So, Who’s a Luddite?

I’ve learned that woodworking is much more than merely working wood or just, well, processing it: that’s for a percentage of people that is. More those who enjoy touching working the material I suppose. You know, taking material from a tree and making something substantive from it and recognising its background in its growing vibrancy somehow. And by substantive I don’t necessarily mean big in terms of project mass but perhaps something quite substantive by the level of its demand on us as makers. Through the decades I’ve suggested that machine making is not the same as hand making. Meaning the two realms of hand work and machine work are nothing in any way like each other and so the two very distinct realms should only be compared in the same way an apple is compared to an orange––both growing on trees, are round, vary in size and have skin. But the tastes and textures are very, very different. In essence, each is exclusive of the other. I feel the same way about machining wood and working it with hand tools. The methods of working make the two realms diametrically opposed to one another. Even so-called hybrid woodworking is not unifying. As it is with the illusion that people think that they can multitask, primarily it’s only task prioritising. Some people can do it well and some cannot. To suggest that half the world’s population multitask and the other does not has always been silly. No one really multitasks any more than the juggler spinning plates, catching balls and flipping clubs. All they do is make judgements according to need and decide which to spin, catch and toss to keep them all in the air. So I see many reasons that machining wood can never really be more than the wood connection rather than the processes of working it.

Critics do occasionally accuse others of snobbery, exclusivity and more if and when they advocate only one way rather than another or that one is more skilfully executed than the other. But that often happens when truth causes others to take offence even when no offence is intended in any way. A well-designed spice rack with sliding dovetails for instance could be as technically, mentally and even physically demanding as a timber-framed building or a garden shed, a coffee table or a bookshelf. What can make the difference is the equipment availability. Of course, in my case, I am talking about hand-making rather than something needing crane lifts, tenoning machines and mortisers.

I have lived just about long enough to witness great changes in woodworking made by small incremental changes. In my lifetime I have gone from seeing just about every woodworker I ever encountered ditch using 95% of hand tools, well maintained and cared for for decades, to become so-called “power tool junkies”. Through the brief transition, machine-only makers have little concept of hand tools and their workings and most no longer know how to sharpen a chisel, a plane or a handsaw by hand.

I watched small, family-run DIY shops on street corners and the high street become subsumed by massive conglomerate chain-store suppliers who priced them out over a five-decade period. Now these small entities offered much more than supplies of DIY and wood. Mostly run by experienced time-served joiners, they offered free advice and guidance along with practical suggestions as to processes and materials to any and all who came in. They also delivered wood cut to size to your door when the shop closed in the evening and even took a look at what you were building.

But in recent decades, the last one in particular, a wide range of new technologies have come in at pace. Seeing the transformation of woodworking as a craft once fully performed by skilled artisans working with traditional hand tools, the men of the day, become a hobby with only hand tools in the middle of the last century to woodworking as a machining process only today, I found myself pondering change. I couldn’t help but wonder if a new phase was upon us, a phase following where hobbyists enjoying the developments in fields of CNC woodworking even for home use could shortly be primarily engaged with their wood using AI alongside the continually evolving CNC processing to make their next coffee table or spice rack. I know, that might seem less likely than likely, but is it too much of a stretch? This thought of redefining woodworking where the new so-called woodworker sends a key-tapping request to the garage workshop two metres away next door and the new robotics could be directed to extract wood (or even make it) and load it into the CNC devices to twist, spin, align and reorient the material into the five rotating cutterheads to have a variety of different wood cuts made to replicate or even reinvent the woodworking joints used to make your coffee table for you. Perhaps grain itself can be colour-coordinated along with grain patterns and configurations for perfect book-matching, things like that. Grain density might be optimised according to task or outcome requirements simply by sonar sensing and a wide range of hitherto unavailable options introduced.

In a recent, brief exchange, I commented that if I were to make a dovetail joint by machine it would for me be a fake make. Now, of course, that is for me because I will never need to make a dovetail using a machine like a power router and such. I decided to make a more careful and considerate alteration to the text so as not to judge others or indeed have others feel judged in some way as to whether their joint if made by machine was any less of a joint than a hand-made one. Of course, it is not: the joint whether made by hand or machine is still, at the end of the day, a fully-fledged dovetail joint and both are of equal worth with regard to the final outcome in their mechanical attributes of strength and functionality, longevity, etc. Whether made by hand or by machine, the joint is in and of itself still a real dovetail joint. The difference for me and many is that on the one hand, the joint is developed and cut by a machine substituting for and designed to replace hand skills whether hand fed to the wood or the wood hand fed to the machine and not by a person manipulating a range of uniquely different hand tools to the wood and uniquely controlled in every way by the innate senses and training of the person applying the tools (and a machine is a machine and not a tool in the sense of which I speak) and their cutting edges to the wood. And it’s this simple fact that makes all of the difference in the world.

And, of course, I realise that this can be controversial if 98% of all woodworking now, whether by so-called professionals or amateurs, is done so by using machine-only methods. Do we become some kind of lesser woodworker if we choose machine cuts to do most if not all of the sizing and fitting work for us? I really don’t think so. I think we cannot compare apples to apples here. In some ways, when you think about it, both can well be considered the more advanced way depending on which paradigm you look from. The test of a person’s skill is, well, very different according to the methods used. I think hand-cutting joinery is the most high-demand form of working wood I know of that there is. On the other hand I understand highly complex work programming requires skills and knowledge I don’t have any clue of and the demand for these users is indeed the inclusion of computer work itself with the machines the computer controls. So that does not mean that setting up CNC machines and developing code is any less demanding, interesting and, yes, fascinating too in its own way. But most such equipment is already set up for the user to plug in and programme according to task. My engineer friend across the way set up his CNC to cut my latest prototype dovetail template in metal and in just 20 minutes the machine ejected six perfect specimens fully saleable and accurate in every way to within thousandths of an inch of the design specs programmed in.

