Singing Work!

I tried singing low and I did, a bit, now and then, high, high, a break, then low, but they sang low, all the time with every note tuned to melodies that filled in harmony as we built a staircase.

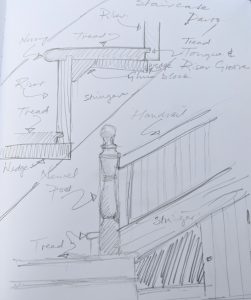

Riser, tread, nosing, wedge, stair string, stringer, glue block, housing, half landing, quarter landing, dog-leg, newel post, balustrade, baluster, handrail, new words rolled off singing tongues, I plucked them from the air, the words about the stair and kept them, stowed them, held them tight.

I was happy in the songs of work and the melody of our saws racing through the wood and the sawdust we thrust in synchrony from the kerf in each falling stroke the saw cut.

It was rhythmic, a rhyming of those compelling strokes I liked the most, poetry in the saw, the plane, the mallet’s beat to mortised hole, a sweeping plane and a muscled straining, planing, sawing, chiseling, malleting and there it stood, a staircase, sung into being by men and boy, a few hand tools and willing hands united in the growth of wood and the standing of a thirteen-tread staircase.

Just beautiful! I can see the work underway, and the joy and pleasure in doing it. Thank you for sharing this,

I have a cheap big box store stare case in my house that is just horid. I have tried everything I can think of to quiet it down when any weight is applied to a tread, all to no avail. I would love to learn to build the stair case in Puals drawings, but there was a reason the young person apprenticed into that trade. I hope Pual and his crew do a series on measuring for stairs and proper construction. Thanks Paul.

They are one of the most gratifying things to make in joinery, especially when done right. I am most grateful for every set `i ever made. And the thing is they are not at all complicated, even with winding steps for returns and such.

A series on architectural woodworking would be awesome. I sometimes watch U.K. TV shows that feature old estate houses and cottages (even old churches) and look past the actors at the doors, paneled walls, gates, stairs, mantles, even lich-gates, (Paul repaired one of these) to try to determine how they were made. The craftsmanship is amazing.

The eye and instruction of an experienced craftsman/joiner could really open up this fascinating subject. I picked up an old book called ‘modern carpentry’ from the early 1900’s and was amazed to see that a good portion of the book was not about joinery, but about geometry; some of it pretty complex (another subject/skill being lost over time). Angles and curves in three dimensions and the like – these old-time builder/craftsmen were much more knowledgeable than most ‘moderns’ give them credit for. The modern approach to house building as pre-manufactured ‘kits’ (with the main emphasis on cheap) has greatly reduced creativity and artistry in a lot of modern construction. And sadly, much of modern society has lost the ability to even tell the difference. (Or simply doesn’t care to).

And when you don’t know any better, you can easily be sold on the the ‘newer is better’ bill of goods. Example: When someone buys a metal pre-made ‘screen door’, they are then locked in to that manufacturer for repair parts, door opening size, decoration, etc. In practice it becomes another disposable thing, because most won’t even bother to repair it if it breaks, but just throw it away and replace it. But if one has the skills to build their own proper screen door (or any door for that matter), all these issues go away, and in the long run, it’s certainly much less expensive.

Who here has not admired the perfect seams of moldings, the beautiful joinery of built-in’s and staircases, shelves and mantles from houses/buildings constructed by real skilled craftsmen of ages past? A small curve above a window or doorway that wasn’t really needed, but was done anyway, and makes all the difference. Sometimes I wish that they had signed their work (A small bronze plaque or something) so posterity could know who they were, and give credit for what they did. Perhaps that would have been too vain for these particular men, so we are left with not admiring just some of them, but all of them, fitting and proper. Personally, they and their work are a continuing source of humbled inspiration and admiration. I’m smiling right now. I can almost hear them singing.

Hear, Hear! Well put L.G.!

I’d love to see historic woodworking tours, like the doors of Oxford post from last Christmas.

…Now if we can only create infinite time for Paul to do everything in. 🙂

Lately I watch these competition TV shows, like Masterchef, British Bake Off and the ones covering sewing, pottery and photography too, and yearn for a woodwork version, with Paul at the helm, obviously. I can see it now: “Half lap dovetails. You have 2 hours. Chop!” Please tell me it’s on the cards!

My view on these competitions is that one learns absolutely nothing while watching those. It is a (Roman) circus where the producer ‘s objective is to show emotions and nervous breakdowns but certainly not how to succeed in making things.

Sylvain

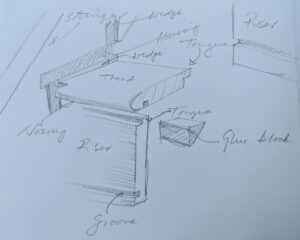

Paul, really enjoyed your drawings and understanding what goes into a well-made staircase. One question on something I couldn’t figure out from the drawings — what is the purpose of the wedge?

The wedges allow a way of massively compressing the treads to the top face of the housing recess during construction in a way that no other method allows because it is nigh on impossible to use clamps. You see the treads must be allowed to expand and contract otherwise they split. Also, the staircase treads can be retightened to stop creaking should shrinkage take place after a period beyond installation. Yes it does mean repair to plaster after gaining access but a single tread can be tightened by cutting a hole, tightening and then patching plaster.

I customer asked me to stop his stairs creaking, yes every step. It had a kite winder & quarter landings, a right 1963 mess.

Simple, from beneath I replaced all wedges under treads and triangular wedges between risers and treads.

As the treads were made from Parana pine, known to split, I had to face the underside of each split riser with 3/4″ ply.

As the whole was covered in carpet I screwed treads to risers (in central 2/3 width…..just in case he changed to a stair runner carpet)

To get access to underside of stairs I removed plasterboard.

In all a days work and one very happy customer

Is this similar to the wedge used in the workbench construction? The one used to seat the legs against the apron?

Todd..each set of tread and riser is wedged.

An oversize housing joint is made into the inside of each stair stringer. A wedge thicker than depth of housing is glued and tapped in.

Sometimes glue can dry leaving a loose wedge, it is best to remove traces of glue, make a new wedge and tap in.

I’m sure if Paul is reading this, he might say “waffle”