Is the Scrub Plane a Sledge Hammer?

Someone wrote in and said, “Sharpening a scrub plane iron to strop level,10,000-grit—Really?” Well, I thought to myself, ‘Where did that come from anyway?” I mean, Yes! Why not? Then I said to myself, ‘Why, anyway?’

I’m not altogether sure if it was a rhetorical question but it felt like it. The short answer from me is yes,always, generally. But I did feel that the question, if asked genuinely, deserved a forthright answer. Whereas most of us do see the scrub plane as a more heavy hogger plane best suited to hogging off masses of waste wood quickly and effectively to get down to the bone and nearer to the final levels without wasting effort and energy, sharpness on our finer planes and such like that. Ain’t nowt wrong with that, so you could just sharpen to 250-grit and the plane will cut off what you want well. It’s more to do with proclivity I suppose. I like to take all of my cutting edges to optimum level even though technically it may not always be necessary in for instance rougher carpentry work, such like that. The reality though is this, most of the time it takes just a matter of seconds to go from a coarser 250-grit level on up to say a 10,000-grit stropping level. The difference is only 30-40 seconds and such effort makes much greater ease to the work and the surface cut leaves the wood silky smooth even from a scrub plane generally meant for coarse-cut working. So in my view the little extra effort is so well worth it. Especially is this so if you use the plane for more than mer stock removal.

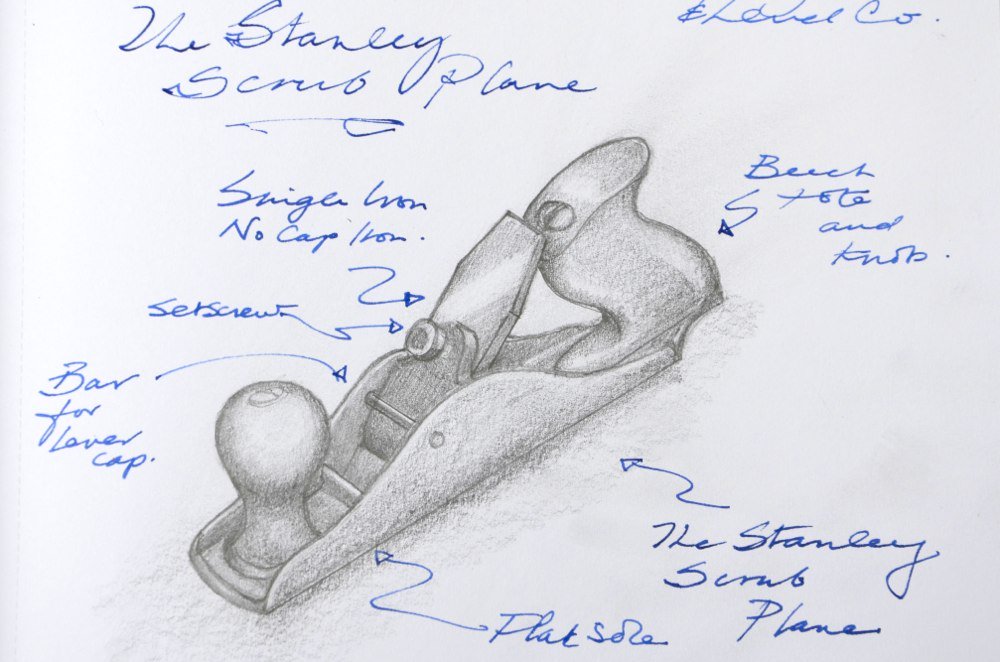

When I used my first dedicated scrub plane I did think it to be the ugliest plane Stanley ever made and I still feel a bit that way about them. As the dedicated planes that they are though, and I am talking about the Stanley # 40, they remove heavy amounts of stock such as defects in a heart beat. Now that we know they work well, they are hard to get hold of here in the UK, primarily because they were only made in the USA by Stanley USA.

