Something New To Think on

I thought I might pass something along, something that explains that might interest you as it does me. It’s solid and it’s mostly about a solidity we might not consider and think about. I have often suggested that what people, woodworkers and sellers of planes and plane irons, often talk about is plane chatter, how what such people name as plane chatter is rarely if ever the very rare phenomenon of plane chatter but quite simply what I call scudding. Those selling thick plane irons rely on the simple phrase to sell thicker steel plates by often disingenuously stating that their, “thicker plane irons stop the chatter you always get with thin plane irons” or “our thicker plane irons reduce the risk of plane chatter“. This not quite truthful practice led to the now common practice of retrofitting planes with thick irons costing two and three times more than the eBay find of a #4 Stanley, thereby negating the bargain price of £20. In reality, the thinner plane irons that came with the plane originally would have worked just fine if only you had the confidence you were gaining stroke on stroke just by continuing to use the plane and discovering your own swings in responding to seeing the scuff marks you made but persevering. As I said, plane-iron chatter is a rare and unique phenomenon, but it’s not usually what people think they are getting from their planes. It’s extremely hard to get a plane to create chatter intentionally, and guess what? My planes with the standard, original irons have never chattered in my 57 years of using them every single day six days a week 8-10 hours a day! I will say this though, those new to woodworking often end up with iterative lines and uneven bumps on the surface of the wood. Especially is the so at the very beginning of plane strokes and then too at the end of a stroke. This, my friends, is most likely not chatter but what I call scudding.

When we are new to woodworking and less confident with bench planes, starting them at exactly the right level and the right point on the wood as we land and start the plane, the plane stroke is awkward. We are unused to this block of cast metal and the location where the blade engages the wood. The short platform of the forepart of the plane’s sole is but two inches or so long. We are bound to be out of parallelity as we swipe forward. Such is the cause of the plane negotiating a level through-thrust that causes the plane to skip, hop and jump. We also are unsure about how to apply what pressure commensurate to the task. Other things affect the plane’s functionality too, things like the wood itself, the wood type, the grain configuration, grain direction and other conditions affecting our working. All I am saying is that it’s not that easy in the beginning and you must persevere, learn to read grain patterns and things that will indeed cause the skud marks that make for disappointment. You will gain mastery by perseverance and not changing the blade for a thicker iron and worse still now the cap iron (chip breaker USA). This weak link between intention and actuality causes us to be less confident and assured that we won’t ruin our pieces of wood. But it is this that causes 95% of our plane skipping at the start of a planing stroke, and nothing to do with blade chatter at all.

So along comes our premium maker of planes and blades with thicker special steel alloys and suddenly Leonard Bailey (who was indeed the finest inventor and developer of hand planes ever, anywhere) is seen as not to have thought things through. Well, that was far from true. He perfected his plane thoroughly through and through in every way. I have yet to see a single maker of his plane, all of the knock-offs, copying his design throughout, which they all have done if they make the Bed Rock or Bailey-pattern plane, give any acknowledgment of his absolutely brilliant designs in these planes. I really don’t mind if someone retrofits their planes with a thick iron if they want to. `i am more concerned about the false information fed to them when all they really need to do is persevere in the learning curve. I have worked with enough new woodworkers through the decades to be able to say new woodworkers generally allow their planes to hop, skip and jump and indeed scud on the wood when they are indeed new to the craft. But every one of the 6,500 I ever taught had it within a few days of practice. 6,500 students adds a lot of weight to what I am saying. My bench planes have no retrofitted thick irons and they have never nor will they ever chatter.

