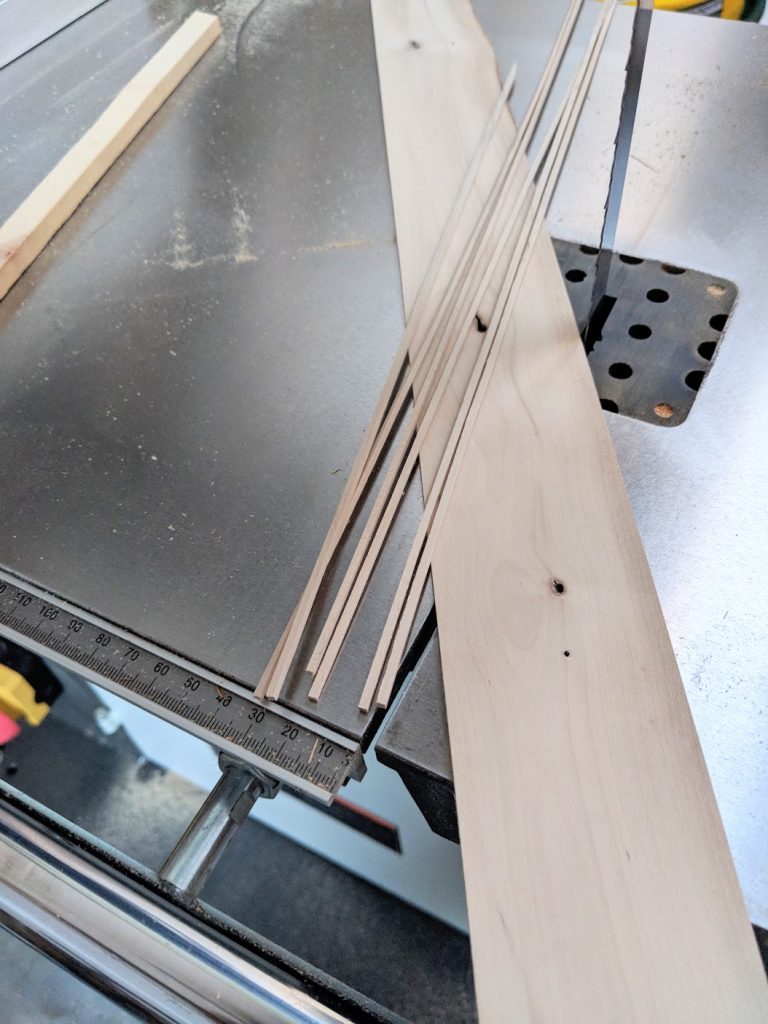

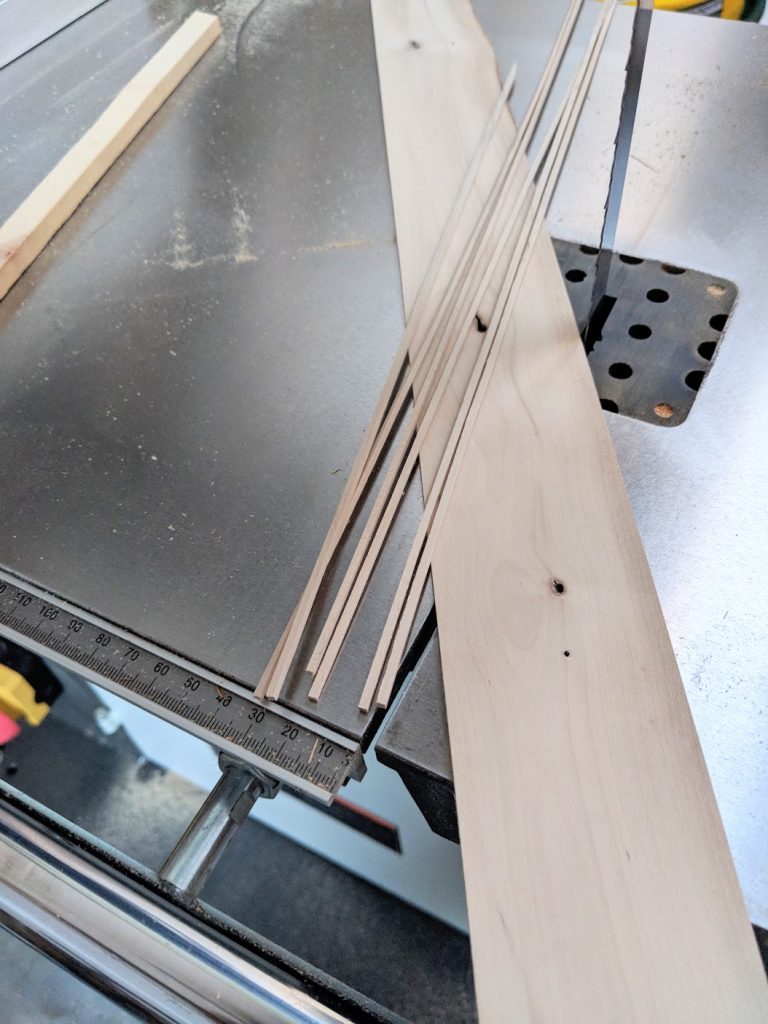

Bandsaw Set Up

Comments are closed.

You must enter certain information to submit the form on this page. We take the handling of personal information seriously and appreciate your trust in us. Our Privacy Policy sets out important information about us and how we use and protect your personal data and it also explains your legal rights in respect of it. Please click here to read it before you provide any information on this form.

Hi Paul. Glad your getting set up and this post is timely as I have some sections of Holly of similar size to handsaw. I’d be very grateful how you if you can share how best to make the initial cut on a round log as I feel rather nervous. Do you freehand it or use a jig to hold it so it doesn’t rock?

