He Rolls Up His Sleeves

He reaches across the workbench for a plane and says, ‘Let’s get crackin’ then.” His plane’s a Woden. Well used, well worn, well ‘broken in’. Mine’s new, narrow, a #4 Stanley. He’d loaned me his when I first started under him but then I saved up and bought my own. Mum told me, “Don’t pay any keep until you’ve got enough for buying your own tools.” She’d apprenticed as a dressmaker when she was 13 years old: she understood the importance of tools and ownership. I earned £3. 10 shillings a week at the time; for a 42 hour week. Knowing what I know now I realise the sacrifice she and my dad had made for me. It was no small thing with a family of six kids. I also started to understand the difference between broken in and the awkwardness of newness. Just as I was new to woodworking, and my plane was still feeling awkward to me, so too I felt awkward at the bench doing the things that seemed always tripping. But George understood this. He wasn’t a boss, who grunted and groaned at everything awkward to me. He was a mentor, though he would never have referred to himself as that. It’s core to the wellbeing of any apprentice to have a mentorship with the artisan supervising the work. You don’t need a teacher, a lecturer, a boss, a professor. You need those people to own the additional qualities of mentorship. Without that there’s no sense of companionship.

We had grown fond of each other, George and I. Rarely did he greet me with anything more than smile, but he didn’t suffer fools. He treated our relationship seriously and seasoned it with grace.

I think we live in an age of instancy; patience is two seconds too long waiting for something to load on the screen when our attention span is only 1.5 seconds. Go on a website that takes two seconds to load and the click of your index finger automatically takes you off on another tangent because it took too long and you couldn’t wait. Woodworking with hand tools is an instant antidote to high speed working with machines, the antithesis we need to heal us from false and over expectations. There is no bolt-on, the app’s not there. You can watch a video a million times but it will not stimulate skilfulness. Skilfulness must be earned by the doing of skilled things even when they have not reached any level of skilfulness and that is why so many people forfeit skilfulness by relying on what has indeed become artificial intelligence. To develop skilled workmanship means you must take time out from the fast pace of our present age to take up the tools and learn them, if, or should I say when, you earn them they become your possession. No one can take them from you you see. The neat thing is that they are omnidirectional. You see using a belt sander does nothing to equip you to use a bench plane, but using a bench plane does equip you to work with a belt sander. Using any machine, a router to cut dovetails with a dovetail jig, such like that, takes a certain level of dextrous movement in the using of it or them. Skill in guiding the router in and out of the prongs efficiently minimises the risk of bit-burn by lingering longer than a split second. But making sure there is no rock as you manoeuvre it through the slalom course of alluminium prongs takes practice and confidence. That hesitation leading to bit burn or digs and divots, dives and such, happens in a heart beat, which is why you see these pockets of putty filling gaps on the mass made dovetails and shoulderlines.

Pursuing the art of hand craft is a patient occupation. We initially learn by observation. Adding into the equation is the reality that, for me, there really was no time set aside for practice. My first planing took place on a real window frame on the bench. George said, “Watch!” and I watched. It looked so easy. I knew I could do it. ‘Easy peasy!’ Or so I thought. Actually, it was. My plane landed perfectly and a shaving whooshed up through the plane throat and curled in a spiral to the floor. George seemed impressed. I was impressed. Then came the intersection. My legs seemed to go somewhere else, while my arms went opposite. How did that happen? The frame had knots. Each knot seemed to argue with me and George saw every stammer. “You’re hitting too hard, too deep and without anticipation you will never develop the right surface. Knots need gentleness and careful consideration. Planning if you like. Knots can be your friend if you treat them right. Pine knots often ‘oil‘ the sole of your plane, but you must ‘read the grain‘ beforehand in a split second, flip the plane end for end, that kind of thing. Anyway, the thing is patience rewards you and your work.

You don’t see rolled up sleeves in a workman any more. Times have changed. At least I don’t. Same way you don’t really her men whistle and sing at work. I sing and whistle every day because it became part of my work culture when I was a young person. If my jeans get holes across the knees it’s because I worked in them and they wore or caught on something. The cotton gets thin you see. It’s a uniquely different cultural shift to live in a culture where people wear jeans intentionally shredded as part of the manufacturing process to make them look like something they’re not. If I arrived home with holes in my knees my dressmaking momma unpicked an unused back pocket and stitched a patch on it. It was unpretentious.

