Why 45 degrees on Cabinet scraper blades?

For more information on the #80 Scraper, see our beginner site Common Woodworking.

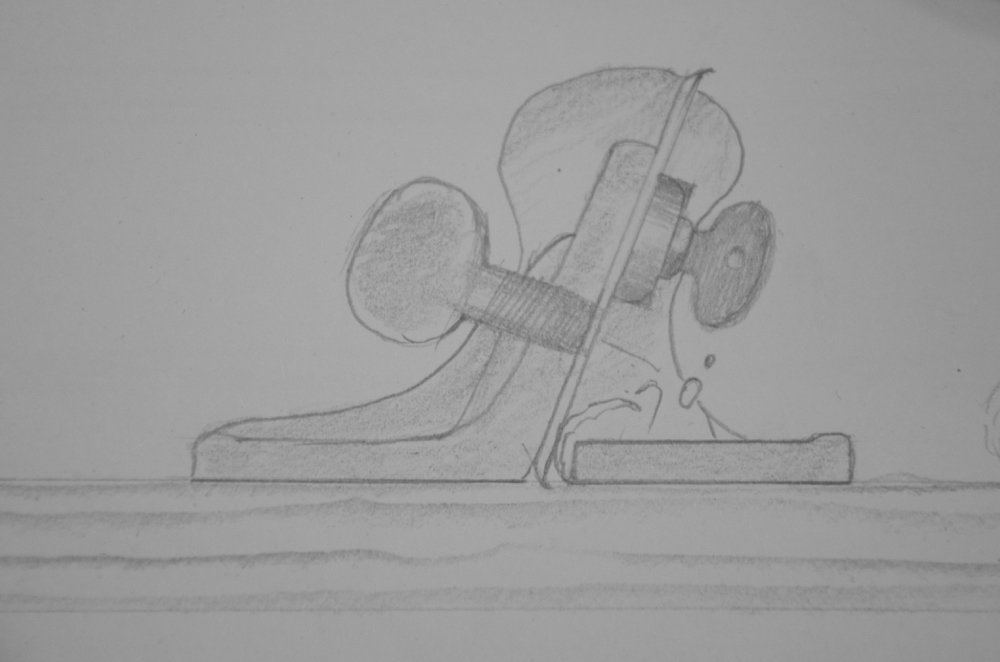

Following the blog I did to redress concerns I had with the Kunz #80 cabinet scrapers, I received some questions because the manufacturers decided to send out the scrapers with square-ground edges instead of with the 45-degree standard bevel required for the scraper to function correctly. The makers may not know this but in my view this would be the equivalent of planemakers or chisel makers sending out their plane edges and edge tools with square edges and no bevels too. I wonder how many people would buy them if they did that. This inappropriate manufacturing then prompted some of you to question why we do indeed use a 45-degree bevel on the cabinet scraper when we use a more standard square edge on card scraper edges? The questions were perfectly legitimate because Kunz is the only maker I know of that doesn’t send instructions with their #80 cabinet scraper so those new to the tool will indeed be left floundering for obvious reasons.

In my new book Essential Woodworking Hand Tools, we’ve gone to great lengths to cover missing and even lost information in both scraper types, the cabinet scraper and the card scraper; for anyone who has no knowledge of what scrapers really are and what their capabilities are. I think we have truly pegged it, but ultimately you will all be the final judges. So hang in there for another few weeks. I’ll let you know when where and how you can get it.

Of course this question is a valid one, primarily because the name scraper for either tool is truly a misnomer and so too is the use of the term burr for what is in essence a highly refined, continuous cutting edge. That said, it is been around for two centuries and I am not prepared to rename what happened most likely by default. Actually, some people in fact use the scrapers, both types, for exactly that, SCRAPING…ARGHH!

So let me say here and now that scrapers do not scrape but slice-cut in a paring manner. There is no tool like it. It’s totally dynamic and it tames wild grain on the skew like no other cutting edge tool can, believe me. That is as long as you review your thinking and think ‘slice’ instead of “scrape” and totally ‘refined cutting edge’ instead of “burr.”