We make personal choices all the time. Some are designated to involve us the more and some are designated to almost take us out of the loop altogether. The latter might well be to eliminate a person’s involvement and is a good plan for any business to work economically and keep a competitive edge, I am sure. The ultimate goal birthed through the Industrial Revolution was to minimise the need for skilled workmen and women and wherever possible to replace them with machines to produce the goods needed for a global feed into the economy’s insatiable appetite for making money, and are we not still moving constantly along that same trajectory? Is this not the very nature of technology in industry? Objectors then became classified as Luddites––degenerates who hated technological progress. Even though crafting artisans were well in the majority and supported the conservation of a traditional working culture in every craft of the age, there would be no democratic vote for it. It was never a democratic consideration but more a control of the workforce being shunted head-on into the factories that needed cheap, controlled and compliant labour on minimum wage.

Looking now at what has been recently happening in areas surrounding creative arts by those protesting against AI being used to take existing content and copy it with a view to reduce the need for creative artists in their different fields, it seems that it is hoped that AI will systematically replace scriptwriters and every other kind of artist there is. I wonder if these creatives, as in the early 1800s here in the UK, might be classified as today’s Luddites and that we are presently seeing history repeat itself. There can be no doubt that just as the emergence of looms destroyed home working and family businesses we also reduced the cost of goods so much that many feel the need and ability to throw away great clothes because by fashion alone they become ‘worn out‘ or over worn, even after only a few wearings. Without the Industrial Revolution, we wouldn’t have cars, petrol-based products and pollution and nor would we be fighting issues surrounding many geopolitical manipulations and machinations. My insulin needles comprise an amazing array of amazing elements ranging from glass moulding, plastic parts, printing in the round and stainless steel needles so fine I cannot feel them enter my arm, stomach or legs. There can be no doubt that life has been enhanced by technological developments. I will park that there.

Lastly. Riding my pedal-only-powered bicycle demands total engagement with the beautifully paved road through a series of gears easing the passage on the hill climbs and into the head-on winds. Though a derailleur-geared ride, the energy expended is still the same only instead of a hard drive in heavier gear I can choose ten times more rotations using an alternative gear to match the opposition. On the other hand, I also use a hybrid bike for more off-the-road rides and this bike, an assist-powered electric version, though it must always be pedalled, is a totally different ride. The difference is simple. I can have the support of electric for a full 130-mile ride up hills and down dales where the hills and winds seem barely to exist. On my one bike, the work is much harder so I use this one on more localised rides to the shops and such but also for short bursts of twenty-minute exercise when I feel I need it. The electric bike takes me longer distances in about a third to half the time. If I can afford the time to take longer rides to different places solely and primarily to enjoy the different elements of cycling and scenery in my ride or go to other places I might choose this bike over the other. Now, of course, both bikes give me exercise and both get me where I want to get to and it’s my choice. In like kind I can also use my bandsaw for much of any resawing I need. This is especially handy when it comes to going through say 8″ oak, knotty elm or wiry other woods or indeed any wood that thick. This again is a matter of choice for me but mostly it is energy- and time-saving in my very full-on days as a full-time maker nearing his mid-seventies.

I need to pace myself the more these days and rely on stamina support on some days. In the case of a younger maker, they too might be more time-strapped and therefore need to rely on a machine or two here and there and now and then. Choices choices, choices. The question for me is whether skill development delayed will ever come if it is always a question of your choosing speed. It doesn’t take 58 years to develop the skills and speed and knowledge I have. And it is easier to learn today than ever in the history of woodworking because we have the internet. The issue in any excess, as we have seen through industrialism, is finding what we really need and finding it when we need it. I doubt that anyone can really cut a dovetail with much gain using a power router and jig than I can if we both start from scratch with wood prepared but both needing set-up time included in the trial. On average, I take 20-30 minutes to make a dovetailed corner accurately. Even if the power router halves that time it is not much of a gain. Where people gain is in having a half-decent-looking dovetail from the machine when done. Where they lose is never gaining dominion over their lack of skill using hand tools, mastering sharpening chisels, planes, saws, card scrapers and then too #80 cabinet scrapers. We woodworkers in our garages are really only likely to cut half a dozen of one size for any given project and will never mass-make anything so it’s unlikely that we would invest in the the mass-making equipment cited above. Furthermore, Luddite or not, you will never see me use a power router with router bits and dovetail guides to slalom through to make any kind of dovetail. I’ve avoided it but never because I shun technology as the Luddites were and still are accused of but for very many, many good reasons not the least of which is it’s actually too slow for me, too noisy, too messy and too expensive. It’s also dangerous, polluting and for me, totally unnecessary. It is for most people willing to put in the time to become skilful at hand-cutting dovetails. I believe that this is becoming true for those multiple thousands if not millions of brand-new woodworkers who have trained themselves to cut good, tight-fitting dovetails every time with a few hand tools and within an hour or so too. If they can do so so can most people. 98% of doing anything is a made-up mind.

There is no stopping AI just as the Industrial Revolution was and has been unstoppable and I am not in favour of halting progress if progress is indeed what happens. Mostly, as it is with almost everything, it is about balance. Through the decades and centuries, no one really asked the majority what they wanted. Times have changed and in recent years social media has taken the helm for any and all that use it. It’s really a question of determining what you want from your woodworking.