By way of expression apparently literally screaming or yelling seems to be a constant at some of the building sites I have been near or endured. In domestic housing construction here a lack of self respect appears to be of a standard. It shows in the quality of the work. This isn’t all of the industry by any means but common enough to be something I try to steer clear of. I quoted on repair work recently for a friend who organised the maintenance for a strata complex and told him I didn’t expect to get it as I don’t bother competing on price. The carpenter who did certainly worked to the phrase ‘smashing it out’ Replacing horizontal fence boarding between a gate post and replaced upright attached to a brick wall demonstrated this attitude amply – the width of the upright was 35mm less than the post, across 3/4 of a metre span it didn’t look the best with the odd taper. My Dad couldn’t sing for toffee, his elder brother was excellent , but whistle he could and well. Winter is the only time I’ll be rolling up the sleeves, our generally warm weather dictates short sleeved shirts and for a lot of the year I’ll be in workshorts, often with small patched holes until they fall into service as rags. Grace is something we all benefit from, along with our mentors. Thanks for the writing about your apprenticeship Paul.

What a wonderful post! Thank you for allowing us a glimpse into your past. I’m envious (in a nice way) that you had someone like George. I never had a mentor as I tried to progress in my “trade” – only task masters.

Like George, you make it look easy for as I watch your videos. Then I try to do it for myself. Thank goodness for my iPad. I take it with me into my workshop and watch the video again and again as I try to correct my novice’s mistakes. Eventually the joint, the jig, the technique comes to me and I’m thankful for your willingness to teach us all through the miracle of the internet. I’m also thankful that you weren’t there to see me struggle.

Looking forward to your next post and your next visit to the USA.

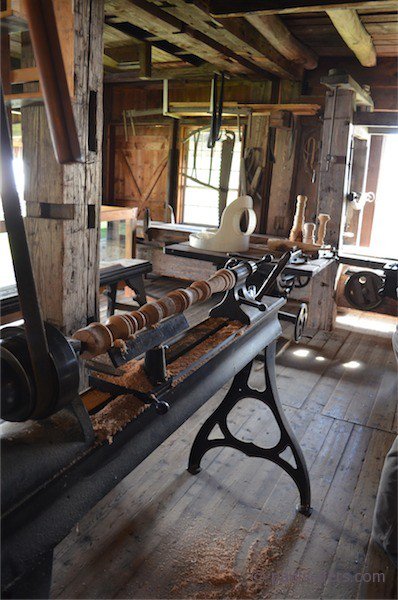

Love the pictures of the old shop. You could sit in the middle of it, and imagine the sights, sounds, and smells of it. In it’s heyday. Or expore it for hours! What treasures are to be found in drawers?

In the shop you apprenticed in, did the other workman have apprentice too? Where most of them treated as kindly as you?

I am almost 55 and start my journey with hand tools tomorrow at Ruskin College with a furniture maker ex boat builder I have never used a plane etc. but have watched many of your YT episodes and been inspired. The eloquence and evocative nature of this post is fantastic and make me excited to learn what I can do. Many thanks Paul.

Paul, I attended one of your classes in Wales a few years back and recall with great fondness your singing the hymn, “I vow to Thee” (Gustav Holst) as we worked. I learned many things during my time with you but foremost was the love and joy you shared with us. I thank George and you for paying those things forward.

Steve (FirstFiddle)

Hi Steve,

Are you the Steve from the US (New York?) who was at the Castle in Wales in October 2014?

leather belts running down from the ceiling, and not a dust pipe to be seen. Where were all the lawyers back then? Seems clear that if you didn’t mind your own safety, no one would mind it for you. Bet it looked just the same in the garment mill where your mom worked.

On watching and doing: My mentor, Roy, showed me how to use my finger to square material to an uneven surface. But my fingers were soft and wandered and his were hard as steel and ran true across any surface. Now, 50 years later, my fingers are hard too. (and not from tapping on my keyboard!) From watching to doing (and doing and doing and doing)

Phill, amazingly, a local large hardware store over here still sells the tools and staples to make and repair those belts. I nearly fell off my chair when I learned about that. They’re special crimping tools/staplers to join the two ends of the canvas or leather belt together. I was amazed that this equipment was still available nowadays, locally and even kept as inventory, not a special-order item.

You hit the nail on the head. I watch your videos a couple times, then go through, pausing to do that part in the shop, resume play, do the next step , etc, very slowly learning the skill and feel. I keep getting emails from Rockler for new jigs they have, and for other massively overpriced “one time tools”, and I thought to myself, if i bought every jig made and ever power tool, i could make anything with absolutely zero skill.

I love the jeans comment, people pay big money for those!

I have several pair that I “broke in” to the point where they are really comfortable. Yes they have holes and are frayed but I use them for working around not for going out. Little did I know I was making a fashion statement! We used to call them dungarees…..I’m assuming they were called that for working around the farm.

You used to be able to sell old levis for more than you paid for them, because they would “distress” them and charge insane amounts of money for them overseas, like in Japan.

