Handling your work

Door handle, tool handle, handling a workload and even your handle as in the name you go by all link to the human hand with which we grip, hold, seize, snatch and grab. Thimble came from the word thumb and spindle from the word spin. In our work as makers of furniture and woodenware or treen, from the word ‘tree‘, we are mostly dealing with the handles to our tools and the handles by which we gain access to drawers and cabinets by way of doors in cupboards and then too to rooms and buildings. Everything takes its root from the hand and therefore how we handle things using said hands.

In most cabinet needs we tend to rely on turned knobs. They are cheap to buy, easy to make and easy to install. Door knobs and handles crop up every place we turn our heads. Bought in, they tend to look the same by virtue of most cabinet handles being turned on some machine to make them round, ergonomic and functional. They survive in our world for the three reasons given. Transforming plain round into a distinctive signature is the art of the designer-maker. When I designed the two credenzas for the White House I chose two woods of contrast, ebony, for its jet black contrast, and oak, to tie in with the oak fielding around the mesquite panels. Symbolically, the oak was taken from the fallen oak originally planted by President Benjamin Harrison on the North Lawn of the White House. I say contrastingly symbolic because President Benjamin Harrison is one of the least known presidents and was known as the “most forgotten president.” Historians and political scientists generally ranked Harrison as a below-average president, so perhaps his oak tree planting was the most notable of things that he did. The Harrison oak is not a type of oak but one of two oaks planted by the President sometime between 1889 and 1893.

Handles can be highly significant, uniquely distinctive or they can be entirely inconsequential to the point of being ignored until you need them. In our world of making we look for complementariness and functionality, purpose, and decorative complimentariness to the greater good of our work without allowing any supersedence. Door handles add the essential pulling power physically, of course, but so too an aesthetic functionality that can cause any user to almost shake hands with the door and drawer. Getting a handle on this can totally change the quality of what we make.

For my latest piece, I chose the oak and the walnut to tie in with the dining chairs I made but in a small way. The cabinet itself is our latest offering for Sellers’ Home designer build project where we design every piece of wooden furniture for a home. This is an unparalleled training concept for teaching and encouraging woodworkers worldwide to build their own houseful of furniture stick by stick and stem by stem. I made these simple handles from scraps of oak and walnut that fell from the saw.

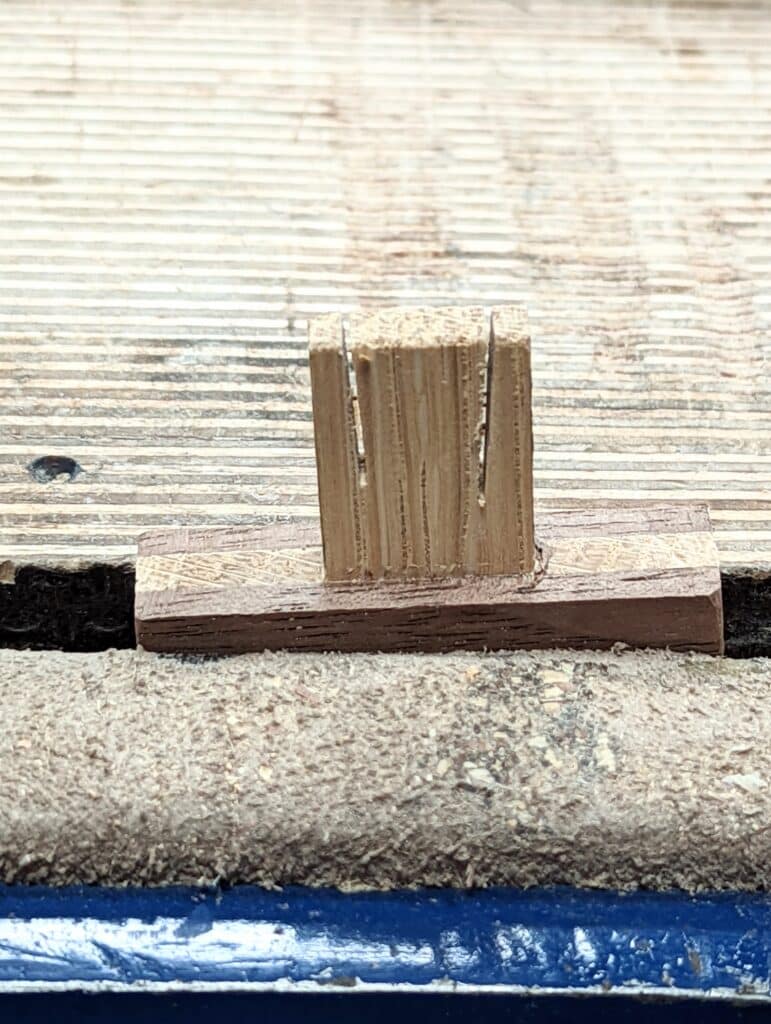

Making the handle is basic. I sandwiched a section of 3/16″ oak between two outers of 1/8″ walnut and then cut a 5/8″ wide tenon to the oak 3/4″ long. I shaped the outer to a simple radius with a rasp and file and then mortised the drawer to receive the stem of the tenon.

In the tenon I made two saw kerfs slightly angled to receive two wedges.

I cut two wedges from walnut for contrast.

I made a 3/16″ mortise dead to size on the handle side of the drawer front . . .

. . . and then opened the outer edges 1/16th either side.

I glued the tenon into the mortise and . . .

. . . drove in the glued wedges to expand the outer edges of the tenon to dovetail it in place.

I trimmed off the end of the tenon level.

Once dry, I hung the sample piece for testing from the underside of a steel beam and clamped some spring-loaded grips to the handle.

I then hung a 44lb (~20 kilos) vise from it as a test for the pulling resistance intrinsic to the wood. I think I could have doubled the weight but I need to get on with my work.

Another useful demonstration of how simple it can be to create beautiful knobs and handles which helps us all. I recently wanted a chisel slightly narrower then 6mm so having some 01 steel handy (from making router plane blades) I made one. I used the shape of my Sorby chisels for the handle, which I like the feel of. All cut by hand, both blade and handle (no lathe). I also made some small round button knobs in Walnut for the drawers in an Oak desk top unit I made from recycled timber for my monitor to sit on. I like the way they look. All only possible for me to do though through following your teaching over the last few years – so a big thank you to you Paul.

Paul,

What finish was used on the cabinet? Well handled.

Jon

You have extra Woden vises “hanging around”?! Would you sell it to me? The last two I tried to buy arrived cracked during shipping

Bravo again

ITS EARLY MORNING READING POST AND INFORMATION HOW HANDLE IS SECURED HAD ME SHAKING MY HEAD AND SAYING WOW THANKS PAUL