Scrapers square and angled

It’s all too easy to say a scraper edge should be turned to this angle in this number of strokes and that only two types of scraper exist. In reality we just need something to shoot for. In reality we probably never hit the same angle twice unless we rely on some kind of special dial-in burnisher (not likely!) that fixes the angle. What a guide gives you is a dead angle and that can and does rob you of flexibility in turning the edge according to task or personal preference. In the early days you will turn the edge to a scraper according to some teaching you’ve followed, but, if you are like me, after a period experiencing the tool in the wood at the bench you will discover nuances you can use to finely develop and tune the edges you want and even keep different ones tuned for different types of cutting work (I avoided the use of the word scraper then).

Sometimes a filed and burnished edge is all you need and on other occasions you will polish out the edge as you might a plane iron and then turn the edge for that truly ultra edge that just defies reality. There have been times when I stunned myself because an edge came to the edge that I had never developed before, enabling me to take shavings I and everyone with me had never seen before. It’s one of those times that just cannot be bottled, canned or otherwise stored except in your memory. Like staring a rattler rattling away square in the face or sensing a mountain lion and then knowing he was just a few feet from you. Totally magic.

With the question coming up in the recent batch as to why the #80 cutting blade is filed and honed at 45-degrees when the regular card scraper is filed at near to dead 90-degrees. The two tools perform the exact same task in that they do not scrape in any way but slice cut the surfaces of wood to a pristine finish even when taken at the juncture where component parts come in at 90-degree angles or inlays comprising a dozen grain types converge in a sphere of absolute creativity.

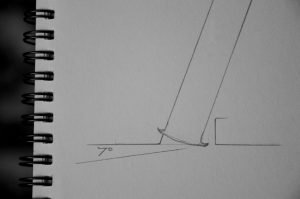

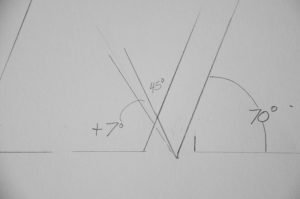

Because the body of the #80 scraper fixes the angle of presentation of the blade and hook on the scraper edge at a fixed and exact angle leaning forward at 70-degrees, it totally differs to the card scraper that is offered at much lower angles and is infinitely variable depending on the stroke, the user, the sensing of the cut and way much more. The edge on the card scraper starts out square and becomes round and hooked from its 90-degree start point. Because it is so flexible in the hands of the user is tackles work no other tool can. The cabinets scraper on the other hand must have some minimals built into it. The blade is fixed at the angle and using a turned, squared cutting edge as with the card scraper will generally present the cutting edge at an angle that negates contact between the cutting edge and the wood. In simple terms the roundover of the developed edge rides the wood and prevents the edge from cutting.

I think this is the only explanation I’ve ever read of why the cabinet scraper is ground at 45 degrees instead of square. Makes sense.

This may be a dumb question but, having used card scrapers a fair bit, but never used a #80, what are the advantages of the #80?

The flexibility of card scrapers is obvious, but are the benefits of a #80 simply comfort (both ergonomically and lack of heat), or is there more to it than that?

The #80 can be set to take a more aggressive cut than I could ever get with a card scraper and the sole limits the amount of hollowing that can occur. That said, the #80 can still be configured for a very fine cut. The card scraper is the sanding block and the #80 is the belt sander (although you can do a lot of hollowing with a belt sander if not careful).

Well put, P.G! Lee

The cabinet scraper #80 is more robustly used and removes more stock more readily for initial levelling of uneven surfaces say where laminated boards are glued up larger and wider surfaces such as tabletops. Though not as thick as say a heavy plane cut, it can remove shavings as thick as a normal plane shaving and so reduces the levels by similar degrees and so can replace the plane for much of this work with much greater confidence than you might feel comfortable with using a bench plane or a bevel up plane. Especially is this so when meeting rising or awkward grain as the cabinet scraper never baulks at wild grain.It never tears out grain like planes can, except in very soft and low density woods

The sole controls the depth of cut in the same way the plane sole does. This serves to control the level of the surface much more than say a card scraper, which generally follows the surface undulations if there are any. Using the cabinet scraper, you may well find you cannot get to flawed areas in low spots and must take down the highs to get down to them first, which is really what you should do to preserve flatness anyway; just as you would a plane.

