Pensioning Off My Vise

In 1965 I bought many hand tools, perhaps one per month, where each of the more productive tools like saws and planes might cost me up to and over a full week’s wage for me to put together a cluster of working tools. My saws and planes took me 46 hours of work to pay for each one, marking gauges a quarter of that. I was paid £3.50 pence for 46 hours as an apprentice. Little did I know then that these tools would faithfully serve me for almost six decades. Using them daily, mostly for ten-hour days, throughout 56 ensuing years has made me realise just how incredible my basic western tools really are. I have sharpened the same saws, planes and chisels throughout my work life. In recent years, rather than see them completely wear down to the knuckle, so to speak, I have placed them into my preservation tool chest to be used only if and when I want to. Having used these tools to earn my living and raise my family, relying on them to put food on the table and clothes to wear, pay a mortgage, bills, etc, they owe me nothing. You likely will not hear such a thing from anyone you know, so I am saying it here. These tools have interchanged with additional tools along the way including more recent types. Not one of them has been replaced by anything better. Where can you buy them now? eBay! And for a very small fraction of the price they cost me. Certainly not a week’s wage per piece.

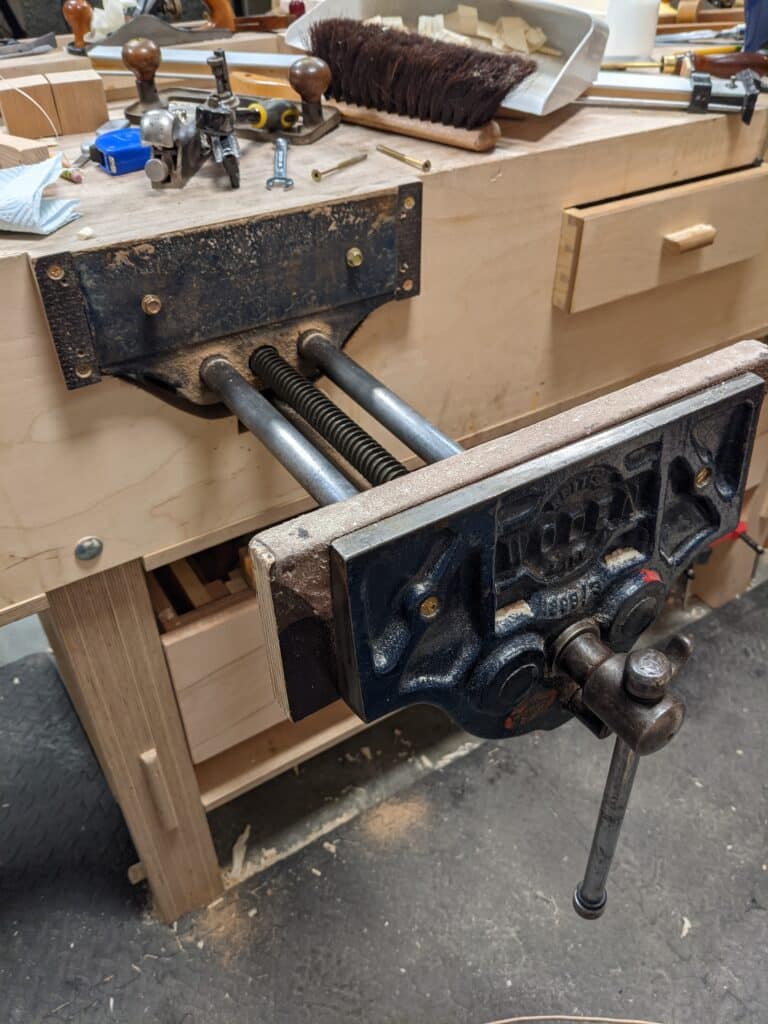

Yesterday I pensioned off my bench vise, a Woden I found secondhand on eBay that was already fully restored. My old vise was showing signs of wear and as with my other tools I did not want to see it breakdown altogether. `i will install it in another, less used workbench. The new-to-me new one will take a little breaking in. It is quite stiff as it is a little-used one and everything is still quite tight. This is a celebration for me. Paying £130 with shipping for so fine a quality vise is a small price to pay. I doubt that there is a maker worldwide that matches such quality anymore. Sadly things have deteriorated in our exporting manufacture to other continents so that we can have cheap good and cleaner local air. A vise I once bought from an importer from Asia made a comparable vise. It was top-notch. But, well, the USA wanted it cheaper so the exporting manufacturer went back to the design and created a slightly lesser version within the brief for less cost. The new version rattled in the ways and the threads skipped when winding. Still, it was, well, OK. But guess what, the chain store of woodworking retail wanted it cheaper again so the maker went back to the drawing board and cheapened production all the more. Was this so that the franchise supplier stores could pass on the savings? Oh, that wasn’t the plan at all. No, no, no! The price stayed the same throughout the decade. We cannot blame the exporters for cutting prices and quality. It’s the importers who know nothing about craft, art and the art of making anything but money!