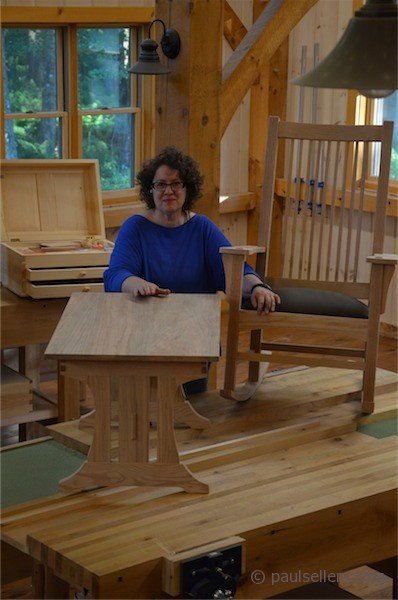

And this is what a dentist nearing retirement looks like when he sits or kneels on the floor to fit an arm to his rocking chair towards the last few days of his month-long investment in learning a craft like mine. Believe you me, if this man can make the tool chest, the coffee table and the rocking chair in three weeks, which he just did and superbly at that, he can make anything you care to name from wood with hand tools and the difference for him is he can still use machines if he wants to.

Life is becoming increasingly difficult. We wanted to have an appointment with our veterinary for our cats.

On the phone we get an answering machine which doesn’t say if the veterinary is on holiday or not.

So we think let’see if there is now a web site. What a chore! Creating an account with password, Then giving all the details about our two cats (known by the veterinary since 16 years by the way) and so on. At least 20 minutes wasted because those so called intuitive interfaces never work as expected.

By the way, “intuitive” means the programmer takes for granted that everybody is supposed to think exactly the same way he does.

As one who is returning to relearn his trade after 60 years of slowly forgetting they once completed a cabinetmaking apprenticeship — I needed your luddite views. It is complex to find yourself caught in the change to mass production brought by “modernization.” In 1963 after completing a 4 year secondary school program in woodworking it was at a dead end. In the greater Boston , Massachusetts USA with population in the 3 million range there were very limited opportunities for a career in cabinetmaking. The few shops with opening wanted years of experience for a new hire. None of those opening were going to hire and give you years of training. A new person in the trade had to accept working in a factory mill feeding machines. Where in five year you might get to move into the last of the custom cabinet shop. Then after more years as an apprentice move into a skilled position.

I am among those you described where choosing machines or hand tools is the problem. Fortunately, this web site has led me the right chose — hand tools. The good part of the web is it easy to find the old tools. The bad part is sellers believe an old rusty backsaw is worth more than a new one.

Beautiful post Paul. To me, the real big question is how do you want to spend your time? What do you want to fill it with? What do you want to be, do, and become? Any job we do becomes a deep part of us and life is too long to let that haphazardly happen. Same could also be said for our free time outside of work. I know some individuals who prefer to sit and watch sports all weekend on the couch. Feels sad to me but it’s their life.

I like my cutting edge technology day job. I also equally love my woodworking with hand tools on nights and weekends in balance with the other obligations.

Joe, I 100% agree with you. What you want to become? Artistotle said that our habits form our character. I absolutely think that’s true.

Paul,

In the modern sense you are not a Luddite, as a technophobe who prefers old tools just for the romance of it, or for re-creating an old time past. If I may say to a Master of Wood –boldly– you absolutely are a Luddite in the finest sense of the word. I looked up Luddites to make sure my secondary schooling knowledge was true. They started out in England as master weavers whose job was industrializing. These folks were the Paul Sellers of hosiery and textiles. Capitalist industry and the Enclosures Act, a law to making common lands belong to a rich elite, had made rural cottage industries dwindle and city factories grow. The capitalists wanted cheap, expendable labor so they could avoid getting devoured by other capitalists and they could get rich. These Luddites said, look I’m making highest quality fabrics and refuse to adulterate the fabric with shoddy thread just to squeeze out a few more pounds out of the customer. They sabotaged equipment by attacking the modern looms that were destroying their families and forcing them from their homes into these dirty, dangerous city factories which also employed their children. Young kids –many were the Luddite’s children– had tiny fingers, great for making textiles and they cost so very little to employ. If a kid got caught in the machinery and were maimed or died, there were ten more to replace them. Wives often resorted to prostitution because they had nothing else to sell to feed their many babies and they weren’t economically important anymore. The formerly self-employed weavers were reduced to a tiny cog in the great clockwork and became broken shadows of themselves.

Luddites were the Robin Hoods of their era. Under the cloak of darkness, they smashed the capitalist machines and though they ultimately lost the war, they went down fighting. To be fair, they also employed violence, which I don’t support…but I live without fear of losing my home, job, and fingers in a mechanical loom. Context matters! To make a long story longer, the Ludds overall were a force for the common good. They risked execution and lifetimes of hard labor in penal colonies to preserve their way of life and throw a wrench at the capitalist machine.

Who else do we know that is, with great patience and skills and a wee bit of dry British humour teaching an alternative to shoddy goods made by a soulless robot to replace and erase the worker’s skilled craft? Maybe we have our own hero: a Robin Hood to admire…King Ludd himself! They can’t kill an idea, no matter how hard they wished this inconvenient truth would stop pulling back the curtain and exposing the sheer foolishness of trading skill for boring fakemake. Luddites were revolutionaries against the abuse of machinery, not technology itself. Anything other definition of Luddite is propaganda by the folks who profit from lies.