The card scraper often follows to refine certain areas and indeed you can flex the card scraper for localised clean up. Both scraper types can be used to take off the finest of cuts. Personally I would find it hard to do all of my work with only the card scraper, but of course I could. The #80 cabinet scraper is an essential woodworking hand tool for fine woodworking of any type, which is why both types are included in my new book.

Thanks Paul. The problem of course is now that you’ve blogged about this the used prices on eBay will be crazy for a few weeks 🙂

A more detailed and finely granulated explanation. You covered it all, Paul. I reiterate, you are the Boss with the hot sauce! L

I was a proponent of scrapers over sanding after building a Fir staircase, I have since discovered an original Stanley #80, and ordered a veritas blade. I’m astonished at how effective this tool is from recycled old growth Fir tabletops to green cherry, this tool can be used for final flattening and finish, love using it with a honed edge and a hook. It was hard hooking an edge polished to perfection but the result is spectacular.

Comfort, inc. lack of heat, are probably the main advantages, the flat reference base is probably the other main one. These advantages allow you to cover more ground, more quickly and with greater consistency – albeit with less sensitivity to small changes and differences. I use and like both. I prefer to use the #80 for fairly large (or very large) flat areas but for small/narrow things (e.g. bows, stool legs) and curved/odd shaped things (e.g. the inside of bowls) card scrapers can often go where the #80 can’t go. I sometimes use the #80 on the convex outside surface of large bowls but usually not. I use both types of scraper a lot – I prefer them to sandpaper and, by choice, I don’t own any sanding machines and likely never will.

I was just about to go through the videos to find your tutorial on the cabinet scraper because I was having a problem with the used version I had bought on Ebay. I had forgotten the 45 degrees for sharpening.

Now that we’re here… what is the minimal thickness of blade that should be used with the Cabinet Scrapper? There must be a minimal thickness. No?

1mm is a good thickness and though you can go thicker you want it thin enough to bow when the screw is applied from the back of the scraper body as the tool does not work at all without this capability. 0.8mm is about minimum as less than that the blade does flex and this can cause chattered surfaces and less clean surfaces cutting sometimes.

Hi Paul, I have a question regarding the angles of the burr (cutting edge). In you drawing, you indicate that you turn the burr additional 7 degrees from the bevel. When I read the instruction manual for the veritas cabinet scraper, it says you should turn the burr much more than that (15 deg. from horisontal when you have the blade vertical in the vise). They use another reference, but if I convert it to the same reference as you use, they recommend 30 deg. where you say 7 deg.

So, unless there is something I have missed, the Veritas edge will engage the wood at 45 degress, while the Sellers edge will engage at 58 degrees.

I know there are some tolerances to that angle, but this seems like quite a lot. Could you please help me understand this.

Best regards,

Kjell

It should read 7-degrees added to the 45-degree filed bevel and so equal 52- degrees on the face of the wood. I rarely ever go beyond this because turning the edge too much edge fractures before the steel even hits the wood in my experience. Also, I find that most people turn way beyond 15-degrees and end up damaging what they are trying to create.

Ah,

First of all, I think we both got our numbers a bit wrong.

When using the Veritas recommendation, the edge meet the wood at 35 deg., not 45 as I first wrote. With your method, it really does hit the surface at 58 deg. (70+45+7 = 122, 180-122=58).

Since the exact numbers aren’t really that important, I’ll just leave at that. What really matters is the practical aspects of turning the edge too much. This explains why I can’t get my scraper to work properly for more than a couple of strokes. This also explains why the burnisher runs very smoothly at first, but after turning the edge beyond a certain point it gets a little bumpy. Probably because the edge starts to fracture.

I’ll try to reshape my scraper tonight.

Thanks,

Kjell

Would there be any advantage to honing a card scraper to 45 degrees and then using it like a cabinet scraper by holding it at a higher angle to the wood?

