What Cost the White House Pieces?

Mesquite is a lowly wood. It covers 56 million acres in Texas alone, more than any of the other few states that host this very unique tree. I have much more to tell you about this tree’s lovely uniqueness but perhaps in later White House posts. For the main part, people, ranchers, mostly, seem destined to bulldoze it, burn it and diesel-poison it. Diesel poisoning is where a rancher takes a quart of diesel and pours it into the ground around the mesquite. That’s a sad affair! For the main part, mesquite is used in Texas homes for heat, ambiance and for Texan barbecues. Some ranchers keep them around with the live oaks to shade their cattle in unending hot Texas summers. The blend of mesquites in the Texas Hill Country and a fine heard of finely-bred longhorns is unequalled by any other breed of cattle, geographic location or tree species. Now there are mesquite pieces in the White House. How ’bout that!

A Texan barbecue is different to the rest of the USA. Bigger and, of course, better! I have seen piled-high mountains of it burn for weeks slap bang in the middle of cattle land. The problem is that mesquite is the slow-growth, stealth invader that silently spreads its roots to plumb depths no other tree does. Vast tracts of land are owned by landowning lawyers and oilmen in Houston who visit their few thousand acres in the Hill Country once in a blue moon. They run a few head of Longhorns for image and meet fancy clients for a weekend’s shooting of anything that moves on four legs and two. Their kids run riot in a vintage, open-topped jeep and stir up the dust doing something called fun and the neighbours are driven crazy once a year by it.

To make the White House pieces I was asked the length of time it would take. I said to the questioner, “It’s three month’s work.” This was in the middle of December 2008. He replied, “We need them by the 25th January 2009!” I said, “OK! No pressure then?”

Ultimately I assembled those who I knew knew my ways of working: men who I had worked with for almost 20 years but men who were once but young boys when I started training and teaching them about hand tool woodworking. School-aged, they had been looking for their calling and found it. They’d become fine men, working men with willing hearts but for the asking. To bring them in meant abandoning their own existing workload to bring two pristine credenzas from a pile of rough and almost hopeless boards, twisted and cracked; the work became exemplary works of art highly fitting for the Cabinet Room of the White House. This was indeed a major ask.

