Wood Slithers work

Sliding in a well-cut slither of wood will work better than wood filler and you are more likely to create a permanent fix with a match to existing wood that will change colour with the surrounding wood if you do use a wood slither. It’s not that unusual in our flawed thinking and humanity to have at least one slice with a saw on a tail or pin that leaves the slight gap that shows the more when the others beside are all perfect. No matter how small, these gaps are usually in unseen places or at an angle where they will never be seen. Open a drawer and you have to do some gymnastics around the neck to check out someone’s dovetails. Most passers-by will never know it’s not supposed to be that way anyway but bug us it does Most people today will open and close a drawer and never notice anything about the drawer anyway but there is something in us that doesn’t like to see even the thinnest of gaps. On my recent project, I had a couple on the prototype I made ahead of the main one which I intended to keep for use elsewhere other than the Sellers’ home house. I try not to waste the prototypes because I have invested time and money and energy into them. Out of 72 hand-cut dovetails, I would be surprised not to have a couple of flaws in there somewhere.

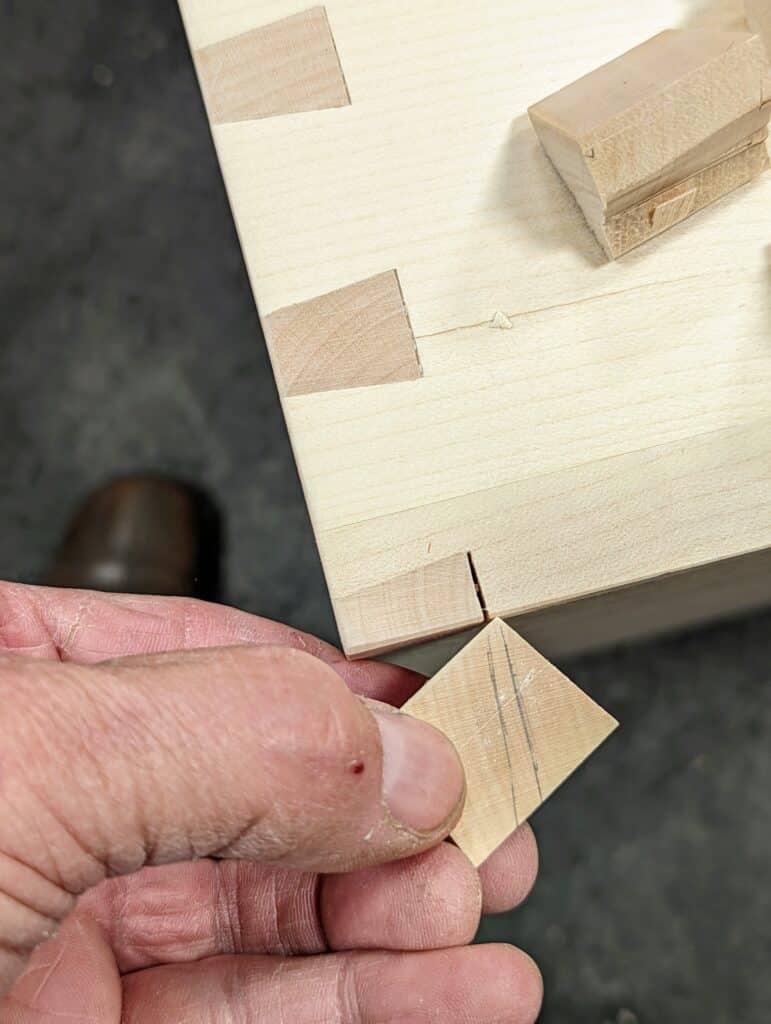

Removing the waste from a pin or tail recess the way we do means we should have a stubby chunk lying on the bench that came directly from an identifiable recess. I usually keep these until the joint is fully seated and I can see if indeed the joints are good. Fixing any joint that needs a facelift is not cheating! It’s no different than edge glueing wood to wood. Mixing sawdust and glue is cheating. Ask me what makes the difference and I cannot tell you. Perhaps it just feels different, more careless, something like that. It’s something I did once at fifteen and I never did again and will never do again. That said, there are fillers that you can make with sawdust and glue that are not intended to deceive — I am thinking of knots that have rotted or elongated fissures and not the ends of joints or joint lines.