Thank you for you explanation Paul. It has been a blessing to have both the card and cabinet scrapers become functional elements of my toolset.

Looking forward to your book.

Best,

Brett

It’s cool to learn the finer details of a tool like the #80 and I really found it interesting when Paul said that the #80 does not scrape, it cuts and that the hook on the blade is basically a cutting edge and a bur. These details really help to understand the tools we use and it’s easy for these details to get lost through the years.

For Christmas I got the new book from Jeff Miller and in there he too explains that a scraper is not scraping the wood but cutting it. I can’t wait for Paul’s new book to come out, as I’m sure there are plenty of other cool tips to be had.

Sooo, I spend some time with my lovely scraper tonight. After 2 false attempts, I managed to create a super nice edge. Lovely thin curly shavings filled my little workshop. Spruce, oak, walnut?? no problem.

I think I folded the edge slightly more than 7 degrees. I think I was slightly less than half way between the 45deg bevel and horisontal. Somewhere between 15 and 20 degrees.

Kjell

One small question to Paul (or someone else who knows more than me):

When you wear out an edge, how do you go about to touch it up. I’m not talking about a complete regrinding of the bevel, only the quick resharpen you do while you work.

I found that if I lapped off the worn edge, I needed to do quite much grinding on the bevel in order to get a new edge. This felt like an operation you only do once in a while.

My second attempt was to burnish the edge away from the flat side. It then came out on the bevel side. A couple of strokes with my finest stone on the bevel side, and it was gone. The I created a new edge.

Are there a better way?

Kjell

On #80s you always refile the bevel and go the full course for honing and turning the edge. It rarely works to simply burnish it as you can with the card scraper. It actually takes only a couple of minutes and most of that time is taking it out of the body and reinstalling after resharpening.The card scraper can be returned three or four times before refiling is necessary usually, but there again it takes such little effort to refile i usually just do it. When you say grinding are you talking about filing? I never grind any of my tools on an electric grinder any more. Totally backwards step for me. I only grind if I damage an edge in some way and I haven’t done that in many a year. Grinding tools on any kind of an electric grinder seems to me to be quite primitive really. I haven’t found any benefit to it unless I get lazy in my honing and start lifting up to get to the cutting edge quicker when I am honing on the diamond plates.

😀 “I haven’t found any benefit to it unless I get lazy in my honing and start lifting up to get to the cutting edge quicker when I am honing on the diamond plates.” – the origin of the convex bevel I suspect! [I have nothing against convex bevels, that’s what I usually have on my plane irons.]

Hi Paul, and thanks for good info.

I didn’t really mean grinding. I mix up the words from time to time since English is not my native language. I don’t own a grinder, and I will probably never buy one.

What I meant was lapping the bevels on a diamond stone, and possibly filing it.

Cheers,

Kjell

Ah, got you.Filing is just the quickest way of getting back to an edge again and because the bevel is angled, when burnished this becomes more rounded than a flat and therefore needs to be filed back to flat and 45. You can skip honing and go straight from filing to consolidation and turning but the edge is usually not quite as sharp, but it will cut and reduce levels rapidly. Then, when the tabletop or whatever is down to level, resharpened and hone this time and then finesse the last levels.

Thanks again.

I just have to say that this blog, and the WWMC is an incredible source of information. For many years I thought that making furniture was too difficult for me to do, but after only a few months with WWMC everything is turned upside down. I had to buy a Norwegian woodworking book in order to learn what everything is called in my own language. After all, what’s a tenon joint or a router plane in Norwegian?, but all the techniques and knowledge you share is incredible. The fact that you personally participate in these discussions is a real plus.

Right now I am working on a modified version of your craftsman lamp, and it’s turning out pretty good. Far from perfect, but I manage do most of my mistakes where they cannot be seen.

Kjell

Hi paul,

in your previous post you said that you only knew of Veritas making a good alternative to the old No.80.

