More Than Just Flipping Boards

When you find a good supplier for your wood it’s worth a strong relationship with them. As it is with many things, the choices of suppliers lessen with each year and with that comes the inevitable increase in prices. A good supplier deserves good support even if we do have to pay more. I bought £650 worth of wood this week but it’s enough for about four good-sized projects. My plans include a shelving unit, a dressing/desk table and an end-of-bed, lift-up lid chest. For these pieces, I am including some unusual use of plywood panelling which will add another £400 so I am looking at £1,000 for these three units plus my fourth and current project now where I am making a compact unit we might at one time have known as a linen press or an armoire.

My oak is what the company I buy from refer to as premium oak. These are shorts at 7’0″ long and the widths vary from 4-8″ wide. The thickness is consistent at 1 3/32″ (27-28mm). Mostly they are quarter-sawn with more or less medullary rays evident in the face figuring but all of the pieces I look for are still within the acceptable quarter-sawn angle (60-90º) and that gives me better stability with less of the cupping and twisting I might normally associate with flatsawn and wider boards. This means less work in stock prep, which is a bonus for a hand toolist bringing the stock into shape using only hand tools and possibly a bandsaw. Only in hand tool handworking do we use every muscle and sinew to work our wood. Otherwise, we stand at the infeed end and simply feed the wood through and and then wait ot the outfeed to catch and feed it either back through or feed it in again for an adjacent opposite cut. Not much exercise at all, knees locked, arms folded and such, a little walk between action now and then.

