Signs of the Two planes

I bought two planes last week. One was brand new, the second was secondhand from eBay. The new one came boxed and wrapped in waxed paper while the secondhand one arrived well wrapped in a recycled and still recyclable second- or third-time used box with crumpled newspaper print as padding.

Unpacking the new Stanley came from me thinking I should not dwell on past Stanley failings but see if they are making the better #4s I have always enjoyed through six decades of working wood. I have several planes from the 1950s and 60s that I use daily in my work and daily for me is generally a six-day week.

Looking over the plane I saw several flaws. The frog itself was misaligned, the abrading of the sole and sides looked to be abraded with something like #80-grit.

Plastic handles, tote and know, almost always break in the winter of the temperature drops below freezing so I can never recommend any plane with plastic handles anyway.

This plane came in at £56 and would need quite a bit of abrading to get it working and feel right. Would I recommend it? No! But more than that, the side of the plane had received some kind of impact that mushroomed the metal both on the side of the plane and then too the sole. I took some swipes with the plane and found half a dozen furrows in the surface of the wood caused by the indent. I’m sending it back. Additionally, these planes might give you the impression that they are still made in Sheffield, UK. They are not. One tiny rectangle affixed to the box as a sticker states UK Importer.

The joint lines along the plastic handles are much more distinct and stepped than they look. They will need filing level otherwise they will blister your hands.

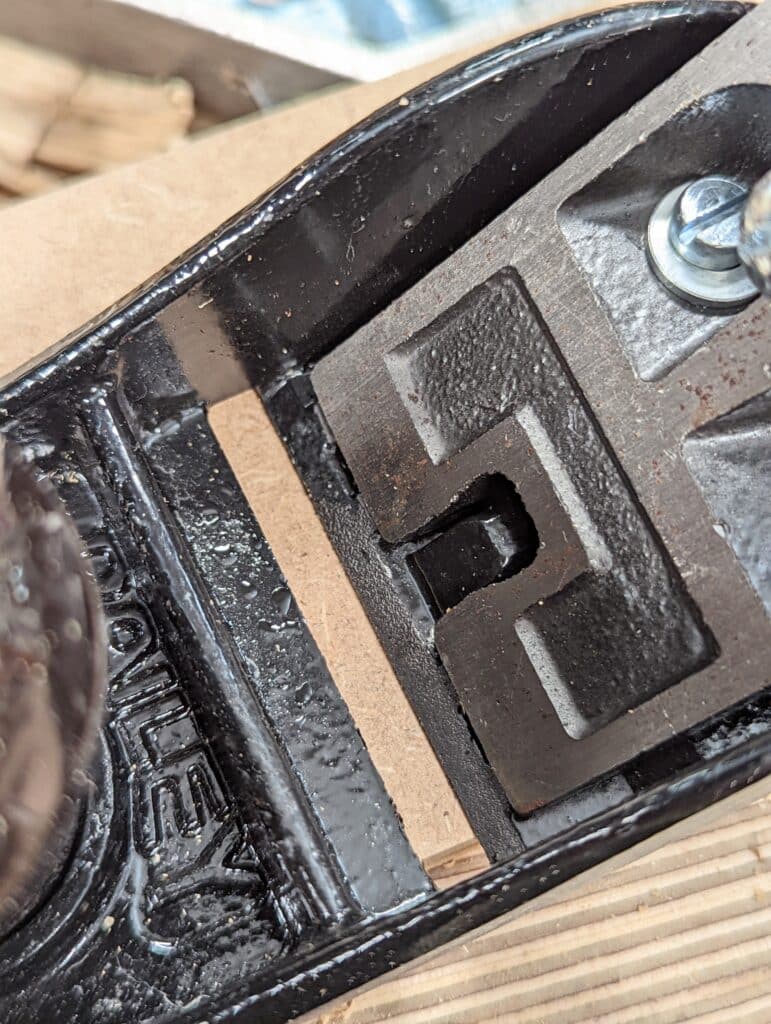

This indent shown below doesn’t look much at all but it badly affected the sole. It would only take a couple of file strokes to remove the swell on the steel but should I?

My second plane cost £16.85 and came in at £20 with delivery. All wooden handles, beech, not pretty, but a plane that would be in use in a few minutes.

All of the components are there and in need of no repairs. It has almost a full blade length so good for about 20 years if used six days a week full-time.

This plane was the better buy of the two planes. Metal clean-up, sharpening, a little sanding and some shellac on the handles and it will be a nice enough plane. That’s less than an hour’s work for a plane that will now last a lifetime for a 20-year-old. By the time such work is done the new owner, having gone this route, will be thoroughly versed in the Bailey-pattern bench plane. A good lesson starting out.

Conclusion:

Even though you can work on a new plane to ‘break it in’, and make it feel good, older planes carry the wear of previous users and the sweat-equity in used versions cannot be over-emphasized. It can take years to improve the feel of any new plane which can only be achieved through human hands working it. They just feel so different and so right in the hand. We are woodworkers and wooden handles can never be replaced with plastic or so-called composition handles. If they have some measure of discolouration or damage (other than cracks) they can almost always be readily revived with some minimal shaping, rasp work, filing and abrasive. Go to my blog and my YouTube for fuller restoration instructions.

Here is the rejuvenated plane after an hour’s work. It works just as well as any high-end plane and will do all that it can and more. The sole was indeed flat and the cutting iron just needed sharpening and surface rust removal. For £20 including shipping, it was a good buy. If anyone ever tells you not to buy secondhand, ignore them; these are people who are scared to get out of bed in the morning. I have yet to come across a plane by Stanley of old that couldn’t be restored enough to take perfect shavings within a few minutes. This one above took about an hour. And the very worst that can happen is you need to return it for a full refund including postage. Just check when you buy that they do accept returns.

Hi Paul,

if i understand well, you buy a new plane for the demo right. It’s to motivate people to buy old one and dont make the mistake. It’s generous of you, because you spend money for that. I hope many people can learn about it !

It would seem that not man understand the quality of tools indeed most things !! The things that don’t age well are people & petrol 😂.

So much is produced in C h i n a ,.

I bought makita tools thinking then Japanese, within a few months my circular saw burst into flame !! On inspection it was made in china , I guess it’s a case of buy old buy once,.

Or buy Chinese buy twice thrice etc etc

Buyer BEWARE .

Being made in China doesn’t correlate to poor quality, it’s disingenuous to discredit Chinese made goods just because they are made in China, and a cheap shot. You can find really poor quality good just about anywhere in the world including the UK. I recently bought a Woodriver 5 1/2 plane, made in China, and the build quality is excellent, really superb.

Chinese products aren’t all c**p but, the majority of c**p is Chinese. The big problem is largely inconsistency. One delivery can be OK, a second delivery of the “same” item can be utter trash. You may be unlucky and receive trash on both occasions!

I, too, have a Woodriver 5-1/2 and it is an excellent plane. It stays on my bench or shooting board and frankly on some days when I don’t really need to plane anything but just need to release a little stress I’ll go out to the shop and plane a piece of cherry or walnut just to feel the rhythm.

Using that plane is better than going to a therapist.

How “square” to the sole are the sides of your WoodRiver No. 5½? The only plane I have that has both sides (or even one, actually) truly square to its sole is the Record Marples No. 4 (made in England) I purchased in the mid ’90’s from the local Wood River store. Its the only plane I can use for shooting, trimming square & etc.

@John Beshaeian

My WoodRiver 5-1/2 is very square. I did take a file to the edges so they don’t dig into the wood.

I flattened the backs of the chip breaker and blade and then sharpened the blade tips secondary and tertiary bevels.