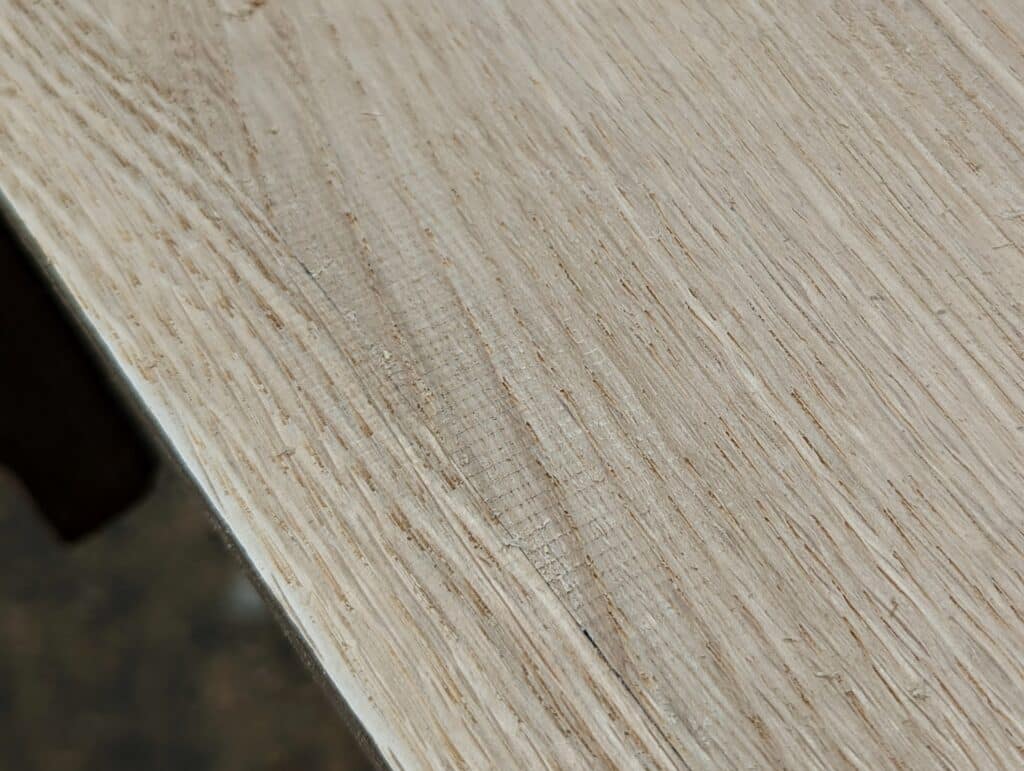

At the risk of repeating myself, I have a reason to go on. In this image, it looks as though I have some plane chatter on my oak surface and this is indeed what plane chatter looks like. I can replicate this anytime I want to yet I cannot replicate chatter with my standard bench plane at a whim. What this is is not plane chatter but unsupported wood flexing under the pressure of the tool as I move forward with a plane stroke. It occurs fairly frequently if and when I extend my wood beyond the vise so that it overhangs the vise by a foot or two. When I plane, the wood sets up a series of minute vibrations under the forward-thrusting resulting in the iterations you see here. I propose to call this phenomenon wood flexing but many would call this plane chatter too. It’s not the result that matters so much as the cause of it. Not at all one and the same.

I was having this exact problem yesterday. I’m new to word-working and this blog has given me some important things to remember. I think I was too far out of my vise and also over reaching with the plane so I lost some control. Thank you!

This has been one of the most helpful tutorials I’ve read here, particularly the part about unsupported wood. Fortunately I didn’t go out and buy thicker irons when I came across this issue…but I did attribute my problem to difficult grain, raise the white flag, and break out the belt sander.

Thanks, Paul.

‘…raise the white flag…’ made me chuckle 🙂

I occasionally get this ‘skudding’ as you call it at the very beginning of a stroke. Drives me batty, as it usually happens on what would have been the last stoke on the wood. Rarely at the end, and when it does it’s the last half inch or so, and when the wood is sticking out of the vise. As you say, it has nothing to do with the thickness of the plane iron. It’s happened on my Veritas smoother with a nice thick PM-V11 blade.

Luckily it’s pretty rare, just annoying when it does happen. I think it happens mostly when I should have sharpened the blade before that last stoke, but I’m not sure if that’s the real reason.

It happens to me when I just want one more pass on an already perfect board because I don’t know when to just stop! It also happened yesterday when I was trying to plane a board with one hand while holding it against my bench with the other because I didn’t want to have to clear the heavy box I was making to make space on the bench to plane it properly! As always, completely my own fault.

Don, it appears that the wood in question has Trust issues. 😉

By George, I think he’s got something there!

Enjoy reading you post. Just finished making your version of your router plane. Got one of Your kits. It worked great.

Thanks Paul. I agree 100% with you. This post brought back memories of the first few times I was learning to use a hand plane in 2015. I got all the marks you mentioned for the the exact reasons you mentioned (being new and lacking confidence, knowledge on how to use the tool). The only difference for me was all of those marks were happening with a brand new Lie Nielsen 4-1/2 with thick iron and all. In fact, if anything, it goes to prove what you just wrote about. Soon thereafter of use, I figured out how to use the plane and the chatter disappeared.