Well, you’ve really generalised there, I see. Most school history books gave very exaggerated generalisations that all crafting artisans worked always to destroy equipment all the time and that they hated progress and technology which I learned in school from a then 23 year old teacher who was little more than a student herself and only ever spent her previous life in education. I distinctly recall hersaying, “And can you believe that these Luddites smashed up the looms to halt progress and go back to weaving in their home workshops?” Well, 60,000 non-violent protesters went on a quiet protest in St Peter’s Field in Manchester UK, unarmed and with no intentions to do anything more than raise awareness to the plight of the poor and the working classes earning way less than minimum, to say that children under 9 were still expected to work a minimum of 9 hours a day and under 19s no more than 12 hours a day and the then rich Tories (conservatives ordered the militia to disperse them for fear of them causing some kind of disruption. 11 people were slashed or clubbed to death by militia men deployed by local magistrates to charge on horseback and 500 people, men, women and children were injured and maimed in the fray. What later stood on St Peter’s Field for a few decades was the Greater Manchester Police Headquarters. Ironic.

I always learn a lot by being wrong…and I’m at least 50% wrong, well at least 100% of the time!

Very interesting history. Yep, the bad press gets around the world before the truth has its morning coffee. Whenever you say Luddite, you get 1 of 2 things: loom smashers and saboteurs or people who hate technology. I never heard of the peaceful Luddites getting mowed down. Corporate propoganda/education.

Capitalists own (by paying, stealing or manipulation) the factors of production. The factors of production are land, labour and capital. Capital is split into two (2) elements being money and technology. So, the capitalists wanted to introduce technology generally to replace labour and become more effective by using the factors of production efficiently. The Luddites – to maintain their monopoly of supplying labour (trade unions, I am a strong supporter regarding their support of health, safety and welfare) – did try to stop the introduction of technology but…? Imagine being the “bottom dog” when sawing a log via the through and through process working in a 6’ deep trench all day? The “top dog” – working above the bottom dog – had an easier job than…! So, make yourself irreplaceable in the workplace if you want to succeed – like Paul’s skillset. Take care.

Capital is useless without labor. Labor is already irreplaceable. Never forget that when you work in a job, you are making money for someone else, and that someone else will exploit, use, and abuse you as much as they can get away with, and discard you without a second thought. Mininum wage laws mean owners would pay you less if it weren’t against the law. Capitalism is entirely corrupt. Capitalism is literally killing the entire planet.

This makes me want to both practice my dovetails harder. I made a maple copy of the dovetail template you found a while back and it’s neat as heck, though I keep forgetting to flip it for the other side of a tail lol

Whoops, forgot to remove that “both”

Sir, I do enjoy reading your musings. Even to read of a bike ride to the pond is enjoyable.

There is something to be said about sitting with a cup of coffee in meditation and prayer as the sun rises. Walking into the garage later and smelling a bit of the last coat put on a project the night before.

This world pulls us all in so many directions. It is tiresome mentally and emotionally. The song of a freshly sharpened saw is refreshing. The kiss of a grandchild with a big hug even more so.

Thank you Paul.

Hi Paul, I want to thank you for your teaching. I am very happy to follow the many YouTube videos where you show how to work with wood. You inspire me to get better at woodworking. I hope you keep producing more videos.

Best Regards Jens, from Denmark

Funny you mention the future of woodworking to evolve into CNC machining methods.

Not to long ago a local woodworking supply house toted the headline “CNC controlled machines the future of woodworking”! I don’t think you are that far off with your musings.

Thank you for this blog Paul. I believe this may be the most nuanced and indeed rational article that you have written.

The Luddites were very much a product of their time, and they had good reason to fear for their future. The term is used today in a pejorative sense, usually accompanied by a condescending sneer. The same can be said for the term amateur, which today is far removed from it’s original meaning.

Much of the supposed dispute within woodworking is, to my eyes at least, a contrivance from someone who is trying to ‘sell’ me their standpoint.

I so often get the sense that much of what I read or watch, is attempting to make me take a side, even when no side exists in reality. It’s as if converting me to their viewpoint is the most important thing, rather than the actual matter which is being addressed.

I’m a hand tool worker because, firstly I enjoy the process, secondly because woodworking is a hobby and interest, and thirdly because that’s what I can afford and have space for. Where it the case that I did it to put food on the table, and not want spend every waking moment labouring with hand tools for little reward, then I’d likely be an avid cheerleader for machinery.

For most of us hobby woodworkers its about the journey, not the end result. The pure satisfaction of accomplishing a complicated task with hand tools the way it has been done for centuries. I maintain that power tools have their place in businesses for the volume aspect and those of us that indulge ourselves in woodwork as a hobby will likely still be inclined to use hand tools.

That said, we start into this hobby with hand tools usually and eventually build up an assortment of tools that do not require power or a large floor space and significant amounts of money. My whole collection of hand planes cost less than my Dewalt thickness planer.

The other thing we all come to realize is that power tools are only capable of doing SOME of the job and sometimes the setting up and cleaning up after take much more time that a hand tool. If you are a woodworker you will ALWAYS need hand tools to finish the tasks. Also I dont have to wear a dust mask or earmuffs to protect me. I have hand tools AND power tools and although I could replace all of my power tools with hand tools I am not likely to as it can be so much work for things like ripping large lumber into smaller pieces and planing a large pile of boards into finished lumber. They all have their place and since most of us are making single projects rather than hundreds the hand tools I have will still get used. The joy of using a freshly sharpened chisel or hand plane is a lot of what its all about. I do jobs for money and I do them for fun. Different tools in both cases. FWIW I do NOT get satisfaction out of using my thickness planer, tablesaw, or bandsaw but it gets a LOT of work done in a timely fashion.