I can resharpen in less than a minute and get shavings you can read through.

I should also mention that I have a bedrock style #4 (don’t know the brand, it’s old) that I got for $12.50 at a reuse center. I bought a new blade but it was thicker and not finding an original screw to hold the blade I cut a bolt off and use it. I prepped the blade and chip breaker same as my WR. That little #4 smooths black walnut and hemlock like nobody’s business.

From what I understand that wood river planes need refurbishment to get it to a working state. As for China unless you’re standing over them 24/7 their workmanship is poor. China once upon a time we’re wonderful craftsmen then again so was Stanley.

100% correct. China will make whatever quality you are prepared to pay for. If its a nasty thing, thats because the importer was happy to accept that quality for a reduction in cost.

I have things made in China and some in the UK. China is quicker, cheaper and nicer to deal with. Any promises are kept and, given the time difference, communication is quick and easy. As a customer in the UK, I am treated very poorly by manufacturers, ‘deadlines’ come and go and quality control is non existant. The days of widespread quality manufacture in the UK are long gone. If I could get everything done in China I would.

Hi Paul,

I am not sure if that is a valid comparison. How much would be a plane in prices of the 50s now? I found wages for carpenters in US were around 1.75$ an hour. Do you remember what you paid for your first plane? So the question may be more how much a good plane should cost today. Seems for 50 you can not expect one.

Still, I would fully recommend getting an old one and refurbish it. Afterwards, you know the plane by heart…

Have a good Sunday,

Christian

Hi Christian,

Trust me – the comparison is valid! I am afraid your economic analysis does not withstand scrutiny. Mr Sellers is considering the price of getting a good working plane in the 21st century. So, the reference to wages in the 1950’s has no bearing. The second-hand plane cost £20.00; the new one cost £56:00. The £20:00 model was tuned and working in a under an hour; the new one, at 2.8 X the cost of the old one, was sent back as substandard (which it is!).

I have only ever bought one new Bailey plane in my life. I have, however, bought around 20 second-hand bailey planes either for my own use or to renovate for friends. By carefully following Mr Sellers video, it has never taken me more than 30 minutes to bring an old plane into good working order. (I clean the tool after I have it working as I want).

The one new Bailey plane I bought kept me busy over a couple of days to fettle it into reasonable working order. The task was physically very demanding – but stubbornness got me there in the end. (It was not a Stanley but a modern, poorly made plane by a 2nd or 3rd rate manufacturer and I should have known better than to buy it!)

A further factor to consider is that, if none of us bought these old tools, they would end up in landfill and that’s not good for the planet – especially when the old planes, once renovated can probably outlive several reasonably careful owners!

Some may feel Mr Sellers has a bee in his bonnet on the subject of tools made in more recent decades. If that is so then he is justified in criticising the poor-quality standards of many modern tools. We need someone to point out the shortcomings of these products. More importantly, the manufacturers need to listen to criticisms and act on it – but we had better not hold our breath on that! Without Paul Sellers’ sound advice, many of us would have made the mistake of paying top dollar for shiny new tools which are not fit for purpose when we can get quality old tools which work better at a fraction of the price. That, in my view, makes those rusted, scruffy, neglected planes the better deal every time.

Hi Ken,

maybe I did not make the point right. I am interested how long you had to work in the 50s to buy a plane as a cabinetmaker. Say two days, 18 hours (at that time maybe even 20 hours). In today wages that would be say around 200 pounds (not 56)? See what I mean? And Paul did not choose a good working one, as he reported many times of the diminishing quality of Stanley. I assume at that time (50s) Stanley was among top producers. Today that would be say a Veritas or similar. That is why I am unsure if that comparison is valid. Just to be sure – there is no doubt that you get an old one working as well as a new one. Also, about sustainability etc. I just think comparing a top notch product then with a piece of low quality now makes limited sense.

Best Christian

I wouls say it sounds more like you missed Mr. Sellers points. First is that despite Stanley being the name on both planes, the modern iteration is only a slightly a step above a Harbor Freight/No-Name (which is about a 1/2 the price), no longer made in the UK despite leaning on that reputation, and generally not fit for task while a well used but not neglected second hand plane of the same model range by the same maker is still more than fit for the task and with very little renovation. Second for the budget concerned there is still not a better buy TODAY, than a second hand cared for plane.

To day the standard vintage Bailey quality level, of which the used example is, more closely akin to a Wood River than a Veritas, so while still more expensive (147 GBP/179USD), it is not comparable to a Veritas or similar quality level in finish or cost. That would be the old Sweet Heart line quality wise. However from Stanley themselves, they still consider the standard BAILEY model to be the mid-range plane. In this regard it is still technically an apples to apples comparison. Simple that the vendor has let the product line degrade. The Veritas plane would be a compariable to the old Bedrock pattern which while of the same quality level as the old Sweet Heart line is not directly comparable to either the Sweet Heart or BAILEY line.

Sweetheart was a label used during one era of Stanley planes. They had two major lines, the Bailey planes and their Bedrock planes. Bedrock was the premium brand. They also made budget planes that they sold with the Stanley brand. They also produced planes of varying quality for other company’s house brands with some basically Bailey planes.

I think the point that the Stanley Bailey plane of today is a budget plane in both price and quality is correct. To compare it to vintage Bailey or Bedrock planes is not an apt comparison. Those were not cheap budget planes. Bedrock was targeted at the Nielson crowd where price was no object and Bailey at professionals and others where price and quality mattered. But frankly even a used Stanley Handyman or Fourquare budget plane of old is likely going to be better than today’s Stanley. But then they probably cost more in terms of the era.

I am not sure there is any new plane that really justifies the higher price compared to a vintage Stanley Bailey in good condition. Except, of course, for the aesthetics of being fancy, new and shiny.

Which was really Paul’s point. Buy a used Stanley Bailey in good condition, clean it up, sharpen it and get to work.

How do we know that the first owner of the old plane didn’t also have to fettle it up?

However, that said, my first two Stanley planes (#5 1/2 and #7) bought around 1970 were bought new and required very little adjustment. Perhaps I was lucky.

I suppose we might also compare a new Veritas at $309 with the used Stanley at $20. That would compare two items available in today’s economy at today’s prices.

I have two Stanley #4 and one #5. Each cost less than $35. A guy who knows how to do this traced the numbers and features, concluding they all were made between 1904 and 1914. OK. The blades on all three were bad. Chipped. I put them all on a grinder and then hand sharpened. Then a good cleaning. I spent about one hour on each.

I have also used, but do not own, the new Varitas #4. Excellent tool. I would be delighted to own one.

In today’s dollars, at today’s prices, my sample of three Stanleys provide the same utility as the Veritas. $35 vs $309. I acknowledge my small sample set makes my conclusion statistically unreliable.

I think you are spot on in trying to compare prices over the years. I have a point of reference. I purchased a Stanley #5 new in June of 1980 for $35.24 (before taxes). This plane has wooden tote and knob and as far as I can tell is about the time of final decline before Stanley stoped production and later started again. It says “Made in England” but that does not guarantee where the castings came from. This plane worked straight out of the box with nothing more than final honing of the blade. This is the first new plane I purchased. At that time I had some experience with a couple of Millers Falls planes I inherited from my dad and figure that this is a fair assessment.

The castings are less refined than any on my pre-war planes, but seemingly not as rough as the new plane in this blog posting.

Adjusting for inflation this plane would cost about $ 124.00 today which is about 1/2 the cost of a wood river and maybe somewhat lesser quality. You can buy a new Taytools #5 on amazon for $120.00 ($100 for a #4). These come from the same pile of sand in India as the Benchdog planes from Rockler. I believe the 1980 Stanley to be of somewhat better quality in terms of castings, and fit and finish.

