Handing Over Work

The front living room is now gutted and skim-plastered over. I hadn’t expected that but removing picture rails and fireplaces leaves holes to be patched and then surface cracks in the existing plaster means filler and such; it was more efficient and more work effective in getting the pristine, clean and fresh beginning we wanted ready to start receiving beautiful designs in wood that will be our new furniture. Anyway, the walls are now white primed and so too the ceiling so everything is appearing as one at last.

I like the way the men work. It’s orderly and well planned. On the first day they seemed to blitz everything to see what could remain and what needed repair or replacement. Whenever you have a building crew in it’s natural for you lose that sense of ownership as they take on what needs to be done for you. These artisan builders were well briefed by both Joseph and the boss, Agnes. As soon as the punch list was created they were off like greyhounds after the rabbit. For me though I feel I was entitled to feel things a little differently. Throughout my 55 years of working I have been always been totally involved in the building process. With two of my former homes under my belt and then restoring half a dozen others.

I was married at 21 and bought my first four-bedroomed house. It took some doing but hard work and saving hard meant that with an additional gift for a deposit I could get on the ladder towards owning my own home. In that house I took the bold steps towards early DIY as I ripped out all of the window frames and made new ones which I then installed one by one. I then rewired with new wiring throughout followed by installing a complicated system of central heating using water-filled radiators to every room. My brother helped me with the plumbing for that. I replaced the whole bathroom and kitchen too, building the cabinets and counters and such. I also took the p[lunge at my first bricklaying and built two new fireplaces floor to ceiling. I say this because I am a hands-on guy that likes and advocates DIY. This time around, handing the work over to another, is not just the impinging of my home space but then too my desire indeed to do it myself. I cannot possibly do it this time around and nor should I. These men will keep me in the saddle making and designing my pieces for the house. It’s a no-brainer.