The adapted scrub plane for finer and versatile work

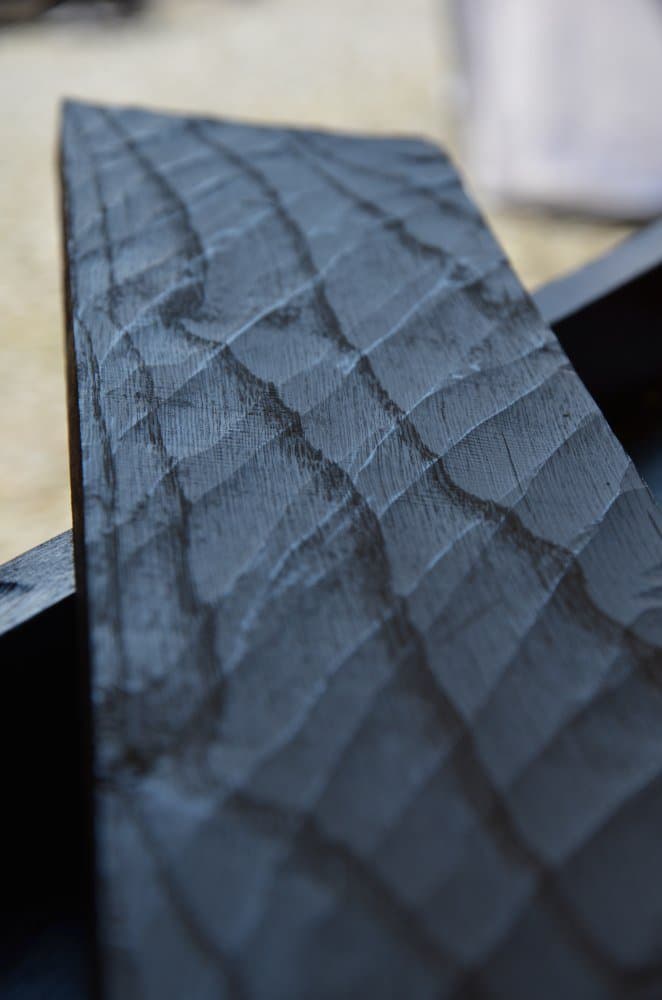

Altering a standard #4 plane to work as a scrub plane does not mean your plane is for the rough work of its original counterpart the #40; not at all. Changing a Stanley the way I do mine means your scrub plane will perform predictably and can be used for refining work too. Sharpening it to the higher levels means you will tear the surface far less, reduce characteristic chatter and skudding and create a very lovely surface where you thought it might not be possible. In fact, it will actually leave a surface reminiscent of the 16 and 17th century craftsmen where the subtle undulations of their wooden block and jack planes with their crowned irons textured their surfaces to reflect the true skill of their hands and leave you feeling this truly is hand made. And I use my scrub plane for other work too; stopped chamfers, bevelled edges for raised panels, roughing out my roundovers, things like that. So instead of seeing the adapted #4 scrub plane as a brutish sledge hammer, I perceive it much more delicately and as an instrument for much of my finer work too.

I find it best to identify the scrub plane with it’s own mark (on the heel). Nothing worse than landing a scrub plane thinking it’s a smoother.

Watch out for another article I am putting together to create a substitute scrub plane too. Coming up!

I recently acquired an EC Emmerich wooden scrub plane. It took me a little while to get the blade set right but it sure takes out a lot of wood quickly, although the width of the cut is quite narrow. I also have a hard time guiding it straight, it seems to want to wander to one side or the other. It must be something in my technique of setup but what? Any ideas?

be sure the blade is ground evenly across the edge. it may appear even when looking down the edge extending past plane mouth but you say a narrow blade so difference may be hard to see. maybe tracing blade edge on paper flipping over and retracing to see if any difference.

also be sure the bevel angle on blade is not steeper on one side. maybe just measuring the bevel angle on each side would show up an issue. Even a very small difference in cutting angle could cause your problem. especially because you say the blade is narrow.

also maybe Try using each side on the edge of a thin piece of wood and see if one side of the blade pulls you off line. I would slightly skew the blade when cutting so the blade does not just slip down the curve of the blade. if it does slip sideways easier on one side I suspect it is the bevel angle . Also when doing this is one side of the blade cutting better than the other. maybe just sharpness issue but suspect you would have tried sharpening earlier to solve problem.

Hi,

due to the small blade and the even smaller cutting surface, due to the heavy camber an ECE iron does have, my guess is that the blade is just following the grain.

You simply have to steer it a tad more.

Additionally, after a few strokes you have produced a “wavy” surface and the plane is now riding on the narrow wave tops.

I’m using that kind of plane for all my rough dimensioning. Personally I find that skewing the plane does help hogging of material.

Keep in mind, this is the first plane which does touch a rough board. No need for being precise at this stage.

Hope that kinda helps,

Stefan

I love this. How much would you think a fair price would be for an old #40? They seem to be listed on eBay in the US for quite a bit more than the #4. I just bid $77 USD on an old one that will need some work. Really enjoying your videos.

Here (Sweden) #40 Stanley copies can be found relativley often for good prices, since most people think they are inferior versions of #4s.

Sharp steels makes the work easier, so I see no reason not to bother with that little extra effort.

Last summer I found a Stanley 40 for $10 missing a lever cap and I made a wooden substitute, until I find one or make one out of steel. My question is would converting a number 4 to a scrub make a better scrub plane, because the number 4 has more mass? How do they compare?

Interesting. Had only considered a scrub plane useful for very rough work.