Bottom line: Listen to Paul and buy a used Stanley #4 from ebay or if you want to remove some of the risk buy from one of the on-line used tool vendors at $50 to $100. Assuming you know how to use a screw driver, it takes no experience to disassemble a plane to clean it up and put it it working order, something you are going to have do on a periodic basis anyway.

My only “bad” experience with used planes is the result of previous owners who dubbed off the forward 1/16″ to 3/16″ on the flat side of the iron. I used to spend large amounts of time flattening this out. What a waste of time that is. Today I grind off the front edge of the plane as I put on a new bevel. In most cases I will never consume the entire blade and if I do, I can buy a new blade for a $20.00 bill. I only have one plane where I felt compelled to use the “Charlesworth ruler trick”. That is a Skewed rabbet filister with no option for replacement.

Like you, I would like to know what a new plane cost in earlier times to calculate the “hourly cost” in different eras. Play this same game with the cost of a TV from the late 40’s to current prices and see what a bargain you can buy today.

Dan

He’s not talking about the cost of a plane manufactured in the 1950s vs. the cost of a plane manufactured today, he’s comparing the value of a tool made 70-100 years ago and one made today, all at today’s prices. A very valid comparison.

A bit of aside: Do you have any thoughts on those brass replacement yokes that purportedly take out the slop in the depth adjustment?

My old Miller’s Falls (I like the name) need several turns when I change directions making the inevitable “too deep; nope too shallow; nope too deep; …”.

I don’t really have an answer here Bruce as I have grown up with the whiplash and after so many decades of use it just takes one spin to take up the slack.

I think you are right, it isn’t a fair comparison. But I have a Stanley Handyman and a Stanley Foursquare which were the budget version of hand planes in their day. They are not as good as the Stanley Baileys from that era but they will still do the job. On the other hand, I have seen some pretty junky old planes that won’t do any better than Paul’s modern Stanley.

Producing cheap junk for people who don’t care has always had a profitable niche. When the cheaper the better is the criteria ,cheap labor almost always makes the difference. That was China for the last couple decades. But, if I understand it right, China also produces some pretty decent hand tools but they aren’t so cheap. They aren’t easy to find outside China where the China brand is all built around price. And they certainly can’t compete on price with a good used Stanley Bailey.

I have a #4 just like your secondhand one that I paid (I think) about £10 for, plus a bit for postage.

It was complete and really easy to tidy up. Like yours it had an almost unworn iron, but it did have a broken tote.

I could have made or bought a new tote but in the end I simply epoxied the two parts together and cleaned up the joint carefully. It’s fine, works great and I don’t mind it having the odd battlescar!

I also have a modern “copy” I was given, still in its box. Plastic tote and knob – check. Misaligned frog – check. Rough sole – check.

It has no adjustment screw for the frog, and no provision for one. Just the two locking screws like in your photo. I spent most of an afternoon trying to square it up and failing until I hit on the idea of shimming behind the frog with strips of aluminium cut from a pop can. It was easy.

I have a Stanley SB3 that says “Made in England” but I happen to know it was made in India. It’s actually okay – straight and decently finished although with plastic handles. I’ve had it over 40 years and now it needs a new iron but I don’t use it much. Generally only for stuff like plywood and plastics where I don’t want to use my “good” planes. But when I use it I actually rather like it.

Interesting. How do you know your 40+- year old Stanley was made in India and not “Jolly Old”? I have a Stanley Bailey No. 6 fore plane I bought in the mid ’90’s w/a plastic tote and knob that also says “Made in England” and now you have me wondering. (Whatever the answer, its a much better plane than the Bailey No. 5 (I bought from one of the major online woodworking retailers in July of 2020) that was “Made in Mexico”.)

I read another blog a few days ago where the host told people to buy planes from the higher end makers. He teaches a lot of people and some are beginners to woodworking. He recommended that people should not buy used Stanley planes because they might inherit problems and that might discourage them. I left the comment that they ought to know how to disassemble a plane and what makes it work. Even a high end plane sharp out of the box ( supposedly) needs to be sharpened after a short time. The neophyte woodworker needs to learn some basic skills at some point preferably at the beginning of his introduction to the craft. I think the problem is in his case that he runs intermediate classes only and the goal is to make an object by the end of the class. He doesn’t have the time to teach the fundamentals.

A lumber mill that I buy my rough lumber from says people leave and don’t buy anything because they want dimensioned and surfaced stock only. So perhaps the problem is more pervasive than I thought.

It is silly to say only buy new and especially higher-end makers. I must have restored 200 #4s alone through the decades, probably twice as many, I’m being conservative here, I never came across one that could not be planing within minutes. Yes, most of them are neglected and they can be abused but the one I showed in the article feels just like my 60-year-old now. Closing my eyes, trying both blind, I couldn’t tell the difference. So, it’s very doubtful that any one of the high-end Stanley knock-offs could do more or even as much.

Hi Paul,

I have 7 planes. 3 new, 4 used. The new planes only needed sharpening. On one of the used planes I have not been able to flatten the sole. After 4 hours of working to flatten I realized it will need to go to machine shop or spend a week working on it. It has a twist. The machine shop cost means I could have bought one of those “high end” planes and saved money. Not sure what to do with it now, maybe scrap sole and save parts. When using it I can really tell it has a problem. Anyway, sometimes the ebay or garage sale planes are more trouble than they are worth and typically cant be returned.

As I said,eBay finds will always be worth the effort as in 200 planes I have never had one that didn’t work. Also, components can be salvaged when this happened. I am not sure why you cannot flatten the sole though. It’s only abrading when all is said and done. You could make a scrub plane from it too. Scrubs don’t rely on a flattened sole.

Hello Paul, a timely blog subject for me, as a young man who has recently taken over maintenance duties at the centre, where I’m a volunteer maintenance helper, asked me about buying a plane after he saw me using one to renovate an oak sign board. I’ve already helped him to restore a Stanley No. 3 plane which the charity owned, but which was in less than usable condition.

I have of course have directed him to your websites and will be forwarding him a link to this blog too.

A Merry Christmas and a Happy New Year to you and all your people.

Hi Paul,

You had mentioned an hour of clean up and the older of the two Stanleys would be ready for use. Out of curiosity, what state would the new Stanley be in if you spent that same one hour fixing some of deficiencies you mentioned. Not that you should have to fix a new plane. Just curious if you spend equal time on the new one compared to the old one what state it would be in. I think, buying the older one is the obvious better choice. Thanks for sharing the state of new Stanleys.

Sincerely,

Joe

The new one would be working in similar or possibly less time but the sole being out of straight would likely take an hour alone and then too, if I didn’t like the rough abrading, all the longer still with the sides tripling the work. The thing is the plastic handles. The only reason they ever went with this is that they, one, relied on their past reputations and, two, they had no visionary.

Stanley Tool Works as it is known now is a mere shadow of there former self. I am pretty well convinced that everything they now make is pretty much predetermined to be disposable. Whether that is a marketing plan or business model I don’t know. Tried to go on their website for parts and link was broke. This is one of the reasons I advise people not to bother buying any of their so called premium lines of tools (planes). I have bought replacement blades for the old bailey number four in the not too distant past and they where decent, but might not be available any longer.

For replacement blades you can almost always find a superb quality match from Hock Tools.

Thanks Paul. Four or five hours work and still stuck with plastic handles. Sad Stanley and others won’t do the minimal manufacturing changes to make them users straight from their factories. Can’t imagine it would cost that much more per hand plane for them to do so. Obviously, they won’t.

