Minimalist tools – dovetail saws

For more information on saws, see our beginner site Common Woodworking.

So you need a dovetail saw. I think that many people think that a dovetail saw is for cutting dovetails and though that is true, it is not so much a dedicated saw but simply a small saw we use mostly for cutting smaller joints and that includes dovetails. A well-sharpened well-set dovetail saw is used as much for other cutting alongside its larger cousin the tenon saw, which also is not a dedicated use saw either. Most tenon saws are sharpened for aggressive rip cut, which is exactly what you need for cutting the cheeks of tenons. A 12-PPI tenon saw with an aggressive rip pattern is not good for cutting tenon shoulders at all. The teeth are really too big and so you either have two tenon saws or use a small-toothed saw like a 15-16-PPI saw, which of course can be a tenon saw. I find I have greater control with say a ten inch tenon saw and this just happens to be the ideal saw for dovetails too and so I keep my so-called dovetail saw close to hand for the shoulder-cutting aspect of cutting tenons. Furthermore, that’s why in general I don’t advocate a 20-PPI saw because the teeth are generally too small and too hard to sharpen. Nothing wrong with the saw.

There is of course much information out there about saws. As sawmakers deliver most of the information, the info is not so much about how to maintain a saw but why theirs is the best or about features of their saws, naturally. But the significance of saw sharpening and the importance of the skill should never be dumbed down this way and never lost in the mass of useless information. There isn’t really much you need to know about a saw in terms of its maker or its material. You need good, resharpenable steel, a rigid back, 15 PPI or less – that is larger, and a comfortable handle aligned for and capable of in-line thrust. These are the ingredients of a good saw.

Though I own many good dovetail saws and use them most days, I actually need only one. It’s a 10” 15-PPI Spear and Jackson made in the late 60’s and has a fine Rosewood handle. Rosewood has a lovely feel about it. Smooth as silk in the hand, quite heavy with good balance in my hand. Though not so available today, they occasionally come up on eBay so if you want one, that’s probably the most likely place to buy them from. Other than that there are Disstons too, which have a nice fruitwood handles that after craftsmen owned them and used them they feel quite lovely in the hand. I have one with a beech wood handle I really like. I hope to go to Texas soon to retrieve my tools back to where they belong right next to me. It’s funny how my tools have become faithful friends.

The most important elements to a good dovetail saw is thin steel and minimal set – No point taking too much wood out. These are elements people don’t know. With smaller teeth you can sharpen with an aggressive tooth.

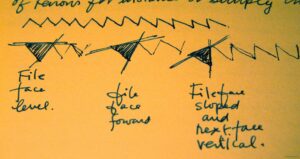

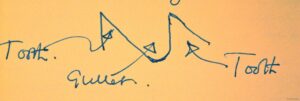

I like progressive tooth shape; that means starting with a passive rake and moving to a perpendicular negative rake. See drawing above. At the toe-end of the saw, for the first 1″, I always start with the top of my file level along its length and also across its narrow width from side to side. Then for the next 1″ I pitch the top of the file forward (as in the second step shown above) and this increases to a more productive cut. After that, along the remaining length I make the adjacent face of my file perfectly upright and this gives me my aggressive power cut – perfect for dovetail cutting when there is minimal cross-grain cutting. Where the saw may be used for more cross-grain cutting than with dovetails it’s best to make progressive change. The shoulders of tenons, for instance, or simply crosscutting wood to length.

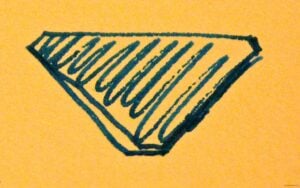

Many people think a saw file to be three-sided when in actuality they are six sided with three large faces separated by a narrow flat face, which creates an appearance of a curved gullet.

This is a pattern for a rip cut pattern used for crosscut sawing.

Paul,

So, why is the 10″ tenon saw the ideal for dovetailing? Does it make a significant enough difference that I should go find one rather than using the 14″ 13ppi Disston tenon saw I already have? I mean, I’ll probably go find one anyway, eventually, because I like to shop for old tools, but is it the kind of thing that will help take skill to a new level?

The closer the work the finer the length. You can of course use any saw with finer teeth but accuracy is lessened the longer the sword. Most of the cutting is nearer to the handle when it comes to cutting dovetails. Also, dovetails always occur in thinner sections of wood. It’s a fineness thing really. Tenon saws on other other are used for cutting through wider sections of wood and need the extra length because of this wider section in the cut.

Hi Paul, what saw depth blade size do you recommend for a tenon saw? I see some are on the smaller size and some are 3″ plus.

I think anything around 2-21/2″ to be best. Of course you can use smaller and larger but these do compromise quality of cut.

Hi Paul,

Just wondering. Why no crosscut sharpened teeth for crosscutting?

