Wood Grain

There is less written about wood than you might think. Oh, there are tomes in works by academics and organisations but what helps woodworkers should be a simple down-to-earth visual for people to see why we must plane and saw and split and pare cut wood differently according to something ambiguously called grain.

In teaching woodworking classes to adults each week, the one thing I needed to get them to understand was what grain was. Visually this was much easier than in text. Split wood in front of a group of men with a chisel and a mallet blow and you suddenly understand grain direction. Plane it with and across the grain and again on end grain or at a tangent and you see the response to the tool’s passage onto and into the fibres of the wood. Magnifying wood’s fibres pulled apart by massive force doesn’t help too much either because, usually, the wood fibres cannot be pulled apart like a concertina but split along the fault-lines at weaker sections like medullary rays or a growth ring, an existing separation, or something else. But understanding the strands and fibres and cells of what constitutes wood is important to us as woodworkers. By understanding this we can better determine how best to effect the cuts we make minute by minute and the best way to develop a cutting strategy for each one of those cuts we make comes from recognising certain facts about wood grain.

In my early days of woodworking, it was passed on to me that you split, sawed or planed wood with or across the grain and that whichever you were doing required a specific method, technique or tool or that you simply adapted the same tool to the tasks accordingly. Saws of all sizes were generally sharpened to a ripcutting or crosscutting pattern, with saws sharpened very specifically to one of the two tooth patterns accordingly. Chisels, planes and all of the other tools knew no such differences even though likewise you did cut across or with the grain according to the need throughout the day.

For the main part, everyone knows wood grain as a flat surface looking and feeling much like a photograph. In most cases, when we touch wood in the day to day of life, we rarely actually touch wood but more the finish that has been applied as a surface treatment. What we see in wood is grain colour and configuration. Workers of wood, on the other hand, see it uniquely differently because we see it multi-dimensionally from the inside where the grain becomes much more a complex and intricate material made up of interlocking strands, fibres, resins and rarely is it merely a two-dimensional surface without texture but with masses of diverse texture that differs with every cut we make.

For my woodworking classes through the years, I found it most helpful when I taped a cluster of straws together to represent the direction of tree growth in its upwards direction and thereby show the direction grain takes in its growing. Making this connection was critical to their understanding simply because the majority of students might never have any experience of actually splitting wood ever in their lives. Taking an axe to a section of pine and axing across the grain showed that the axe could only sever fibres to a certain depth but could never split to strands as it would with or along the grain. There in the US, most older men had indeed split their firewood and kindling as part of the family chores if they had in fact lived more rurally as many did. It was the city dwellers that were less likely to have ever done such a thing. That was then and this is now. Now, living as we do with gas and electricity, most people will never be exposed to such things and therefore are more unlikely to know of wood splitting beyond watching a video. When you start woodworking you soon learn that wood splits in certain ways and that we often take advantage of its splitability in working its fibres. Often, mostly, wood splits quite positively and readily, depending on the wood type and the relationship of parts of the tree to any deviations in grain according to its growth with bends, knots, roots and so on affecting it as it grew. Some woods readily split whereas others can never be split along the grain with an axe or wedges alone; I have known some wood types that had fibres comprising the weirdest configurations of interlocking grain that truly defied split-cuts while others seem to split with just a mean look.

Try to imagine wood grain as long strands of string glued together with lignin that holds the cellulose fibres, fibrils (minute fibres), together in similar fashion to a more elastic type glue. In my classes, I took long lengths of string and made them into a bundle to show how a saw with chisel teeth failed to sever the fibres cleanly when cutting across the ‘grain’ but slid in between the strands when ripping with or along the grain. Exaggerating the size of grain this way made everything much more visible as indeed making artificial saw teeth enables me to show the difference between the shape of rip-cut teeth to cross-cut teeth.

The correlation between these two tooth types and then seeing the strands of wood in long-grain fibres made the images much more clear for my students. This was how I could help them to understand visually on a macro level what was in actuality taking place at the level with wood under the saw, being split, pared and chopped with a chisel and of course, much more with other tools. We cannot generally see the micro-level of fibres as we work them. It is important to think-see them so that we can generally work our wood and tools accordingly because grain direction and type, etc determines how we do everything we do.

Thanks!

Now I must re-visit your video on cross-cut sharpening (though so I remember you writing or saying that the rip-cut pattern on the likes of a tenon saw, was not only common but practical for most applications, both rip-cutting and cross-cutting?

Once over a certain number of teeth it doesn’t make a difference and rip cut can be used:

WHAT TOOTH PATTERN SHOULD I SHARPEN TOO?

For any saws that are 10ppi plus we sharpen them to a rip cut pattern for both ripping and cross cut work. This covers all the saws that we use daily at the bench. It is only when we go for less ppi than 10 that we would sharpen cross cut.

https://paulsellers.com/knowledge-base/saws-sharpening-refurbishment/

I remember an old lilac in my parent’s garden which had fallen.

The trunk, which had a diameter of about 30 cm, was completely twisted like the threads of a rope.

We have burned firewood all our married life and splitting fire wood logs is an education in grain structure. Elm and Box Elder and some Cottonwood fall in to the category of intertwined grain and conifers pose a challenge with all of their knots. Both of these can put strain on a 20 ton splitter. Locust and Black Walnut both split nicely along the grain although these are usually saved for making projects and the off cuts are fire wood unless rot has occurred. I made my work bench top out of three foot firewood logs cut down to 2 x 4 size and laminated in a pattern link building a brick house. It is finished now and works wonderfully. Paul thanks for your incite.

