All in a day’s wood work

I’ve been a maker all of my life. From age fifteen, I’ve made and sold everything I’ve ever made except the things intended for my home and my family and friends. That’s over five decades and some thousands of pieces large and small. I don’t sell now although I could but I don’t know if I would these days because the work I do now is not to live, as in times past, but to pass on what I now know better and do and did. I remember the first pieces I made of my own volition. My sister’s boss wanted some bench/bar stools for his staff to work from. He drove two cars, a Jensen and a Lamborghini. He ran me like he ran his business. Everything was about making money. Unwittingly, he cut my price for making them in half and when I was done he got hand-made stools for the bargain price of something mass-made. My stools were fully jointed with hand-cut mortise and tenons and all of the tenons were shouldered on four sides to tapering legs meaning that no shoulder was actually square but all were angled and married to the legs. I would that I would have known then what I now know. Read on!

A man made the chair above. He would be one of millions of the anonymous makers through the millennia who knew no fame and usually had no recognition for anything made. He would have never wanted any nor expect any – no disappointments there. It was an era of no competitions for first place, second or any place in those days of the real makers, there were no fakers, no stages for and no showing off even though there would have been so many trade secrets and hidden gems of wise working. This era of making will never return to our world of woodworking and no one should try to compare what we have today as hobbies and pastimes with what was had back then. It ended when the Industrial Revolution and global economies displaced them with mass-making and global trading on the widest scale in human history became what it is today.