Can’t remember how I came to own it but I needed a vice to do some small project work and decided to mount this uber cheap vice that I had to the side on my workmate (I don’t have a bench)

Two issues. The workmate is a cheap knockoff copy made using the cheapest metal, and the vice only just qualifies to be classed as a vice (yes it is that rubbish)

If you look at the bench it rattles and wobbles, The vice doesn’t clamp square and loosens off as you work on it, but it is all I have for now till I get to making a bench and then I can look for a good wood vice.

But yes, the quality of stuff on the market is shocking, knock them out for as cheap as possible is the only way they know how.

And when buying stuff online, without spending £100s, when was the last time you read a “honest review” and got a product that would live up to that so called review? That’s why I no longer buy new tools.

I think we’re all familiar with the “It’s all I have for now” concept, Brian – I know I am. I started off with no vice at all, but I did have an old scaffold board that I clamped a piece of wood to using a valve-spring compressor (I know!), So you can imagine my surprise when my friend turned up and said pityingly “Look, for God’s sake, have this – it was my dad’s, and I never used it!”

“It” was a ‘Parkinson Perfect Vice’ of pre-war vintage, and it was the big one that would open wide enough to hold a small shed. Well, perhaps not that wide, but you know what I mean!

That was it for real luck, and the rest of my kit has taken years to amass. Paul is, as usual, quite right, and it is my old tools that have lasted because the initial quality was (and still is) superb, and most of the new stuff either disappoints or has worn out. As Paul says, tools used to be manufactured to a quality – not a price.

I still have my Parkinson. We are both pretty worn by now, so – will I replace it? No, we’re used to one another now, and I old friends are the best!

May you find your Parkinson one day soon, my friend!

Chris

Is the new one a record?

I work in the US as a Patternmaker and Cabinetmaker, to say that the new stuff is junk is to just scratch the surface. The manufactures have been driven to China and other places by the politicians and the media who chose double talk as their trade. By seeking to remove any pollution from their sphere of influence due to pressure from the small but noisy (lazy) activists who do no work that is redeeming, they outsource everything. The politicians then underwrite these useless lives and pick the pockets of those of us who produce to fund them. It is the dragon eating its tail who will soon consume itself.

To this end, I offer 2 Thessalonians 3:10 “If anyone isn’t willing to work, he should not eat.”

And 1 Thessalonians 4:11-12 “seek to lead a quiet life, to mind your own business,[d] and to work with your own hands, as we commanded you, 12 so that you may walk properly[e] in the presence of outsiders[f] and not be dependent on anyone.”

Placing the blame for the decline of manufacturing on environmentalists is absurd and abhorrent. The environmental issues that we have had (and continue to have) are very real and have resulted in 100s of thousands of deaths annually through respiratory diseases, cancer, and other vectors; not to mention global warming… which is real and happening whether you believe it or not. Clean production is possible (I know because I’ve seen it first hand), but it is more expensive. Production was outsourced to China, Mexico, etc. mostly due to labor costs and secondarily environmental regulation. But, manufacturing could have stayed here if companies weren’t so greedy. The cost of things would be slightly higher than it is today, but it still wouldn’t have been anything like a week’s wages because we are much more efficient today than in whichever decade Paul had his apprenticeship.

Will, you’re fortunate that there are people working on your behalf to clean up the mess we’ve been making of the world even if you evidently despise them. Do you think creation is just a trash can for your garbage?

To Albert who is using electric power and an phone from China while wearing synthetic clothing and claiming to be an environmentalist….well….

please dear think again

I get people driving into our ranch to tell me how bad cows are for the environment…..I just point to their vehicle and say wasting gas to yell at someone who produces food is the one who is bad for the environment.

Zhinka, I’ve seen this argument before and it really falls apart if you even give it a little thought. Yes, here I am in an unsustainable society arguing to make it sustainable. If we already lived in a sustainable society, that wouldn’t be necessary. Naturally, I do the best I can given the choices that the economy presents to me and encourage others to do the same. But moving to a yurt in the wilderness and foraging for food wouldn’t do the world any good at all.

