Stuff’s Happening

Two things off the top of my head.

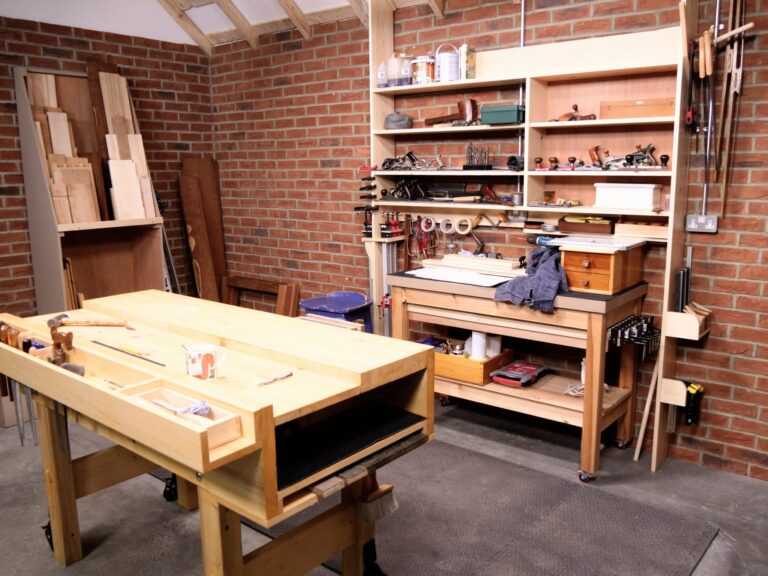

The Open House day is Saturday and that’s going well. Everyone here is excited to meet everyone coming and share their experience, show you around and explain things. I am going to give a presentation we will be filming to send round after the day, alongside a video update on my upgrades to the garage workshop and my workbench too.

The trestles I used in the workbench build intrigued many so we videoed the process and made a two-part series for both Woodworking Masterclasses and YouTube and that went up even as I was typing. It’s a quick, inexpensive and uncomplicated way to a first workstation that can then be used for a wide range of practical uses ranging from barbecue picnic tables to assembly tables and so on. Here’s the video:

A fried suggested that I first build a saw bench (or benches). Before getting into hand tool woodworking. I put that off for a while and recently (6 months ago) thought about it and made one!

WOW, why didn’t I do that earlier?

I plan to build a second one since many times you need two saw benches for holding work.

Paul I am curious why you didn’t suggest building saw bench(s) prior to the workbench or the trestles, saw horses etc.?

The audience we reach do not necessarily go straight out and build the workbench but bide their time. We have had videos and blogs available for years on the workbench build and indeed the sawhorses. Now that it’s out a global audience can see what’s needed, what’s available and choose order for themselves. Of course I did use the workmate for some of the work and you can build a workbench solely with one of these too. Just options.

I must say that watching you plane the trestle parts on the floor on your hands and knees was not only bizarre, but incomprehensible.

Do you really believe that people will purchase hand planes before they get a bench to use them on?

This is for a global audience. Perhaps there are people starting from scratch with very limited resources?

I think the answer to your question is a simple yes.

I’m not so sure it really always matters what sequence education comes in? We often receive information ahead of likely use, maybe even not knowing we might need it down the road, and file it away for another day, when it’s needed? Otherwise we watch something like this and get inspired to do it ourselves???

Oh, and yes, most people I think will indeed buy some tools before they acquire a workbench and indeed you can’t build a workbench without them. I know it might seem silly to some, but just owning tools can be a very big thing.

If you have the Internet you’ve got a table on which to plane a board and if you can afford a plane and a crosscut saw you can afford a clamp to fashion a stop.

Goodness gracious here.

Just a little FYI for David. A while back I put together a couple set of starter tools for a missions trip to Haiti. They did not have a bench, or trestles or saw horses. Along with the tools, I sent them instructional videos to watch (at the home of the missionaries).

So, as stated, it is quit possible that you can watch videos and have tools without a bench. It is even quite possible that they people (since they grew up in an orphanage) did not own a table of their own.

This is my personal thought. I took a class of Pauls a couple years ago. He, his family and Phil (which I met personally) are very gracious people. They do a lot of things (beyond what you see here) for free, to help people. They care about advancing woodworking for everyone, rich, poor, etc…. If you want to nit pick things, this is probably not the best place to do it.

I have do doubts regarding Paul’s graciousness, his generosity, his honesty and his devotion to the craft he so ably and skillfully practices. I also don’t doubt of your veracity in claiming there are, in fact, places (orphanages, Haiti) where people may have access to tools and not have access to a table.

Even so, I thought it silly to plane pine boards on the floor in that video. I am a long-time paid subscriber to Paul’s Masterclass video program, I have watched every single one of his videos, some multiple times, and have assiduously read his blog entries for many years. I hold him in the highest esteem.

As such, I don’t thin k it inappropriate to offer a mild criticism of one of his videos. Paul isn’t perfect. In this case I think he made a mistake.