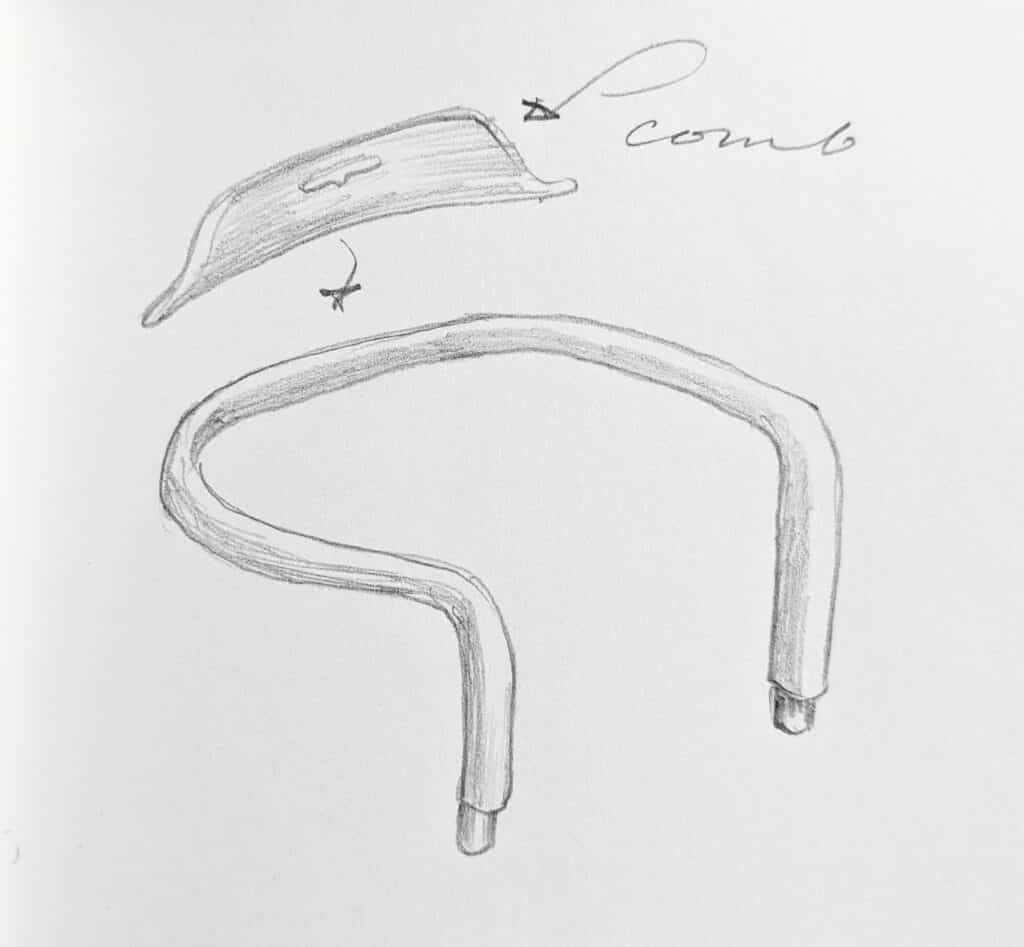

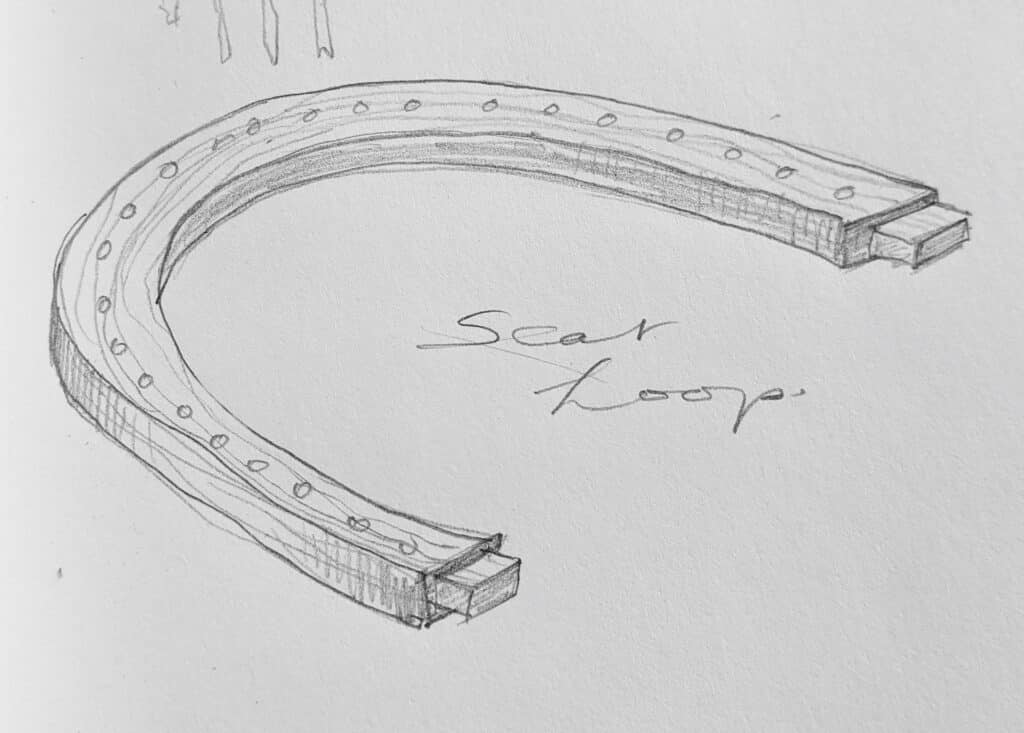

The chair arm he bent from staves split with froe and club, wedges and a drawknife too. Those days would soon disappear and chairmaking would grow on the continent of Europe in countries like Romania that would for a long season supply the world with cheaper but well-made chairs. His arms for his chair would be bent weeks before fitting and so too the seat’s for a frame held by two mortises as shown. I saw the chair in the back of the auction room with a black number 202 on a white card backer and fastened to the damaged seat.

The man made the chair to last a hundred years and it did that and more. The bidding started and ended with my offer of two pounds. This three-dimensional work of art, as have dozens of other such pieces purchased and seen, became my walk with the craftsman. How could I deny the humility of a man expressed through the thing that he made? When a man in times past made a piece to sell became the, “little man I found in the village“. The phenomenon of nameless “man” referred to as “a man” only may be a British thing. But again, the anonymity continued as if some secret but well-kept knowledge preserved the ability of the monied to get work of any kind done by someone unknown beyond a first-name acknowledgement of him being somehow an owned being.