Tom, we used to call them dungarees on this side of the pond also. Years ago I got curious about the origin of the word. Here’s the info from Online Etymology and Dictionary:

“A coarse cotton stuff, generally blue, worn by sailors” [Century Dictionary, 1897], 1610s, dongerijns, from Hindi dungri “coarse calico,” said to be from the name of a village, now one of the quarters of Bombay. Dungarees “trousers made of dungaree” is by 1868.

Your mother teaching you the value of and respect for tools. I wish more people had that view nowadays, for ‘tools’ in the widest sense of the word. As I’ve been intending to learn to sew I was looking for a sewing machine. Two weeks ago I bought one at a fleamarket. I was immediately attracted to the sturdiness and solid robustness of the machine. Heavy, 17 kg. All steel. A Gritzner GZ from the mid-’50s, later also sold as a Pfaff 139. In excellent condition, complete with all parts. It was also refreshing to read the sewing machine’s German manual: it didn’t assume its readers were idiots and didn’t start with 9 1/2 pages of warnings. This machine will far outlast me. Cost? 5 euro…. and an evening spent cleaning and oiling it. Last weekend I bought 4 scissors, all good brands, with three in new condition without need for sharpening. Total cost… 1 euro. The same seller gave me a #65 curved-bottom spokeshave for free, with the remark ‘nobody is interested in that old junk’. I didn’t argue but thanked him for it.

I think these insanely low 2nd-hand prices for tools ares very telling of society and the value people place on tools. They see old junk, not the potential those tools give to make other things. But then, who still makes anything anymore? It’s cheaper to buy, isn’t it?…. Or might it just be the excuse given for not having, or bothering to develop, skills?

Buying tools, even 2nd-hand ones, is the easy bit. Learning to properly use them takes more effort (though, often, less effort than I initially feared).

What I wouldn’t give to work in a shop such as the one in the photos. I my youth, I worked in several machine shops (metal) and I enjoyed it immensely but to work with these belt driven beauties would just be to die for!

Love it. Thanks for an interesting and entertaining read. My shed doesn’t have power connected yet, and I have enjoyed working only with my handtools (I only own a bandsaw and a small miter saw anyway). I only want power for lights so I can work after dark!

I really appreciate the old ways of doing things, and I really appreciate the people on the internet who keep them alive.

Thanks.

One of the more important statements in this post is that you cannot obtain the skill just by watching the videos. Or at least, I cannot. I have to do the task – many times – to begin to understand it and gain a little proficiency. Sometimes I have to get away from it and think it through.

The other aspect just grazed upon is the “first planing on a real window frame”. Decades ago I was reading books on how to oil paint and the one concept I ran into there which stuck with me was the concept of the “premier coup”….the “first attempt”. The idea was to finish what you started and don’t re-do it. Acquire whatever proficiency you can gain from that project and then move on to the next project.

So if I am cutting a stopped rabbet and it isn’t great, I don’t get out a new piece of stock, plane and cut it to shape and try again. I use that original stock if it’s at all usable, and finish the project. This does two things:

1) the project actually gets finished and

2) I can come to grips with the fact that the project isn’t perfect because I don’t have the proficiency.

Next topped rabbet (and there will be another one coming along soon) will be better.

Anyhow that’s what I’ve noticed over the last few years – take it for what it’s worth.

What IS valuable are the entries Paul makes…what a fabulous discovery.

Absolutely spot on I think! Thanks for sharing. I’m a software developer by day and I personally think that learning by doing is the best way of learning. I have applied that all my life to my hobby and then profession (software) and now to woodworking. I’m so thankful for Paul’s blog and videos. Without these I’d have no idea how fun all this was. I’ve never used my jigsaw as much as I’ve already used my new (old!) hand saw and the hand saws cut much straighter too!

My first woodworking project? Paul’s workbench of course! Does it take forever to plane the first 2×4 for the bench top S4S? Is it still actually crooked after squaring it? Of course, because of the damn rounded corners here in Canada, me not knowing how to plane, how to properly sharpen etc. But who cares? I learn from it. Second set of legs? Much better already!

Saw doesn’t cut straight, gets stuck all the time! Try nail punch setting. No improvement (sorry Paul, maybe I’m just too dumb to do it that way. I tried ;)) . Get a saw set and whoosh my eBay Disston cuts like it was new! More on the way. I’m hooked! Restoring them is half the fun. Broken eBay plane handle? Wood block already acclimating in the garage and now waiting for the bench to be finished (LeeValley has a downloadable pattern for all the Stanley plane totes if anyone wonders) so I can clamp it all up in a vise properly. I’ll learn to cut screw threads too since the broken handle comes with a bent tote screw as well and getting another one costs more here than a set of thread cutting equipment, even if it was for just this one time use. So much to learn. So much fun.

Spot on as usual, totally agree. Thanks Paul.