I had started with a Lie Nielsen because I lacked confidence to adjust and fettle a vintage tool. Now my most used hand plane is a vintage No 4 Craftsman brand likely from the 1940s. It works as well as my premium tools and I like its light weight. In fact, if I could only have one hand plane, there is no doubt it would be this $25 vintage Craftsman No. 4. It is without a doubt my most favorite hand plane. So much so that I have been slowly buying a complete line of vintage Craftsman brand hand tools and will be building a traditional jointers chest to house them all in. To call them a brand is also a bit of a misnomer. They are just rebranded tools from the major manufacturers as was done frequently for store brands of tools.

Am I going to sell my Lie Nielsen hand planes? No. They are nice too. Just not necessary for fine work as you have demonstrated for decades.

I have two Sears planes; one is just that, a “Sears” (not Craftsman) brand version of a No. 4 I bought brand new in the mid-’90’s that is marked Made In USA. It was dead flat when I bought it and it tuned up nicely. Just as nicely as my Record No. 04, as a matter of fact.

The other is a Craftsman adjustable mouth block plane I paid about $5.00 for at a yard sale that is marked 306 and 307 on the underside of the lever cap and the underside of the body where the mouth adjustment plate goes. It is about the sweetest cutting block plane I have. (Although I do not have any really “High Dollar” ones to compare it to.). New replacement blades, unfortunately, are not available from Sears as they haven’t made this model in decades.

I like the traditional or stock Stanley irons. First, a thinner iron means less material to abrade when sharpening. Second, and more important, the stock iron was specifically designed to work in harmony with the stock cap iron and stock lever cap. These components create a single unit in combination with the rest of the plane (frog, body, etc). The cap iron and lever cap mate the iron to its bed on the frog. The fact that the thin iron has some flex makes all this just work. The end result is a cutting edge held in tension flat to the frog. This obviates the need for a perfectly machined and flat cutting iron. With the introduction of the lateral adjustment lever we have an easy way to compensate if we sharpen slightly out of square. The baily style plane is a “system”. Moreover, it is a system that is designed and optimized to compensate for all manner of real world idiosyncrasies. So sure, switch to a different cutting iron if you want. If you feel this works for you, then more power to you I suppose. Still, it’s a stretch to think that breaking up this well tested and tuned “system” used by thousands and thousands of professionals of the day is necessary. It’s a bit arrogant to think oneself more clever than all these thousands that came before. It begs the question of why thicker irons weren’t used by default, or offered as an option by stanley (who loved to introduce tons of options in their lines), or offered by a third party. Maybe I’ll design a new safety razor for shaving with a blade that is 50% thicker. I can market around this and make a mint. Bigger and thicker must, after all, be better.

I agree. The Stanley/Bailey design has a lot in common with the Gillette safety razor. There were various designs of sharpenable safety razor blades and also of replaceable plane blades but neither of these caught on.

Hmm. Makes sense… And if some of the scudding comes from not being assertive enough with the plane, the thicker irons may actually be having a placebo effect by increasing confidence that the plane can and should do it’s job.

It might be interesting to hand a group of novices planes set up identically but of varying weights and see how that affects their results (outside of fatigue, of course). You’d have to control for increasing experience during the sequence, of course. Probably not worth the effort, but as a thought experiment it might give us some additional ideas on how best to introduce the tool…

These “thin iron” planes have worked perfectly well for centuries, millennia even.

I was looking at a Roman soldier’s tool bag at the Vindolanda museum, much the same as my own, no screwdrivers of course, but nothing else has changed since the Romans left Britannia nearly two thousand years ago….including his plane.

Similar in all respects to my coffin plane, formed from and wedged with fruit wood, hand ground and sharpened exactly as I do.

I could see the impressions of his fingers and thumbs.

He could have picked up and used my tools, and I his.

“He could have picked up and used my tools, and I his.”

And it was at that point that I was asked to leave the museum….

hi paul this is a useful article thankyou.

is the ‘fix’ to stop this happening at the start of a stroke to make sure the front part of the plane is seated firmly and flat on the wood before starting the stroke, then just go for it with a bit of oomph?

