Doing It Yourself

Do It Yourself was a 1960s movement that resulted in DIY shops abounding on Britain high streets and back streets to provide small quantities and tools for the weekend warrior. It was very much a man thing, of that there is no doubt and though there have been some changes, it has not been huge. Back then it was a Saturday morning thing to cycle down to the DIY shop to buy nails and glue and sheet goods cut to size by the store owner and leave with panels and sticks lashed to pedals and crossbars. In the UK it was an era when on my street of a hundred houses only three or four residents owned a car. The electric drills all had plugs and battery driven drivers were still decades away. England and Britain as a whole was perhaps two decades behind the US when it came to so-called power tools. Black and Decker had introduced its drill power and kits that fit the chuck to drive the first circular saw with a 3″ circular saw blade, a jig saw and a folded tin stand to convert the electric drill to a spring-loaded drill press.

My dad had no instruction and no internet, but he had perseverance. Late into his 60s, my age now, he spent hours in his shed down the garden. There was no Men and Sheds charities then. I would that there had been, just for him. There was no YouTube and no googling this or that for him, but I picture him now with his jars of nails and vintage drill he bought back in the 1950s drilling and installing shelves and curtain rails and so many other things. they were never pretty. They were cobbled together from something else, but they were always functional. He never fulfilled the William Morris tenets about beauty and functionality and having nothing in your home that wasn’t functional and beautiful. But he was happiest when he was tinkering. I remember when I told him I had just finished making two pieces for the White House Permanent Collection and my delivering them to the West Wing. I made him a proud man.

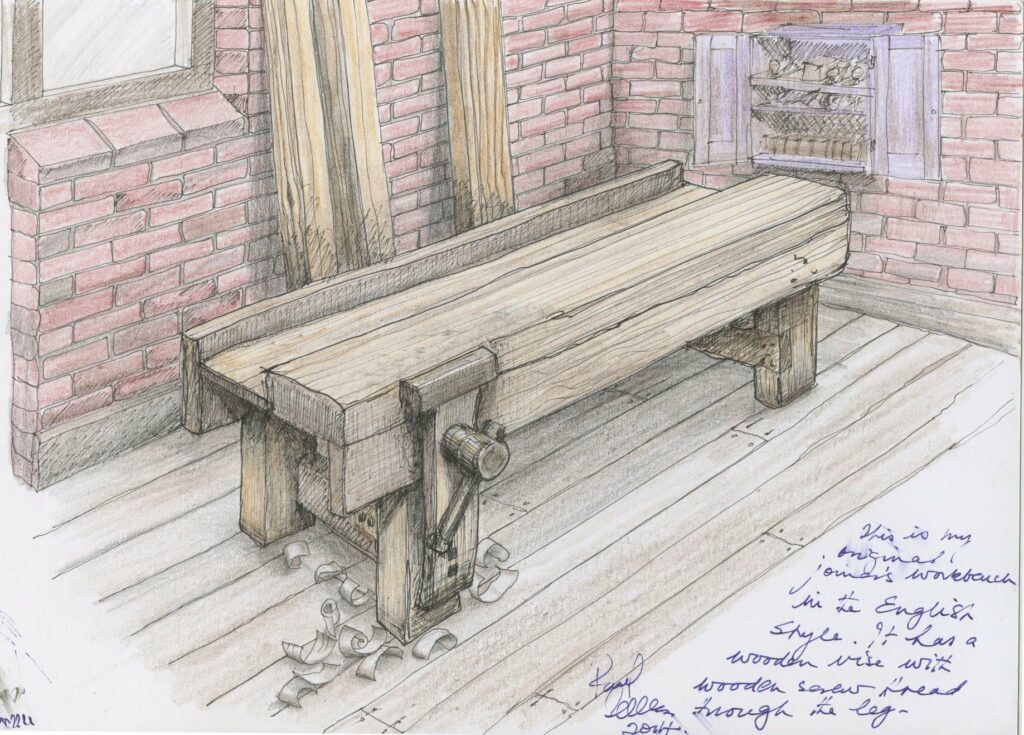

We are on a DIY journey my friends. My garage-type/size workshop has always been key to its success and your success. Find a corner in the attic or shed and join me and others on the journey. If you could see what we have made over the last few years it would both amaze and encourage you. Not thousands of pounds/dollars worth of equipment, no fancy workshop, no fancy workbench either. A few years ago I wrote blogs naming this work we strive to do the Real Woodworking Campaign because for me I was on a campaign to reverse the effects of negative training where all cuts in woodworking came from a machine. Today 1.5 million people follow our work every month and it needs to keep growing if indeed we are to continue our success in making woodworking a Family Woodworking effort. Getting the kids involved early is a key to success. They have been left outside the workshop doors for far too long. The campaign is ever advancing but we need your continued support and encouragement. Have a great woodworking weekend.

AND YES, YOU, You can do it! …… yes I did Paul, I did my first housing dado tonight, night before I did dovetails and last week i did my first mortice and tenon. No power tools used because I have no power. I will show the kids early. Thanks for the encouragement Paul. I will make fine furniture one day.

Yes I owned one of those B&D drills complete with Circular Saw attachment. I used to work part time for my Father in Law doing home renovations. Very crude against today’s standards but effective when you were cutting up building boards to make stud walls and the like. No big box stores in those days. We had to get our materials delivered by truck from the timber merchants.

About kids – I have an 8 year old daughter who is interested in my tinkering and wants to join in. I however try to keep my tools sharp which is sharp enough to badly hurt the hand of someone with the motor skills of an 8 year old. I know dull is more dangerous, but still.

So yes I’d like to encourage her, but with the safety concern, where to start? Any tips?

