Prepping Wood V

Choosing the wood we use in any project precipitates wood on the benchtop. At the timberyard, we search the racks and flip each board to try to preempt any possibility that what we buy might cause us problems after we’ve left the store. We consider everything that could go wrong with a particular board if there is a split or some wiry-looking fibre in the piece we chose. This anticipation helps us to stay focused when and as we begin our search for good wood. Minimising the waste of our energies is important and so we must think ahead. Flogging off massive twists with a bench plane can quickly cease to be fun. In times past, a man had an apprentice or two for the donkey work. No such luxury for us. The wood we will choose can result in the waste of a piece or section. But secure in the knowledge of our future piece, enables us to envisage different pieces in the grand scheme of things. This or that would have worked better here or there in the overall piece rather than where we thought it should be: think straight rail with arching grain, busy, turbulent grain can dominate whereas passive submission would have worked perfectly, and so too the dark, heavy depths of colour can clashingly imbalance amidst its counterparts.

Just as planning ahead by drawing, enables you to plan buying by taking off a cutting list from your drawing, so too thinking about the individual parts to your piece will help prevent a crash in the middle of the whole when done. A panel with cherry sapwood that can sometimes not be detected in a newly cut and planed surface and edge can almost always be detected in the end grain.

In a month or two of daylight, the whiter sapwood will contrast markedly and will likely ruin the midsection joint line of a laminated tabletop. Take time to think and look. The heartwood on some woods will darken whereas the sapwood will not.