Like one of the other people above (and perhaps from nerves to not mess it up!), i have had this on the last stroke or two when tidying up a box… and the scud marks show up extra well once you put on some shellac! 🙂

hi paul,

Can you recommand the diamond plates? I knew you said the eze-lap sets were best, but how about DMT or atoma(made in japan) plates? I have a little trouble to buy the eze-lap sets here. Does these two brand’s products last well? I used the diamond plates from china, very well, but 240# worn out quickly, 600# and 1200 last well.

thank you paul

He uses the inexpensive plates that can be found on Amazon for about $10 apiece plus shipping. Just do a quick search here and you’ll find all the required details in another blog post.

I had initially used the word “cheapo” but decided to use the more refined word “inexpensive” as it is more accurate. Being the proud owner of three of these I can assure you they work quite well. I’ve had the opportunity to use some rather expensive DMT ones and while better, probably not thirty times over!

He uses the inexpensive plates that can be found on Amazon for about $10 apiece plus shipping. Just do a quick search here and you’ll find all the required details in another blog post.

I had initially used the word “cheapo” but decided to use the more refined word “inexpensive” as it is more accurate. Being the proud owner of three of these I can assure you they work quite well. I’ve had the opportunity to use some rather expensive DMT ones and while better, probably not thirty times over!

Upon further review of your comment it appears you are already familiar with the Chinese made ones. I stand by my comment… Just buy a replacement for the #240

thank you ANDRW,

I have read that blog before.

errrr….Is there $10 on Amazon?!!! I bought it here locale market about ¥7.4,equals $1…..

It works well, but of course can’ last very long time

I tried various modern sharpening options including 3 expensive ezelap plates, jigs etc. After a lot of trial and error I went back to Norton

oil stones and freehand sharpening. Quicker, easier, cheaper. Sold the Ezelap, the Sorby proedge etc.

Still have couple of jigs in a drawer but haven’t touched them for many years.

thanks jacob,

oil stone or waterstone are good, I don’t like them before because i have the mistaken idea that stone should be kept dead flat before use it.

now i rethink about this question and once accept hollow is inevitable.

I’ve never experienced scudding or chatter with stock Stanley irons. I will however caution the new user about the quality of some Stanley irons.

85-90% of the irons that I’ve sharpened work fine and hold an edge for a fair amount of time. I have come across a few that dull within the first 10 strokes, no matter how I sharpen them. I also confess to using Hock aftermarket irons which are just a little thicker. I first bought one as finding a replacement iron for my 5 1/2 (2 1/4”) was difficult. eBay prices were through the roof as I guess they’re collectibles. Hock had a good price and I really like the consistent quality. Don’t get me wrong, I’m not hawking anybody’s brand and 3/4 of my planes have original irons, but it’s nice to know about alternatives.

Doug in New Hampshire

Paul –

I much agree with you, except with perhaps but one point…and perhaps in that point you may make some concession, rebuke the statement (or something less severe), and or provide insight valuable to us all…I imagine and hope it so. I suppose it’s rather a question really, framed in the format of my current understanding…with no further adieu:

Scuffing may have multiple causes?.. I would absolutely concede that an unevenness in the planer’s stroke caused by a failure to commit thoroughly to the geometry of the stroke – beginning to end, or interrupting the cut by stopping the tool prematurely – will do the trick, scudding there will be. I also would agree that only experience can answer to such a problem. I experience that often, one sweep may have a scud, and the next the entire surface is perfect, shining, almost burnished. Anyway – as you mentioned about reading the grain – I would like to focus on that – the grain in the wood. From piece to piece it can be so different: from a smooth piece of oak with no knots and a consistent tight predictable grain – always assuming the same attitude throughout the piece – to a piece of knotty pine that has wide very soft summer growth rings, and rather dense winter growth rings and a grain that porpoises through the billet seeming to arise around the knots, and falling into the channels betwixt. The grain rising here, and now diving there, as a turbulent sea, with it’s iron hard knots stubbornly holding their way as icebergs ready to deflect and bruise the ships hull and the planes iron alike. As traversing that cold north sea in any vessel may be treacherous to the mariners body, traversing a piece of knotty pine with a plane may be maddening to the planner’s mind. In the end though, I don’t mind a couple of scuds myself, it seems evidence of someone’s personal attention – refreshing in our now so mass produced, mechanized, and automated world – I even romanticize it as being more of an ancient look, but perhaps that’s all just a cop out for shoddy practice, or just my own way of dealing with scuds… learning to like them. In regards to the grain though – surely you would agree? No?… yes?… no?…I’m curious for a response. I know this: maintaining the irons edge seems to be crucial to me in dealing with the scudds and tearouts that I perceive to be influenced by various and ever changing densities and directions of grain. When the knots just seem to just get polished by the plane, I sharpen and it seems to help. When it’s too bad I have attacked the knots with a chisel first, then let the plane bring the rest of the surface down to meet.. perhaps a toothed plane could help, never tried one. In summary – some boards really do seem down right pesky, or at least more challenging, and won’t go down without at least a scud or two. Or so it seems to me.