I guess there is no longer anyone there at Stanley to make educated decisions. They’ll keep living off daddy’s reputation actually believing in themselves until they eventually die out — hopefully.

Yes Joe, I agree wholeheartedly. We may not have the will to carry out foundry operations in the UK (mores the pity in my belief) but there should be a mindset to take inconsistent Chinese output, quality check it, reject no-hopers and carry out some basic remedial work that delivers a quality product commensurate with its price point. There is no point shipping rubbish to a customer. If a working tool cant be produced for £56 don’t sell it !!

Hi Paul,

I’m curious 60 years ago when you got your #4 did you need to do any work on that plane to make it work well or was it good out of the box?

Just wondering if craftsmen from 60 or 100 years ago just assumed all new planes need tweeking before use.

I have restored several of my own old Stanleys and would not consider a new plane for my own use. Thanks!

Hi Paul, and a Very Merry Christmas to you and everyone involved that makes your videos possible. FYI to your readers: There is a You Tuber that has several videos on restoring hand planes, and has a very good two part video on repairing a broken tote if it has a clean break. His channel is “Plane Collector”, and the title of his how to video is “Part 1 – Plane Tote Repair and Finishing” and “Part 2 – Plane Tote Repair and Finishing”. I have used his method to repair a few hand planes I have acquired and they turn out very well for a user plane. He like you is a very good teacher. May God continue to bless you in the coming year. Jim Light, Goshen, Ohio USA

The relationship between wood and craftsman are established when using a plane.Thier no better feeling when you pick up a plane you use it doing what it supposed to do with out forcing it do anything extra .I have4 old planes that were bought from retired woodworks .

Hi Paul, Thank you for all your generously-shared insights. Since retiring and reviving what little woodworking skill I had, I’ve learned a lot from you. I’m completely with you on second-hand planes. I’ve had my Stanley No.4 from new in the early 70s and although it was OK out of the box, setting it up properly never did any harm, and it’s great now. I bought two Record planes, both second-hand, both ‘Made in England’: a No.4 (now set up with a back-bevel) and a 5 1/2 (dating from late 50s – early 60s) which I enjoy using except for the main blade adjustment assembly. I cannot find out why the larger plane has a right-hand thread. This seems perverse, and catches me out from time to time. Did Record try it for a while and then drop it? It’s also quite stiff to adjust for my ageing fingers, despite attending to all the points you cover in your advice on the subject. I’m a bit stumped!

stone Sargent planes have the backwards depth adjuster, any chance the frog on your plane is a Sargent?

So do some US Stanleys.

I have restored a few planes and they work great. I bought a Hock blade and chipbreaker for one and it is quite nice. Just ordered another Hock for a wood shooting plane I about to make!

But there is no benefit to changing from a standard iron to another iron just for change’s sake everybody. None at all. Just saying. If you can’t get a regular plane iron to work for you you will not get a Hock iron to do any more. And they start at almost £40 a pop too

I’ve had a Stanley No4 many many years purchased from a classic old fashioned ironmonger used straight from the box, and has served me well all this time. However I was given a Stanley No 5½ which was in a neglected state but with some TLC brought it back to life and now gives beautiful shavings any high value plane would give. I have to say this is now my go to plane over my No4.

A shame if Stanley has gone down this route. Its also a shame that shops are not available so that visual purchases are limited, rather than Internet unseen purchases becoming the norm.

Paul I always appreciate your comments on promoting hand tool woodworking. Hope this information helps.

Hi John, I started work as an apprentice joiner in 1965. the town I lived in we were fortunate to have two high-quality ironmongers. They only stocked quality tools. I bought my Stanley no 4 and two Tyzac sons and turner saws from them. It was a pleasure visiting the shops and browsing the stock, the staff never hurried you along recognizing that some single items cost more than you earned in a month’s work. My uncle gave me sound advice: save up to buy the best you can afford and then wait for another week or so and get something better. You cant beat quality tools.

Phil,

Your uncle was a wise man. My father was considered a tool maker (“Not by East Coast Standards”, he wryly told me) and believed the same thing. I just picked up a Tyzack. Son & Turner 10″, 12 ppi backsaw off of e-Bay and found a little glitch. With the handle on, the blade has a slight bow. With it off the blade is straight. Since I’m not a collector (and this is not really a collectible) I’ll either have to straighten the handle with steam and clamps – just a’ crossing my my fingers, toes and eyes while hoping it works. Or, I could accept the handle’s warpage as settled, resaw the slot true and shim the blade tight in its newly enlarged slot. It’ll be a nice user though.

I bought the same new Stanley 2 years ago and yes, it was ‘orrible. the plastic tote failed within six months, I wondered why I kept getting tramlines in the wood (now I know) and I could never get to grips with the huge mouth/frog arrangement. I’ve bought three used Stanleys on ebay since, without really knowing what I was looking for, and all have been so easy to use….

Hello Paul,

I use to sell hand and power tools many years ago. There are other manufactures of hand planes, two instantly spring to mind are Record and Footprint. Footprint may still fit their planes with hardwood knob and handles, but they were less Machined Finished than Stanley and Record. I presume Record still use Hardwood, but Stanley were using Plastic Fittings over 40 years ago. The Blade Locking Clamp on Stanley Planes where the Machine Screw has a Curved Slot where as the Record has not, which could make it harder to disengage from the blade. Final Comment, Stanley’s 131B Yankee Sales died out years ago as Cordless Power Tool Sales became more and more competitive, and once apon a time hand saws were sent away for a week to be sharpened. I doubt if anything is made in the UK or Abroad. Stike history in the 60s and 70s, – why would they invest money here. The workers totally abused the system.

Of course, Record is now Irwin and for some dumb, dumb, dumb reason they changed from the lever cap to a knurled screw. The quality of the planes is not anywhere where it should be and it is doubtful that they are a UK-made product. I use both lever cap types and have never seen the benefit of the kidney shape over the keyhole one. I stopped using Yankee drivers when I turned more from joinery to furniture making simply because on a cabinet door, one slip or unwanted extension could ruin a door or cabinet side. `they were great for mass-making window frames and in skilled hands were faster than a drill-driver anyway. I guess “stike history” should read strike history. Yes, I was there in the three-day weeks and hours of electricity outages as the country came top a standstill. Looks like we are on the same path these days.

Hi

This not important but have served my time as a Vehicle coach builder when they were wood .

Been at school we went through the ritual of checking the tools. Then it wood be a Mortise and tenon every week that I found very easy but on one occasion if found myself

Putting my plane on the soul then getting a smack at the back of my head for not putting the plane on its side. I know time move and change but at age of 71 We’ll when I see it

It still greats

Regards

Malcolm kerr

Interesting read. I also apprenticed and worked as a Carpenter and Joiner. Paul’s comments are true and accurate. He and I use hand planes regularly. I have done so since 1970. New, quality hand planes command a good price. Well worth it in my opinion. I always bought Stanley’s when I trained. They served me well. Record of that era are equally quality planes. Over recent years I have purchased other brands of quality by Veritas and Neilson. Also purchased Japanese chisels and marking out tools.

All are incredibly well made and nice to use. Have also purchased used planes in recent years, made by Stanley and Record. Approximately half the purchases of used planes from eBay etc had been messed with. Some had parts from other plane makers which the seller’s fit, then clean the planes for resale. Beware of that as it’s not obvious untill item is received and thoroughly inspected.

I have had one or two cannibalised between Record and Stanley but they always work so it’s not a problem anywhere as far as I can see.