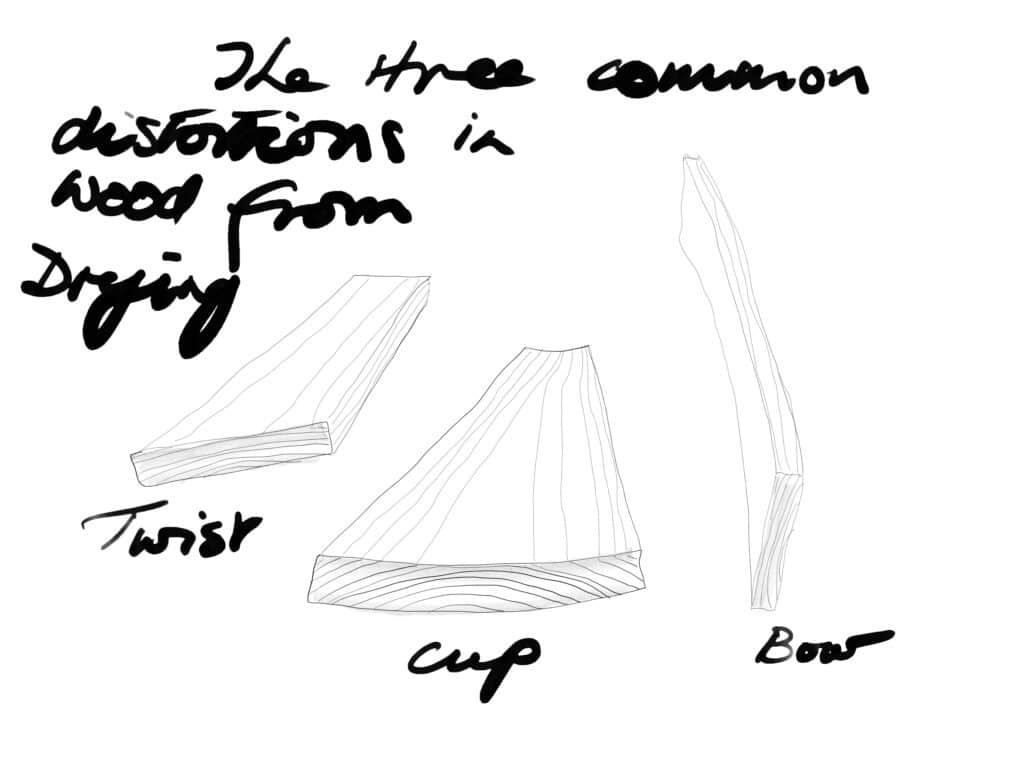

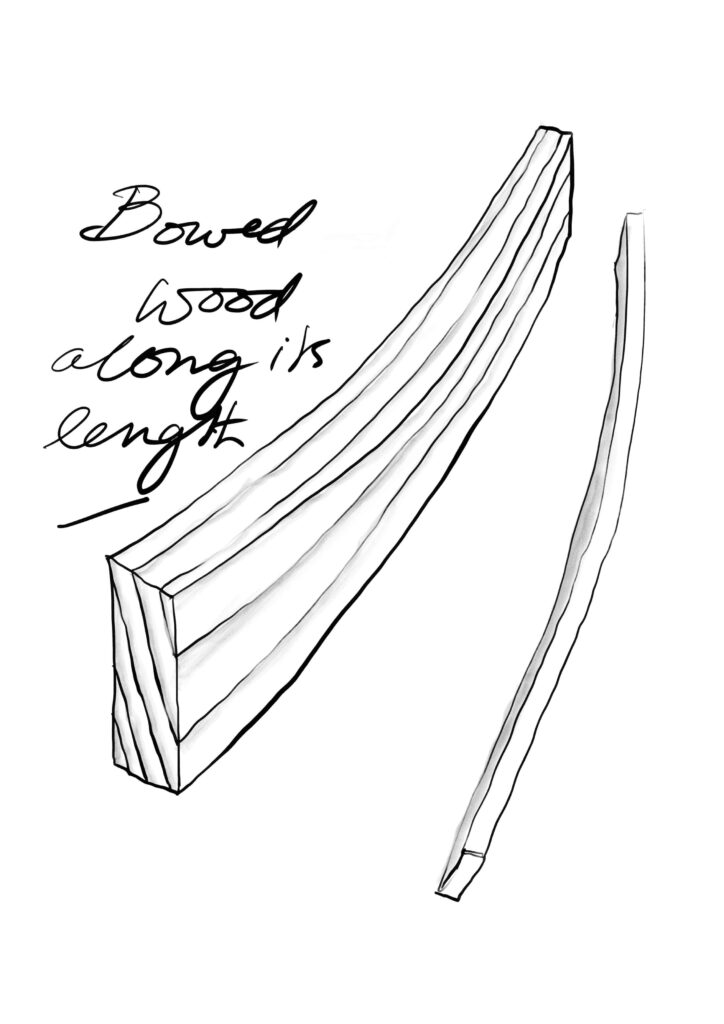

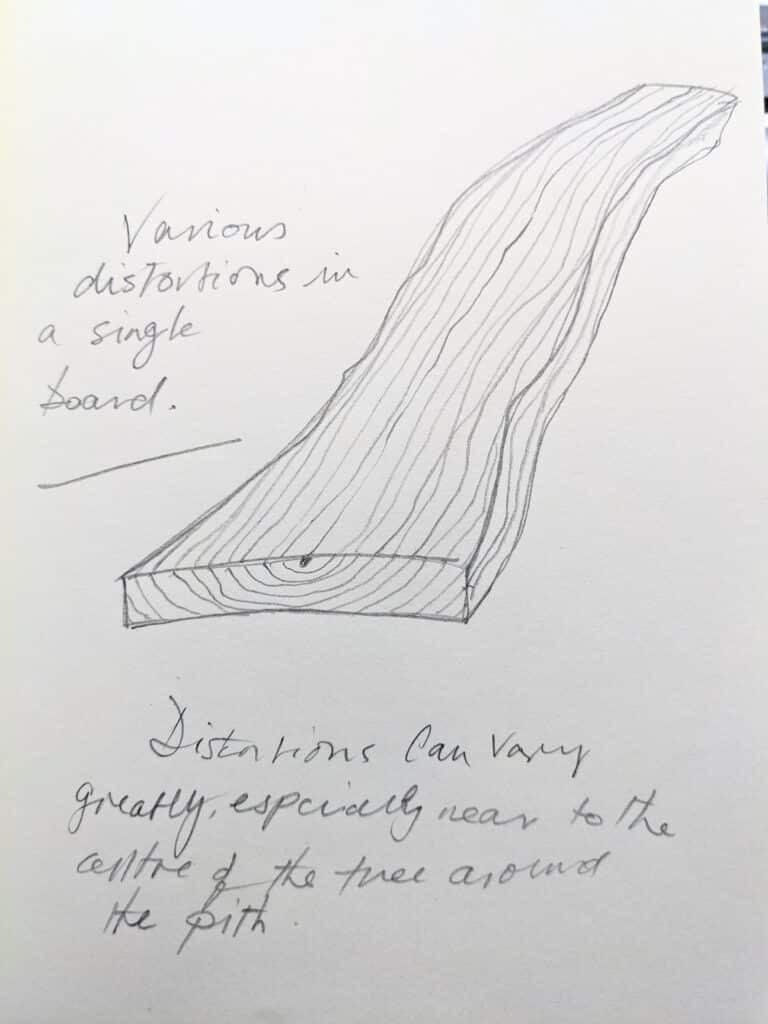

Cupped boards, long bows and short, twists are all standard when buying wood. Most can be salvaged but not changed as in applying opposing pressure or bending in an opposite direction once dried. To resolve such distortions necessitates the removal of wood and doing this using hand tools: primarily saw and plane, is time and energy consuming and the wood you take off is lost too. Wood with wane to some is character but to most it is waste you will ultimately pay for in wasted wood. Most people as customers buying your pieces and makers selling them do not like or want waney-edged items. When the advertisement describes “Character oak” expect everything and anything from waney-edged boards, massive cracks, patches of wood rot, wormhole, deep and dark discolouration, deep pits and inclusions and more. Most so-called ‘character wood’ takes some working with. Sometimes it is stunning, often it is over-domineering, overemphasised as a term, and quite ugly. In my world, it is on a par with pallet wood when compared to furniture wood. As I said, every so often something comes up that can be made into something stunning. I have dealt with too many sellers describing their wood as character this and that and only been disappointed when they try to sell me some bog oak from a foundation of a building that was thoroughly rotted.

Cupped boards will be present in about 80% or more of the boards we buy simply because when the wood is cut green, as it almost always is, drying still must take place. Drying results in distortion of different kinds and at various levels and most of these are indeed predictable to a greater or lesser degree. Cupping, twist and bow will always be acceptable but not always accepted. If you go to a supplier looking for a flat, rough-sawn board every time, you will mostly be disappointed. I briefly covered the ways we can work it into our work in Why Shrink here. In other words most of our wood, once dried down to around 8%, will indeed be cupped to some degree. This cupping occurs as the wood is dried and it’s because wood does not shrink to an even width or thickness and nor does it shrink in perfect parallel symmetry to its outer sawn faces, we must accept that we have yet more work to do.