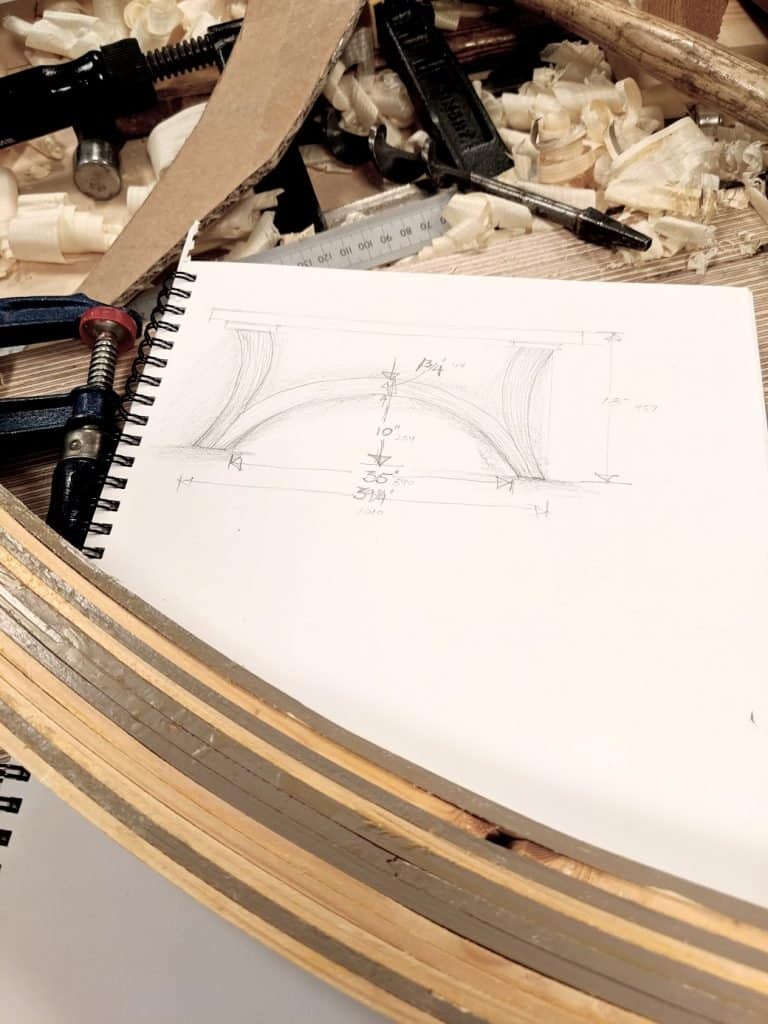

In the garage, my very personal creative workspace, I have a series of steps that I have taken to ramp up things for considering the first piece. I find myself not so much lacking confidence about how I build the first piece but more how. having all of you on this journey with me really helps. I know that perhaps the majority of you will not have nor could ever have a shop full of machines and so I am keeping my focus on my ever-important quest to work mainly with hand tools. The bandsaw has really helped me because sometimes I have to make even three of the same piece to iron out the bumps. Yes, I know, you like seeing me make mistakes, but I am not really talking about mistakes. We actually do leave most of them in. I really don’t make too many. Joseph has always been a behind the scenes support, mostly because he never really saw himself as camera material and he has given unwavering support because he believes what I do is important to me.

So now my woodworking has a special cause. A greater cause if you will. It’s about design and helping you to think through processes professionals may never have time for. I’m prototyping and filming snapshots as I consider the components, the sizing, the drawings and such. That way you too can access so much of what I may have taken for granted for years. Do cardboard coffee tables have any real validity in the grand scheme of things? Well, yes they absolutely do. They pave the way to stop you just jumping in on a design and having to live with perhaps a negative result.

Thanks Paul. I am looking forward to this series.

What I would find interesting to watch in the videos would be the evolution of a design in going from paper concept, to cardboard, to 1st prototype (or more) and then to final piece. It doesn’t need to be all that long but hearing the thought process and how you decided to make changes would be helpful.

I am 4 years into my woodworking and still very much a beginner. One of the goals I have is to build a series of bookcases to wrap around my living room so it has the feel of a library (I just love books). Learning more about the design process will be especially helpful to me.

If you encounter plaster that is basically sound, but has separated from the lath, there is a magical product that I’ve used before that can save tearing out large amounts of plaster. I’d have to find the name for you. You bore an array of approximately 1/4″ holes throughout the area to be stabilized and spray a thin liquid into the holes. This liquid binds the dust behind the plaster as preparation for the next step. Next, you inject a caulk like material into each hole that spans and fills the gap between the plaster and lath. Finally, you run screws through a fancy form of plaster washer into the lath. You now just have a job similar to covering drywall screws. The gunk injected into the wall stabilizes the plaster against inward wiggles and the screws stabilize against outward.

Amen to cardboard! We had a complicated kitchen in the sense of not much space, three doors, and a complicated flow-through pattern for how people walk. We wanted a table and an extra counter. We put cardboard on top of stools to mock up the table mass and similarly for the proposed counter. We lived with it for a few weeks, trimming a little here, taping some extra back on there, and then knew exactly what we wanted as far as gross shape / mass. It took 30 minutes to setup the first pass.

Very much enjoying your reporting on the house!

Your mission and task is big enough without more.

Stay well, keep going, your energy is flowing thru to everyone watching and that’s why everyone wants to talk to you and express gratitude.

But yeah,,,We need to be doers not hearers.

– Ed, I think Paul’s house has brick walls.

– One way to deal with plaster separating from the wall here and there is to use glass-fiber wallpaper. Sometimes you have to redo the plastering completely (e.g. before tiling a bathroom)

– It looks like the crew used cement to fill holes in the plaster. That would be bad practice. Using cement where plaster is strong enough makes life difficult for the next person who has to work there.

I like the way you use card full size models Paul, I remember being give great advice when buying a flat screen TV, make a full size template of the one you want and put it in the room before you buy. Things look smaller in the showroom and the same goes for furniture I think

That is a Great

That is a Great work i love it.Please keep it up

I hope you will replace the picture rail. After moving from our wonderful house into a tiny apartment, it is the thing I miss most (after missing the actual house). When we find a new house with room for a shop, adding a picture rail to the new house will be one of the first things I do.