None of this has anything to do with greed, private pensions, government, environment, or consumerism. It’s basic economics that would apply to any good.

High quality hand tools cost a lot because demand has fallen like a rock. In days gone by every carpenter we now see framing a new house used a hand saw instead of a Skill Saw. Moldings were cut with hand planes, not power routers. Hammers, not air guns hung on every roofers’ belt. And the computer stuff? Computers didn’t exist.

All those guys depended on high quality hand tools, just like they now depend on high quality battery drills or drivers. They have to last all day, day after day.

So, the demand for quality tools remains strong. However, the tools in demand have changed. Look at the tools professionals who use them all day use. They are not cheap junk.

But, you say, more and more people are taking up hand working. Sure, but their numbers are a sliver compared to what they were when everyone needed the hand tools.

So, we are a niche in the market. I can find very good tool that are brand new. And I can wander through Craigs List, EBay, and garage sales. But, I accept that I have chosen to travel down the niche. OK. I enjoy the trip.

I would place the blame on the US pension scheme which relies on private pension funds and greedy CEOs.

Private pension funds means people have their pension paid for by the work of people in other (poorer) countries.

Except the failing of public pension, and the religious belief in the market as a panacea, I don’t see where is the government fault.

Don’t blame governments, environmentalists, or greedy corporations for the cheap shoddy construction. Consumers, including you and I, buy the least expensive tools available which means to compete a company has to constantly lower their price. The only way to do that is to manufacture overseas with cheap labour and lax environmental laws. If a company produces a quality tool with local labour it will simply be unable to sell enough of them to make it worthwhile. Their tools would be the same cost as Paul paid in the 60s when a Quality Tool took a week’s savings. As long as consumers shop by price and not quality, quality will continue to decrease even in so-called high quality tools which already seem very expensive in comparison to their knock-offs. We can manufacturer in the west quality consumer goods but we will all have to be willing to pay more and to buy less.

@David Ricketts. You are right. We”re always looking for bargains in the wrong direction and for the wrong reasons. Expecting quality but not willing to pay for it. We are spoiled and lazy. We rather buy stuff that looks like a tool because it’s cheap. Which it is not, because it fails at the first job.

My (entire) set:

ECE /Pinie wooden scrub, jack, smoothing 49° pitch, and try plane

ECE cross-cut & rip frame saw, Heckenrose backsaw 15 tpi

ECE router plane, Pinie rebate plane, Narex chisels 6—>32 mm,

Pinie / ECE marking & mortice gauges

Handmade plough plane,

Kunz spokeshave & n°80 scraper and spokeshave (yes! mine is great ; ) )

Eclipse coping saw, S&J hand and backsaw* (hardly get any use since I have frame saws)

Stubai marking knife, Swan Morton, Stanley.

Pinie mallets barrel type and block, (I also love the Thor)

Vogel square and Sola sliding bevel

Kirschen veneer saw (used for sliding dovetail housing)

Stabila folding rule

Brace and bits & eggbeater, ‘Alpen’ drill bits (great for drilling at slow speeds!)

Skandia hammer (German type bench hammer)

250/600/1200 diamond stones and strop * the budget ones, but they do work

roof tile (!) to sharpen scrub plane ( just check Tischlermeister Jakob)

red/blue Lyra carpenters pencil

black Lyra wax crayon

compass ( dividers)

pair of winding sticks ( very fancy handmade pine cutoffs planed straight)

Wiha screwdrivers wooden handle with leather cap

pine workbench (a certain ‘Paul Sellers’ style) with 9″ quick release vise made in CZ

Saw horses (from that same P.S.)

A very traditional ‘continental’ set that perfectly fits a ‘Dutch’ tool chest (not the bench and the sawhorse… and the frame saws!). Not Dutch at all, probably, but that is another rant… I made one and it is great. And I didn’t have to sponsor an author/ journalist/woodworker. I rather support a woodworker /author. There is a difference!

Everything is made in EU except *. Very similar to the contents of the Ulmia/ECE tool cabinets.

Brexit and custom fees made me turn around and look inland (I am in Belgium), only to discover the continent with its rich tradition in woodworking.

And you know what: it wasn’t expensive at all.

Yes, a Chinese knock-off will be cheaper and may work well, or not… Or change manufacturer the next time you buy one. Or materials… Not as faithful as you would expect ;).

I have replaced all ‘made-to-price tools’ gradually with actual tools and the quality of my work has improved in doing so.