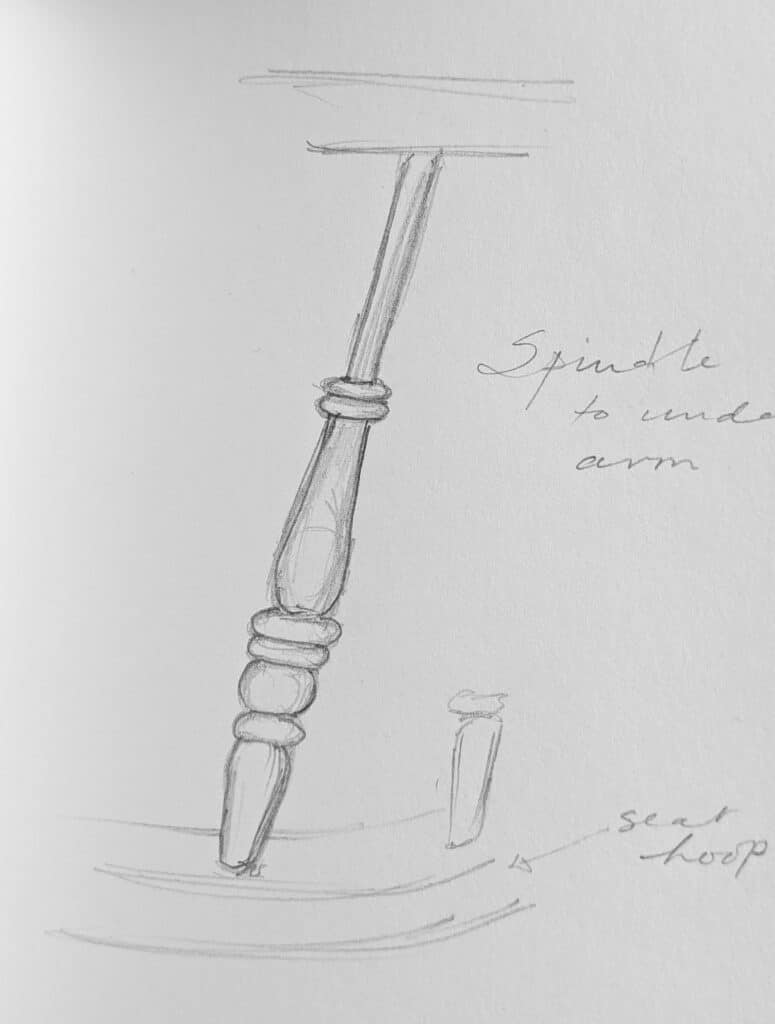

The spindles, each mildly different one to the other, showed just enough difference to know that each was eyed for shape and minimally different after turning many a few thousand over a life’s working span.

The chair, painted white when I bought it, had a solid framework of oak, and luckily the paint and the chair were both old enough for the paint to flake readily away as I removed it. As a woodturner as well, I could fully relate to the making of spindles, legs and rails as much as I could the framework. Woodturning for chairmaking makes chairs simple and fast to make.

The turning has nothing unique to it but likely more so compared to today’s woodturning made all the easier by much modern chuck gadgetry including the multispeed lathe itself. Rolling the gouge on coves and beads turns out a spindle in a minute or two and with just thirteen and four legs we’re talking an hour’s work there. The bending too is just a question of creating a steam chamber and heating the wood for an hour before the bends begin. Once bent, the wood is either heat-dried in warmed sand or left to dry for a few days and the remainder is simply bored holes and tapered spindles driven and wedged as necessary. Spindled chairs are the easiest to make because they are the simplest form of joint with no shoulders to fit and no tenons as such. When you look at the continuous arm you see the dynamic of transferring upper body back and shoulder weight to engage every spindle to the upper body support of weighty people.

Looking back on events like my experience with my sisters rich boss, at first can leave a bad taste in your mouth, but I learned to admire the success less and look more to the man and the character. I never entered into the bargaining syndrome as I grew in my confidence and became secure in the knowledge that they couldn’t go anywhere else to get the same that I could give. The man saved a few pounds but when he asked for more work some years later I declined by saying I didn’t want to work for him. When he asked why, I told him that he had taken advantage of a teenager and he should be satisfied with that.