Here I had an issue where somehow I did not hit the spot but it certainly did not show until I took the clamps off. Keeping the offcuts from the joints enabled me to find a half-decent colour match but, not the adjacent location.

I first angled the block to a similar orientation with regard to the growth rings and drew an inline angle to saw to.

I cut down to depth disallowing any wobble in the saw which would create fluctuations in the line and show as a gap. Then I cut an angled cut into it to make a shallow wedge.

I small amount of glue and a gentle tap in place secured the wedge . . .

. . . followed by trimming with the chisel.

This is the end result.

Did you mean “wood sliver” instead of “wood slither”?

No. A slither or a sliver works. A slither slides in a sliver is a splinter.

thanks for clarifying it.

every birthday we have a second slice or wee slither of cake which usually ends up being a wedge. Skelp is another one we use for splinter. Worst wood for skelps in my experience is larch. if I even looked at a board the wrong way it lodged in my hands.

I thought a skelf was a splinter. My Scottish father told me that he once tried to use a rough plank as a play slide and my Gran had to pull all of the skelfs from his bum!

Well, for what it is worth, The Scotts have many words as an alternative to those south of its border. I’ve heard so many that would only make sense there and then those in the highlands and islands too that would make no sense to the majority on the mainland.

Nice word.

In the West of Scotland a skelp is what I got if I came home with the knees out my trousers again. A skelf is what I got if I walked into the garage to see what Dad was doing, trailing my hand across the wood as I went.

Yes, Donald! Snakes slither.

Neat work though.

Interesting slither appears to be informal English for sliver.

I did check the OED for both words sliver and slither, befor my original post. But of course it does not account for “informal English”. Where did you find that it was so?

I agree with you wholeheartedly

Just google “slither noun”

What a great tip!

Made a large blanket chest with my wife. Best piece of furniture we have made. Hade close to 50 dovetails in it. There was a plethora of tiny gaps. Used this same technique. It is now 4 years later and I have a hard time finding any of the “fixes”. The cherry had darkened naturally and matching grain direction really made a difference. It was Paul who started me on my hand work journey. We have 3 English joiners benches now. One in the garage and two in a workroom in the house. Thank you Paul!!

A workroom in the house sounds like a wonderful thing. I wish I had designed my own house with such a room designed in.

I made a somewhat similar repair to a desk but for reasons I know longer recall went with a contrasting slither or sliver of wood and the customer was ecstatic. She even had me match it later for some in-out trays.

There is a tradition with Amish quilt makers that you include an obviously wrong piece – mis coloured or wrong pattern orientation – because only God can make perfection. Maybe wood fixes should be the same, to remind us that we are only human. I have certainly made many missteps in my pieces. But I have learned a lot from you, Paul. I enjoy making by hand (but I do love my bandsaw).

I’m afraid there is no way I could agree with the Amish with regard to their philosophy on what God expects of His people with regard to the quality of our work. And I make enough wrongdoings in a given day to see and know my humanity without including woodworking in there. Had I not ‘fixed’ my mistakes through the decades I think I would have disappointed and even lost some of my customers.

“I make enough wrongdoings in a given day to see and know my humanity without including woodworking in there.” Speaking of myself, of course — isn’t that the truth!

the true craftsman is one who knows how to correct his mistakes in such a way it is not readily visible to the casual onlooker. with my skill level I’m getting a lot of practice.

I’d quite like it if every now and then you used one of your occasional slips to prompt people to share theirs.