I agree about the Thor mallets with their high density heads they work well. The only thing I dislike is the round handle. With a (rounded) rectangular or oval handle your muscle memory works out which way the head is facing without looking at it. With a round handle you are forced to look at the mallet to ensure you are hitting square rather than the tool. I suspect this is why carvers and stone masons favour cylindrical mallets.

Pinie chisels are great to – probably the last manufacturer of proper firmer chisels.

So it would seem many of the new comers to the trades of working with their hands are betwixt the devil and the deep blue sea. The price of decent tools goes up for a large variety of reasons and now the price of lumber itself has become akin to the gold field where nobody can even afford a pick and shovel much less the price of the claim with no gold on it. Just this week I’ve run into gasoline shortages in the Southeast US so my choice is to either do without the lumber or risk running out of fuel to buy what is increasingly more difficult to find.. I have 17 doors and 5 drawers to make with what amounts to enough lumber to make 8.. Fun times indeed.

Just recently I bought a new table saw. Immediately after that there were over 120 table saws listed on craigslist in one day.. People are selling off tools simply because the price of lumber is too high.

Crazy times.

Actually, most tools more than adequate to do the work I do can be done with inexpensive hand tools that can be had from many sources. It all depends on your perspective. Whereas I do respect what Lie Nielsen and Lee valley Veritas have achieved in recent decades by bringing either replications of existing designs as in the case of Lie Nielsen or all the more impressive redefining designs with new and innovative tools as in the case of Lee Valley Veritas, it’s certainly not necessary to spend more than £25 on a #4 bench plane,£20 for four Faithful bevel-edged chisels, a Thor 318 chisel hammer £14 and a couple of saws like a tenon saw and a panel saw for around £25 a piece made by Spear and Jackson and a Crown 10″ gents saw for #18. Amtech combination gauges are up for grabs around £15. What else? Well, a router plane,not essential but nice to have for levelling the playing field. This will be the highest dollar item as a direct result of my work, no doubt. By then there is always my poor-man’s router that as easy as wink to put together. A plough plane, you’ll get for under £50. A knife you can make or buy and this is on my blog or in my vids somewhere. Now, this just about addresses the issue. Now I just bought enough wood for two beautiful rocking chairs, two coffee tables and a six-foot bookcase for about £450. Divide 450 by five and you get 90. So, you’ve paid £90 for a very unique rocker or a totally new design coffee table or a seven-shelf solid hardwood bookshelf. Now, this is heirloom quality hand made furniture in solid cherry made with tools that will easily last for a lifetime of daily use. Much of what I am saying can be had for even less if you are patient and keeping a watchful eye out. Vintage mahogany or oak dining tables of under £10 and skip finds are aplenty. Pallets work for some work too. I refuse to call tablesaws tools for my own reasons and I don’t care that people sell their tablesaws to buy decent hand tools and discover life beyond the plugins. I understand that people making to sell for a living rely on machines, I have no problem with that, they are not my audience. On a global scale, a vast percentage of those watching my efforts are looking for skilled work and the passage that takes. ~this is great to me.

Sorry about your petrol shortage. Can’t really say anything about that except we have been paying three times more than the US for decades now. I recall paying a dollar a gallen for gas in the late 1980s. I guess those days are gone.

Great point Sylvain, I need to learn more about the role of private pensions in our economy.

Ultimately the problem is that middle class salaries have not kept up. My grandpa was able to support his parents, wife, and children on a single income. We have had 40 years of policies that have shifted the sweet spot up the economic ladder. So the only way to preserve the semblance of a middle class lifestyle is double income, plenty of credit, and cheaply made foreign goods.

Is it the salary, or what people expect to be able to buy with it now?

‘Want’ vs. ‘need’, perhaps.

Watching woodworkers with an LN or LV backdrop doesn’t help.

They make people feel they’re second-rate if they don’t have the ‘top notch’ tools.

A €/£/$ 400 plane will be of great quality. But what will you make with your treasure chest full of first-class tools? When ‘anarchy’ really means snobbery, you know woodworking is not the first point of this man’s agenda.

Open a catalog of one of the high-end manufacturers and you forget what you were looking for: ‘a’ saw, or ‘a’ plane. When looking for a new van, the RR site is not the best place to start. A Silver Shadow will no doubt have the HP you need, but the leather seats will scratch too easily when you throw in your 2x…

Keith, it’s both the salary that hasn’t kept pace with inflation combined with the relative increase in expenses like health care, education, and housing. Food and many consumer goods, relatively speaking, are cheaper than they once were, but not enough to offset the increase in basic expenses. I’d also argue that cheaper consumer goods are a false economy.