Hi Paul,

Good that you bought used planes that are free of problems from eBay. I received delivery of a few that have been messed with and have parts from other models that do not fit well. That’s annoying.. Some seller’s may not be woodworkers or engineers. They probably buy and sell as a business, regardless. However I have delegated tasks for each plane. Specialist used planes bought on eBay have been exceptionally good.

Hi Paul,

Did you notice any difference in quality of the irons between the two planes? I have a Stanley No 5 and a Record No 4 both about late fifties/ early sixties vintage. I have only once had a chance to compare them with a modern plane. My impression was that the newer plane was inferior – didn’t hold an edge, but it wasn’t a Record or a Stanley.

Thanks for all the work you do and the impartial advice and information.

Best wishes for Christmas and the New Year.

Malcolm

Interesting article Paul, thanks. Think I might get myself an old 5 1/2 for christmas this year! I have done a few no. 4s, and never had issue (I did have many issues with the new no. 4 as you suggest). You can actually get a refurbished old Stanley for < £75, and a Record for around £50, so if you were really unwilling to put in the hour of work, somebody else has done that for you for around the same cost as buying new. The experience of refurbishing any old tool is definitely worth it though. There's not much to understand about an old plane, but it's still valuable information available in a short amount of work.

I understand that the Stanley plane was not as it should be, but there are many Stanley products that have come out recently that are still a good deal. I have purchased hammers, tape measures, levels, etc.. I have been satisfied with each of my purchases, and don’t want people to think that they only make junk. I am not affiliated with Stanley.

But I only discussed the planes being way below grade and never mentioned any other Stanley products.

Hi, Paul,

Have you tried the Stanley 62 that is made in Mexico? I don’t recall ever reading anything from you about it. Having purchased one two years ago, I find it to be an excellent everyday user. Out of the box, all it required was removing the waxy grease it was packed in, and honing the blade. I don’t care for the aluminum cap iron, but aside from that I love this plane. I have restored some old Stanleys, and find them to be great planes, but really love the new 62. I have never owned a “high end” plane, so can’t make a comparison with the Stanley. I would love to know your thoughts on the 62, if you have tried one.

I could flatten it but it would take a weeks worth of elbow grease. Literally. This one isn’t a minor flaw.

Turning it into a scrub is a great idea though. Thanks for that.

Before I knew better I purchased a No4 and a No5, both by Stanley, around 2015 or so. Plastic handles, rough soles and I had to follow your instructions in your youtube videos to make them work.

Since then I have acquired a 1920’s era Stanley No5 and a 1950’s? era no name No4. Even after replacing the tote of the No5 with one I made from walnut I was wondering why I still keep reaching for the old planes. Then one day I picked them up to show a friend, and suddenly knew why. The new ones are considerably heavier!

I’m so happy I have the old planes – they are such a joy to use – and I often wonder what all they have been used to make, and by who.

I’m interested in your comment that the Bailey is better than the Bedrock. I have a few Bailey’s and a couple of Bedrocks. I’ve thought the performance of the two was the same, but I’ve not read that Bailey’s are superior. Why?

I have discussed the fallacy of BedRocks being reintroduced as somehow being superior plane type over the Bailey pattern and doing so on the basis that heavier is best, that you do not need to remove the cutting iron assembly to reset the frog and thereby the throat opening and other issues here. Each time you adjust the frog on the Bedrocks you automatically change the depth of cut immeasurably too. On the other hand, you tighten the screws on the Bailey-pattern and back turn a small fraction and you can fully adjust the Bailey-pattern plane throat easily without affecting the depth of cut. Heavy planes are a slog for full-time, all-day, all-week year-round users. They do not benefit from thick bodies, heavy frogs and thick irons. It’s all been a bit silly. Neither do Bailey-pattern planes ever chatter either.

I have a couple bedrock planes, I don’t see any difference with the baileys. One of them, a 608, is old enough that it has no adjuster for the frog at all. Its heavy. I use it but I wouldn’t want to use it all day.

But I wonder if the Bedrock was not more a premium home owner plane. If you only owned one plane for everything having an easy frog adjustment could be useful. You have the ability to open the mouth for hogging off wood and then narrowing it down until you could use it for fine finishing. We live in a world of abundance, but as you point out a plane could cost a day’s wages at one time. That’s not terrible if you are in a trade, but the typical homeowner of that era isn’t going to buy a collection of planes at those prices. The Bedrock easy adjustment might have enough value for them to pay a little extra.

No. The BedRock was offered as a premium plane within the trade and not for the homeowner/amateur. The trade never accepted it. It was too heavy and cumbersome for real use hour on hour and indeed too costly. Remember these men were coming from the wooden plane era where even jack and try planes felt half the weight of a #4 on the wood.

I’ve bought used Record planes on Ebay for years, usually in the $25-$50 range. Recently the shipping price to USA has gone way up to $50-$70 which seems inordinately high. I would love to meet tool sellers in England who would ship for less than Ebay’s global shipping program prices. Any suggestions? Thank you, and keep up the good work!

In my visits of flea markets during 2016 and 2019 (before COVID changed so many things) I’ve bought several #4s, a #4 1/2 and one #5 by Stanley, all of them covered by rust and absolutely abandoned. I bought one that had the look of being forgotten in an absolutely dirty and wet place since Genghis Kan attacked China. All of them, following the procedure that Paul gives in his video and in his book, work like a dream now, specially one o f the #4s and the #5. The highest price I’ve paid has been 10 euro. Some of them for 5 or 7. The only exception was the #4 1/2, a Stankey made in USA with almost 100 years (I did a research on Internet following the patent number), wich did cost me 30.

Since these planes are in my shop, my #4 Stanley Premium plane, bought brand new, sleeps in its box. I feel it clunky, heavy and difficult to adjust and use. I’ve restored them and come back to life, and I enjoy using them now.

As a young hobby woodworker, I favoured secondhand tools because money was tight and they were cheap. But the #4 I bought new in the early 70’s has done sterling service. It will see me out, and probably whoever has it after my time. When my Father died in 1997 had the unenviable job of going through his tools. He was not a woodworker, but amongst his tools was a plastic-handled #4. It held no appeal, but 26 years on it still gets used. Aesthetically it’s not pretty, but what amazes me is that the iron holds an edge like no other bench plane I have. An unexpected legacy.

I have a Stanley No4 that I purchased in 1980 and it is first rate with wooden handles. I purchased an old No 4 for £30 5 years ago on E-Bay and that one was probably 50 years old. I purchased an old Record No 4 as part of a job lot which was rusty and the handle was in need of some of wax and oil. It cost £20 and came with a rusty Eclipse saw setting tool a Stanley Brace and bit and a Fret saw all were in need of restoration. I spent a couple of days refurbishing them and job done.

The picture of the sole looks to me to show a potential crack at the nearest side of the mouth.

I’ve used some old Stanley No. 4s, even ones welded on the side, and never had trouble. My wife bought me a No. 62 which was a horror with machining marks everywhere, including on the iron. I gave up with the iron and complained to Stanley UK who sent me a new one and didn’t ask for the other back. The new one is perfect and my goto plane. A local engineering company kindly honed the iron of the horror for me and that is now pretty good. But one thing – you cannot buy a new iron for a 62 and Stanley could not supply one – hence I got the new plane.

I’ve restored several 5 1/2 Stanley Bailey planes, several #4 Stanley’s, a couple of different – but very similar brands (Dunlop, Shelton, and a Union, and even an old Stanley Handyman plane with a sort of razor-type blade instead of a plane iron) – all purchased at the local swap meet for ~$15 USD each. A couple were even repaired prior with brazing over a break in the sole, but work perfectly!