What?

You can get “chatter” with a heavily worked rebate plane. Instead of a smooth slice sound you get a more of a “zip” sound and the surface of the rebate may show closely spaced parallel lines, at an angle if a skewed blade. Not a problem for a glazing rebate out of sight.

I first noticed the marks when I started renovating old windows and as they were so neat and regular I thought they were machine marks such as you get with a PT roller. Later discovered that I could generate them with a woody rebate plane if worked very hard, zipping through the work!

PS forgot to say – never had the problem with a normal Stanley/Record except as a beginner. With experience you get into a routine and these things just don’t happen.

I couldn’t agree more. a sharp iron, a well-fettled plane, a bit of candle wax on the sole if it’s ‘gummy’ wood, and practice, practice, practice… did I say a sharp iron?

Years ago when I traveled extensively I would buy Stanley planes at antique shops, fettle them and practice using them. They were quite reasonably priced at the time and the shop owners were quite happy to get rid of a low profit margin item. I tried the Hock Irons and found that I lost the ability to adjust the throat settings without filing the mouth wider. I ended up putting those irons into a plane for a family member when he brought me a plane to “fix” that he had since childhood. The real problem was the angle of the bevel, he had lost the 25 degree setting by a wide margin so the cutting edge wouldn’t engage the workpiece. I gave him the thicker Hock Iron, it was also much harder steel. Since he was going to use his plane only occasionally and he didn’t care to learn how to properly sharpen it was a good solution to his issue. It cut like a charm when I gave it back to him, it’s been ten years at least since I “fixed” his plane. He most likely has never used it since, most certainly never sharpened it.

It sits in a place of honor in its own special holder on his shelf as he uses power tools and abrasive paper to achieve his results.

It was all part of the learning curve for me, I really wanted to use hand tools. One reason to acquire the skill another was to learn how it used to be done. Most people will not go to the trouble and time to do this. I’m glad I took this path but it’s not for everyone.

Good morning Mr Seller

I recently bought two planes at an antique fair,£90.00 for a Bailey transitional and a Varvill and son plough plane. After the usual fettling the Bailey was pressed into service, thin original blade in place, it was a revelation. the first stroke produced the proverbial solders belt with no more effort than with any of my other wood or metal planes with adjustment I was getting a shaving that I could see through; well satisfied. Now, onto the plough plane. First off does anyone out there know what the thread of the adjuster nuts are and where I could get a tap to cut a new distance (rear) nut thread?, my plane ,whilst otherwise perfect, has a none original one and it would be nice to turn one up from box wood. Second ,how many blades should it have? I have a No 2 and 6.

I doubt that anyone can give you the thread adjuster screw size as all makers had or made their own. As to blades, any plough plane blades will fit; you could hold out for Varville but why would you? Just buy as you need and watch out for Varvilles over the coming weeks and months.

I love my Stanley planes for all the obvious and aforementioned reasons.

I was a bit surprised though when I happened to find a #5 with a smooth sole (not serrated like all the others you find in Sweden). I have a few Brittish made with serrated sole that I’ve used for years with excellent result but I want at least one #4 and one #5 with smooth soles “just because”.

Anyway, I was surprised at the significant difference i weight between Brittish and U.S made #5’s. The Brittish ones that I am thoroughly used to are much heavier than the U.S made one. Sometimes, taking heavy cuts, the heavier “5s feels nice – probably due to years of use, they feel so familiar so to say. I don’t have a preference, both get equal use, but I wonder if anyone else has noticed this difference – and if so – do you have a preference?

I should mention that I this only goes for the “5s. My smooth late ’30’s #4 and my more modern serrated ones feel the same weight wise. They do feel different in other aspects though, but that comes down to totes and differences in set-up – not weight.

Janne Olinsson.

From my (limited) experience I occasionally get scudding at 2 main times. 1. when I’m almost finished and I’m looking for that last swipe and 2. at tbe beginning of a board, when I’m almost out of time and I’ve slipped (mentally) into an unfocussed “one more for the road” swipe. I tend to think that I’ve allowed the possibility of an error by taking my eye off the ball and Sod has enforced the Law. Irritatingly I only seem to scud when things are almost as desired. Once it also occurred when planing around a box’s top edge at the transition of corners – when I slow down in anticipation of the turn/grain change. But that was almost sharpness and strangely I’ve learned that one.