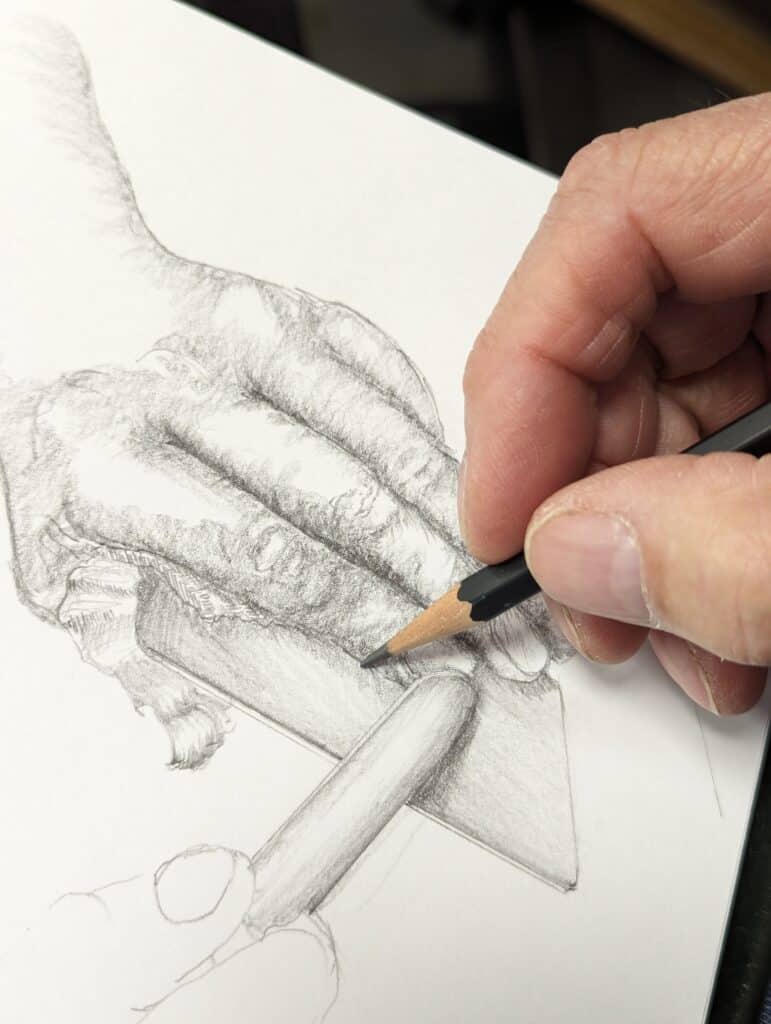

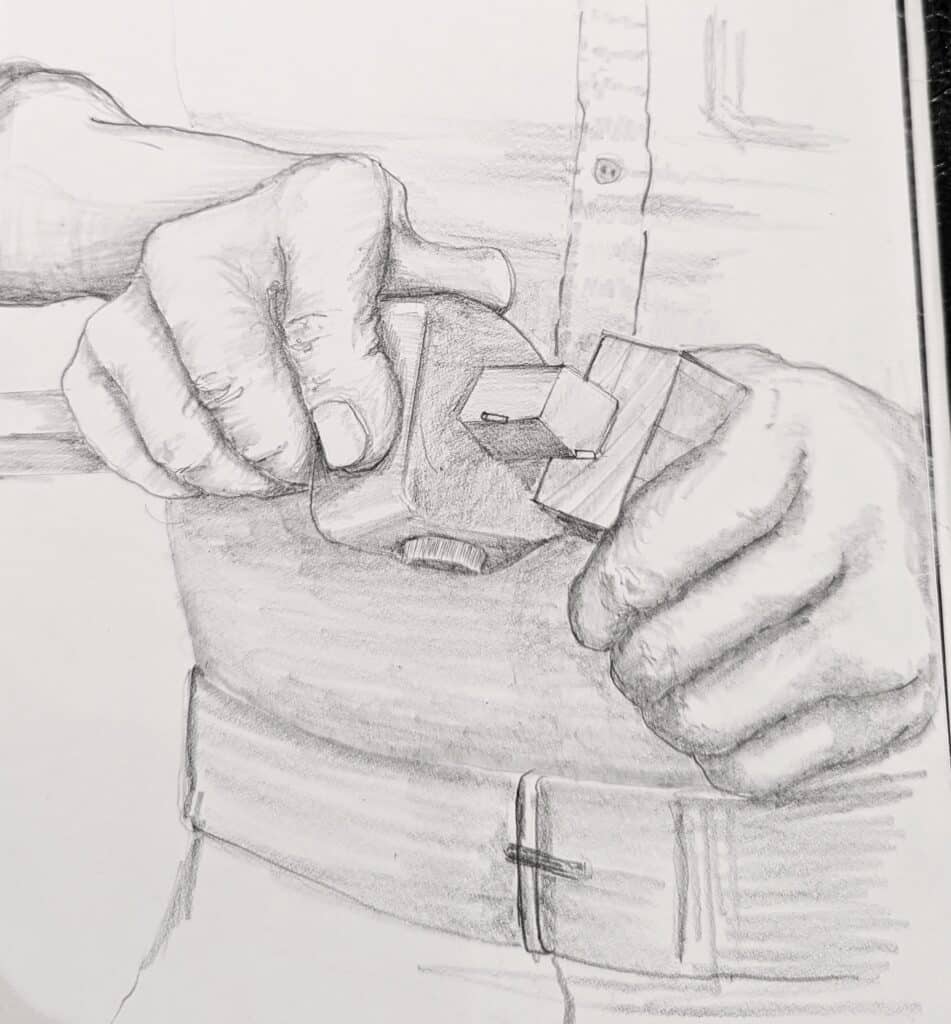

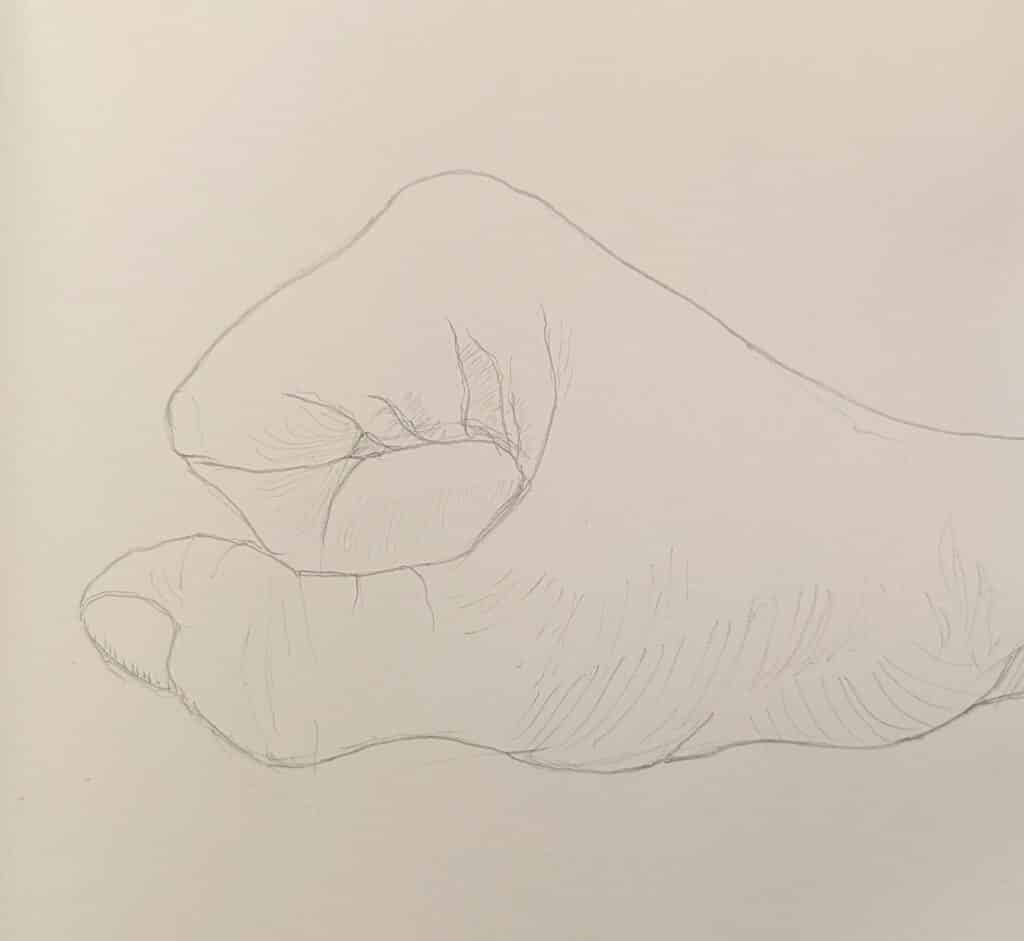

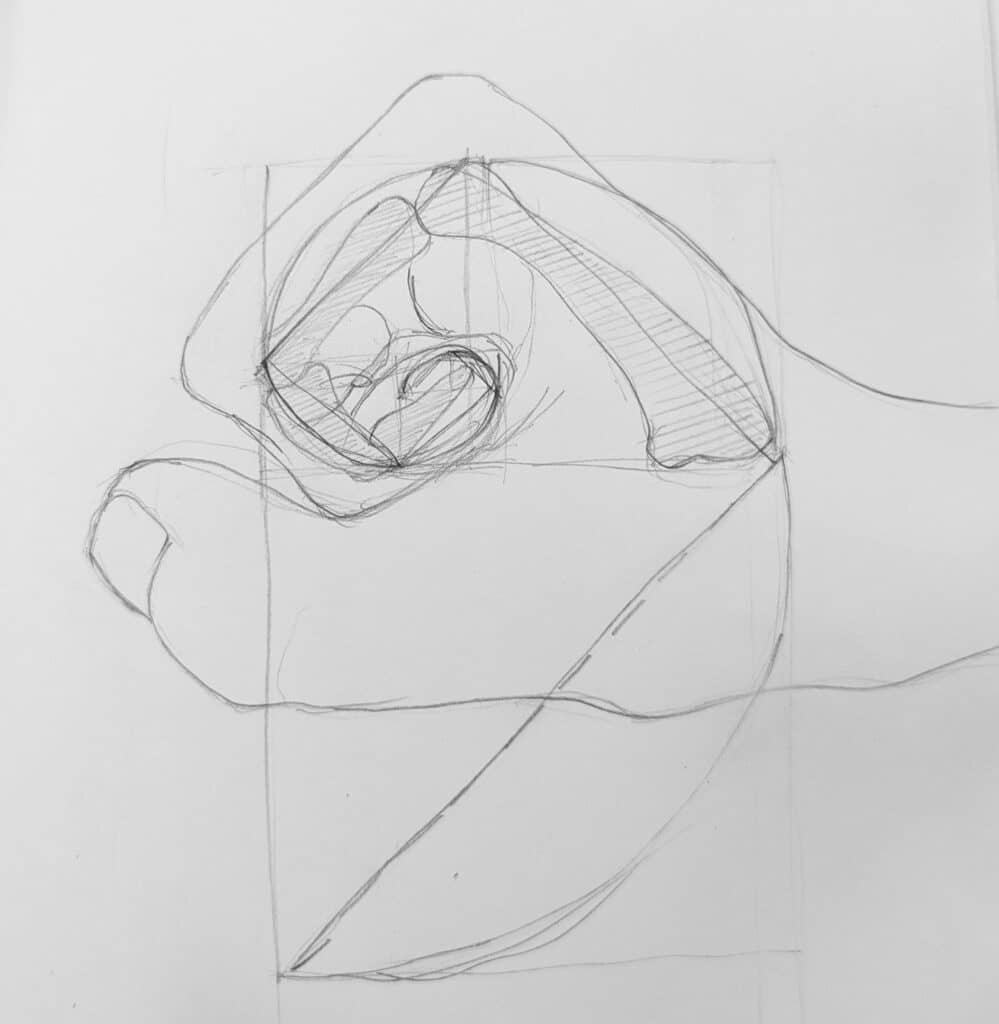

I study hands from watching the hands of others but it’s getting harder to find these ‘others‘ these days. Actually, I can’t really find them any more. Only Hannah, who’s worked with me for almost a decade now really uses hand tools for all her work. `Ever since I was a young apprentice I have been fascinated by the working hands of those relying on their own two hands to make be they seamstresses, woodworkers, blacksmiths or whatever. Who do you know that makes any more for a living as a maker in handwork? I always try to catch movements, grips, twists, stretches and so on at my graphite tip on paper. It’s a fascinating thing when you think that there are 27 bones in each of our hands and that’s 25% of all the bones in our body.

Imagine these all intricately and inextricably woven together in our mother’s womb and now full-grown and fully linked by ligaments aided by muscle attached to bone by tendons to conform to just about any task we put our hands to. Imagine this though, we talk about clicking on and following this or that link these days but they have nothing to do