I’ve used a sliver before – last time I used maple and remarked it’s a shame I didn’t notice that sapwood. Dad said wood grows the way it wants.

My latest error was in cutting tapers on the inside faces of coffee table legs. I was so obsessed with checking and rechecking the locations for the cut that I got to my final cut, to be surprised by my waste ‘X’ being on the wrong side of the line. I looked…saw, line, x back to line and saw. Kings, crivens, help ma Boab.

So I finished the cut, planed the leg and offcut, glued it back and tried again. (Lost 2mm of the height because offcut needed slid up a bit.)

You sometimes get those strange grain anomolies on (my) legs.

*Jings not kings

Didn’t notice sapwood in maple? Usually most if not the entire board is sapwood in maple.

I used maple for the sliver and blamed the resultant contrast on sapwood.

Hi Paul, thank goodness you rarely but sometimes have to rectify some joints in your woodworking. I sometimes thought it was me slipping on my skills for cutting a joint with a slight gap staring me in the face of reality. I know this only happens once in in a while, but thanks for reminding me we are all human. Great blog once again.

There is British English and American English ,either is correct and most know what you mean it’s just semantics.

Just remember to err is human to really screw up takes a computer.

If you don’t point out your mistakes no one but you will know.

Paul,

I was taught that repairing a wooden joint with a piece of wood was called using a Dutchman.

Is that the same as a slither?

a dutchman goes across the grain and is usually to repair a slit in the wood surface

what is a flying Dutchman? a european pilot?

A ghost ship.

Isn’t Slithern one of the houses in the Harry Potter series ?

This is a great technique and as always Paul executes it with skill and humility. Paul, I admire your attitude and spirit as much as your skill. God bless you and all your team.

I did check the OED for both words sliver and slither, befor my original post. But of course it does not account for “informal English”. Where did you find that it was so?

Your cutoffs from chopping the dovetail waste are shaped quite differently from mine. I need to go rewatch you chopping to see if there’s something further to learn. Your cutoffs have flats from the original, milled surface, then a sloping bevel, then another small flat, then the final severed section, which appears to be about 1/8″ thick. The sloping bevel on my cutoffs is much more shallow, perhaps half the slope you produce and tend to extend much further out towards the edge. I don’t think I produce that second small flat. Instead, that slope (formed on both sides) just comes together to the final, severed section, which is not nearly 1/8″ thick as yours appears to be. I don’t see how you would produce that second, smaller flat unless that is you walking back towards the knife line, but it seems far too wide for that. Time to go rewatch one of your videos! The learning never ends! It seems that so many times when you post a closeup photo, I tend to learn something.

Mystery solved- The shape is because of your prying / splitting technique. I don’t think we learned that in class way back when. I’m not sure I see the advantage, but will try it and see what it feels like.

Sorry, my comment, “Splitting technique,” was cryptic. If someone else is curious, see the first episode of the Sellers Home Side Cupboard at the Masterclasses site.

“Where did you find that it was so?”

Just google “slither noun“

I thorougly enjoy plugging the holes left by the plough plane when making drawer bottom grooves! So satisfying to match the end grain and make an almost invisible plug! So I do understand the satisfaction in dovetail gap repair. Of course, I myself never need it (joking).

I’m not alone in saying I would buy Paul’s mistakes and they’d be better than 99% of the so called expert wood workers around the globe.

ps can I get a discount?

Like many others the word “slither” caught my attention! I’ve always referred to those fixes as a Dutchman but then I was born in Amsterdam and like to relate to my heritage!!

Anyone can learn to make dovetails, only a craftsman knows what to do when they go wrong.

After cutting some dovetails I spent a great deal of time cutting tiny wedges and sliding them in to disguise the gaps left by my errors.

I now feel better knowing that even someone as accomplished as Paul has to do this on occasion, though no doubt not as often as I do.

I’ve been fixing my mistakes (there have been many) this way for years, it just seemed the natural way to do it.