I had a great time doing the restoration, and have put all of them to use at one point or another. I have two favorites that reside on my bench – a 5 1/2 and #4 Stanley, and they get constant use.

I’ve bought a couple of new planes in the past, and the only one I like and use regularly is a Woodriver 5 1/2. It’s a bit heavy though and can really give you a work out!

But most important for me, is had I not discovered Paul Sellers on YouTube, I’d have never gone on to collect and restore any kind of hand planes – or use them correctly!

Thanks for sharing all of your knowledge Paul!!

I heartily agree with your what you have to say: “But most important for me, is had I not discovered Paul Sellers on YouTube, I’d have never gone on to collect and restore any kind of hand planes – or use them correctly!”, Mr. Gibbons. I would add handsaws, saw-sets, saw vises and more.

I just checked now and Bailey No4’s are like $50 with shipping. Better ones are more.

I’d love to know where you can get for less. Funny thing is, I pay more for after market blades and sharpening stones than the plane bodies themselves. Improper blade sharpening haunted me for years before youtube.

Try the Spear & Jackson #4 and #5. I have tested the four out and it is a good plane requiring just a little work. John has been using a #5 and loves it.

Seems like nothing has changed in the tool world. In the early 70’s I returned to working at a small lumber yard after Vietnam. I remember buying my first Stanley plane then because the new ones I was putting on the shelf came with plastic handles. In my teaching career, students always wanted to know which tools to buy and unfortunately, very few makers had affordable and quality tools. Frustrating to say the least. I still use my #7 corrugated Stanley which dates back to the early 1900’s but my go to planes are Lie-Nielsen. I’d rather spend the money than take chances on eBay tools; rarely have I had that venture be worth it.

I have never used eBay, but have had very good luck with Craigs List. It takes more patience, but it’s surprising how many good, old tools pop up within a 30 minute drive. And there are also the ones that meant a wasted 30 minute drive.

That’s funny! Exactly the opposite of my own personal experiences over 12 years. All my premium planes are in plastic boxes and 200 restored planes are now distributed around the world being used by individuals and I am glad I took the chances on eBay because not one of them posed any iota of a risk factor. 200 planes at £300 plus = £60,000 or 200 at under £20 = £4,000.

To true Paul. Thank you

I too bought one of these UK imported planes and I was aghast at how poor the quality is. I stuck with it flattened the sole smooth and like you suggested, changed the handle for wooden ones.

What a sad story, that of the new Stanley. The thing to remember, though, is that it is we, the customers, who allow this to happen.

Everyone should be quite aware that Chinese manufacturing nowadays can be on par with European or Japanese. It is all dependent on what the customer specifies. In the Stanley case, I weep for the owners of the Stanley brand as they drag the name through the dirt by choosing to specify crap manufacturing just to be able to sell in heaps to people who do not know better. There is no pride in the products and the tradition of the name. If they wanted to, they could have specified the production of brilliant planes on par with Lie-Nielsen or Veritas, e.g., but of course, that would have meant having to do some serious marketing work instead of just plowing cheap stuff containerwise to Woolies or wherever.

Basically, we must do what Paul does: get a second-hand plane and spend a little time with it, be it for a gift or for yourself. Or give half a new, fine plane this year and the other half next year. Stop buying crap and tell everybody else why they should also do that.

Another fine benefit is that it’s much better for our nature, our environment, if we buy fewer but better planes that also last longer.

If you are a little older you understand why Asian goods have labour under a poorer reputation as they are presently judged by. Most of the Asian countries in the 50s and 60s produced the first iteration of inexpensive plastic goods as in toys and household products. They always broke and could never be replaced as returns would be impossible. Combs, dust pans, toilet brushes and so on came in at half the price and then tools that once came in cheaply from what was called Eastern bloc countries started rolling in from Asia. these too kept breaking for a long season. Wrenches snapped and adjustable tools lost their ratchetability. Gradually, these countries continued to upgrade despite our demand for ever-cheaper goods while our domestically-produced goods continued to deteriorate. Hence Nicholson files and Stanley tools are now made in other countries.

Mr. Sellers,

You may be old enough to remember a parody Christmas song about the !2 Days of Christmas from the ’50’s that had the tag line, ” … and a Japanese Transistor Radio”. (Even I had a Heath Kit transistor radio back then.) Yes, the Japanese made great strides in producing quality consumer goods since then and have remained on the path towards quality products. (Today, the very inexpensive [read “Cheap”] “Japanese” chisels are made in China. South Korea makes excellent model electric trains in both various scale gages as well as the “O-Gage” Lionel uses. India, it seems, is starting to take some of China’s business with inroads into the hand tool market – some of acceptable quality, some not so much.

It looks to me like the only thing we, as consumers and users of hand tools can do is to pass on our knowledge of what makes up a good, working tool; why it is so and how to determine the difference between them – regardless of whether or not they are new or used.

One thing not to worry about would be the coarse “80 grit” grinding.

I flatten plane soles with 80 grit. In use the sharpness disappears very quickly as the ridges get smoothed over. May not look nice but will be low friction.

But otherwise the new one obviously a complete dud.

I love restoring old gear and getting it working again.

Some years ago I was at a Scout leaders’ training event and one of the people running it brought along an old Primus stove explaining that it was “obsolete” and would not work any more. I happened to have my own group’s Primus stoves in my car as I had just serviced them.

So during the coffee break I got the a needle and some fuel, cleaned it up and by the time everybody came back it was roaring away.

The owner was really delighted. He called all his friends over and proudly announced

“This stove hasn’t worked for 25 years until today. It turned out all it needed was a prick”.

You can go off some people!

Hi Paul,

I’ve just started up joinery as a hobbby having just retired. The last time I did this was at school. I’ve got myself a decent selection of hand tools and yesterday took delivery of the same new Stanley plane. I’ve checked it over as per your guidance online, and all I can see is the blade needs lining up properly so I may be lucky with this one. It’s a bit of a minefield trying to find a decent one, taking your budget into account as well. Didn’t want to go over the top just yet. I have a Faithful jack plane on the way, and I won the bidding for a Record 044 plough plane so that’s on its way too. I’m hoping to start my saw horses in the new year, followed by your workbench. I suppose this is when I’ll find out if the tools I’ve bought are up to the task……fingers crossed as I’m looking forward to the new hobby.

I struggled for months trying to get cheaper Stanley planes from the 70’s (inherited from my Grandfather) to work properly. I almost gave up completely on hand tools and went pure power tool. My daughter bought me a Lie-Nielson #4-1/2 and this changed everything for me. I have since bought a 1950’s era Stanley #5 and a 1920’s era Stanley #6. After some restoration work and sharpening the blades, these work as well if not better than the Lie-Nielson. Each of the Stanleys cost me about $50, about 1/5 the cost of the Lie-Nielson. I am sold on older Stanley planes and I am looking for a #4. I am grateful for the knowledge Paul has pasted on and now I am almost completely a hand tool user. I find what was once a struggle is now far more enjoyable than using power tools (and less dust).

On the matter of buying Chinese tools and components!

I needed a collet holder to fit my lathe. I had just bought a range of second hand collets at an auction for a good price with a holder which was oversize. I identified and bought a suitable collet holder from a Chinese company and found that the collets were not sitting properly in the collet holder. There was a disc of metal which had not been machined from the holder, but I was able to rectify this myself by removing the excess metal in my lathe. All-in-all the collet holder was a good price in spite of the initially difficulty. Chinese products are generally fit for purpose and much cheaper than UK equivalents, even with postage added. By the way, I am sold on buying old tools. They are excellent value!