I don’t experience it on unsupported wood because I either plane faces on the bench top with a plane stop or the clamp in the vise method or long edges by additionally clamping to the apron.

In fact a lot of my errors occur when I should have stopped (various reasons) but didn’t. Apprentice user error. If I had someone to skelp the back of my head I’d be perfect. 😉

The only time I’ve encountered genuine chatter; is when the frog to sole contact isn’t tight enough, or especially, on budget planes where the contact area is either poorly machined, or paint to paint: Spear and Jackson, Acorn, and Stanley Handyman being prime examples. I’ve managed to significantly improve all of the aforementioned, the only exception where I was unable to eliminated chatter to any degree; was on a hideous yellow Czechoslovakia plane, where the movable aluminium frog was cinched with a single thumb screw.

Agree. Some budget planes are truly awful. They can be made to work, but I’m concerned that most beginners don’t have enough experience to solve the problems. So they reach for the belt sander… My advice to beginners is if they are struggling, consult someone such as yourself. I’m not an expert but I’ve helped quite a few beginners solve basic mechanical issues with their planes, and suddenly they can make thin shavings!

One thing people don’t comment on much is the historical context of the competition the Bailey-pattern planes faced when they were introduced. (Paul has, though)

Think of a world where almost all woodworking was done with hand tools and almost all hand planes were wooden with relatively thick (sometimes laminated) irons. There were the occasional infill planes, also with thick irons. These were used for hours daily by professionals who knew how to get them to work perfectly – and whose income relied on this.

Now, the Bailey-pattern planes had to break into that market. Sure, they were adjustable, which gave them an advantage, but if they did not perform as well at their job of planing, there is no way the professionals of the time would adopt them. Remember, their income depended on their tools working perfectly.

So, would Stanley and the other companies have taken a chance with giving them a sub-standard iron in the plane just to save a few bucks? They were the new kids on the block, with no proven track record in this market. If they offered a plane that was even occasionally prone to chatter, they would have lost the professional market. The usual business process is to offer excellent quality for a few years, capture the market, and then slowly save money on manufacture by decreasing the quality. Stanley did not have this luxury at the time.

Of course, the plane design instead allowed the adoption of a thinner blade that was hardened throughout. This was easier to sharpen (a time-saver for the pros) and coupled with the cap-iron still was as good as the laminated thick irons of the older planes.

Modern plane-makers have to give people a reason to buy their amazingly well-made (in the case of LN and Veritas, at least) planes that do have a significantly higher price point than the vintage ones (especially when compared to pre-pandemic prices). They know that the users are occasional users who are not going to use the plane more than for a few minutes a day every now and then. They sell the ‘solid feel’ (weight) and the visual impact ‘thick and pretty’, knowing these will be selling points to users and even some professionals in a modern world.

Dear Paul,

I am worried if you suffer from a severe chatter obsession. Entering “chatter” in the search box gives some 6 pages with some 10 entire each. To chatter about chatter is not wrong per se, but I am wondering what else we do not learn from you while you deal with the chatter? Furthermore, Mr. Bailey, a genius defended so forcefully by you, for sure enjoys a chatter free time in paradise. And the evil marketing guys (and girls?) meanwhile know they will face hell planing long beams with chattering thin irons until they finally… Not to forget the chip breaker/ cap iron…

Chatter has been dealt with in all precision. Something new please dear Paul!

Best,

Christian

This blog dealt with an issue people would not know as a possibility. I personally have never read anything about this issue of poor support. It addressed how unsupported will result in issues surrounding acceptable levels of workmanship and helps people to consider that the issues may well not be down to them and to think through additional options of actions. If I can identify other issues that might cause poor surface planing then I will present them. This issue is that different surface results are coming under a term that does not truly identify the problems. I see that my post offended you but I make no apology because you are not my target but people new to facing such problems common to woodworkers and identified by others saying that it is caused by thin irons and called chatter. You have the right to your opinions and we place a click button as an option not to read what I have written. I can’t be fairer than that. My thoughts are for others to understand everything possible.