Personally, in terms of tools, I have a handful of nice new things (3 LN chisels, a block plane, and a LV router), but mostly use pre-war tools that I found very cheaply and restored. For a lot of things, garage sales and thrift shops are my first stop because you can find things that are 1. cheaper 2. better constructed and 3. reuse is better for the environment.

Cheap consumer goods a false economy? Depends on the consumer’s objectives, and it depends on the goods.

How often will the good be used? High use? Low use? If a cheap good will fall apart after X hours use, how many hours will I be using it? If it is considerably less then X, the cheap good is a wonderful buy. I have lots of them.

Each consumer makes that choice for himself. Each consumer evaluates the options, and none of us has standing to tell the other guy his specific or aggregate purchases are false economies.

You take a part-time job today and support the family at the same standard your grandfather did. It’s a choice. Choose your lifestyle. What was your grandfather’s monthly cell phone bill? Internet subscription? Cable TV? How many cars? TV? How many? What did he pay for air conditioning?

Outside of government, there are few private pensions in the US today. Most have switched to an IRA or Keogh plan where the employer matches employee contributions in a tax deferred plan.

I don’t even own a proper serious wood working vice. I made my bench from scrap 2×4 material and vice is made from a pipe clamp and some ply wood for jaws. I can’t bring myself to spend the money on a vice that may or may not work. And new ones are just as bad and so expensive. I’ve not found a good one on ebay yet. Any advice?

Try this address.

https://www.fine-tools.com/spindel.html

Jon, I bought one of these awhile back and have been satisfied with it so far, but this is my first real vise so take that with a grain of salt! But it is big heavy and solid and opens nice and wide. I mounted it on my first real woodworking bench and have had no reason to complain yet.

https://www.ebay.com/itm/283657501067?ul_noapp=true

Although when I got it it was closer to $65 it seems the price has gone up considerably. It is the same as some name brands as far as I can tell like the Irwin you can find on Amazon but this one is unbranded.

Jon, not knowing where you live, this advice may or may not be of value. I live in southern New England and in the past year I have obtained a wooden screw leg vise for $15 on Facebook marketplace, a decades-old 7″ Columbian quick-release vise for $59 at a consignment antique shop, and a newer but decent quality Taiwan-made 9″ vise at a garage sale for $18. There are deals out there, it just requires patience, luck and a willingness to go picking.

I live in Texas Hill country. And folks hold onto tools around here like they are made of solid gold. Lol. But will continue to look. Thank you for the leads on where to start though.

Jon,

I was lucky enough to be in a woodworkers store the day a man came in and asked the owner if he would be interested in some vintage tools to sell. He stated he was part of a board of a Christian Girls School and they had purchased the estate of a man who was a woodworker. They had sold all his power tools but had some hand tools they wanted to get rid of. The store owner said he wasn’t interested because they sold new stuff. I told him they were several wood turning , carving and MWTC folks around who might be interested in what he had and that I would glad to come and see what he had a woodworkers tool box of some homemade turning tools and some local manufacture planes like Fulton’s or maybe Craftsman. Turns out they had a 10X20 storage building crammed full of Planes, chisels, saws, workbenches (2), Adazes, broad axes, hatchets, brace and bits pipe wrenches and all sorts of odds and ends. I was awe struck and what was in there. I made them and offer and was happy to get the whole lots which I carted from Nebraska to Missouri. I don’t need 38 brace and bits or many of the other tools that I have. I thought about putting them out on Ebay but would rather they go to people who really want and believe in hand tool working. I also have manufactured saw vices, wooden molding planes and everything from a 9″ coffin plane to a 33″ wooden jointer. If you would get me a list of your needs I would gladly sell you what you want at a reasonable price. Paul has my email attached the this reply. Lynn

I think all I need is a hand router plane and a good vice. I can not find your email address attached to the reply.

Persistence is the key when tool hunting. Over the years I have found all kinds of things. But finding it all did take years. If you’re willing to pay more you can speed that process up some. The best deals are rare. You increase your odds of running across them by looking a lot. Where you look is important too. You’re in a great place to find lots of old artifacts. It’s like prospecting. You have to mine where the ore is. So far this year has been off to a slow start. But I’ve found a few things already.

I cannot say anything about longevity of course, but my Eclipse 9” quick release vise bought brand new from toolstop.co.uk (it is available from other sources too, I’m sure) works very well. It seems to be very well built, and has not let me down yet. I’m guessing it will last for the rest of my life (I’m 43) as I do woodworking as a hobby, not a career.

