Comparing Saws for Getting Started

For more information on saws, see our beginner site Common Woodworking.

With so many requests as to which saw to buy to get started I took on the task to work with a wide range of different saws including the now overly ubiquitous Japanese throwaways. There is much between the different types that should be discussed to debunk the self-appointed experts and the misinformation mass-information constantly spews out that ends up being regurgitated across the globe. Perhaps I will get to some of that too, but today I want to answer the question that keeps coming in and that is, “I don’t feel confident in buying a secondhand handsaw on eBay because I don’t know what to do if it needs corrective work like you do. That being so, is there a saw I can buy that perhaps will get me started for now?” Of course there are high-end saws that come with superbly sharp cutting edges ready to go from the box, and then of course the hard-points do cut exceptionally well for crosscut work for almost no money; either way you at least get to work with for few weeks. It doesn’t take too long though before you realise that the resharpenable high-end saw is becoming ever duller and cuts less productively and the throwaway needs replacing too. What you are really looking for though is to be in control and throwaways for real woodworkers is never really an permanent option unless you are cutting OSB all day long. My guess is that a new saw is usable only for somewhere around 30 hours before it needs sharpening depending on the wood, amount of hard knots, snagging, grain direction and so on. Dedicated crosscut saws dull much, much sooner because the pinnacle-point teeth fracture more quickly; perhaps half as much. These are the things people don’t know these days. The reality of the situation is that you MUST learn to sharpen your saws. If you send them off you are without your saw for two weeks. The cost of posting is £15 return with insured handling and you only get very standard sharpening with no customising. The cost stacks up and sharpening will be anywhere between £10-20. My advice? Learn to sharpen.

Of course the problems mentioned in buying secondhand are real. Most secondhand saws are indeed sold because usually they no longer cut well at all. The best saws like the ones I have shown over the years are there in abundance and I continually buy the ones that stand out for friends, students and my own needs in the school when we have a sharpening class, but prices have steadily risen.

The important thing in my view then is not to put off developing your saw sharpening skills for too long even if you are new to woodworking because the skill can and should develop alongside your woodcraft. I learned to sharpen my first saws within two weeks of starting my apprenticeship. Also, saw sharpening soon becomes one of the most essential aspects of your woodworking. It will be best not to start out with problematic saws requiring more expert attention or even a complete tooth recut. This article is about that. The problem then is which saw do you choose—£10 ones or £220 ones? Perhaps somewhere in between?

Because of my research I often compare different saws by different makers—old, new, old to new, old to old and new to new. It’s surprising how different they all feel. Some feel clunky, heavy in the cut and quirky too. Some benefit from weight while others are well suited because of their lightness. This can make saw choice difficult until you know what you are looking for and what you want from your saw. There is no one saw fits all but the first choice of saw can be important. I am always amazed if one saw maker makes a variety of saws under old trade names when the saws themselves are basically the same saws. I mean the steel plate is the same from saw to saw and so too the handle made from walnut rather than beech actually adds no difference to the functionality of the saw and to be honest beech is well proven as a saw handle wood when walnut was a scarce alternative if ever chosen. Of course the best saw handles have always been fruitwood. Primarily because it resists splitting, rubs out to an ultra smooth patina in a few months of use and indeed it takes a crisp pattern if the handle is carved as they were in times past. I recently put two saws side by side.

Saw comparison

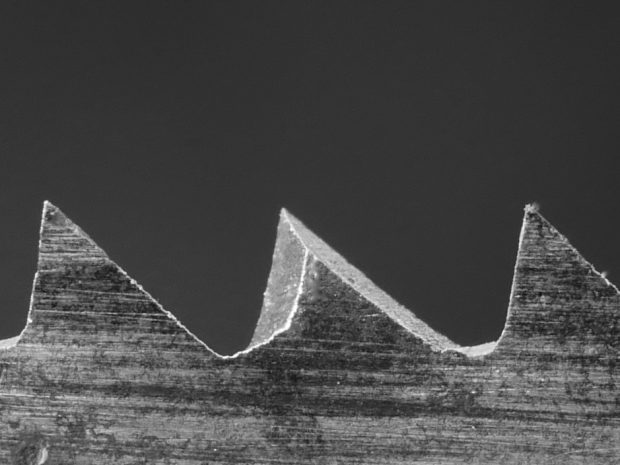

I decided to take a premium saw but based my decision on price and appearance mostly. One saw, a premium ripsaw with 7 PPI made at the Lie Nielsen factory, cost me £220 plus shipping so £230. For my second saw I selected an online option Spear & Jackson resharpenable crosscut that cost me £22 including shipping via Amazon.co.uk. This saw was a crosscut because S&J shortsightedly don’t make or sell a ripsaw version. Of course the two saws could not be compared initially because of the diversely different tooth patterns so I changed the spear and jackson to a rip pattern for the purpose of my comparison and I sharpened the saw to the same angle as the rake on the LN saw. Reshaping the tooth pattern and sharpening takes me less than 10 minutes. Unfortunately most people including most professional woodworkers (perhaps especially professionals) would not know the difference and try comparing the two types side, which would be an unfair comparison. Using a crosscut saw for ripcutting is about 50% less efficient.