I wonder how the mortices for the spindles would have been cut, with a drill (then mated with the spindle using Paul’s spokeshave technique), or with a reamer (and a tenon cutter for the spindles), or something else? Very interesting historical example.

I think simple bored parallel holes from what I see close to.

My mother recently came into a table and chair set for her dining room. I guess it’s that they are at least 75 years old maybe a hundred. They are all mortise and tenon construction. Beautiful pieces.

I would like to buy copies of Paul’s books, old versions and new. Would you send or post information on how to acquire them?

” I told him that he had taken advantage of a teenager and he should be satisfied with that.”

Brilliant reply. Both barrels, point-blank range, dignity maintained.

One would hope he might have actually learned something from that remark. Often people try to lowball my work so I just tell them to find someone else to do it for them. I know there is nobody else. One fellow challenged me when we were talking about one of my detailed toys so when I got tired of the conversation, understanding that he had no idea of how much work was involved I said “Tell ya what, you make them and I will buy them from you”. End of conversation. Then there are those that try to change the dimensions of a piece of furniture after all the pieces have been cut……

I love Paul’s remark to the rich man. I would never do that to someone naive. But, sometimes it’s done with innocent ignorance or being brought up the wrong way. Good Lord knows, I was once that way, but I realized a man is worth his salt, and if I determine his work is overpriced, I thank him for his time and move on. And I send a silent apology to those workmen that I bargained down. Life’s lessons dully learned.

I love a happy ending! Paul ” sticking it to the man”, yeah!👍

Well said Paul, respect and dignity intact

I thought I was seeing things Paul, and had to look twice.

I was given an identical chair years ago, but identical from the seat up. The lower section was four intersecting swept wooden legs on casters, but with a cast iron support under the seat with a threaded steel section to adjust height.

I asked a ‘friendly’ neighbour that worked for an antique shop in Putney few decades ago how much it would cost to re-seat in leather supplied by me. £25 was the quote and I gave the go ahead…..it quickly racheted up by the boss to £50 when it was returned ‘because it had taken so long to fix the perimeter nails’ – awkward when dealing with ‘friends’. Seems to echo your experience. Never quite saw that guy in the same way again!

Hi Paul, I remember reading another of your blogs about the stools as your first paid order.

You said that you made them in your porch and when he paid you ,you thought you were rich although it wasn’t a large sum of money. I have £13 in my head but could be wrong.

It’s always the rich who pull stunts like that. I’ve had it, one time i had been talked into reducing a price for a Saturday call out on a promise of more work and i arrived at a huge mansion with staff who told me how wealthy and horrible the bloke was, he was a stockbroker type who helicoptored in on weekends. I worked hard and did a good job and when he paid me it was from a huge wodge of cash. I was annoyed with myself for reducing the price for him and there was no more work and I remember thinking how much more i would rather reduce the cost to anybody other than him and it left a bad taste in the mouth.

I’d like the opportunity to turn him down if he called again.

“It’s always the rich who pull stunts like that”. That’s why they are rich. Very often they take advantage of other people’s naivete.

Re: The chair.

That chair is not only beautiful but it seems to be saying, ‘Come and sit here’!

Re: Your sister’s boss….

An old friend of mine who spent most of his working life in business once made the following observation,

“A good business deal is where, at the conclusion of the deal, both sides walk away happy and each feels they have gained from it”

This is not just about the hard finances of the transaction but, for example, the potential for future business between them as well as the potential for future business from recommendations.

Your sister’s boss probably thought he was being clever or that his duplicity was ‘just business’, but I’d be willing to bet that he made no attempt to pay his outstanding debt by sending his friends and acquaintances to you when they had need of a wood worker. I doubt it would have occurred to him. I also suspect he had few friends.

With or without Jensens and Lamborghinis, you have lived a richer life than him by far.