I try to use it with a bit of caution, as I know some tasks should not be performed in the vise if one intend to have it for some time. Hard welly work is done on top of the bench (preferably above one of the legs) and I try not to put very heavy loads in it.

You can make a vise. I found the remains of a woodworking vise in the cellar of my old house and remade the rotten wooden bits of it over. But lacking that I could have just started out with some threaded rod and a nut and gotten there too. Some types of car jacks can donate that hardware. Square Acme thread is best. Leg vises seem to be the easiest to make. The vise I made is a tail vise. I also not too long ago made myself a Moxon vise. It was simple to do. I also found a cast speed vise at a flea market for $2. The guy really wanted to get rid of it. It needed some cleaning up but works. It’s some imported no name brand. What do you want for $2? Things like that do not come along every day. So you have to look a long time to find them.

I built a wooden leg vise for my bench and have not regretted it. The steel screw cost about $40.

I hear folks use scaffold jacks as vise screws a lot. One place I’ve seen a lot of suitable screws and nuts is in certain kinds of car jacks. It would take some creative metalworking to liberate the pieces you want though. Then some creative woodworking to incorporate the parts into a design. The nuts tend to be odd shaped. So carving pockets for them may pose a challenge. I get a special thrill using tools I’ve made myself though.

Bought two on eBay

1. Paramo 250mm wide jaws x 380 open

2. Record 225 jaws x 300 open

Both quick release jaws……….cost 99pence!!

that’s the tutorial many of us miss on our YT channel Paul…..how to build a decent bench vise….

Nah! There is nothing beats a QR vise and that’s metalworking.

I ment a wooden bench vise Paul…or aren’t they any good as a metal one ? in evening class we had those

Especially two QR at 99p

It’s so refreshing to use a new tool! like moving to a new place or even just cleaning up your workplace and put things in order.

But I have a question. It’s hard for me to imagine one of these vises break down, I’ve seen them broken (by misuse and putting a lot of pressure on them, usually from the back jaw where the half nut is), but what was the signs of wear on this vise? how can we use our vises so they last longer?

thanks

Nothing usually breaks without good reason. In this case the vise has been used for a hundred years on a daily basis.Things just wear that’s all.

About thirty some years ago I installed a craftsman 12” vise in my workbench. It is a quality vise but I installed it wrong so a couple three years ago I took it out. Now, I am starting to use hand tools and it has dawned on me that the vise is just what I need so it will be reinstalled correctly. It takes time for things to get done right around here, just ask my wife.

Having a solid bench made a huge difference to what I can do.

The vices on it are a Lion brand QR vice. Wasn’t expensive second hand, but have been pleased with it. And a restored (by me) wooden one. Basically 2 oak blocks, 2 steel rods and the screw mechanism. This one just cost me the time to replace the timber with some very old oak.

Very pleased with both of them.

when people ask what tools should they buy first, I would reply a good solid bench and then a good vice. i know, you will also need a few tools to make the bench,

Paul mentioned the vise threads skipping in the late model vises. Mine does exactly that. Anybody got a remedy for this?

Hi Dan, if the threads of the nut are full of dirt the rod tends to slip under tension. I – following the advice of Paul – take my vise apart from time to time and clean the nut with a toothbrush. You can also buy replacement nuts for some manufacturers (at least for York which is the brand I use) in case the threads in the nut are badly worn.

The first time it happened to me I was very disappointed because I had thought that the thread was completely gone. But after closer inspection I found that it was just dirt.

There are different reasons for skipping so there is no one change fitting all problems. You will get there by gentle engagement. My vise closure on my new-to-me replacement is still very tight – too tight. By the time I have broken this one in I will be in my 90s. I have taken a file to the two side guides (ways) of my vise after measuring how they change the closer I turn to closure and measuring with a vernier from the insides and outsides of the ways. I found that they were too tight at those points and this can mean in between the ways and on the outsides of them. Filing them a little at a time will help free the captivity and this releases the QR. I will take my time. I want it similar to my old vise without risking shortening the longevity.

Once I bought an old milling vise that was in worse shape than I realized. I cracked it in half and cut the threads deeper in it using a Dremel with a cut off disc. Which I thought was a crazy thing to do so I gave it a low chance of success. But I can say today that it did work. So sometimes hair brained plans can happen. If something is messed up it never hurts to give it a try. Because until you do you never really know. Like the Great One said, You miss 100% of the shots you never take.