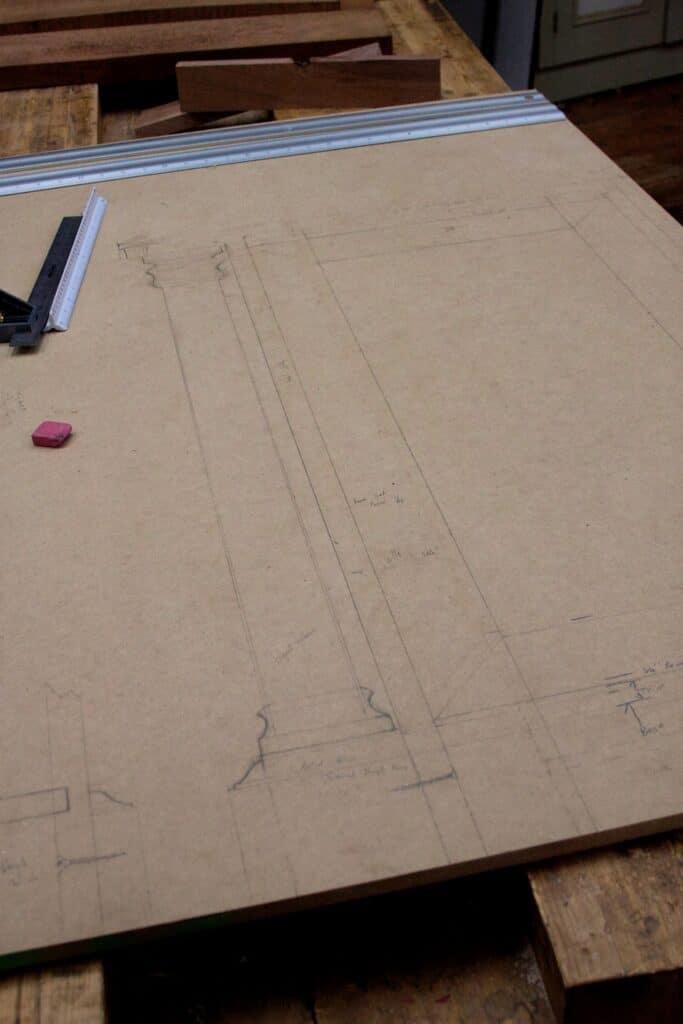

We sat together in the workshop one evening to work out what could be done by when and how we could actually pull off the impossible. Remember we wouldn’t be programming a CNC machine of any kind. I’m not even sure if they existed then, but we never would have used that system anyway. We knew craftsmanship and skill were of the essence and we knew we had this to the man. Mostly we would rely on the standard machines for the donkey work dimensioning and then handwork would take over to just make things fit. How many joints were in each piece I have lost track, but we had plenty. . . and the days were ticking away, with Christmas slap bang in the middle of it, and we hadn’t even sourced the mesquite at that point, we had our work cut out for us.

Without this cluster of friends, I could not have completed the work on time. Things happened, we were slowed, but we never stopped working way into the dark, cold winter nights for a full-on month. Oh, and we delivered a day early–the 15th January 2009. George Bush was giving his departing speech before the Obama Inauguration on the 20th, clipping a week off our delivery date. Could we do it? We didn’t find this shortened time slot helpful, we didn’t know until two weeks before the due date that this would happen. We then worked twice as long, twice as hard and three times as smart. No mistakes! The one thing we never compromised was the quality of workmanship. We delivered top quality. That was all that mattered.