I get what Dr. Christian is saying. $2.00 in 1950 is worth $24.75 today.

eBay didn’t exist in the fifties.

If you buy a veritas or Lee neilsen #4-12 or # 5 the cost is probably over $400.

Divide $400. By $24.75 and you get how many hours it takes to buy these planes today if your earn $24.75 today not including taxes on your pay or the plane.

Ken your looking at the from a different angle the good Doctor is.

Best Regards,

Mr Mac.

Nuh uh! It was silly from the start. We are comparing planes that can be had in fairly good condition and decent materials with a new version that has been cheapened by the same company and passed off as one and the same plane. They, they alone, set the price on their new plane. I am closing this silly discussion as the reality of what I presented made good sense to 99.9% of people reading it. Vintage Stanleys are good value for money, excellent. New Stanleys are not a good way to go. Veritas and Nielsen were never mentioned. Another straw man here.

I can understand why Stanley moved to China but what I can never understand is why they let their tools deteriorate so much in Chinese hands. Have they no longer any self respect? In my view it is deplorable to see these companies thrive on the good name their predecessors worked so hard to make. It’s a crying shame.

Bottom line, follow Mr. Sellers’ advice, do your do- diligence, research, check out photos and history on ebay, and then place your bid or order through ebay.

You may pay more for a #4 Stanley that “appears” to be in better condition than for another #4 that needs obvious restoration. I have gone down both paths via ebay and have yet to be stung. And since taking up wood working in 2020 I have purchased Stanley planes 2-8, including 4.5 and 5.5, and all have performed well after cleaning, sharpening, and a light protective coating of oil. I couldn’t afford the Stanley #1 so had to settle for an excellent Lie-Nielsen # 1. Also have a 4.5 and 7 Lie-Nielsen…great planes, and heavy.

Paul,

You mentioned you think the traditional Stanley model is superior to the Bedrock. Would you consider discussing this in a future blog? Or if you have already done so direct me to it? I love your articles, keep up the good work.

Kevin Spacher

USA

Both are Stanley, Kevin, a Stanley BedRock Pattern and a Stanley Bailey pattern. The main difference is that the BedRock adjusts on an inclined bed cast into the sole and the Bailey pattern adjusts parallelly. Generally, the Bedrock can adjust the openness of the mouth without removing the cutting iron assembly whereas the Bailey pattern generally is assumed to need the removal of the cutting iron assembly to access the two setscrews. In actuality, these two screws do not need bulldogging down and so the frog can be readily adjusted if you tighten the setscrews and then back them off a quarter turn. The truth is this though. You may only need to do this twice in sixty years, as is the case with me. Also, something that is never spoken of by the makers and sellers of the BedRock pattern is that as soon as you do alter the throat opening you automatically change the depth of cut immeasurably. This will help here. And this.

Paul’s biggest appeal to me is his no BS commentary. It’s rare nowadays and so appreciated. Paul has a lot of videos out there now, but for those of you who haven’t seen it, I HIGHLY recommend viewing his first workbench video–the one where he’s in his back yard (How to build a workbench). It’s a rea gem!

Hi Paul. Have bought several Stanley #4 planes from eBay, love restoring them, they always come out great. I’ve always thought there must be a business restoring and selling on at an affordable price compared to the rubbish new, so called Stanley planes.

Hello Sir,

I am a beginner hobbyist woodworker with a new found interest in using hand tools. My interest has always grown every time I watch one of your videos. I bought a vintage stanley# 4 from a local seller. I realized a couple of issues with my plane.

The blade didn’t seem truly flat and had a belly that made initializing way too difficult for me. Also the blade seems to be not completely true and has some impact marks, maybe someone tried way too many hammer blows on it. I tried for a couple of days on sand paper but couldn’t get it flat. So, I went ahead and bought a new blade from Rockler (around 15$).

I could initialize and sharpen the new blade but it is way too thick compared to the original one because of which it wasn’t aligning properly in the mouth – seemed like it was about to ram into the front part of the mouth/opening. I then watched one of your videos where you have shown how to adjust the frog. I tried to do that and then realized this stanley# 4 doesn’t have that screw! I read somewhere that this could be a post war version which had the feature removed for cost cutting. Is there a way to make it work? If not then I guess I have to buy another one.

By the way, I tried your chisel hammer trick on the old blade too but couldn’t get it straight. I don’t have the confidence to try too many things to restore it since I am really a beginner and it would take too much time to make it right.

Your thoughts on this? Thanks!

Are there two screws that holds the frog? You don’t need an adjusting screw (although it is the better option); just loosen those and move the frog. Tighten gradually until locked. You need to remove the blade for this, of course. A bit of fettling and you should be good.

Then save up for a decent plane with the screw. 🙂

Thanks. I am playing around with that now. Also came across a youtube video where the suggestion was to file the mouth of the plane to make it larger – that would be my last option but I will first try to see if I can still make some adjustment to the frog and make it work like you have suggested.

It sounds like a Stanley acorn or handyman. Similar, but the handyman is even more down market. You can adjust the frog by moving it physically. I have the stanley acorn, its OK but not as good as a Bailey. Mine is used as a scrub plane.

I had the same experience several years ago with a Stanley plane. It took hours of work to get the sole flat and perpendicular to the sides. The Chinese are masters at deception. They will always manage to slip in some cost saving, even if it is tiny. once bitten, twice shy.

This is exactly my story this year, sort of. my father gave me his Stanley 4 (quality), so I bought a 5 and a 7 new. Very very annoyed with wasting my money. So with Stanley’s reputation in tatters I went looking else where. Lee neilson and Veritas had many videos but Clifton was my stand out. Buying 2nd hand online from the other side of the planet for me was too risky. The Clifton planes arrived wrapped neatly in old school brown paper, double boxed, with the plane bagged and packed in foam beads inside. The build quality is absolutely extraordinary. The Stanley’s are doomed for extremely rough work and only if i feel like fitting wooden handles other wise tied in a bundle and used as a boat anchor.

I’ve considered a brand new Veritas or Lie-Nielsen no.4. I have a Record 04 and a Stanley 4 already, but those are older planes. I would love to get some experience using a premium modern plane, especially with a hock blade or something similar. For no other reason than to check for myself what the fuss is all about. Logically, I cannot see any reason why my old ones should be sub-par, but without personal hands-on experience I cannot conclude.

I have several old Stanleys now – 5, 5 1/2, 6 and a 7. All of them works very well and I get the results I am after. I can plane a table top dead flat (measured with feeler blades to within 0.05mm). That ought to be enough, or am I missing something else? I am doubtful…

There are two good reasons why one should buy a Veritas or Lie-Nielsen (or any other premium brands):

1. Supply of vintage planes in usable condition is limited or nil in the country one lives – here in Norway, the supply is decent but often the prices are usually ridiculously high. International purchases might be difficult or costly in some cases.

2. (and this is a good reason) To get a plane that’s ready to go straight out of the box, so that you know what a good plane is supposed to feel like.

That being said – I have never “felt what a plane is supposed to feel like”. I have sharpened mine by hand with good results, and perfect results with some training wheels courtesy of Veritas. I can take a shaving pulling my planes with a string. That should indicate that they are sharp enough.

Still, I’m getting my ears tooted full of the wonders of these marvels of modern engineering and the benefit of higher angle frogs, bevel angles, bevel down aficionados. Am I missing something? Is Paul too biased, too hung-up in old tools? Too focused in preaching cheap tools to get people into woodworking?