AI will likely NOT be used by hobby woodworkers as it is expensive and very job specific. Yeah, might be nice to have one but that money might be better spend on some pretty hardwood…..

“AI”. Ugh. I consider artificial intelligence to be fake intelligence.

It’s not intelligence at all, that’s just marketing baloney. It’s 1s and 0s, just like any software. And, just like all software, it incorporates the biases, limitations, values, and flaws of the people writing the code, and the designers of the software. I am a software engineer, and I have chronic headaches from this kind of marketing rubbish 🙂

This how AI works: brute-force search, and endless chains of if/else/gotos, just like the bad old days of batch files and programming in C. That’s it. Only now we have vastly cheaper and more powerful computers and storage, and massive distributed computing resources.

AI “learns” by storing successful search results and re-using them. When you read about Google and other big predatory tech companies stealing datasets for “training” their AI, they are poaching masses of data for their AI to use. It is not learning anything, but only behaving according to its programming. Garbage in, garbage out. Or, as the father of computers, Charles Babbage said: “On two occasions I have been asked, ‘Pray, Mr. Babbage, if you put into the machine wrong figures, will the right answers come out?’ I am not able rightly to apprehend the kind of confusion of ideas that could provoke such a question.”

We are drowning in data, and the biggest problem with data is not collecting even more of it, but knowing what to collect and how to use it effectively. The current state is hoarding, like creepy rich people who never have enough money and just want to keep accumulating bigger piles of it without any plans for using it. Human intelligence should be applied to first deciding what problem to solve, and then deciding what data to collect to help solve that problem. Hoarding everything is just hoarding.

I’m sure most of the people here already know this intuitively–you know how marketers/spammers have been promising since forever that their snooping and stealing every morsel of our personal data they can is supposed to benefit us with “targeted ads”, which will magically improve our lives? You know it’s hooey, and I know it’s hooey. They use it to spam us, and to buy and sell our data. Trading our personal data is big money, and there is even an industry term for it: ad tech.

Anyway I am stopping now because I feel my blood pressure rising. Rant over, and thank you to Paul and the good people here for all the great teaching and information, and keeping it real.

An odd detail: apparently power tools are a bit of a worry if one has a pacemaker. I have had two different ones installed in the last sixteen months and in both cases the post procedure literature warned against operating power tools close to the chest. The magnetic forces engendered by the electric motor of the tool can sometimes affect the functioning of the pacemaker. I take it this means not leaning over the tool, since no one would operate the business end of the tool near one’s torso!

Even before the heart business, I had been in a transition to hand tools, seeking less noise and dust and greater peace and sense of personal accomplishment. I have a long way to go to reach even basic competence, but health permitting, but I would rather spend that time, if I am granted it, learning the skills of hand tool work… without worrying about what electric motors might be doing to my chest.

What a most interesting and thought provoking post. I have now read it three times and each time it makes me look deeper in to my thoughts related to it. I do wished I had the plans for that open toll box shown in the picture though.

Keep up the good work.

I think you make some valid points about recent “full time” college courses. But it wasn’t always so. Bear in mind that originally the “Techs” were set up to supplement not replace craft training. It was the norm that people attended either night classes or day release to learn the technical aspects of their trade that weren’t available to them in their day job, either because of lack of time or lack of technical knowledge in the trade concerned.

When carrying out their original role of supplementing work based training and providing a route to technical and trade qualifications the techs were a superb asset in the community. I know, I went through that system in the 60’s and also spent several years teaching those technical skills that many students weren’t getting elsewhere. I was often shocked by how little knowledge of the technical aspects of the trade students were receiving at work. Even basics like geometry/triganometry that are fundamental to many trades.

The problems started to arise when there were fewer workplace apprenticeships yet young people were still looking to be trained, then colleges were encouraged to take on full time students to help meet that demand. Some courses were good others very poor, entirely down to the quality of the staff and the constraints of syllabus placed upon them.

Your own work and training programmes are superb, but I’ve also seen great examples as well as poor in the tech college system, not all are poor that’s for certain. I just hope we get a move back to the quality that many colleges turned out in the 60’s coupled with more industry led trade apprenticeships.

Well, I have zero confidence that that will happen because all college courses are industry led and industry fed. Politicians are governed by industry and so the Revolution continue. Its most likely that we will see all woodworking continue to be farmed out to another continent and what we call joiners and carpenters will continue to become mere fitters and installers with NVQs and such matched to that end. A friend of mine is lead engineer in design and technology at Stamford University and we had this discussion 10 years ago. We both concluded that it was impossible to reverse. This made me all the more intent to record everything that I know and learned for posterity via our technological advancements. That at least is working for now.

Actually many college courses are anything but industry led, in the UK they are funding led and that funding is public not private money, so ultimately they are politically led…which is major part of the problem.

Colleges are driven to balance the books so courses that attract funding and students are offered.

Nope! Industry and money always dictate and politics does what industry says. Both college administrators and politicians tell educators what to teach and train according to industry needs. The industrial Revolution saw to that.

Since we’re refusing to do anything about our many problems, it just makes sense to invest in hand tools that can last centuries and don’t require a power cord. Besides, everything with a power cord ends up in the dump/tip.

You implied that modern timber framing requires machinery. I would remind you, first, that you can craft almost anything with a small set of sharp tools and, second, that the Amish have built barns for generations using a small set of hand tools plus a community working together as a team. Machinery is now required for timber framing only because communities dedicated to teamwork are hard to come by.