My first thought took me back to picking up the Lie Nielsen ripsaw back somewhere in 2011. It was very lightweight and felt as smooth as silk. I liked the traditional look of the handle and it felt lovely as all Lie Nielsen saws do. I think that this consideration is important and often sadly neglected by makers of tools in the western culture these days. I am not sure if Stanley or Record ever put customer satisfaction high on their list of priorities but Spear & Jackson of the 1800s absolutely did. Two world wars took its toll in that British makers of hand tools produced a line of tools clearly stamped “For war issue” because the demand was too high for production of quality during that period. All brass was used for munition shells and so brass knobs and fastenings were replaced with steel or nickel-plated steel and press-fit studs.

This article prefaces the comparison I will be presenting with a video shortly. It will make the way for new woodworkers to get started without it costing them an arm and a leg. Sorry that this is a long introduction but the next will be more nuts and bolts.

Hi Paul,

Thanks to your videos and books I am now able to sharpen all my tools with little effort.

The only problem I have encountered is the cost of some items like saw files which cost more than a new saw with hardened teeth. As an example I can buy a brand new panel saw (hardened teeth) for $10 whilst I can only buy one saw sharpening file for $14. Even though I am careful to cut on the push stroke only, these files only last for about 2 and sometimes 3 saws before being useless.

I will keep on sharpening my own files because I dislike waste and enjoy having the ability to do things myself even if it makes little economic sense.

Thank you for being so generous with your expertise and I always look forward to your blogs and videos.

No! Lee Valley Veritas carries all Bahco files for around $5-6. I expect Bahco files to generally sharpen 10 to 20 saws depending on the steel plate of the saw. Here is the link for LV.

Sounds like you are getting burned on files. I purchased the LV saw set to redo a collection of saw I got off ebay. Compared to my Home depot files, it is night and day in both durability and cutting. Getting the flat and needle to to finish of my collection simple becuase of the better value. Now if only I could find rasps equivalent of the Bahco files.

New Spear & Jackson handsaws are made in Taiwan, yet can barely be seen in Taiwan’s shops. Pretty sad.

How often do we see that these days. It is so unfortunate that what is made in Asia for us here in the western world is not available in the country they are made in.

Paul,

Were there alternative tooth patterns that might look like cows and calves? I have a crosscut saw on which the pattern of teeth is so uniform that it seems unlikely to be clumsy sharpening. The pattern is alternating big gullets and little gullets. This is a 22″ Disston D-7 that was stamped 12 and is still 12 points. The odd pattern goes all the way, toe to heel. Imagine sharpening every other gullet deeply, flipping the saw around to do the other fleam angle, but only going about half as deep.

Ed-

I have one of these my self but about 26″. I am pretty sure these are greenwood pattern teeth, but I can’t find much on the pattern to figure out how to sharpen it.

I can’t answer you, Ed. Sorry.

Hi Paul,

Your recommendation is for Bahco files. Fortunately there are available in France via amazon (as well as Spear & Jackson saws).

But I remarked that you mostly use tapered files. Barko also produce two-ended files. I suppose that, by reverted the file in the handle, it can last twice the time of a tapered one as we never use the full length of the file.

What is the difference in using a tapered instead of a straight file? Why to choose one or the other?

Regards

Jean-Luc

Both the two ended and single ended files are in fact tapered so both work just fine. Often the double-ended saw files are the smaller files so you usually get say two file surfaces of 75mm long.

Hello.

What do you think of the amount of set on these Spear and Jackson saws?

Would you apply the same amount of set if you had to re-set them?

New S&Js are overly set so it is a question of taking set out so, no, you don’t need to until you have sharpened the saw several times and the set has gotten to little. Usually 6 to 10 sharpenings.

Dear Paul,

I have my eye on an 1896 Dyson D7 11 tpi panel saw; it’s probably a cross-cut saw based on the information I saw taken from an old Dyson catalog.

Would you recommend the purchase (currently around $25) and would you recommend that I re-sharpen the teeth to a rip saw pattern?

Best,

Steve

Are you saying dyson and meaning Disston and autocorrect is changing it? No matter really. I also know most people advertise saws as crosscut saws with no clue really so it makes little difference as it’s more likely they will be ripsaws anyway. £25 is never too much to pay for any saw.

Disston D7 lol. I guess I’ll find out when I look at the teeth. I thought that this saw might a good first saw to saw along the grain to resize small pieces of stock. It looked like you used something similar during the wall clock lesson. That said, would you recommend changing crosscut pattern (if it is a crosscut saw) to a rip saw pattern? Or does it make a difference?

If you use the search button on my blog you will find information on saw sizing and type being linked to teeth per inch. The smaller teeth, say 8 to 10, can be used for both ripcutting and crosscutting using the single ripcut pattern for the teeth.

Paul,

Thank you – will do. I’m enjoying your blog and your videos. I’m collecting a set of fundamental tools, and I am looking forward to starting the wall clock project when I am done. Your generosity in sharing such valuable information is exemplary..

Best,

Steve