3 yrs ago I bought a large used cabinet in a closing sale. I put castors in it and towel bar to push it with. I used that for 2 years as a bench and a tool chest. I remodel most of my home with it. Now last year with the help of a friend that had power tools we made my bench top. I now have a very small workshop with all my tools in it. Not everyone has the means to have it all at once. I still have the cabinet anchored in my workshop.

I think it’s more likely that the one’s deciding to build the trestles or workbench have some type of work surface already, be that an old kitchen cabinet with a counter top, a workmate-type of bench or even an old table but these are sometimes rickety and unsuitable to support wood for planing. By showing the unintiated that you can do it on the floor, using a board as a stopper, Paul shows that it is possible to start out with very limited means and I really approve of this.

I have an old kitchen cabinet in my basement workshop myself with almost no way to clamp anything to it so I’m often using the wall or a thinner board as a stopper for the board I’m planing. Unless I had this to work on I would find it easier to plane something on the floor than across a couple of sawhorses.

Also, the trestles he builds are far sturdier than the simple workhorses you can buy at home improvement stores, and will make it much easier to progress into making a workbench as well as something that you will have a lot of use for in the future.

I did buy a plane to trim a door 30 years before building my workbench (doing only house repair at that time).

Working on the ground is not very comfortable but it is only for the time to make the two trestles.

I had the “luxury” of a Workmate but it was skidding on the ground. It was more stable when I could clamp the newly glued-up workbench-top with it and then use this hybrid bench to make the aprons and leg frames.

I was impressed by the first Paul workbench video from 2012 where he was working on something wobbly with a tree as planing stop.

Before building my workbench, I had also used my plane with a picnic bench as a workbench.

Sylvain

I think one message of this video is “don’t procrastinate, just do it”

Sylvain

I was about 60 seconds into the video when I saw Paul do what I have had to do on site. You make do with what you have to facilitate a job. The easiest way to plane a door edge is for the door to not go anywhere. A block of wood offsetting it from a solid wall/post etc means you aren’t fighting it from moving with the plane. I have an older carpentry book which shows how you can facilitate a set of wedges directly nailed to the floor to hold a door(if you can get away with nailing into the floor) Of course I usually use a couple of different types of clamping systems to hold it upright. Sometimes I will use an electric plane! I think what Paul is demonstrating to the uninitiated is there are many ways to achieve an outcome. There are some ingenious methods using very little to hold timber to be worked and some of these can be invaluable to a person of limited means.

Yes I did

Yes, I did just that, mister Katz.

I suggest you purchase an inexpensive clamp to create a temporary stop on a table in your house instead of getting on your hands and knees on the floor. Learning to use and sharpen that plane will be far easier standing up than kneeing on the floor.

You know David, this is nothing more than opinion and we are all entitled to one. Why on earth you drag this out this way I’m not altogether sure. I’m 68 years old, had no problem kneeling to plane for ten minutes, and I actually enjoyed it and without invading the house, taking over a dining table or using an internet table. Believe me, it was enjoyable AND it showed it could be done simply. I think we’ll park this now.

Fair enough. We are, btw, the exact same age.

David Katz. I went and purchased hand planes before i had a bench to use them on. I then used the hand planes and a cheap home depot hand saw to build the bench. I am sure many others besides myself did the same….

I think you completely missed the point. Paul demonstrated that you can start with almst nothing and build the trestles that become the temporary bench you can use as you build the real bench. That’s real world my friend.

I built houses for a lot of years and every one of them started with some guys on their knees in the dirt knocking together saw horses. So what you saw Paul do is a great demonstration of what’s possible if you’re willing to make the effort.

I did

I owned many tools and did a lot of DIY stuff over the years without a workbench. I often worked on the floor. I put a crude fold up bench together last year after getting interested in woodworking. I wish I had seen Paul’s videos then – I could have avoided some silly mistakes.

I just ordered the lumber to build my woodworker’s bench yesterday. It may be weeks or months (if the wood needs to dry). Paul’s comment rings true for me that people do things at different intervals. I’ve done numerous projects and built several tables boxes benches, etc., both for myself and others before ever having an “official” workbench. I skimped on clamps too – in the beginning. Even today I only have 6 pipe clamps and 6 Bessey F clamps.

Doug, what I found out is that no matter how many clamps you have, you’re always one short. Harbor Freight has some really cheap bar clamps and I’ve got a bunch of those in addition to my Bessey’s. They work just fine for edge jointing panels.

Great video Paul. I enjoyed it and all the updates. My woodworking skills are always improving and I have you to thank.

This is an old thread, but still fwiw:

All cabinet makers I saw as a child (in South Asia) worked on the floor — planing, mortising, and assembling. They used a high surface only for sharpening. Working on the floor is common in Asia and I see nothing ‘incomprehensible” about getting on your knees. Woodworking on a bench is a Western thing — sure, its convenient but using the floor to build your first set of trestles sounds a natural choice.