It never ceases to amaze me the short-sightedness of greed. As a toddler I stole some toy boats from my cousin. I showed them to my parents. They scolded me and had me return them and say sorry. The shame I felt I can conjure as if it were yesterday. These greedos seem to lack that basic experience. Me me only me! Imagine being their family. Yikes!

“A good business deal is where, at the conclusion of the deal, both sides walk away happy and each feels they have gained from it.”

True, but more importantly, often a friendship has been kindled.

When it’s all over, relationships are all that really matter.

Lovely discourse on value and meaning. A history of art forgery I read recently noted that even or especially in the “fine arts”, and even in the western tradition, if you go back far enough, anonymity was not just the norm but integral to the value of the work. When a subsequent artist equalled or surpassed a predecessor, it wasn’t called forgery but rather, inspiration. The ultimate monetization of an artist’s work in modern times is to establish a finite limit to its supply through its creator’s disability or death. Not a very deep measure of value. Banksy’s career offers an interesting twist on the relationship between artistic anonymity and the “value” of their work. He’s supposed to be anonymous, but the work is supposed to be his, in order to command the prices it does!

Paul, your story of your sister’s rich boss struck a chord with me. My dear old dad was a time served joiner who became a self employed property repairer in the 50s and often worked on properties owned by an Egyptian GP here in Sheffield. I mention his nationality as his behavior may have been a function of the culture he was born into.

Dad agreed a price to build a large double garage at the doctor’s home. After two days work he came on site and asked for a 5% reduction. As Dad had cut the price to the bone to get the job, he refused and told the lads to stop work. After they had loaded the wagon the doc relented and work began again. The next day saw a repeat performance and after a long argument, Dad reduced the price.

After that, all jobs he did for the doc had 5% added on and then knocked off again. After three years doing work for him, Dad finally told him to get someone else who could afford to waste many hours arguing!

Interesting that Paul could see the worth and solidity of the piece through the layer of paint applied by some later owner. That is experience, when you know from a glance that something is “right”.

Hi Paul

I started to watch your videos and then I read your book not for making furniture, but to restore some old one that belonged to my family. Understanding how, at that time, they were hand-made helps in restoring (as well as using similar tools to restore). And doing so I often wonder about the man who made them long time ago, for who he did them, etc. It is melancholically fascinating thinking such a thing.

The phenomenon of nameless “man” referred to as “a man” is a custom in Italy too, but we usually say “a little man” I do not know why.

Here too they said, “a little man” also. I think it was to make sure he would be seen of significant importance to the listener as being owned by the buyer of his talents but of no importance elsewhere; that all should know him to be the lesser and the other the greater.

https://youtu.be/SsyXhv0q_fY

This is beautiful and inspiring video titled ” The Touch of the Masters Hand”. Not sure if you have ever seen it, but I am confident you would enjoy it. It is incredibly inspiring.

David Shepherd the artist, related the story of the first painting he sold at an artists market in London. A prospective buyer, bumped him right down in price, as it was his first sale he reluctantly agreed. The new owner asked for the painting to be carried to his car……………a Rolls Royce!

He vowed there and then, never again to be beaten down in price.

This post inspired me to remember this old video, “The Touch of the Masters Hand”

Encourage all to watch it!

https://youtu.be/SsyXhv0q_fY

Good for you Paul, Having had the same experience I know how good it feels to turn down rich clients with the words – “I don’t want to work for you”.

“The man saved a few pounds but when he asked for more work some years later I declined by saying I didn’t want to work for him. When he asked why, I told him that he had taken advantage of a teenager and he should be satisfied with that.“

I’m 45, I started to work when 20 in graphic design and advertising field.

Countless people greedily took advantage of me, and I’m still not feeling strong enough to openly say what you said.

I learned a lesson here… another of the many you are teaching me.

I think that it is a tricky one because you both need work, need to establish your name and you need to work out whether someone is benefitting by cheating you or recognising that they are gaining as you are actually learning on their work. I recall a new guitar maker taking 200 hours to make a guitar that takes an experienced maker 100. He felt that he should charge the top rate even though he took twice as long and never understood why he never sold the guitar until the price was eventually halved. He always felt bitter after that.