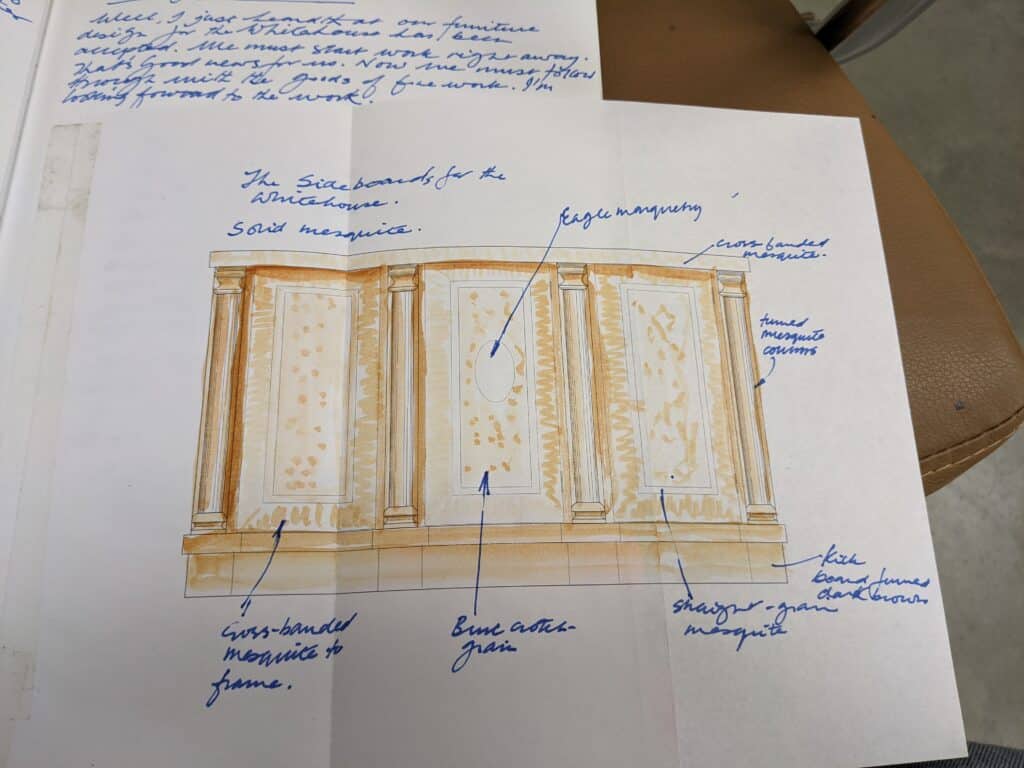

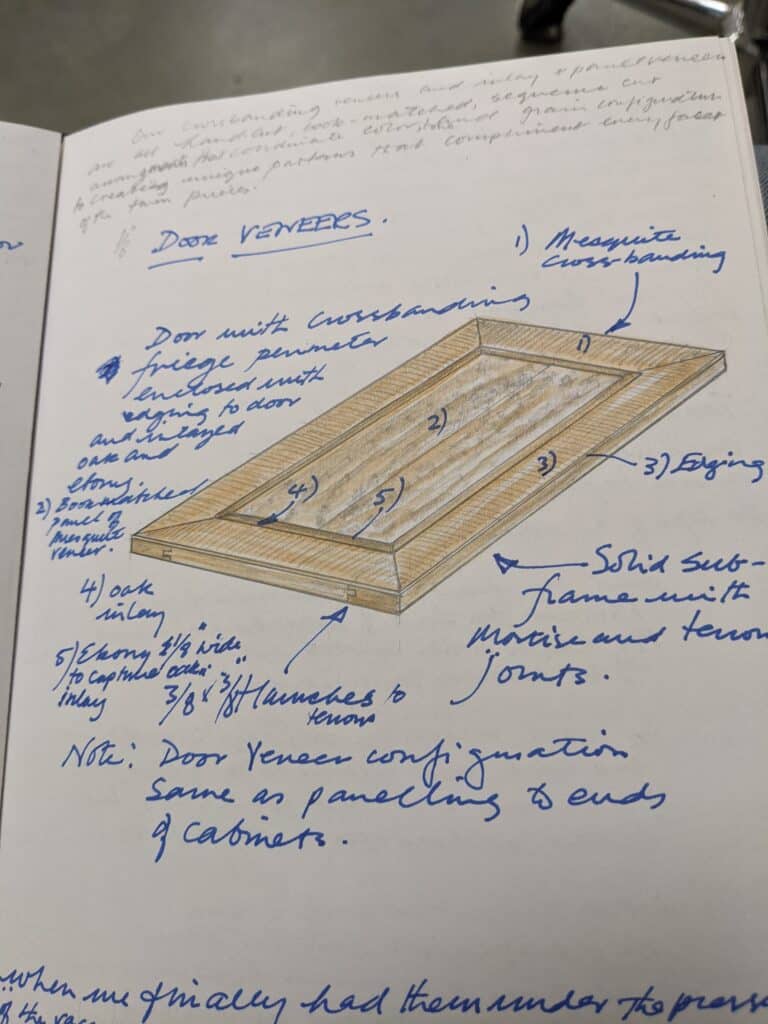

To say that both designing and then making the White House pieces was an honour for me would be to miss the point. I was honoured privileged to give the designs my best effort and so too the making of them. Looking back through my journals of the day, seeing the drawings and the notes, I found myself thinking about the men involved with the making. Believe it or not, at an advanced stage in the making I had a week-long class. Visitors kept coming in too and the two pieces stood side by side on leveled stands in full view. People would ask about the customer but we kept our secret. Well, until one of my students came over to me and leaned on the bench and said, “These are for the White House aren’t they?” Whereas it was the White House that made these pieces important to me, more than that it was the men I was working with and grown to love. Just as the mesquite wood itself had its idiosyncrasies, so too the men. Their individual personalities came through. The ones that joked irritated the sober-minded and the sober-minded irritated to jokers. Suddenly everyone burst into laughter when they saw the funny sides of things twixt the two and the work kept going. These men gave their everything to creativity and every plane and saw stroke meant something to them. One mistake by one would telegraph through the piece to affect another area of the work. They were each of them uncompromising in their work. Framed doors with mortise and tenons interchanged between openings as though each one was fitted to the other. Watching over them as a sort of pastoral shepherd I was amazed at how well they were willing to defer to one another in every way. The wood went from rough-sawn to silky smooth beneath a mere smoothing plane. Hinge recesses were perfected by deft chisel strokes. But more important than all of this was this one reality. As each piece of wood was made to fit the composition of the whole, so too the men working together were being tested and tried by their work and their working. The minor irritations of abrasiveness seemed aptly able to wear down the rough surfaces in personalities. At the end of the work we all hugged and breathed a sigh of relief. We knew at a certain point that we would, at last, be able to deliver on time.