Dear Paul,

no, you did not offend me in any way. Reading your blog for some years, my impression is that on some topics you are “hooked”. Let them go, so you have more free time to teach us what you know, but we do not know yet. There are not many Sellers left, and we do not know for how much longer we can learn from you. Focus.

And sense the irony in my post 😉

Good evening from Lake Constance,

Christian

You are telling me what to do yet again which only suggests perhaps more of a control issue. I try not to tell people what to do even through my blog, I simply guide them. For any blog I have written on this issue there are over 5,000 blog posts alone on other wood-related subjects. We will drop this here.

Settle down. It didn’t impact your life negatively to read a blog about chatter. A lot of people will benefit from this and there will be an new one soon.

Doctor, I say this with no malice or sarcasm towards you: please take a moment to reconsider your position, and try your own prescription (okay, just that lil bit of sarcasm). Your comment vexes me as it antagonises our host.

I come here humbled by Paul’s take in life, I come hungry for learning, I pay not a cent to read these blogs or watch the whole majority of a thousand high quality videos… and I learn. Paul has no personal gain from teaching me (heck, wasn’t it for this comment my entire existence could easily pass unnoticed to him), yet he gives me gold. (As I humbly learn, I know it to be unanimous in many languages/cultures: He taonga te mātauranga – Māori for knowledge is a treasure)

Not only that, it is knowledge built on a ‘slow cooked’ solid foundation of no-nonsense DOING.

I try my best to listen and watch with an open mind (Japanese call it shoshin, a beginner’s mind), though I don’t know if I will one day truly ‘feel’ all that my brain thinks it ‘learned’ (mostly because I haven’t moulded my life as much around woodworking as master Sellers did, few do).

If ever in doubt, remember who’s life we are learning from …the very least we may do is let the man tell his own story the way we want to, and hope his wants don’t change soon.

We’re all entitled to an opinion, and within reason to express it (thank you Paul for allowing free and easy comments on your sites!), but when your comments threaten to spoil it for everyone else, some will have to let you know: you misspoken.

Looong rebuttal, I apologise to all readers, but like I said I was vexed 😜 don’t spook the teacher, as you said it yourself Dr. Cristian, there are not many left.

Maybe bluntly, but actually kindly,

Paulo

Erratas:

Obviously I meant “… tell his own story the way HE want to”

and, missed an h on Christian

Ps: The inability to edit my own typos/mistakes out vexes me …but I won’t tell anybody to change their sites to suit my whims 😆

Although the new information, for long time readers, is in the paragraph under the last picture, it is only a few minutes reading. Why spend time to search how many times Paul spoke about chatter.

Anyway it triggers some interesting comments.

Why does it happens to many when doing a last pass?

Is it due to the plane, in some way, sticking to the already smooth surface? (like two mirror finish gauge blocks). Then two things: using the rag in the can oiler and… don’t mirror finish the sole.

I have, for some time, been wandering if the best sole might not be a scraped surface (machine way like) which would get more oil in its scratches. (didn’t try it yet) Paul has explained why he doesn’t like corrugated soles which were supposed to cure sticking.

Any elasticity might trigger vibration. The plane body itself can flex. See Paul’s post “Plane soles should be mostly flat” dated 17 February 2012.

So, I was also wandering if pushing downward on the plane (and so flexing it) to try to compensate dullness might not be a scudding cause.

Mr. Sellers,

And here I thought “Scudding” was limited to clouds and sailing vessels and “Scuds” was a colloquial name given to small aquatic insect imitations tied by fly fishermen in pursuit of trout. “Who Knew?” indeed. Keep it up, my dear sir.

Yes Sylvain, the last picture and caption says it all. There is “chatter” only over part of the width of the wood, so as Paul said, it’s the wood flexing (where the grain appears to be slightly different?) and not the plane. I don’t think it could be due to flexing of the sole of the plane by pushing down too hard. Cast iron is much stiffer than all woods, so if you are flexing the plane will you almost certainly be flexing the wood too?

Interesting comment about scratches on the sole. Slide valves on steam engines were lapped to a matt finish for just that reason, although that was metal sliding on metal. A polished finish did not work so well.

I am primarily a wood turner. Some tool makers sell a “chatter” tool specifically designed to create chatter patterns for decoration. These have a cutter designed to flex, which is much thinner and more flexible than a plane iron or a saw plate. I found that I could create a chatter pattern with a wood turning scraper because the (thin) workpiece was vibrating. I have never seen chatter when hand planing but can produce “scudding” when I am not being careful or with awkward grain.