Knowing Your Customers and Being Known by Them

Anyone offering an honest piece of work will indeed stand out and the quality of work always sets us apart because, no matter the background, it seems to me that a percentage of people always seem to recognise quality workmanship. I recall a furniture maker in Texas lowering a car onto four of his small oak tables made with traditional joinery to prove the value of what he had. The legs sank into the earth 3” but the joints held and the car stayed there for three days. He sold tables and other pieces throughout the weekend and established himself as a fine furniture maker based on his educating strategy. He never had to do that again, but that was what it took to persuade people that his work was different.

I strongly think that we woodworkers need to give more insights into what sets us apart and whereas the car trick was a bit over the top, and it is unlikely that most of us could indeed offer such an exhibition, we can’t usually just expect people in todays world to understand what we are bringing to the market.

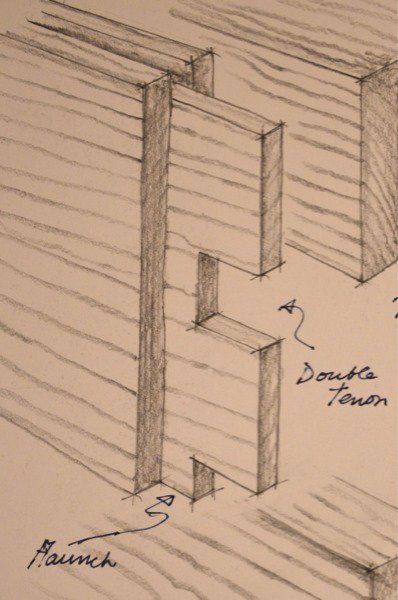

In my workshop I have several joints sitting out in the visitors area for people to look at. These joints tell a story and especially is it of value in relating to what might otherwise not be seen inside the jointed areas of say a table or a chest. Dovetails especially seem to impress people.

This week three people from China came in to see my work. The older man was a woodworker also and he was happy to see what we were working on. He seemed a modest man, humble in spirit and expressing only appreciation without saying a word. His wife too seemed of a similar disposition. The daughter, in her mid twenties, assertively insisted that I could sell my work and “make a lot of money.” It seemed to this confident visitor that I had never thought of that and now at almost 65 I needed someone to help me see where I had failed myself.

So, it is important to educate your future customers. This can be done in different ways. Video is much simpler now than ever and a short film can show you at work making the joinery. You can also demonstrate at the workbench at craft show venues as I did for decades. This really works well. I once saw a man demonstrating carving a ball and claw chair leg at a show and people stood there for half an hour totally glued to his demo. Creative work is always electric and of course you can print a brochure of what goes into your work to support any audiovisual you might have there too. Drawings of Mortise and tenons and explanations of which joints you used where. Before many minutes pass people are asking questions and most days when people come into my shop they are asking if this or that is for sale and how much would it cost to have something made.

It is important to take your work to an audience of you don’t have a venue to work from that shows your work. In every shop I have owned I have always set up a reception area showing my work. Sharing what I do is as important to me as the actual making of it. It’s here that I engage the most and it’s here I can best explain my ambitions and goals and indeed my life as a lifestyle woodworker. There will always be a percentage of people who want to buy a piece knowing it was carefully made by hand. I’m not saying it’s an easy passage being a maker, designer, marketer and salesperson, but somehow it seems so much more relational and you develop something so much more substantive when people know that the piece in front of them didn’t come from a factory or from another country or continent.

Paul,

Most inspiring. I have an aquaintance that designs and sells fine quality art furniture with marquetry and classic construction. He is an excellent designer and craftsman like yourself. He is also knowledgeable about the people who buy his “expensive furniture.” He told me ” I can’t afford to buy one of my pieces. LOL!” He told me he invites the customer into the process at different times of the build in his beautiful shop. They have brunch of fresh fruit and pastries while the client becomes involved.

During our last financial downfall many excellent woodworkers did not survive. They didn’t understand the people part of selling what we do.

There is a segment of the market that opens the drawer to see the joinery, but there is a larger population that does not? Hopefully our paths will take us to the higher ground.

Great Blog!

Food for thought. The situation in Germany is a bit strange: it is mainly at the behest of the trade guilds, who I think are mainly concerned with the welfare of the guilds than their members.

I was on a demonstration stand run by my college last year in an exhibition, and although I was even worse at dovetails than I am now, I noticed people loved to watch. Perhaps fortunately they also wanted to talk so I was never able to finish them…

Andy,

I love your comment. It’s the antidote to hubris in todays world.

John

Paul,

Are the pieces in this blog post all pieces you have made? Would you consider a blog post of say 12 – 15 of your favorite builds? A picture of each with a description of each build? I’m sure I’m not the only one that would appreciate seeing them. Thanks.

Bill

I’m not sure how interesting they would be to others really. Not even sure if I have the images during the builds.

As much from a technical aspect in terms of construction detailing as to the nuances of each piece that speak to you I would be happy to read about it. I realise that the workload you have is probably pretty high however and the methodology in your approach to all manner of things which you construct and craft and do demonstrate regularly would cover this to an extent. When I read Bill’s request I thought of James Krenov’s The Impractical Cabinetmaker and some of his writings in relation to specific pieces. I found it quite revealing as to Krenov as a craftsman.

I second Bill S on the notion of a favorites blog. I’d be very interested.

Me too. I admire Krenov but don’t find him encouraging. It all seems so difficult. What i find so pleasing in Paul’s approach is his emphasis on quality without ever going near elitism. And he is always encouraging. I’ve first made things in wood when he was still a schoolboy. I made a kitchen cabinet with traditional dovetails, and stub tenons, panels, and drawers to a design to my dimensions. I found out what the traditional joints were by going to junk shops and local autions and looking at the as much as I could. In the late 50s and early 60s damaged victorian furniture was still being offered and one could investigate the construction details. I made the kitchen cabinet in western red cedar because a local cabinet maker persuaded me to take the wood off his hands for a knockdown price. Wonderful wood but very difficult to work unless the tools are all super sharp. My woodwork then dipped for nearly forty years while I was a maths teacher, a mechanic, a jazz musician, and much more besides. In more recent years I’ve worked back to wood. A lot of what Paul teaches I had sort of known but what he now offers me is the realisation that on should practice workworking skills as I practice my musical instruments. You know when you are becoming something of a good player when you start to enjoy playing scales and patterns. Paul has also taught me to start on a piece of work and follow through without changing the design as I go. Work it all out properly, detailed drawings (freehand or with instruments) and measurements and then a method. Check it all out in the head or on paper and then start on the wood. The work with plane, saw, chisel, marking knife doesn’t take for ever, and it is less time consuming if one has thought it out properly before starting. I’ve avoided the work quicker because I’ve learned the hard way that to do ones best work one should not work in haste. There is a proper speed for each task and to exceed this will compromise the result. I have mastered a whole gamut of machines in recent years. In spite of mastery I never felt good about this work. It has no soul and it is not pleasurable to do. I never or almost never make the same thing twice and were it otherwise the machines might then come into their own. But that doesn’t grab me and I don’t need it. So from Paul a real joy to be had in mastering the hand processes and how much to be learned by his example. Always unhurried, always focussed and productive. I too would like to know more of the process from start to finish: a favourites blog. But only if it is something Paul and his team want to do. At the show in Harrogate (November 2016) I watched him making dovetails three times. And I had already watched his videos on this several times. It is not just his skill and his knowledge but his mental approach. Not too little, not too much as the old Erasmus Shaving Soap advert had it. He’s better than books on meditation.