with the links that perform millions of tasks large and small in the everyday use of our human body. It’s easy to take the commonplace for granted and yet without them, we would be utterly lost in all that we do. Imagine the devising of such an amazing linkage capably performing all the tasks we ask of them by a chemical sending signals through our synapses in split seconds to each hand as we work through tasks in the every day. The other thing is this: they never refuse what we ask of them and neither does the left hand say no to the right. What a partnership! Here we have the unique transmission of electric nerve impulses between nerve cells (neurons) or neurons and glands and muscle cells. These synaptic connections, neuromuscular junctions keep our bodies working in the day-to-day and mostly we ignore them.

I picked out my wood with Hannah, flipped each oak board to find what we wanted, and made minute-by-minute decisions to accept one board over another and then reject another, which meant agreement at both ends of the boards. This too is a synchrony established through working together and a willingness to interact. I have worked with others who never worked as one and always twisted the board the wrong way. These are the difficult people you sometimes, maybe often, have to work with at different times in your life. Hannah and I advantaged each other by the twisting of one end to be grabbed by the other and that, I realised, comes after eight years of working alongside one another where there is an unspoken agreement through understanding what we are considering, yes, but also how we are considering.

Fibonacci sequence, Archimedes spiral, whatever you want to call it, is highly evident in the human hand almost more than anywhere else and yet we may not even notice it. Go ahead. Close your fist and look at it sideways. Unfold your hand slowly from the clenched fist and be amazed by this simple unfolding. Now think of what just happened in your brain by this simple doing.

In picking this oak I know that I can get a consistent 7/8″ thickness for my project after my hand planing and truing, thicknessing to equal parallelity and such. I can even get some pieces to finish out at 1″ quite well and that is just by using quarter-sawn. This reality is very helpful to us as individual, small-scale makers making and selling one piece at a time or working on a small batch production now and then; that’s us as the ones working in our own garage space on a more domestic scale.