Sorry – should read bandsaw not handsaw!

Do a Google search for “resawing sled”. There are many different designs around, but fundamentally you just need something to hold a round log in order to prevent it rotating (and also to provide an initial flat surface to run against your bandsaw fence).

You can freehand, but unless you have a very smooth and even log, and are ripping straight down the middle, I probably wouldn’t recommend it.

The simplest one that I’ve used is just a sheet of material (e.g. MDF) with a couple of screws up through the base into the log. One long edge runs against your fence, and the log width overhangs the other long edge (in order to be sliced off by the blade). Once you have that first flat face you don’t need the sled.

I’m so happy to read about band saws! I hope you do many articles. I bought my first saw a year ago and, although I’ve used them in prior work, I’ve never been responsible for one, so I find myself noticing details I didn’t pay attention to before, when someone else set up the saw. So, I find myself wondering how much vibration to tolerate and how much wobble in the blade. The band saw has made a huge difference in my work because of its ability to resaw. I need to resist the temptation to be lazy or let it substitute for me developing skill, but I definitely turn to it for long rips, too, and preparation from rough lumber.

Hear, hear. I’ve been hoping for the last five years that Paul would do a video or blog series on setting up and operating the bandsaw.

It’s nice to see some machine use – makes us feel less guilty about using bandsaws for rough work and long rips and the like, which when you have limited time in the shed and you’re working on something with a deadline (like say, birthday or xmas gifts or the like) is sometimes a practical necessity. Personally I think if it was something you’d hand off to an apprentice back in the 17th and 18th centuries, it’s perfectly fine to do it with a machine today, but guilt is a funny irrational thing…

I have never wanted anyone to feel that they were cheating or make anyone feel guilty. This is often some kind if internal mechanism resulting all too often from peer pressure mostly I think. I never want to rob myself of exercising my skill and indeed keeping it finely tuned. I doubt many Olympians would want to say use a discus or javelin with some jet propulsion in their equipment or Tour de France cyclists use let alone want an electric bike. It’s mostly not about replacing skill so much as saving time and effort of a different kind. Finding the balance is mainly what it’s all about.

I enjoy dimensioning wood with my bandsaw. It is an old Craftsman 12” that I had to rebuild and then tweak for my needs. What fun that was. I truly enjoy taking wood from log to picture frame or box. I don’t consider using a bandsaw cheating in any way. I use hand tools for those thing where I want to feel connected. I also use my bandsaw and drill press and table saw for those jobs where it makes sense.

I know that Paul is budget conscious and he is very much aware that many of his followers are also budget conscious too, so cannot afford a large expensive bandsaw for hobbiest work.

But perhaps he could do an article not recommending any particular brand, but at least recommending a suitable type of machine for a home workshop, and what features/must-haves to look out for…

I’d certainly be keen to read that. My little bandsaw is a workhorse, for cutting turning blanks and for general jonery around the house, but I can’t say I’ve ever managed to get it set up to its optimum. Ripsawing in particular I’ve never really mastered. I can’t tell if the machine is underpowered or it’s me. Probably the latter …

Blades make a huge difference on a bandsaw; even an underpowered machine will often do quite well with a decent blade. For some reason many manufacturer supplied blades seem to be pretty poor.

If you’re in the UK I would recommend taking a look Tuffsaws. I have no relationship with them (other than as a customer). Their blades designed for cutting green wood were OK for a 5″ thick rip cut through some freshly felled maple (on my 1hp bandsaw). Not easy going, but possible (unlike with the OEM blades).

Their M42 blade (which appears to be made from stock supplied by Starrett) will rip through 6″ thick pine pretty much as quickly as I can push it.

I’ve no doubt there are other good suppliers, but the point is that a good blade makes a huge difference.

Hi Paul, I enjoyed reviewing the information in this article which is rather timely as I am just setting up my second band saw. Would you please list the details (kerf, TPI and width of each blades that you purchased to give me an idea of the types and range of blades that would likely be necessary for the average hand tool worker and turner. I would like to have a range of blades on hand to suit the type of wood, shape and the cut as I do not have easy access to band saw blades so prefer to store some extras.

Thank you in advance from New Zealand!

It looks like Paul is freehanding the log through the blade, but wouldn’t using the fence be better for a straight cut? I guess I’m not familiar enough with how to use a bandsaw. Maybe Paul will expand on the procedure he used.

Hi all, what is a good trick in cutting a round piece of timber, is planeing a small flat edge on one side, and placing the edge down on the saw table. This will stop any rockin and rolling if you get my drift.

Regards Larry.

I’ll have to remember that trick. I’ve used my jointer to flatten an edge but sometimes the fence and guard get in the way if the log is too big around. I have a 15 inch bandsaw with a 4 inch riser block. I can’t remember how large I can re-saw up to but it’s significant. Any decent sized log would be too heavy to manhandle through the saw if it was of any real length. I’ve often ripped the log in half before using the resultant face flat down on the table of the bandsaw. I suspect a long plane, like a jointer would be best for this hand plane trick of yours.

Cheer,

Daniel

Hi Daniel any plane would do, better still if you have a draw knife, it works well, especially if you have a large lump of timber.

Regards Larry.

Hi Paul

Still Axminster blades? How did you find their M42, I saw a post 4 years back when you said you were trying them out, but no follow-on

thanks

I have not used Axminster in a long time but I have relied on a company here called Tuff Saws. I am currently trialling a series of different blade types they make up and so far all their offerings have been superb. Here is the link: Tuffsaws

Thanks Paul, I’ll give them a try

Ddi you find the M42 worth the money? A better performance?

thanks

Really, excellent post.! That is a great article, informative and helpful as well! Thank you very much for sharing