I watched a YouTube woodworker hand plane an end grain, and off came a continuous shaving. He preached that great woodwork can only be achieved by using the best (most expensive) tools. I have struggled to understand his message. Great woodwork obviously means something different to me.

But then I had an epiphany.

If I purchased a $400 plane, that cleanly planes end grain immediately after unboxing, I am ever moving closer to using a machine. Why not just purchase a planer and edger. Current technology may deliver sharper tools with less effort. But what is missing for me is the effort to master the hand tool challenges necessary to become a master of this vocation/avocation/hobby. I want to invest myself totally in the hand tool experience – because that will be my metric for great woodworking.

Hello Paul. As you correctly point out, the tools we chose for our woodworking projects boil down to personal preferences, and neither choice is wrong. A lot depends on the goal…as you also point out, in the end, a joint is a joint, no matter what tools were used. I remember when I started watching Norm Abrams 30 years ago on PBS and how envious I was of his workshop which had every power tool imaginable. Of course he was in the business of cranking out reproduction antique furniture, speed and efficiency were important, so perhaps the end justified the means. Over the many years since, I have learned that for me, the journey is more important than the destination. I have come to love the meditative, quiet and connected nature that comes from working wood using only hand tools – almost like a Zen experience. Of course I occasionally power up my bandsaw or tablesaw, but I always enjoy coming back to the simplicity and skill refinement associated with handtools. That’s my choice and others can make their own choice – no judging. The only sad thing that I lament about in the trend you have described is the the disappearance of the small tool & hardware stores that were usually staffed by old timers who knew a lot about working by hand and sometimes even showed interest in my latest project. They could also find bits and bobs in dusty back cabinets that the big box stores simply don’t carry. Long live the handtool luddites!

Wow! Lots of viewpoints it’s almost overwhelming.

I worked in the metal working industry for 30 plus years and a further 10 years as a teacher in a technical college before retiring. Technical collages are teaching people to find employment in industry so naturally what’s taught should meet the needs of industry. If not then that student was not served by the college and should demand their money back.

A hobbyist or amateur practitioner working for personal enjoyment will not be well served by a technical college course. Technical colleges are teaching manufacturing not making. That distinction must be understood.

Machines in and of themselves are not a problem, the Shakers invented the circular saw and their furniture is universally admired for it’s beauty and design. Machines don’t do anything without the guidance of a human hand. Mostly machines are labor saving devices and as far as wood working is concerned most machines are pretty crude devices. Table saws, joiners, planers, routers etc. won’t make a design easier or faster to produce if you’re making one of something.

I think wood working machines occupy a place somewhere between manufacturing and hand only work. Manufacturing requires very precise control over processes where repeatability and accuracy are paramount. That accuracy and repeatability come at a cost a great cost in process development, trial and error and prototyping until the product can be produced over and over within a certain tolerance range. Think a factory that produces kitchen cabinets for a big box store. The individual parts go through a somewhat automated process station to station with some human input. The goal is reduce error, reduce cost and produce finished parts which can be sold relatively cheaply.

A small cabinet shop will most certainly have machines but not on the scale of a factory. In order to build custom kitchens with dozens of doors, drawers and so on and multiple orders for multiple customers machines become necessary to stay in business. In this case though the people need to be more skilled they are not just feeding parts into an assembly line but need skills like print reading, design skills, machine skills and some hand skills. The final product is much better and more expensive. The joinery isn’t hand done but the components are joined with dovetails and mortice and tenon joints made by machines guided by skilled workers.

Individuals who makes custom products like furniture and cabinetry probably have some machines as time savers. In lieu of having a few apprentices to hand plane wood slabs to size a joiner and thickness planer take that role. Rough cutting parts on a chop saw or table saw saves a lot of time and effort over hand sawing. As hand work increases so does cost. That means the customer base shrinks to those who can pay for that hand work and quality. The cost for hand built tables, chairs, cabinets and so on is much higher than the average person can afford. I’ve known a few people who do custom work one offs but I can’t afford their work.

I have a wood shop in my basement and make cabinets and furniture for myself, family and friends. Even when I make something for myself the cost of the wood alone is higher than most people would pay for a finished product. I do a lot of hand work mostly joinery and finish planning or scraping. My dovetail joints aren’t interchangeable as they’re hand cut. I don’t need to make sure my processes are rigid as I can adjust my projects for whatever discrepancies exist from piece to piece.

I don’t have to worry about batching out a hundred sets of drawer parts and I never will. I use machines as time savers because I don’t want work 8 to 10 hours a day in my shop. I’m not willing to devote that much time to wood working. It’s not my job or my life, I’m an amateur wood worker who enjoys doing hand work and uses machines to save me some labor so I can do other things too.

I don’t get the machine / hand work controversy. Some people are fascinated by technology and want a CNC machine in their garage. Some people don’t want to spend the time to develop hand skills. It’s not that they can’t they just don’t want to. Some people love machines the more the better. Some people collect hand tools and never touch them to wood at all! We’re all different and there’s room for all of us.