Ninety-nine per cent of choosing takes place in the first glance of a board. You can identify almost every issue in a plank without touching it or flipping it as issues on one side telegraph through the board to the visible side. Before either of us makes a move the initial sighting is followed then by looking for any kind of damage elsewhere. It always surprises me just how much damage is caused by the points of the forks of a forklift that send a split through the edges of boards. Distortion will always mean loss of volume and even a small twist or cup can mean a loss in thickness of between 1/8″ and much more depending on how judicious you cut near lengths to.

‘It always surprises me just how much damage is caused by the points of the forks of a forklift that send a split through the edges of boards.’

Yes! Same here. So annoying. Especially when you pay so much for it.

Long term lumber yard and sawmill worker here, why are they selling you boards pierced by forks? Tell them to rip off the damage, they can’t be charging full price for that.

I am overjoyed that you brought up the Fibonacci sequence. Most of us ,myself included may miss all the times this sequence shows up in so many objects. I believe that it shows up in the outer universe too! Undoubtedly, at some point we will see things in that sequence that are still hidden from us, for instance: why it is there to begin with?

I recently learned that there is an arithmetic equation for the Fibonacci progression. It is one-half times one plus the square root of five. I’d give it as an equation but I can’t figure out how to type the square root of five. 🙁

It’s actually this – F(n) = F(n-1) + F(n-2), where n>1

Bob, that is the golden ratio (1 + sqr(5))/2 ~= 1.618

The ratio of successive terms in the Fibonacci series tends to the Golden Ratio as N tends to infinity.

Adam this isn’t quite right. The idea of adding the previous 2 terms needs a starting point of 2 terms – 0,1 or 1,1 or 1,2

0,1,1,2,3,5,8…

by the time you get to 5,8 the ratio is close at 1.6

Every designer leaves a mark of distinction, technique, and recurring types in what they create and the beautiful world we live in and the universe beyond is no exception. Paul’s work for example is very distinctive, type oriented and has his style of design choices and techniques embedded in them all and so it is.

that’s been my experiences here in the States

Andy

It always surprises me just how much damage is caused to fresh fruit by the grocery store workers who handle it from truck to display shelf. I have been guilty of this myself when were were short staffed but still had to get the work done.

I like to look at the hands of well known guitar players , Tommy Emmanuel , his brother Phil (deceased) , Joe Walsh , Andres Segovia , Joscho Stefan , Brian May , Django , Roy Buchanan etc …………. Each and every one of them have/had hands like shovels . Muscular , extremely educated extremities that , when working with the brain , fill my life with joy .

As a retired surgeon and amateur wood worker I find this blog AMAZING AND INSPIRING !

I am approaching 83 years young and enjoy wood and its intricacies more each day.

Mr. Sellers is a true treasure.

Wise words from a wise man Dr. Turner. There should be a statue of Paul in Mersey Square, Stockport.

Or replace the now resighted statue of Cobden on St Petersgate and Lord street?

Thanks for all the insight!

In the past few weeks I have had the pleasure of watching my 44 1/2 year old son who was born with CP learn about his left side of his body. His mother took him to the Grand Camin Island and there he received a treatment. of Stem Cell transplant. Some of them worked so he is now learning how to control himself in a totally different way. I am happy toto see the look on his face when he realized he could straighten the fingers of his left hand.

Seeing that I just turned 87 years young I know I will not be present to enjoy all of his transformation but I belive I will be abled over look ddhis outcome from the other side dddof the vale of life.

It is great to work with someone who is of the same mind, and so much easier.

I tell my grandchildren that no machine can ever do what your hand can do, or replace the computer in your head that controls it.

Even the very best AI can only make a poor attempt at what Adam could do!

Paul, I am a graphic artist and I have always contended that “really seeing” can be obtained by drawing/sketching. Very glad to see you are drawing.

Al, in the Sonoran Desert of Arizona.

I don’t want to spoil your fun, I’m sure You and Hannah developed a bond in the work.

You are right handed and Hannah is left handed. This certainly makes the movement natural for the two of you when flipping boards.