The nut on my vise doesn’t always engage. I have to think to look at the position of the quick release mechanism handle. If it didn’t came back in the rest position, I have to make a quarter of a turn in anti-clockwise direction with the screw handle and solely then tighten the screw. Otherwise when tightening it will make a loud noise, opening a little bit and … my piece will fall on the ground.

Like everything today it seems that quality has gone the way of the dodo bird. In its place we get cheap products that don’t last long. Craftsmanship is another fading trait in our times. There are few people today who take pride in producing quality products as well as pride in doing so. These are the far and few between. It is sad to say that we may never see the day where we return to the yester years of quality workmanship and pride in what we do sad but true.

The trouble is how many are willing to pay for what quality costs to produce? Better tends to cost more to make. Our society places a high value on value itself though. Which often means perhaps not the best at substantial savings. But that mindset is a slippery slope which has lead to the world we all live in today. Awash in inferior goods at the lowest prices. We’re racing to the bottom. No one is prepared to blink either. Not consumers and not manufacturers. We keep buying it and they keep making it.

I own several ebay-saled Bailey’s and other vintage, kindly-used woodworking tools that will undoubtedly serve my remaining years…however, when I must buy new, I search for a “maker” to first consider. If I can find an individual who makes what I require that has also earned high repute, I willingly spend the extra money to patronize those makers. I would rather support those makers than corporate scammers who knowingly peddle low quality at near the same price.

A tip for replacing a woodwork vice

I replaced the top of my bench last year with two thicknesses of 25mm plywood. I embedded 12mm T Nuts in the bottom sheet to screw the vice bolts into. When I cam to fix the vice I was faced with the problem of holding the weight of the vice from below while screwing the bolts in. Not easy and no help at hand due to lockdown.

After A bit of thought cut a piece of 12mm plywood the same width as the vice jaws and then screwed a block of 50mm square wood to one face. I then clamped this in the vice jaws with the block flush with the rear jaw and overhanging onto the bench side of the vice. I then offered the vice and block up to the bench and the vice hung there will all the weight being taken by the block of wood on the bench surface. It was then very easy to insert the bolts and a couple of thin shims to get the vice jaw level with the bench top when tightened. The hook made the job dead easy and well worth the few minutes it too to make it

Thank you Paul. I wanted to build my own workbench from timber I gathered and took from place to place over a 30 year period. I carried and still have the plans that I followed in one of the children’s school exercise books that I used to draw up plans and ideas over the years.

I used a Workmate lookalike with a small clamp vice for those years and more. A couple of G clamps are still used.

Finally I built the workbench, fitted a second hand woodworking vice and at the other end a Dawn vice that belonged to a friend’s father. I use them.

I will never wear them out but I respect them and don’t abuse them. Tools last if you use them wisely, keep the sharp and clean and appreciate the years of design that makes them work, even in poor hands like mine

At some point I really will need to replace my cheap n nasty vise. It becomes a real chore using it. But I did recently manage to get a Record 071 hand router and a Record 043 plough plane with some change from £90. Alas, it’ll cost me a bit more yet because both only had 1 cutter but I was reasonably happy – and happier still when I first used them. (After the vise I’ll get another #4. I’ve got 2 of dad’s but one was missing the pin which held the doodah that held the iron that enabled lateral adjustment – I cut a similar size Allen key shaft, rounded it a bit then persuaded it into place and it’s not moved yet.)

The more ‘needs’ I strike from my list the more space for ‘wants’.

One of my finest purchases was a 100-year-old vise from Abernathy of Chicago. An old area of Kansas City that once housed small manufacturing shops was abandoned and awaiting demolition. For $25 I got the vise. It was probably used on a daily basis in the Kansas City shop for all of those hundred years, and now it’s on my Paul Sellers bench. I imagine someone will still be using it in another 10 years.

Now I see an ad on Craigs List for seven Disston saws, all for $100. The pics show the logos, and lots of use. With luck, they will be mine this afternoon.

The tools are out there.

CORRECTION:

I imagine someone will still be using it in another 100 years.

Before laying blame look in the mirror. Is that t-shirt you have on locally made of good cotton or cheap foreign petroleum based product. That watch on you wrist. Will it tell you the time for the next century or is it capable of telling you everything you didn’t need to know but you’ll be replacing it with another one with even more useless features because its the “in” thing. Not a single manufacturer moved their plants to foreign shores for environmental reasons. They moved because it was cheaper to manufacture there. We are the problem and We are the solution but are unwilling to pay the price. A wiser man than me once said “people end up with the government they want” that goes for most things.