Sorry Eugene, you’re not telling any of us anything we don’t already know well and we did give credit to both camps. It’s rather a long explanation too for something we really all know. The machines are set up and overseen by workers able to set parameters according to digital readouts or indeed just dialed in. This only takes but a few minutes to know which screws, knobs and buttons to tweak. Sorry, no more than that. Is this skill or simply knowing whether to press the red button or the green one and then letting the power feed send it against the fence. I question your use of the term or reality of skilled workers in 95% of machine work I am experienced with. The chopsaw is a machine that supports the length of the wood along the long axis and the operative reaches up when the distance is set and pulls the machine down into the cut. Job done. Power planers support the wood and the operator pushes it over the top if it’s a jointer and into the autofeed for thicknessing. Most people can do these things within two minutes instruction on personal safety and safety of the material. I think what you describe as skilled workers might be better put as safe workers. Mortise machines are really a no-brainer. Set the distances for travel to the length of the mortise and the depth stop for the depth of cut and, reach up and pull the lever hey presto you have a mortise hole. I am trying to think where the skills are in specific instances and think I learned all I needed on these machines 60 years ago in a 20 minute tutorial on each one of them as an apprentice. I was between 15 and 16 years old at the time and I’ve used them ever since without a single minute’s refresher course. I think woodturning to be skilled work when done well, yes. Scrollwork is too. Drill presses? Not really much too hard or skilful about them either––another lever-pulling device that drills holes. Power router? Mostly this piece of kit relies on router bits with bearing or fences and tables and so many jigs I’d go dizzy. They can be scary if you are not used to them though and safety really is an issue. So I say this to say that I think I could train any individual to use almost every woodworking machine there is in a machine shop safely in about half a day for all of them. The bigger machines, the more industrial ones, well they are a piece of work simply because of the danger from flailing cutter heads and massive chunks of steel whirling around at thousands of RPMs. I’m talking tenoners and spindle moulders here. Oh, and we weren’t knocking machinists as woodworkers here. You introduced that when it wasn’t there. I don’t personally think as you say that machines are crude devices but highly refined engineered pieces that deserve proper recognition. You also mentioned the Shakers and that their, “furniture is universally admired for it’s beauty and design.” I’m not altogether sure which pieces you are speaking of and I am not so sure admired quite fits it nor beauty and quality design really. Not when compared to the designs through the centuries. Quite, well, basic really. I might like one or two of their pieces, a bit, maybe, but not for the design quality or beauty. I would not want to sleep in one of their beds or sit in one of their chairs for more than a short mealtime. The chairs, all of them, are notably uncomfortable. We’ll leave this here for now.

Paul,

It’s odd how you read my response I actually agree with much of what you say and I wasn’t trying to tell you anything you don’t already know.

I am not criticizing your working methods or choices but you do seem to regard those using machines to be somehow lesser craftspeople than those who use only hand tools.

I’m sure I don’t want a CNC machine in my basement shop. I have decades of experience programming, setting up and running CNC machines so I know what they can and cannot do and one thing they can’t do is make wood working more enjoyable for me. I doubt any of your followers want one either. We work wood for personal pleasure and the satisfaction of making something lovely. Some of us may use machines to make our projects, wood working by hand and machine are not mutually exclusive.

I simply wanted to make a distinction between industrial processes and amateur woodworking. I don’t think we need to worry about AI and CNC machines invading our basement and garage workshops.

eg

For some reason Mr. Sellers you made me think of my old boating days. We owned a sail boat and when we first bought the we knew nothing about sailing. We learned rather quickly and eventually became good sailors and so did our two children who grew up on the boat and learned to sail befoe they were 14 y. o. So what was the first thing I really heard about sailing was the ongoing debate between sail boat owners and motor boats owners. Some called the motor boats “stink pots” and the debate goes on and one.

Philosophically I see this similar to machinery working wood and hand working wood as you mention.

We inherited some furniture from the 1800’s which we use daily . Generally that is not so unusual but all this furniture was built by my wife’s great grandfather on his farm in Iowa. Two rocking chairs were built ‘suit to fit’ for his son and his wife (great grand dad’s daughter in law). It is wonderful stuff and of course he had no electricity and no water powered machinery. He did it all with hand tools. Beautiful stuff and we praise his work often.

i was trained on machines and the use of a few hand tools. when i went solo, i dimensioned by machine and then did all joints by hand and finishing by hand. by only making on commission i was able to make a living. i remember how hard it was to make a piece and then sell it to cover my time and costs against mass produced items onm tne open market. the one thing i love most about hand working a piece, is that it forces me to slow down and appreciate what i am doing. retired now and only making for pleasure.

Most hand-tool woodworkers, in my experience, use machines to dimension lumber and hand tools for joinery and finish preparation. Spending hours resawing oak with a hand-saw makes absolutely no sense unless you’re trying to prove a point. That’s ok, prove your point, but leave the rest of us alone so that we can make things.

Absolutely. Totally agree. Use whatever methods you like. I’m not quite sure why, “Spending hours resawing oak with a hand-saw makes absolutely no sense ” got introduced into this as it doesn’t come from this site anywhere but my small 16″ bandsaw takes care of lots of resawing 6″-10″ oak and any other hard or softwood you care to name. Also, there are times when ripping thin sections of oak, and crosscutting it too, makes absolute sense. If for instance you do not own a machine nor can you nor do you want to, for instance. It is funny though, the different perspectives people have. Sadly, I see how some sectors will automatically assume that everyone in the world has access to buying half a dozen machines to work wood with, the electricity to run them and then space under cover to keep them safe, secure and dry too. Not at all according to our stats that come from the polling surveys we’ve done. It might surprise many just how few people have even the possibility of any machine type at all, let alone a shop full with a building to support them too. I think that this is a cultural thing. I recall living in the US where some people had all kinds of machines available be that a mig welder or a saw mill, table saws and planers and so on, just as hobby kit. Not the case here in the UK at all. I think mainland Europe too. I think it is true for those living in East Manhattan or part of any other major US city. The audience here is mainly those interested in hand tool woodworking but far be it exclusively. All are indeed welcome. We don’t tend to talk much about machine work. Maybe one day we will but we are answering the questions people are looking for answers to of just how can you make this or that using mainly hand tool methods.