Time passed all the quicker as Christmas came and went and I found myself planning the route that would that would make the pieces a reality.t Throughout what would have been the holidays and indeed Christmas day meant me working through the realities. Planning is one thing, engaging in the actual physical work another. No one of us ever missed a beat. Twelve-hour days were needed and they quickly went to fourteen-hour days, fourteen went to sixteen- and some later days even went over twenty-hour days too. I was so proud of these young men, which included two of my own sons!

– Teasing title but the blog tells us what it would cost to us (time and effort) to (try to) make pieces like that.

– looking at the link “yet another Texas treasure – 23 December 2016”, I (re)discover a piece like the desktop organiser (of which I made two following your videos) except that this version is much more elaborate. Could you tell us more on how the frame and panel lid was made? Viewed from above, the rails don’t seem to be in one piece. Is there a banding on the frame?

Paul, over your long career, do these Whitehouse pieces sit as the most memorable and important for you? I imagine you have other pieces which are more personal and sentimental, but for items that you’ve been commissioned for, are these the ones you are most proud of?

I can’t wait for further instalments of this tale …

A non woodworking aside – those lawyers and oilmen run cattle on their land as a tax dodge – in Texas a landowner only pays $1 per year in property tax if they have cattle on it – no matter how many acres they own.

Have read the story with pleasure and interest, with the central message coming over very well. But in the background there’s something that irks me quite a bit, in that I find the attitude of that client highly disrespectful to the craftsman/craftsmen who are expected to build it.

To expect such a work to be completed on such short notice, and to top it off unilaterally subtract another week of time as well. Combined with the disappearance of your original drawings (Troy), it’d have left a bad taste in my mouth w.r.t. the client. The fact that excellent planning, cooperation and execution on your part saved the day is irrelevant in that respect.

I can’t help but wonder if you’d have felt the same way if the task had been asked by, say, some British royalty or other high-ranking person.

When people say, ‘I want it yesterday’, I feel inclined to respond, ‘well, you should’ve asked me the day before yesterday then, not today.’ From what you have told so far about the way the cabinets were ordered, designs approved (seemed a bit careless/disinterested to me, the way they ok-ed it) and then time-schedule pressed on and even shortened by a week, I can’t help but feel a deep disrespect to you specifically, and craftsmen in general.

‘Poor planning on your part does not necessitate an emergency on mine’, is what comes to mind.

We need to petition folks to get your pieces in 10 Downing St or perhaps a chair for one of the Windsors :-)?

Other than your family who would you want as a client? What wood in the UK would be like mesquite in the US ?

Is there a piece you’d like to build that you haven’t?

I’m hopeful that these posts are rough drafts for a short book!

Sounds like it was the ultimate “final exam” of woodworking. What cost the White House pieces? Years of improvement in woodworking skill, maximum focus, and total engagement of men doing real work. Good thing the White House didn’t contract government woodworkers or it would have cost twice as much and been a year late 🙂

– what do you mean by “government woodworker”?

– do you think Paul worked without some kind of contract?

We in Texas have the 16th Century Spanish explorer Francisco Vasquez de Coronado to thank for the invasive species that is the Mesquite tree. When he and his expedition went searching for the fabled 7 cities of gold they brought sacks of the mesquite beans with them to feed their horses. The horses left the mesquite trees behind them quite literally. And a few hundred years of cattle helping out and there are mesquite trees all across the Southwest US.

Lest we witness the birth of a [nother] urban legend, a further clarification of the mesquite tree is in order:

The Spanish explorers may well have fed the beans to their horses… [and themselves] but they didn’t bring them from their European homeland.