Mic

Hi Mic,

My chisels are and always have been as sharp as a scalpel. My son, too, wanted to try his hand at 10 years, so I made a chisel blade out of a scrap piece of oak, fixed an old handle to it and showed him the basics on some foam packing (the harder stuff). Here he learned how to control the tool and if he missed or held it incorrectly, he’d hit his hand but would not cut himself. After a few hours of practice, I handed him the real chisel and a piece of pine. My son is now married and he brings my granddaughter to watch me. At 2 years, she sits and watches as my son and I work together on occasion.

Yes put your arms around her to guide the saw or chisels

For two reasons one possible safety and most important for a cuddle……..children are only loaned to us

I have taught hundreds of boys woodworking with hand tools, a few girls too, I never held the chisels, planes and spokeshaves from them, super-sharp. In all the teaching I did I always insisted a parent be with the child. I am not responsible for teaching AND discipline. I don’t recall anything ore than a nick happening. Not saying it can’t happen.

My dad was more of a carpenter, that is he could build houses very well but when it came to the finish work it was functional, presentable but not the prettiest. After WW2 he built our home and he bought his first electric circular saw. It weighed about ten pounds, the housing was solid aluminum and of course the plug was ungrounded. When used it screamed like a banshee, of course there were no carbide blades so he would just touch it up with a file to sharpen it. He would wait until 8:00 am precisely to run it figuring the neighborhood had gotten enough sleep. When he passed people came up to me and mentioned that they knew exactly what time it was by the sound of that saw on Saturday and Sunday morning. He never had to tell us as kids not to touch it because we were all terrified by it.

Paul,

I have hit on it, your writing style. Why you are the Thorough of woodworking. I sincerely mean that.

Wow that one got me thinking of my father. ( I wish I could talk to him now!!)

His “workbench” was our coal bunker…no electric drill just hammer and nails, nails in a piece of newspaper stuffed in his pocket from work.

A lump of wood to replace the seat of my second hand peddle car. I’m 72 and can remember distinctly not knowing how to get it moving by pushing the peddles.

Men pushing a bike…wood on peddles….children lucky ones had home made seats on the cross bar…….powerful stuff Paul…….me talking while he tried to check his football pools coupon !!

Loved reading this. Similar memories. The dog chain I was supposed to be holding tight to me tick, tick, ticking in the front wheel spokes as I sat side-saddle on the cross bar, down the cobbled hill at ninety with my boxer dog running along side trying to snatch the dog chain as we barrelled past the world around us. My dad was shouting, “Bloody ‘ell, Paul, get that chain in or we’ll both be done for!”

Ha fantastic.

The picture of the Black and Decker drill advert reminds me of the drill my dad used to own. His was made by Bridges I think, which was taken over by B&D.

My dad’s DIY was functional rather than beautiful too, although I do have a

picture of squirrel that he carved into a piece of wood hanging on my wall which to me is quite lovely. Not because it’s a masterpiece, but because my mother drew the squirrel outline (she was a bit of an artist) and he carved it; they both passed away a while ago.

Although home DIYers had no internet or YouTube in the early days, there was television – in no way can he be compared to what Paul offers us, but anyone in the uk remember Barry Bucknell?

They didn’t have internet but they did have magazines such as Popular Mechanics. I like to read this old magazine, from about 1930 to about 1960 (all old issues are available for free download as pdf on archive.org); lots of Yankee ingenuity in it. I like the ads for the tools too. In those days they were advertizing the tools that I buy nowadays at fleamarkets for peanuts. Back then when new, they cost an amazing amount of peanuts….

Popular Mechanics dealt with anything – from nuclear submarines to sharpening and using your Stanley #4 or brace & bit, making simple, practical furniture and building your own house.

Loved this, US memories but the same feeling of home and of learning from my father.

One point – today’s “Maker Movement” was begun on the principle that “if you can’t fix it, you don’t own it” as a way of combating waste, planned obsolescence… Happily enough it has evolved into a broad community from geeks to artists and from young to old all focused on making things (it seems like they make everything!).

It’s really cool to see both craftsmanship and caring melded together. One 16yr old build a solar powered centrifuge from spare/cheap parts with the plan to distribute it to areas where doing basic diagnostics lab work is near impossible. Gives one pride and hope our sons and daughters will turn back to the principles you share Paul.

My dad was more into engineering than woodwork, and sadly passed away before I caught the woodworking bug, so never got to see the workbench I made with my own hands (under Paul’s video guidance, of course). But he’s always in my mind when I approach that workbench to start/continue on a project. Reckon he would have been pretty chuffed with the things I make.

Paul,

My father bought in to that same movement here in the US with much the same results, I wanted nothing to do with all of those sharp moving pieces that could remove a digit in a fraction of one second. The results from those projects didn’t turn out so well either! I always knew there must be a way to use the so called “antiquated” tools that have been bumping around here for 100 years and when I stumbled upon your website by chance a few years ago I knew I found the way for me. Since then, I have even attempted to give up my eastern throwaway saws, the Dad found a good source of old Disston hand saws that were ready save for the rehab. We have had a blast, he sourced enough saws to last two lifetimes and I am well on my way to relearning how to sharpen a western handsaw. Dad is 83 now but turned out to be pretty good at finding old hand saws – with a lot of emails back and forth we have had much fun talking about hand tools and what can be accomplished with them – both of us have been amazed and learned so much – thanks to you and your team of people. Keep up the good work and thanks for setting us back on the path we lost 50+ years ago here in the states. I think this adventure has even brought Dad and I closer discussing all of your projects and hand tools in general.

Cheers,

Mike Z.