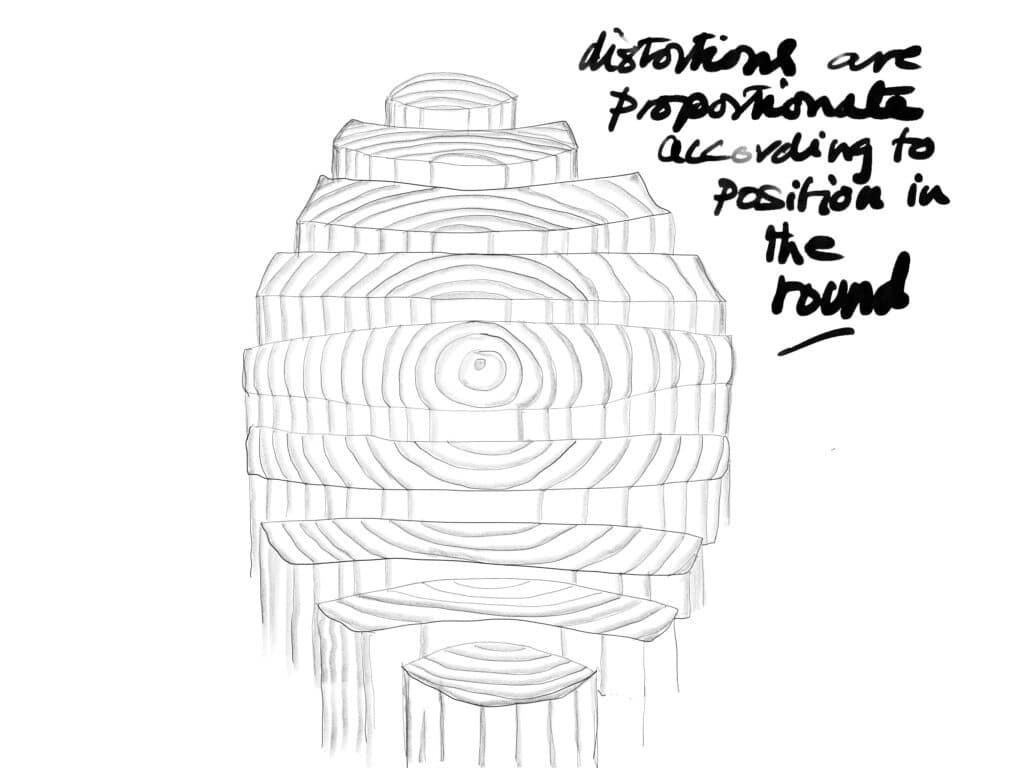

It may be tedious to see the same drawings depicting the ends of a sawn log showing the end sections of planks and beams in dotted lines that in turn delineate expected distortion but they are indeed worth studying. From these, we can see that rectangular sections often dry to diamond shapes and then too that the nearer to the outside of the tree stem that we take our wood the greater the amount of cupping. Also, the twisted stem of trees will indeed yield twisted boards and though twist may visible on the outside of the tree, no logger will anticipate nor be concerned about you picking out your dried and twisted wood in the timberyard. On the one hand, I might advise anyone to reject twisted boards because there can be a lot of loss after correcting a full-length distortion. If short sections are needed, then the loss will be much less and the board may well suit your needs. This is true too of long bowed pieces. For short sections needed in chairs and such, there will be little if any loss. Especially is this so if the parts are lathe-turned for whatever piece you are making.

Distortions should always be expected in general

No matter how wood is dried, distortion will take place at some level with the lowest levels of distortion taking place in quarter-sawn wood. Most of the wood we buy will be sawn through and through which means that the tree stem is slabbed with every pass through the saw being parallel to the first. Three or four boards will naturally be quartersawn; quartersawn material distorts the least during and after drying. Depending on how close subsequent boards are to the centre of the tree determines how much the boards will cup. We have no real way of considering this when we are in the timber yard buying our wood (I am not talking construction-grade softwood here). The ends of hardwoods are almost always painted to reduce too rapid shrinkage at the end sections.

So we learn to work and live with board distortion as and when we buy and work our wood – it goes with the territory. I have always said that life is like wood, it comes with knots in it. Well, in picking out our wood, it comes with much more than a few knots.

FYI “Especialjaluaply” should be likely be “Especially” in the sentence: “Especialjaluaply is this so if the parts are lathe-turned for whatever piece you are making.”

I think we can safely blame Paul’s computer for “Especialjaluaply” but there are words I don’t recognize or don’t recognize in this context. I’ll google “teist” for example, in case it isn’t a typo for “twist” but what is “wane” when it isn’t in a sentence about the moon? But all this does raise a question for Paul or the other readers. Is there a convenient glossary or dictionary of woodworking terms, preferably online? Thanks!

I’m surprised no one has a little bit of extra tolerance here and there for an odd typo in a blog but there you go. I always respond and try to please so it’s now fixed. Remember that my teachers told my parents when I was 14 and leaving formal education, “Paul can never be educated.” They seem to be proved right, right? And then there are others below who perhaps can join up my unjoined up words who carry away the core information, one of them even says the post was clear and precise.

Great read, as always. I’ve been spending more and more time reading through the blog. It’s fascinating to have the thoughts of a craftsman available and at our disposal, and yet, we still judge typos. C’mon.