A few days ago I picked up my nasty Fischer-Darex #4-ish plane with plastic handles and a large throat. It was a gift, so no looking it in the mouth, I suppose. As I was holding it wondering whether to keep it or not, it struck me that it’d be a perfect candidate for conversion to a scrub plane in the next few weeks, as temperatures in the shed are slowly becoming more bearable. Was intending to re-view one of your videos on making a scrub plane, but will now wait with any modifications until I’ve seen your upcoming article. No doubt the wait will be worthwhile.

Won’t have to mark the heel of that Fischer-Darex as a scrubber though…. I doubt I’d ever mistake it for one of my nicely restored Stanley #4’s !

I had the same thought for my Grandfather’s old #5 Dunlap.

Will be perfect for this since I already have my #4 smoother

I recently converted a #4stanley that I got for $5 dollar at an antique shop. I followed Paul’s instructions to the T. It works fantastic ! It takes about 2 minutes to go through 3 stones and stropping. I will have to mark the heel as I have caught myself using the scrub plane instead of the smoothing plane. Great blog Paul.

A few years back after watching Paul convert a #4 to a scrub plane I saw at Harbor Freight an Windsor Design #33 bench plane for about $15. For myself I wanted a sledge hammer to get the wood into shape for a #4. Marking a 7 inch radius arc on the cutting edge of the iron and power grinding the arc, the now scrub plane works fine for me. The Asian people probably have smaller hands than I do. I did have to make the cut for the hand wider. There ain’t no mistaking it for a #4 and for my use it works great.

In a comment I made about this several years ago someone else said they done and had the same experience with that plane.

Make no mistake it is in no way a quality bench plane other that a scrub plane.

Paul you are using it for other things than a “scrub plane”. As a “finishing plane” I can see the need for the extra sharpness but as a strictly “scrub plane” that is like using a silk purse to carry rocks, not precious stones, but rocks like in the driveway. Overkill.

I really like your analogy however I’d like to also point out to Paul’s Credit on the advantage of the extra bit of time spent sharpening … the dragline silk of a spider is about 5 times stronger than steel of a similar weight.

So your silk bag of rocks is actually a really good analogy for an extra sharp scrub plane

I think that if you have a real need for a scrub plane, you should remain on the lookout for the real thing. The #4 trick (I used a 5 1/4 sized plane) works well, but it still takes more effort than the real thing because it’s heavier and wider. I definitely think that if you’re converting a 4, you won’t regret the extra few passes to get it in tip top sharpness. If you have the real thing…well, there’s no reason not to sharpen that either, is there!

I too have a # 5 1/4 set up as a scrub, and it works well. However, I have an old #35 transitional plane set up as a scrub and it is awesome. The worn old open throat clears shavings like a champ and the extremely low friction of wood on wood makes it glide like an ice skate. Almost all you can feel is the edge cutting the wood. Low cost, highly recommended. Save these old treasures.

I have a converted #4 as per Paul’s guidelines, and with a heavy set it removes a bunch of stock quite easily, the weight of the plane, an asset, as far as my perceptions conclude. As I arrive closer to the point of switching to a smoother, I back-off the cut and remove a lot of the deeper groove/texture from the heavier cuts, always cutting “air’ before wood — never the other way around as that scrub will knock out some big chips from the edges if you get too close!

Also by spending that 30 too 40 seconds more the blade lasts a lot longer between re-sharpening

Sometimes I think all three of my planes are scrub planes.

I have Stanley/Bailey #5 and Windsor Designs (Harbor Freight) and admit to honing and polishing both – although not to the level of a smoother. Increased edge retention and reduction in friction during use is a worthwhile benefit to me.

I have 2 No 5 tried to sell one on eBay it’s a faithful, plastic handles, cracked sole…..all explained and it works ok. Didn’t sell……decided to plane off my worn bench…..wow it works an absolute treat. It has a wider mouth than my Stanley but a straight iron. I also have a very old VERY worn wooden jack plane with wide mouth, again straight iron. Cuts through easy AND heavy knots…….so an answer to your “hogging off” is, have a big mouth like mine-:)-:)

Hi Paul,

You’ve said that the #40s where made only in the USA. What was used in England instead of the scrub plane or should I ask is there an alternative to a scrub plane?

Best Regards,

Shavit

I think you will find that it was harder to convert the English woodworkers to metal planes than their US counterparts. Wooden scrub planes are more efficient and easier to use wood on wood. Here is a link to a blog I wrote that will help you: https://paulsellers.com/2014/07/old-men-old-planes-old-ways-now-gone-the-origin-of-scrub-planes/

I am of the same opinion about sharpness. Over the last 40 years or so, I have come the opinion that a quick 1 minute stropping refines the edge making it tougher and longer lasting – a good time investment.

Hi Paul! This might be a little off-topic but looking at the first picture I wonder are there any reliable books or online resources about roof framing using traditional joinery?

Thanks for everything Paul you are an inspiration.