I was gifted (well, I used my wife’s credit card 😉 ) a very good, pretty faithful copy of the ’80 sold by Axminster Tools under their ‘Ryder’ brand — same dimensions as the original; Sole just needs a bit of wetndry; thumbscrews and with a slightly thicker (I think) 2 3/4″ (70mm) wide O1 spring steel blade, ground at 45′ on one edge.

Cost me £29.95. They also advertise a replacement blade for less than £6.

It’s nicely finished and cheaper than secondhand fleabay originals.

I’ve no interest in this company, just thought I’d share my experience of a good alternative to the Veritas.

The issue we found with Faithful brand 80s was with the recess holding the too thin cutter was too deep and the cutter was only .5mm thick which. They haven’t resolved these flaws so we have been unable to recommend them even though a director of the company said he would look into it and get back to me.

Hi,

I have to own up to making a false claim.

The Rider No.80 actually lacks the correct edge angle – It is actually ground to just 25′ — I’m afraid my eyes deceived me.

Thanks for the sharpening advice Paul. I previously tried following the instructions that Stanley provided with the no.80 in their pamphlet, which said to turn the edge 30 degrees for a total of 75 degrees. I always found it would just grab or tear at the wood.

Last nite I flattened the back, re-ground the edge to 45, honed it on my diamond plates and turned the edge another 7 degrees or so with a steel rod. What a difference! It now shaves the thinnest shavings I have ever seen, leaving the surface as smooth as glass.

I’d always considered the 80 to be just a so-so tool, now I can see where it will be used quite a bit.

I’ll be glad when your new book comes out, I’m sure the information it provides will be invaluable to me.

Best regards

Stephen

Paul, you have come up with this wisdom at the right time for me. In September, I purchased a Faithfull No 80 scraper. I resisted using it until Christmas as it was supposed to be a present from my family. The quality of finish on the tool was poor, with the usual machine marks and a crack through the casting starting at the mouth. I contacted the seller, who replaced it without any problem. The replacement arrived about an hour ago and the blade does not sit flat in the casting, due to too much metal or finish in the mouth. Easily fixed with a file! The blade clamping bar is askew by 2mm and it looks like the drilling was done by eye, not in a jig. There is the possibility of a crack on this one as well, though it may be just a score. I’ll see if flattening the sole gets rid of it.

In summary, I have fallen foul of the old adage “Buy cheap – buy twice”. I will not send this one back as no doubt it will be resold to another sucker. I wish your advice had come out 3 months earlier.

Thanks for all yo do to educate us.

Keith

I’ve been reading several articles on your blog about scrapers since I just purchased a #80 Stanley and needed to know how to sharpen and use it. First let me say “mission accomplished” I now feel I have enough information to be dangerous and start learning through practice. In another article I read where you said I could use a “card” scraper of no less than 1mm to make a blade. So I started looking for one. I started laughing when I read in this post your angst at the thought of people using a scraper to actually “scrape” Why did I laugh you ask? Because when I found one that is 1mm, the description read “The two thicker ones are 2-3/8″ x 6″ (60mm x 150mm) and are for heavier stock removal, the 1mm scraper being suitable for paint removal”. I guess the word hasn’t gotten out to this particular, oft touted tool supplier.

Yup, gotta watch tool traders selling snake oil. A little omission here and a little extra hype there. Paints are really hard on scraper edges because they often have powdered minerals that are highly abrasive and these damage the fine edge of the scraper. Better to buy a bonafide paint scraper like the Skarston scraper or the Bahco 650 scraper, which are actually scrapers and not a highly refined cutting edge tools.

The veritas seems to be out of stock everywhere. It is difficult to get a good cabinet scraper at a reasonable price unless one is lucky on ebay, not easy with todays ebay prices. Can the “bad ones” like the kunz be made good with some work? An hour work to make one ok to work with is better than having none.

I’ve been having good luck with card scrapers and decided to buy a Veritas cabinet scraper. I polished and honed the back and the bevel. As I was forming the hook I noticed light reflecting from the junction of the bevel and the back. I took this as an indicator that a hook had formed. After installing the blade I was able to use the adjusting screw to change the scrape from a fluffy shaving to one similar to a well adjusted #4. It’s a joy to use.