Is there a video on turning a log into stock? All too often I see nice oak logs and just don’t know how to cut it into usable boards for projects with hand tools.

As always, many thanks to you.

I think it’s a lot to chew off without the right equipment, Jay. In my life in the US and Texas I had a couple of associates and friends who had a Wood Mizer mobile sawmill and one called a mobile dimension mill that had two blades set at 90-degrees to one another and ran into the wood at the same time, one smaller diameter and one large for the wider cuts. It was powered by a VW motor and it worked great. You might think about log splitting in shorter lengths working around the log and then air drying. This is especially good for chair making.

You will definitely want to take a look at Peter Follansbee’s blog, just search for riving oak in there.

Some oak is not well suited for lumber so before spending a lot of time working it be sure of what type of oak it is.

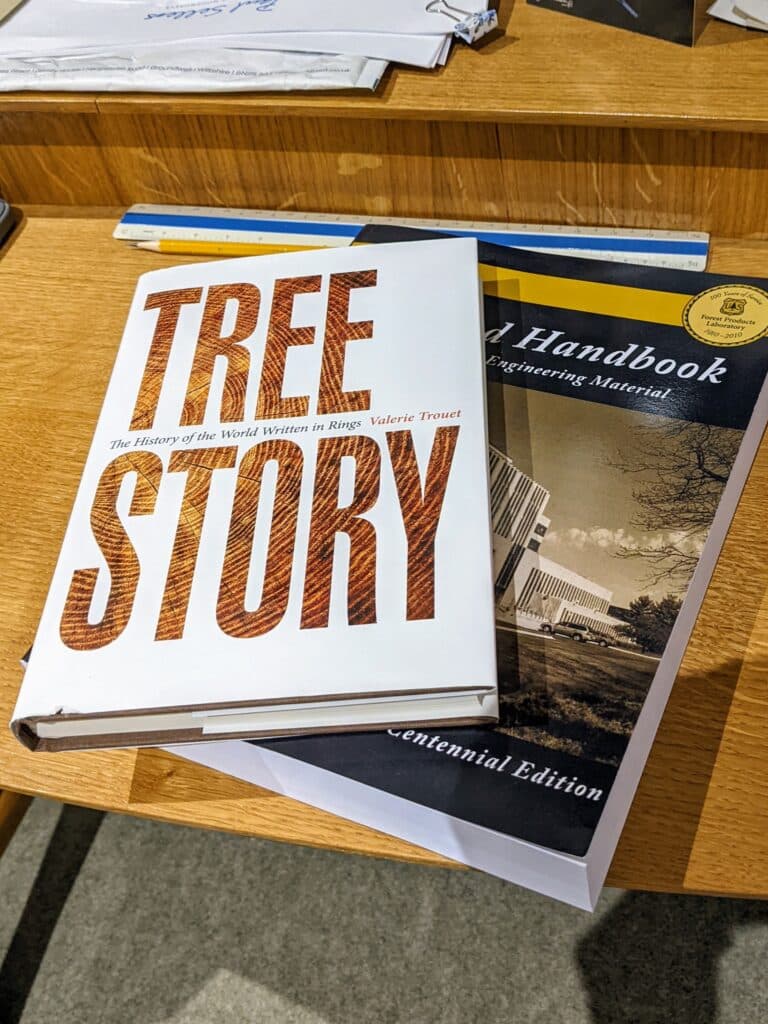

Not a book on grain, not woodworking generally, but if you’re interested in trees then ‘Around the World in 80 Trees’ by Jonathan Drori is absolutely wonderful. 1-2 page monographs for a range of the most interesting common, and not so common, trees of the world, with stunning illustrations by Lucille Clerc, it’s a orth buying for these alone. The beautiful hardback version is only £15 on Amazon UK at the moment and I’d recommend it to any woodworker. With your love of wood and your drawing ability Paul, I’d guess you’d really enjoy it.

A good source for craftsmen is Paul Hoadley’s “Understanding Wood — A craftsman’s guide to wood technology”

I bought it when it came out in 1980 and still use it as a reference. It has been reprinted and updated a couple times and is still available.

I have just got this and I am enjoying going through it. If others are looking for it the author is actually R. Bruce Hoadley.

Sorry, for some unexplained reason I had Paul on the brain.

Beautiful description that illustrates cutting wood and how grain impacts type of blades to use.

I often think that buying timber in straight lengths of rectangular section we have lost something from the past. Then timber was often bought because of a particular curve that was correct for its intended use. Curved lengths were often not rejected when we might now only use straight lengths. I retain an image of an old farm barn were the rafters were anything but straight when looking up at them, but made no difference to their function. they had been cut with the grain, and presumably much stronger.

This is all very true, Keith. Boat components, parts for buildings caused carpenters and woodsmen to seek out the curved section to create ‘knees’ from for loft galleries and gantries and the combined elements of boat hulls, etc. I’m not sure I agree with you about losing anything by using straight-grained woods. I think that there is a place for everything one way or another and that we often create according to a personal preference and yet without compromising anything. In furniture making, we have always relied heavily on heat bending of different forms be it direct heat from steam passed through a pipe and then a steam chamber going directly to the wood. In some spheres of furniture making straight-grain is more attractive than wild grain but that does not mean there is no place for more flamboyant personalities.

Now Paul; I thought you regarded yourself as not doing well at school .

You’re diction, illustrative skills far surpass the average.

Thank you for most helpful video and article postings.

I’m learning a lot even at my age.👍☺️