I really, really doubt that. My own results using the tools I have speaks for themselves (so far). I get the job done, my joints are dead tight and that table top I planed over a year ago is still dead flat. I used my old Stanley #4 with stock iron. Perhaps a premium blade would’ve made that top “deader flatter”? One might wonder……

Hi Paul,

Rather recently, I’ve seen that Jorgensen is starting to sell a new line of hand planes and block planes. The Jorgensen No 4, new, goes for $70is. Curious how its quality stacks up relative to the new Stanley. I still think used is the way to go. Others have put out some YouTube videos but truthfully, I really only trust you on this. Mind you, I have all the hand planes I will ever need so this is mostly just curiosity to see if there is a modern, non-premium manufacturer, who can do it properly.

Sincerely,

Joe

Just took a peek! It looks like a remake of a flawed concept instead of seeking advice from those in the know. I was disappointed once again. What’s wrong? The non-lever lever cap iron for one. It’s a lazy engineers solution to create what engineers think we need rather than what we really need. This kind of mindless manufacturing discounting the experience of actual users is more prevalent these days than ever. I hate these types of lever caps where screw threaded knurled nuts are used. They are far less effective and very inefficient and inconvenient. Yes, they work, but they are slow and unnecessary and always need adjusting. Reading the verbiage they describe this plane as follows:

The Jorgensen has designed all new bench planes and other wood planes using premium materials and workmanship. Precisely made, fit and finished, these planes are ready right out of the box and minimum honing is required. Heavy gauge (3.0mm) Pro O1 Steel blade is more durable and provides a solid cut with minimal vibration. Ductile iron is far stronger and more resilient. Stress relieving metal ensures the machined casting will stay flat over time.

Heavy gauge (3.0mm) O1 blade is more durable

Ductile iron is far stronger and more resilient

Stress relieving metal ensures the machined casting will stay flat over time

Adjustment screw helps provide preferred cutting depths

Notice that the bulleted items only repeat verbatim what’s in the opening para. This alone tells me that they really have nothing new to tell us.

Anyway, it is highly doubtful that the blade is in fact any more durable than the 2mm ones. I say this simply because thickness does not translate into longer lasting. Two: they say, “Ductile iron is far stronger and more resilient”. Again, then what? what are they comparing anything in the plane too. It is doubtful that what they offer will result in greater longevity and the suggestion here is that what exists doesn’t last. I have used the same plane (Stanley #4) for almost sixty years and it shows no signs of deterioration. Three: “Stress relieving metal ensures the machined casting will stay flat over time” Again, no comparison and introducing a straw man in suggesting other planes will I suppose not stay flat over time. Plane soles are worn in many ways and will go out of flatness by wear. Four: “Adjustment screw helps provide preferred cutting depths” Same mechanism unchanged in 150 years.

I think what is most telling is the opening claim where they say that they have designed “all new bench planes”. This is really a lie. The plane they show is a replicated knock-off of the Leonard Bailey Bailey-Pattern #4 bench plane. But no one will care if they lie, what matters is no one really cares. The engineering looks very good to me and the price seems affordable if indeed it is $70.

Hi Paul,

Thank you so much for looking at the Jorgensen plane.

Hope you and your family and enjoying the holiday break.

I am enjoying my extra free time woodworking. Currently making my 8th “Paul Seller’s clock.” This one is out of genuine mahogany. I’ve never worked with it before and was curious what it would be like. Donating the piece to my local church for part of an upcoming auction to raise funds.

Sincerely,

Joe

Paul,

I am interested (for more than just woodworking reasons) in your reviews of new planes. The Spear and Jackson in 2019 and the Stanley this month. Wanting to see if the S&J was still on sale and for how much I went to Amazon, and was surprised to see that the most recent review (4 out of 5 stars) was in your name. Was that really you? What had changed since 2019 when the tool was unusable?

As it is with many things, manufacturers often do not stay in the same place, some makers let standards drop, as in Stanley, and some improve. There are consistent standards with some companies employing product checks on a consistent basis but the prices are 95% of the time prohibitively exclusive for several reasons, not the least of which would be the commitment of spending £350 on an initial outlay. In the case of S&J, I feel that they produce a plane I can live with and use into the decades. The only way to do that is to do it. So I run it alongside my regular planes whereas I would never run the so-called premium planes alongside that way simply because I generally find them uncomfortable for the way I work planes as a real woodworkers in the saddle of day to day making.

Many thanks Paul. A good answer, and as we approach a new year a timely reminder that, despite our perceptions (perhaps instincts might be more accurate) that things are steadily getting worse, that is not universally the case. Here’s to a good 2023 for all.

Yet again another post to enjoy… I could not but agree about wood for the ‘andles. Plastic/Composite seem to make the job so much harder on the mind if not the hands at my age. Am I the only one who has spent silly money for “a ‘pretty’ replacement set of woodwork” for a favorite plane? I can now hear you muttering something about ‘make your own’ but my skills are not quite there yet. I really do hope that ‘Keith Jenkins’ might get a glimpse of that image…

A belated Happy Birthday and a Satisfying ’23 to you and yours…

F

I have several planes, only one I bought new. A Stanley with a wood effect plastic handle that I bought from a Dept. store whilst at University, if I remember right it was on offer. The handle broke after a year or so and was replaced with a new Record one from a tool shop, a very good one that sadly no longer exists. I did consider replacing the front knob, but 50 years of wear have made it as good as a wooden one. I also have a black plastic handled one (second hand) that is far better. Keep meaning to shellac the handles on this one. The rest of my collection of old Stanley and Records have wooden handles.

I have bought all of my collection from junk / antique centres. I like to see what I am buying, locally there is a plentiful supply (of 4 – 5 1/2″) at prices similar to ebay when you add on postage. Typically £20 -£35 for Stanley or Record 4 to 5 1/2. Other brands are cheaper around £10. It is far better that these are recycled.

Are Bedrock planes better thought of by some because they were reject at the time, now expensive because rare, thus thought to be better.

I recentley came close to buying a Woden no 4 that seemed cheap at £35, but I already have 4 no4s so resisted. There was also a Stanley router at the same price, but was in the middle of making Paul’s version, so again resisted. Do regret not getting that more.

I’ve been blessed with the fortune of having discovered Paul Sellers and his honest and practical advice and wisdom, too late, unfortunately, to have avoided the mistake of buying a couple of premium bench planes for a small fortune. I have a Lie Nielsen 5 1/2 and 4. They really are next level engineering, especially the 4 which has a solid bronze body and is so gorgeous that I feel guilty using it instead of displaying it on my mantelpiece. They cut really well and perform flawlessly. However, they are really unnecessarily heavy, the 5 1/2 obnoxiously so, and sharpening their excessively thick A2 steel irons is much more labor intensive than sharpening the classic thin O1 tool steel irons of the vintage planes, unless I resort to a grinder. Subsequently, over the past couple of years, I’ve acquired a couple of Stanleys from circa 1912 in superb original condition, a Stanley 4 1/2 made in England around 1960 or thereabouts that is new in the box, a dead mint original and unrestored Record 5 1/2 from around 1950 and a 4 and 4 1/2 Woden in excellent original condition. They are all superb and perform as well as the Nielsens, while being much lighter and more pleasant to wield, and while I paid substantially more than the mythical $20 finds, they were SIGNIFICANTLY less expensive than the Lie Nielsens. Plus there is something alluring about using a tool that was making furniture when my grandparents were infants and was well cared for and cherished by its former owners who no doubt were professional craftsmen on a higher level than I will ever be, and which has now been passed down to me. There’s a romanticism about that which no new plane, no matter how premium, can give me the satisfaction of experiencing. For me as an amateur enthusiast, hand tool woodworking is a labor of love. Luckily, the Lie Nielsen’s retain their value very well, and I can sell them for nearly what I paid for the new.