks Paul

Maybe a brief description of how you cut them to length (what is the exact length dependant on the size of the frame saw being made, so what length would you suggest for the one you are constructing in the video) and drill the respective holes would also help us all.

Can’t wait to get mine completed because I could really use one of these especially one that I make and know that it won’t cost me an arm or a leg (that I’d probably have to cut off to buy a brand new one from a supplier!) haha – Just kidding!

bob

Hi Paul, Thanks for the tip on blades ( and thanks for the frame saw video!). Do you re-sharpen them or just replace. Thanks .

Randy

Thank you! 🙂

One way of making holes drillable. with-out having to heat the blade ends. ( appoligies for lack of proper terminology, escapes me at moment ) Is to put a old driil into drill press, upside down. Then you can burn / change the metal, at the point where it needs drilling, simpler, more controled and quicker. cheers Peter

That’s new. Should try that. Those things usually happen when I don’t want them to.

Should(Can) hard-point teeth be avoided? My local hardware store keeps several bandsaw blades in stock, all of them with hard-point teeth. The blade I’m considering: “Universal, for metal but also for wood”, 14 TPI, 6 mm wide, 6 mm thickness and hard-point teeth.

Erik

It is a hard one (no pun) because I have found some of the metal cutting bandsaw blades will file quite readily with a regular saw file. I am not bothered so much because these blades will last for months of use on wood if not years as long as they are not used on metal.

If you want a resharpenable blade you should avoid those hard-point teeth I think.

Even bandsaw blades for wood are too hard to file so don’t think they are going to allow sharpening. Not sure why they are harder than the metal cutting sometimes. As I said, I wouldn’t worry about resharpenable because they are inexpensive and will last most people for years. I have had mine in for 18 months and have cut metal with mine on a couple of occasions.

Matthias Wandel shows sharpening a bandsaw with a dremel on youtube. His way is basically the same as how you put a back bevel on the edge, but he uses a cutoff wheel in a dremel to do it. I’m not sure if it will work with a file, I came here because I was looking for the blade source before I went to the effort of making the saw. I’ve found that cheap files (less than $1.00) work well to sharpen hard steel but destroy the file in the process. works for one saw and saves me a bit of money. I use it on those stupid stanley sharp-tooth saws that are hardened so it is a pain to sharpen them, but it is $1 opposed to $25 for a new saw.

Hi Paul,

Sorry to be picky, but the blade you used in the frame saw making video seems to be about 1.5 to 2 inches wide – ideal for accurately cutting dovetails. I can only find similar items within the EU at: http://www.fine-tools.com/gestell.html Do you know of anyone in UK supplying similar items? I guess bandsaw blades are better used for turning saws?

Also “cowboy-cutter them” needs a trans-atlantic translation (for me at least!)

All the best – Richard

Not picky at all. Actually I found that the 1/2″ metal-cutting bandsaw blades with 14 TPI cut dovetails to perfection and better than the the 1 1/4″ frame saw blades. The same blade cut tenon cheeks very well too. That said, the bandsaw blade at 1/2″ has less beam strength and therefore has a little more flex but I just added tension to compensate. The frame saws are resharpenable and so a lifetime saw blade which I always prefer over anything disposable so as Fine Tools are the ones making the blades available that is the way to go.

And ‘cowboy cutting’ comes from my days as a Texan and means bending the wire back and forth until it snaps instead of using wire cutters or pliers.

If you’re in Europe, you can get ECE frame saw blades at http://www.fine-tools.com/gestell.html. That web site seems to suggest that the western-style blades can be resharpened.

Hi Paul. What blades do you use in the UK?

Look at the second comment where Paul gave a link for buying the band saw blades in the UK.

Good to know that. Thanks.

The real poor man’s way to make a hole in any thin hard metal is to punch it with a broken drill bit.

Also the real poor man’s blade is made from a main clock spring.