Fact is, the several species of mesquite are quite native to SE US, Mexico and some parts of South America. Seems there are something around 6 varieties in the area. But NONE grown in Europe.

In fact, mesquite beans were a staple in the natives of the area for thousands of years. Well before the Spanish arrival…

More than Spanish horses spread the seeds…

I loved the eloquence and affection you heaped on your coworkers, including your boys. It makes me miss the days when I was working in the US cabinet shops, with all the joking and petty feuds it entailed. But so happy to have found you and your team, teaching what SHOULD have been taught to all of us professional woodworkers, a.k.a. woodworking machine jockeys.

Just thinking. The fellow workers who put in the long hours, it seems their names should be mentioned.

Paul, do you ever think that you are making history? That in 200 years some assiduous White House researcher will come across your notes in triumph to say “ah yes but so and so made the dovetails in the.. “.

We all like to make things we hope will be treasured. When I was at school I loved woodworking having failed academically but was encouraged by Mr Pook our woodwork teacher. I made a nice quarter sawn oak trinket box with neat dovetails as one of my projects. So I was surprised to find that my second daughter had tucked it away and it was in pride of place 60 years later. Maturity found me with a degree in maths and computing, aeronautical engineering and an additional degree in teaching. But in retirement I am back to woodworking, but my dovetails are still not as good as under the tutelage of Mr Pook.

ancient and medieval Latin,

As a Texan I must say you do a fantastic job with essentially a trash tree. We use it for weather forecasting and grilling. Mesquite doesn’t bud out until the last freeze. Barbecue uses hickory and post oak. Mesquite is for amatuers. But it is a great wood to work with.

Aloha Paul,

Very formulary with Kiawe[Mesquite in the mainland] , If not for it being used to feed cattle on board ship, during the transit[1824] to Hawaii and than being thrown off the ship and survived the swim to shore, the cattle[with their bowels full of seeds from the pods they were fed, might not have planted the World’s First Honey Forest as Nat Geo 1915 declared. There was just one more thing needed for this to work…Honeybees. Bring the cattle, was to grow their own Beef in the islands. Feeding them the Kiawe Pods might have just been a Cheap fed for on board ship, but it turn out to really be just the right fed for them. The cattle were to live on land given by the royalty. The cattle pooed their own forest of food , in that the Kiawe sends it’s roots down the deepest of any tree, 250 feet in the deserts of the mainland. And Hawaii has many underground rivers in the lava rock some just a few feet down. Intense heat in these are such that nothing grow there until the cattle poo full of Kiawe pods were dropped . Soon Kiawe were growing and everything looked good or did it?

Turns out , Hawaii had no pollinators for the Kiawe. So in 1857 they found out they needed honeybees to do the job, and the rest is history. Kiawe = Fat Cattle, but the bees had even more on the ‘bee-brains’. Hawaii has non-stop nectar on all islands and no winter below 8,000 feet. And nice wood too.

Paul, you very correctly used the word “invader.” I was born in southeast New Mexico and have lived there again in recent years. Through my twenties I visited relatives there often and have seen what mesquite has done to the land. In the 1960s that area was covered in prairie grass 2′ to 3′ (600-900 mm) tall. As mesquite encroached it took most of the little rainfall available and killed off the prairie grass. The farther west you travel, the smaller mesquite becomes. Having traveled between SE New Mexico and the Dallas area many times one of the remarkable things seen is how the mesquite bushes of far West Texas and New Mexico become substantial trees 150-200 miles east from New Mexico. They are still water hogs and have greatly changed the native flora. It is easy to understand why farmers and ranchers bulldoze it by the hundreds of acres.

Nights coming here and I think of driving home thru paddocks of dry grass and sucking in the cool air with my head out the window as a kid. And the focus and calm of meeting friends or anyone in a quiet room at night and sort of really being in that moment — that night before work began on the credenza must have been very exciting.

What ever happened to Paul’s Christmas blog?? Not this year??