I suspect you have thousands of American viewers and subscribers who have both machines and hand tools in their shops, as I do. As I said above, I don’t think I’m alone in dimensioning project lumber using various machines, but once that’s done, most of the time I’m at my bench using my planes, chisels, marking gauges, saws and other hand tools for the joinery and surface prep. I know dozens of woodworkers who, like me, have been woodworking as hobbyists for decades, and after retirement we spend most of our free time in the shop. I started woodworking in the 1980s, in my forties (we are the same age). I started out very modestly, but as my skills improved, so did my kit. Here in the USA I think my situation is the norm. I don’t doubt that in the UK and in Europe fewer woodworkers have the kind of shops that we do here.

I can’t say anything about making a living and a industry, but as a beginner amateur (about 1 and a half year experience) i do feel that i’m getting tired about dimensioning lumber. Where i live only hardwoods i can get are big long boards 5 to 8 cm thick and they don’t offer planing and thicknessing.

I do enjoy making joints, cuts, shapes, angels, roundovers and whatnot by hand (tools) but i can see that actually i’m spending more time on ripping and book-matching by hand, and dimensioning 2 faces to be flat and parallel thicknessed than on actual projects.

So personally, my goal is to get a bandsaw first and thicknesser (or planer thicknesser) later so i can invest majority of my time on actually finessing all types of joints and shapes by hand.

I just own a bandsaw and make everything by hand otherwise. I’m 73 and find it to be some of the best exercise i can get. When you learn to fine tune a bandsaw you can get it to cut very accurately and the wood needs only minimal planing. the other benefits are obvious, minimal noise, little mess, you don’t need dust extraction nor self protection either. The greatest benefit is you can also have you kids in the workshop when you are using your hand tools. Oh, you do need extraction when you use the bandsaw though.

Oh the tiring part was not intended in physical sense but in time consuming sense. Personally i can say it helped me a lot because if forced me to learn how the different woods, tools and body interact. So i would advise anyone to start like this, even if he/she intents to use lots of power tools in future.

I just hope that when i buy and learn to use/set a bandsaw it can buy me some time. And i’m far for being a excellent hand tool worker so i know (and want) there is so much to learn. For extraction i will have to manage with the shop vac somehow (and a diy cyclone dust collector) , for now.

Hi Paul. I typically read your blog during lunch breaks to re-center myself and remember that MY CALLING is indeed caluable and shared by others in this world. Thank you for doing so much to pass on your craft to me and so many others. I have been a full time cabinet-maker in a so-called “custom” shop for years, and I have been PASSIONATELY pursuing hand-tool only woodworking for years longer still. I spend at least 3 hours each night using hand tools and closer to 8 hours on weekends.

Sometimes my spirit can take a beating at work because the men around me have no knowledge of hand tools and therefore don’t believe they have any place at all in a cabinet shop. I have been scoffed at for removing an arris with a single stroke of my #4 or for flushing and leveling rails and stiles on cabinet doors with a #4 or scraper. Even though my methods are 10x faster than retrieving a pneumatic sander sandpaoer, air line, etc… And my doors end up as a one plane surface rather than just being dished out at the joint lines.

I need this job because my wife and son rely on me for financial security, BUT I would feek so empty without using all you have taught me. Every day I witness even my relatively small company try to implememt procedures that allow employees of lesser and lesser skill to assemble and “make”. I will make sure ti do my part in ensuring that traditional woodworking is passed down to my son and others.

I’ve run the whole circle since my grandfather handed me a Disston, farming square and pencil when I was 8 years old. Keep sawing till it’s square and leave the line. Worked as a saw man for a framing crew during summer school breaks although too young. You cut square or you went home. Learned to plane, chisel from a old German trim carpenter. Built period furniture with no electricity except lights. Started a kitchen cabinets business using all machines. Woke up my morning and my throat was closed off due to dust. Contractors that stapled plywood cabinets could under bid me anyway. Made custom rifle stocks using machine and hand tools. Ran a lot of walnut through my drum sander and woke up unable to see from all the dust in my eyes. Ended up with pneumonia and I’m a person that hikes long distances and never had lung problems. That was it for me. Moved all my hand tools and bench in a large empty bedroom. Building Charleston desk and bookcases, Pembroke tables, double dressers with no electricity once again. From rough lumber all the way. I don’t need to sell anything.

Maybe I’m wrong but I see this as the difference between writing gossip articles for a newspaper and writing a book. The articles fill the account, the book fills you. And this is nearly the same. To make thing fast and sell, it’s better to use power tools (if they speed things up). To make things for their beauty and without a time limit, go the hand tools route. Ikea vs handmade furniture. And everyone is on a different point between both extremes.

I think it’s funny how people have different perspectives rating things by speed and money mostly (I think mostly in rich countries).IKEA and Walmart cannot compete with me and never have been able to because they cannot, repeat, CANNOT, produce what I make so there is on competition. In my years of making for a living I have not one piece left that did not sell and I never had a day in my life when I did not have work. That’s coming up for 60 years as a full time maker six days a week. As to being “without time limit”: there are always time limits to hand work and there always will be. It’s no different than machine work in that sense. To suggest you have unlimited time really distracts from the reality I lived. No one lives in a world of unlimited time and if they do, I would think that there is possibly something quite wrong.