As most of us are not ambidextre, it is always interesting to have a leftie in a team.

I have been maried for 40 years but there is always an hesitation when folding linen together.

Hi Paul. I know you don’t like to promote individual companies, but would you mind saying which timber merchants this is – or even narrowing the search to a county? I’ve struggled to get a place that will supply quarter sawn oak, beyond some online dealers that are charging eye watering sums – for wood that they choose and deliver. Many thanks. Alan

I suggest you use Yell.co m for your county or a nearby one. It works well. Put in timber merchants and you will likely get a dozen or so to look at. I no longer give website details for a few reasons not the least of which it is not fair on other suppliers in the region. I also like to avoid anyone saying because I buy this or that from them that they feel the liberty to use my name as a measure of my endorsing them. I don’t endorse any of them really though I might if they are truly entrpreneurial, have truly unique product or something like that but that’s become more the rarity.

You’re an absolute gentleman, craftsman and scholar Paul! Your woodworking skills aside, you are a fantastic human being. Thank you for sharing, everything! and the woodworking tips help too.

Peace and Love from Boston

Chris

I have been getting my wood from dumpsters here in Pennsylvania. The pallets being tossed are often made from hardwood, including white oak. Taking them apart and removing any nails takes a couple of hours. Jointing and planing, leaving me with acceptable boards at no cost. Plus, no healthy tree was cut down for my woodworking.

We do cut down healthy trees with good reason and without depleting the planet’s resources. Not all trees should last for ever and neither are they intended to. Trees are often cut at optimum times for the best yield and these days are not like the 1800’s carnage of ripping out and strip cutting. Today’s foresters plant many to replace one as an investment in the future. Palletwood comes from killed trees, by the way. It’s all about balance.

The main hardwood seller that I used in the past seems to have cleared their stock, on their website now most is now only available to order. They were mainly geared to to large customers, but did tolerate the likes of me. perhaps their main customers have gone out of business. Sad, they were very close.

Yesterday afternoon in between washing the car, weeding and pruning, I made some oak bars for the cramp heads I bought on saturday. the oak has had an interesting history. Imported as ships ballast, acquired by by neighbour (ex harbour master) to use as fence posts. They were fine for decades, but I recently replaced one section of the fence as some of the posts had rotted at ground level.

I rescued the best of the timber from the posts.

I know some people are scared of using oak with iron / steel, but having weathered for many decades any tannin has long since washed out.

I cut up the oak to give me 1″ thicknesses, and planed smooth. Looking at the freshly planned wood it seemed a shame to drill a series of holes in them, but I did.

I know that you can now buy aluminium clamps were the aluminium isn’t more like lead, but after my experience with the last ones I bought, I vowed not to buy any more. I now rely on vintage steel record ones and cramp heads with wooden bars.

The average price I have paid is about £7. ( i have seen silly prices for them on ebay, but prefer to buy any in person. Much cheaper than any aluminium ones and they will outlast them by generations. I just put up with the extra weight. I avoid the newer cramp heads that use bolts rather than pins, too fiddly.

Paul, your recent blog has reminded me of how so many people these days take their health for granted. My point for this is regarding my wife. She loves to cook and bake and garden when she feels up to it. However, as of late she has all but lost most of the feeling in her hands and thus the use of them in most cases due to muscle lost. It makes it hard for her to do simple tasks at times which is very frustrating for her to say the least. As an old saying goes, youth is wasted on the young. I suppose I will be at that point one day, but in the meantime, I will still pursue my love of working with my hands as often as is possible for as long as I am able. The young ones will all be in this same boat one day but hopefully not until they have had a chance to chase their own dreams.

I was 14 when I stopped learning to write and do mathematics by leaving school and the teachers that couldn’t teach me. I became negaged with my future for the first time and lived as a master making things as at that time unmade. I never after that had a day when Ididn’t have paying work but I didn’t work for money; that just came with the dedication I had to my craft. I am sad to hear of your wife’s loss. Even the thought of it is unbearable. I do hope and pray that something will return to her and that she takes courage to look anew at her future beyond the changes that have happened.