Paul, you write very well and I am professionally qualified to make that statement. A poor writer makes simple ideas sound complicated. A good writer can make complicated ideas sound simple. (Or at least comprehensible.) You are the latter. As to typos, please accept my apologies if I made you feel bad. Typos happen to all of us. Sometimes they’re embarrassing and occasionally they’re funny, but they are scarcely ever important! Thank you for your writing skills as well as your woodworking ones.

No, I never feel bad or offended by comments per se, I just don’t feel writing comes naturally or easily to me – in other words, I have to work at it to make sense. The good thing is that second to woodworking it is my favourite thing to do. The errors are because I cannot touch type and look at the page, so by the time I have typed out an article the words are either conjoined because my right side of my space bar sticks a little. I do not feel that my typing is in any way slow, I just need to see the keys. Autocorrect or suggestion becomes permanent before I see or know it. I just do not really have the time to go back through my typing because I type around 3,000 words in my workday. Please don’t worry about my feelings. I understand that typos are very irritating. Very!

I was a technical writer in the software industry for 20 years, so I’ve worked with quite a few writers in my time. Not one of them who said writing is easy was a good writer. It’s not easy.

Master Sellers, depending on their definition of ‘educated’, those teachers’ prophesy may have proven true. That you seen to have ‘wised up’ and ‘learned’ without the ‘education’ (conformation to the norm?), may be seen as the last laugh on the matter. Not to mention the fact you, even now (typos and all), continues to transfer knowledge to other uneducated, uneducable subjects.

😉

I hope an occasional (and needless) criticism doesn’t jade you, Paul. I think the overwhelming majority of us are able to skim over a rare typo or two, and know what was meant. We understand that these words are not from a publicist, but from your hand, and probably late at night. We appreciate what you do for us.

“Paul can never be educated.” I seem to recall roughly the same thing being said about a certain Mr Churchill and Mr Einstein and they both did alright.

Google search, the everything glossary: what is a wane in wood

Wane: The presence of bark or the lack of wood fiber along the edge of a piece of lumber.

Excellent writeup Paul. Please keep them coming.

I don’t know that Paul is mildly dyslexic, but it fits with his life story and his other abilities. My third-grade teacher told my parents the same thing. I graduated from law school with honors, but still have problems with spelling, and cannot proofread.

Paul is a master at what he does, and we should all cut him some slack in his blogs. We are here to learn woodworking, and at that he is a master.

Haha I’ve been a diesel mechanic nearly 50 years and still have trouble spelling “diesel”!

Good thing my phone knows!

I spent 3 years of grad school studying the Brian ??

…cut him some slabs, perhaps?! 😉

“Should be likely be” should likely be “should likely be” in Sherlock’s helpful proofreading comment.

I always find your writings so informative. I learn more about wood and wood selection and buying each time I read one of your teachings. Your time is valuable and so thank you for giving so much of it to help us all become better wood workers.

Always a clear and precise explanation: straight to the point. Thank you.

This is a very interesting series of posts Paul. I’m learning and enjoying, so benefit is double. Once again, thank you very much for all you do.

By the way, I think your teachers were completely wrong about you… or maybe your teachers and me have a very different concept about “education”…

I have had some success with removing cup from wide boards, for long enough to get them fastened in place, by placing the concave side down on damp grass, on a sunny day.

But that is not permanent though.

Paul, What does end grain on quartersawn wood look like? Vertical grain perpendicular to the wide dimension of the wood? Thanks

Yes, but it can be from 90-degrees at perpendicular down to and angle of around 60-degrees

Great series Paul and one that is answering several questions that have occurred to me as I learn this craft. One that I am still asking myself is do I plane a board that will make several components to thickness as a whole board, or cut the pieces to approximate length and plane to thickness individually? I have done both and each offers its pros and cons.

This is very good information, Paul. I did not know, or at least did not think about, that flat sawn boards cup more and more the longer you move outwards from the centre. It makes sense, though.