In some US states, a big box store can get all the permits necessary for construction in six months. In others, the exact same store takes four years. (This does not consider California with its earthquake regs.) And that’s without the environmental or NIMBY lawsuits.

There are lot of reasons for siting a plant. Labor cost is certainly a major factor, but it hardly crowds out all the others. The time it takes to get the goods to market is also a major factor.

At the outset, I’d like to acknowledge that I don’t make my living out of my shop as Mr. Sellers has(and does), and I’d hazard a guess that most of us commenters here are probably in the same circumstance. Please keep that in mind as you read on. As an amateur woodworker/maker who developed a side-business to fund my shop, I can say unequivocally that the item I have sold the most of is not cutting boards, or charcuterie boards, or wine/beer caddies, or bottle openers, or coasters, or floating shelves, or epoxy river tables, or anything else that is currently going like gangbusters for the vast majority of home-gamers like myself. What I’ve made and sold the most of by far is marking knives. This is not a shameless plug, but perhaps some evidence, albeit anecdotal, that solid, good quality tools are coming back into vogue, just not through the same channels we all may be expecting. I won’t be so foolish as to call the tools I make the best there ever will be, but I make as quality a product as I possibly can and my happy customers/clients are all the proof I need that I am at least on the right track. Of course, not everyone is going to be capable of making their own tools, and certainly exceptionally few, if any, are equipped with facilities to house a foundry for casting iron. Cast iron, however, isn’t the only material that one can make tools, specifically vises, out of. Plenty of perfectly serviceable and long-lasting vises have been made out of alternative materials while a camera was rolling. The products of which can be seen on a relatively obscure video hosting website called YouTube. Even our gracious host has a small, but mighty concern on that very platform. I’m kidding, of course. The point of all this rambling is that good, quality tools aren’t required to come from eBay, or Craigslist, or LN, et al. I wouldn’t call myself tool-maker… yet. I’m certainly no expert, rather, a student of the craft, but I can make, and happily use, my own tools because I practice doing it enough and they are good enough for me(and a few others if my sales are any indication). For me at least, it all boils down to this; to define quality, don’t ask yourself whether or not the tool does every job, ask yourself whether or not it does the job you need it to well and reliably regardless of who produced it. If it doesn’t, make it better if at all possible. You’ll be glad of the newfound skill and independence, and your wallet will stay a little fatter.

On advice from one of your earlier posts, I purchased a Jorgensen 41012 about 18 to 20 months ago. I purchased in from an Amazon seller. The comments said it was now made in China and shipped to the USA, but using the original equipment. It does have a metal handle rather than the original wood – not too much of a bother.

I’m relatively new hand tool working but it’s been a very good vice once getting the hang of the quick release, etc. It really looks great on my American Elm bench (I salvaged the wood from a tree the power company took down on my property)

I live in Temple, Tx. , central Texas and the market for old hand tools is non-existent, just like Jon Bowers said about the Texas Hill Country.

Pawn shop owner said he can’t remember the last time he saw a hand plane (I’ve visited all of them in Temple). They have power tools galore. A year of visiting garage sales, estate sales, etc. got me a terrific $4 tenon saw after filing and setting and an old Crusader jack plane which I have given up on making ever work properly.

I’ve decided that this area was too sparsely populated 50-75 years ago when the tools I most desire were made to have many around unless someone moved here with one in their baggage.

I recently bought a NEW Stanley Sweetheart No. 62 jack plane and fell in love. Out of the box wispy shavings and a handle big enough to fit my hand. No more scrunched up fingers.

There is an argument for buying new, if you can afford to, and that is your purchase results in employment for some people. It is perhaps regrettable that the manufacture of those tools probably won’t be in your own country, but the business that sells it probably will be.

I’ve started woodworking again after a gap of nearly 60 years (I’m ignoring various DIY jobs made with MDF and ‘B&Q wood’). I had no decent hand tools, so I bought quite a few new hand tools, mostly from Workshop Heaven. These tools have been made in China, Japan, and the Czech Republic. I am fortunate in that I can afford them, and I am very happy with them. Will they last? Well, at my age I expect they’ll last long enough.

I have bought some tools from eBay, the latest being a 22″ wooden jointer plane. After a bit of fettling and some significant re-grinding and sharpening it works a treat. Thin shavings and a lovely whistling sound as it cuts. And now, thanks to one of Paul’s other posts, I know why the cutting iron is tapered! It seems to be laminated too. Is that likely?

Oh, one hand tool I had in the ‘in between’ years was a Stanley Replaceable Blade plane. A vile thing!