Mmmmm…..wonder how big the clock spring on Big Ben is and if they’d miss it………

Paul, I just checked those blades and prices on Axminster and I’ve had to wind down my pacemaker. A 10tpi blade costs £12.25 but a 14tpi blade leaps to £39.46. No way can I justify nor am I willing to pay 40 quid for a bandsaw blade. Looking at their spiel it’s just the typical sales pitch of many words that end up telling you nothing. I suspect that the blades are a standard hard toothed carbon steel that can be sourced from most blade manufacturers.

My supplier Tuffsaws, sells hard toothed carbon metal cutting blades a 5 for £35. Some difference, plus he gives you all the technical info you might need on the many types of blade.

Right, griping over. Paul what do you know about the bi-metal, high tempered, cobalt blades, the M42? I understand they are a mite thicker than standard but do you think it’s worth giving one a punt at £26 or should I stick to the 5 for £35. More so as I’m one of those that is in the permanently boracic bracket as I have to rely on whatever twit is currently in No. 11 for my income.

ATB.

Scott

I just checked and the one I got is here at £11.76. Oh, and that gives me three bowsaw blades. You could add some extra inches to get four or more for £3 more. £4 a pop is good value I think.

For those puzzling over the last sentence – From Wikipedia:

boracic British informal Having no money.

[From boracic lint, rhyming slang for ‘skint’]

Thanks for the prompt reply Paul even though you’re probably in bed now. Just checked Ax again and I’m now assuming the blade you have is a 10tpi for that price. I think I’ll ask Ian at Tuffsaws to take a peek at Ax’s site and get his opinion. He’s a man to be trusted to speak the truth.

I know we must drive you crazy at times Paul but just another question if you don’t mind. Is it worth ‘feathering’ the teeth at the front end as you would a tenon saw? More so if it’s a 10tpi perhaps? Sorry, I’ll get me titfer.

Ok, I should say clock main spring. Try it and you will like it.

Hi Paul,

I was wondering how thick the blade was for your frame saw. I wish to make my own blade but I don’t know how thick the steel should be.

Hello Paul.

Would you mind teaching us which direction the saw teeth are supposed to be in ?

Which end of the blade is the handle end ?

Anthony it should cut on the push stroke.

Hi Paul. I was certain I once saw a video or read a blog once where you heated the Milwaukee blades with a small torch so you could then sharpen them, or at least shape them a bit. For the life of me I can’t find that post or video. Ive built the saw and am happy with it but the teeth on the blade seem to have too forward of a rake maybe as the cut isn’t as smooth as I would like.

Would heating the teeth then make the steel too soft to effectively cut?

I don’t think it could have been me you saw as I haven’t done this myself nor would I most likely. I don’t know if the results would be acceptable or not but it costs so little to try it. That said, the steel is spring steel and you may well remove the tension you need.

Have you ever done a video (or blog) where you heated the teeth of a saw blade with a torch? Or am I losing my mind?

No, never have.

Hmm. It seems the internet has eaten both of my attempts to comment. I was trying to link to the Woodworking Masterclasses video where you demonstrate sharpening a frame saw, and use a torch, but both attempts have vanished without a trace. Ah well. Ryan, if you read this, I suspect that’s the video you were remembering. I’d almost forgotten it myself, but your question jogged my memory, heh. 🙂

I can check on this tomorrow Luca.

Dear Mr. Sellers,

Just discovered your YouTube channel recently and I love it. I used your method of saw sharpening to revive an old Jorgensen miter saw and it worked beautifully. I also sharpened my chisels to shaving sharp with your help. Also I am now using Bahco files, which are wonderful. Thank you so much. You have made a huge difference in my life. Can’t wait to make my frame saw with the band saw blades!

Just discovered your you-tube channel. I had to tell you I think it’s great. Better than most. You have so many projects I want to try I don’t know where to start. I am setting up a sharping station now. I think the “bow saw” will be next, and I found a couple of inexpensive back saws I had kicking around, one of which I had sharpened a while back and am now starting to use with great results… Keep up the good work!

Jerry

Hi Paul I have been watching and reading you blog for a while now.

I have enjoyed It. I wanted to know where you got the taller blade

from. I live in the USA and would like to use that as well as a band saw blade it that a power hacksaw blade ?

Thanks

GregP