This series of articles are extremely useful. Here in Norway, small sawmills pops up “everywhere”. Logosol (now Norlog), Wood-mizer, Frontier, a bunch of OEM manufactureres (different color, different sticker, sometimes a cheaper Briggs & Stratton engine in stead of a Honda – but in all other aspects, the same as their more expensive counterparts) do good business. People are spending 30-150.000 kroner (about 3-15000 $/€) and becomes hobby sawyers. The main product are construction materials, siding and such. Rarely they are spending time to make high quality cuts for furniture.

Articles such as this will eventually “leak” onto that community as well, and I suspect they will start cutting their wood with greater care.

I did a bit of “slabbing” myself; an old oak up to 95cm in diametre (about 3 feet) was felled and cut to planks. I focused on quarter- and riftsawn material over wide planks. After one year of drying, the planks I can see within the stack seems to be very straight and without any noteworthy cupping. The flat sawn ones does cup, at least in the upper part of the stack.

It will be interesting to see what is going to happen once I start picking from the stack. Since I know every board and have a general idea where they were on the stem, this new-to-me information will be valuable in selecting boards for projects.

As for typo’s or “odd words”: Not every dictionary is complete. The web site “urban dictionary” is often very helpful for me as a Norwegian to understand certain phrases and words. I have a small woodworking blog, and I try to better my English and to include dialect and slang into it, in order to keep the reading interesting. I too find writing very enjoyable, which clearly can be seen from my often lengthy posts. Oh, well.

Again, great series, Paul!

A question, if anybody has any experience: I got a few ash planks the other day. They have spent at least 30 years in the loft of a barn – well seasoned, I recon. They are at around 15% moisture content. I run a dehumidifier in my shop, keeping it stable around 45% relative humidity at 18-20 celsius.

Will I be able to reach 8% MOC, and if so – within reasonable time (the planks are 1-2 inches thick)?

Paul, I took a cabinet making course 25 or so years ago, unfortunately it was all power tools. One of the first projects I did was a small Shaker inspired table, made it out of butternut, When the wood was delivered to the school I started to go through it, there were “defects” which looked good to me so it became a matter of how do I fit this into the project. The table came out very pretty and I had a happy wife. When I go to a wood shop I tend to look for wood that leave behind because there are possibilities not seen or dealt with and I usually can find some that with careful planning will be useful. I’m a fan of natural or “live edge” projects they can be lovely.

Awsome article!!

When the slabs still have the wane, I usually estimate how the cross grain runs, even though is painted; it mostly follows the wane curvature near the wane itself and from the angle I get an idea where the slab belonged in the log.

Poor Donkeys LOL. I’m sure George did not bray at you too much. 😎. A lifetime of understanding wood, in a 1000 words. Maybe in another couple of years will I be able to say, Ah, now I understand you Paul. I ‘Tut’ when I go to the big box. So much junk, unless as you say, you want short pieces.

I bought most of my wood years ago from B&Q .Above the racks of wood were huge hot air fans , I always chose separate pieces rather than multiple pieces packed in plastic . By being fussy about twists and knots I have had no trouble . The hot air fans automatically eliminated the duds for me . What were B&Q thinking to have dry heat fans right above the wood ?

Multiple packed wood strips always had good stuff outside and rubbish inside .

While this will involve some planing can I mention a Spear and Jackson plane I have similar to a Stanley No 4. It would clog up very easily . The break through came when I noticed the mouth inside at the front was vertical. Stanleys have a slope forwards there . I filed the inside of the mouth just like Stanleys and it transformed the action . Now it`s my favourite plane .

Some persist in “majoring in the minors”. Keep it coming Paul.

Just a slight addition. When talking about grain orientation we are often talking about boards and panels.

Perhaps there’s some movement risk in the following approach that I’m not aware of or have not experienced yet.

If this is too obvious then forgive me but for posts n legs it’s worthwhile being conscious of end product orientation. If I’m doing square dimensioned stock then flat will do. If I’m needing 44x38mm stock with a 44mm quarter sawn show face then in buying flat sawn boards I just need to be sure to buy a thickness that will leave me 44 finished. After all, when you cut from a flat sawn board and flip it 90 there’s your quarter sawn. If I need rails less than 50mm I’ll just get 50 mm thick boards and have the choice.