Hi Paul,

while I do not write much, I do enjoy reading and learning from you. I am one of those folks who hate that the website does not come up within seconds. I have worked in IT for the past 35 years now. I get to work on million dollar gear. The one piece I got from this article was to slow down, which is what I have or am learning. I finished the build of the two draw unit for my bench. When I finished I looked back and noticed a lot of mistakes, rushes that could have been avoided had I taken more time and had patience with my work. So this past weekend I built it again, and while it did take longer, my cuts were straighter, my dados were so much better. In the end, this version is turning out a lot better one I can be proud of. The TWO major things I know I need to do is, one slow down, and two read the plans, and double check before cutting. I am one of the lucky ones, as I have the money to buy the new tools and good quality ones, but I also know the Tools do not make the craftsman it is the person who works a learns, listens and puts into practice who becomes the craftsman.

So thank you for your articles they help me think and to learn, our digital world is great that we can communicate with each other no matter where we are in the world. The one thing we still lack is the human bonding, and being able to show someone what or how we are performing a task, and then turn and ask for help to show us where we are making our mistakes. Yes, we can continue to perform the task many times till we feel it is right, but it would be nice to have that option to talk.

Thanks, Paul for all you do, I will make one suggestion, Please write a book on your years as an apprentice.

My grandfather always whistled when he worked. He was a machinist and when building something, he was in his own. It was pleasant to watch and hear him him work. I do miss him

I started my apprenticeship the same year as you Paul, but only received 3 pounds for my troubles. I remember the first time I saw a orbital sander in the shop I was so keen to be the first to use it. It was not to be, it was confined to a shelf, I never saw it used. The oak church doors we worked on all scraped hand until my thumbs were sore, but as i cycled the five miles to home I was proud of the finish on the doors. Job well done.

Thanks for all the memory’s, so many times you have reminded me of good times passed learning how to perfect my craft.

Paul- the best. I loved the comment on buying clothes that are already shredded.When we wore jeans they gone worn down to the point that they began to disintegrate. At that moment Mom would not let us wear them anymore until she put patches in and made us, once again, respectable. The idea of buying clothes that are cut and shredded is hilarious and a poor comment on the nature of what we think of as culturally valuable.

I met my first tradesman at age 16 . Hey you pick up my bag ,thats all he said to me . All day long I toiled as an apprentice pipe-fitter . Jock the Glaswegian never said two kind words to me . After about 6 months of this we had settled in a rythmn ,him bossing me about ,at the same time instructing me . ONCE and once only on any particular new skill . As I was going home one night at 5 pm ,Jock was going for his customary pint ,he turned to me and said ,youre buying the first one laddie. I joined him in the pub for an hour or so . Then on ,I became his partner not just his apprentice ,He was a hard man but fair . Pretty skilled but I became better and he knew it and he was proud of me . I missed old Jock when he retired . My new apprentice arrived and went to pick up my tools . No ,I’ll do that ,I said ,you just learn . Then I retired 45 yyears later ,after innumerable apprentices ,and thats it . Youngsters nowadays have not much respect and not much skill other than twiddling their thumbs on some electronic device it seems . Time will tell what we have done with our heirs.

You are like a spiritual father to me Mr. Sellers. I only wish i would have found you earlier in my life. I really enjoy your stories from your apprenticeship days. They lift me up and help me continue on my path even if i started late. Robots and machine may try to replace us but once you know who you are, nobody can take away anything from you. Thank you once again.

Thanks for all that you do Paul, I stumbled across your mortice and tenon joint video initially. It was just in time to change my direction which was going to be machine woodworking. I planned to sell a motorbike to make space for a garage workshop and was looking up and about to buy a bandsaw, tablesaw and thicknesser. Im so glad that I have found your channel as I’m getting a lot out of the process of setting myself up with the handtools I need any bits and bobs to ‘initialise’ and maintain them and have just started using them. I’m thankful nobody can see me making every mistake possible, I’ve learned from them all. Anyway thanks again, I like your presenting style and personality very much. P.s. woodworking has a simularity to motorcycling for me in the sense that it demands my full concentration which frees my mind from the usual stresses and that’s a great thing for me.

I had the inestimable pleasure of watching my grandson try using a plane the other morning.

I was planing up some stuff for a bench strake replacement and he was watching every move, fascinated, running his finger along the planed oak.

I found a bit of clear pine and set a little coffin plane to a very fine shaving.

Clamped the pine in a short workmate and showed him once, then let him have a go.

A few misses, a few jams, but give him a break, he’s only 20 months old.

We all have to start somewhere right ?

I have noticed you don’t monetize paulsellers.com,

don’t waste your traffic, you can earn additional cash every month with new monetization method.

This is the best adsense alternative for any type of website (they approve all websites), for more info simply search in gooogle: murgrabia’s tools

The assumption on your part is that everyone wants to do something for money. I have been turning down such schemes and sponsors for years now. This is my blog. I like to keep it clean and productive without making money a goal.