Greetings, Kees (I really like to read your blog)

Good question – simple answer:

In an ideal world fleam cut teeth make the best crosscuts. Veritas saws have a very fine fleam cut, steepbut effective. The problems occur in sharpening them to the same angle though with practice you can do it. There is insufficient difference between fleam and rip in this instance to cause concern and so I advocate a more refined tooth shape in a rip style that compensates for the lack of fleam and the difference can scarcely be seen. Because all dovetail saws have smaller teeth the teeth are then commensurate with size of cells that are the structure and substance of the wood being cut though this dies vary between species it makes little difference. So smaller teeth make cross-cuttingand ripping about the same.

That’s good to know. Sharpening crosscut teeth is indeed quite a bit harder.

I am 5’10”. Yes, they can be laminated.

You will master dovetails after a couple of tries I am sure.

Another question for you. Talking about saw sharpening and saw files, how do you tell when your file face is used up and it’s time to move on to another face?

OK, good question, simple answer. You aways choose a saw file that has facets slightly over twice the height of the tooth so that whenever you rotate the file through the sharpening process, both faces are wearing but not the whole face, only half, the half that’s in the gullet, that way, when you rotate accidentally or intentionally, these two faces are actually worn at more or less the same level. Remember that you are not sharpening one face but two; the font of the one tooth and therefore the back of the other.

Paul,

I love your blog – Canadian woodworker here moving towards more hand tools/work. I’m a bit of a minimalist, and looking to have no more than 2 saws. I was fortunate enough to find a Tizack Turner & Sons 12″ tenon saw that I need to restore (I read your article or re establishing teeth on a saw – the teeth are completely uneven).

If you were to have only one 10″ or 12″ saw, how would you approach it’s setup? 12-15 tpi? Rip pattern with progressive rake?

Regards, and appreciate all your output.

Julien

We have something coming very soon that totally transforms any old saw in a few minutes to the very best of the best. Watch out for this and just hold off for a short time for guaranteed results. It’s innovative and something you have never seen anywhere before.

Awesome!

Very interesting thoughts on dovetail saws Paul. Very much like the current debate about water stones, do you have any thoughts about the apparently current vogue for Japanese saws certainly for cutting dovetails with their very thin kerf. Regards, Chris Bailey

I have no need for them in my work. Some say that they prefer them. I cut dov err tails and other journal with equal success using either type but I prefer wester-style saws in my day to day work.

Thank you Paul for taking the time to reply. Normally, I use a western saw but I am currently trying a Japanese saw. So far, no conclusive result…..

Paul,

As a new woodworker, what makes the most sense as a first back saw?

This would be used on tenon cheeks, tenon shoulders and dovetails and other general cutting.

I am guessing:

10″-12″

Progressive Rip

15-16 TPI/PPI

Regardless of whether I am right or not, what would you suggest to buy?

I really hate the Veritas moulded spines.

I can’t find anything in my suggested configuration on eBay that’s from an old maker I know is good based on your blog and videos, whic is basically Spear/Jackson, Disston, Tyzack. I couldn’t reconfigure one but I could probably sharpen one. The 12-14 PPI ones seem to be available but that’s it unless you get a really short saw like 8″.

Modern makers — I’ve looked at Crown and PAX “tenon” saws, but the TPI seems to most commonly be available in 13. Also regarding PAX, I’m not sure of the quality.

Thoughts?

I think a 12-14 tpi tenon saw is good for tenon cheeks, 12-14″ long is good. So, a 13 tpi is just fine for this as I think 15-16tpi to be OK but a little better sited to dovetail and smaller work. I rarely will recommend more than 16tpi because most people cannot sharpen the small teeth accurately enough because of the smallness of the teeth. Both Crown and Pax are made by Thomas Flynn using the same methods except the Pax may have a final touch up on the teeth using a saw file ti finalise the teeth tips. The Crown is little cheaper, same metal sizing and so on.

I like the look of the PAX saws. My idea would be to buy a rip-cut tenon saw as you recommend above for cheeks, and then a smaller saw. Their dovetail saws look attractive but (having on experience of sharpening saws) I’m worried about the idea that I might buy a 20tpi re-sharpenable saw and then not be able to sharpen it.

If I attempt to sharpen a 20tpi saw and make a mess of it, what then? I’m sure that kind of problem is fixable, but I’m not sure I would be able to correctly assess things to figure out what I had done wrongly (in order to correct it).

(I’m finding both your blog and your videos to be excellent resources, thanks!)

“A 12-PPI tenon saw with an aggressive rip pattern is not good for cutting tenon shoulders at all. The teeth are really too big and so you either have two tenon saws or use a small-toothed saw like a 15-16-PPI saw, which of course can be a tenon saw. I find I have greater control with say a ten inch tenon saw and this just happens to be the ideal saw for dovetails too and so I keep my so-called dovetail saw close to hand for the shoulder-cutting aspect of cutting tenons.”

I was staying away from 13 PPI because you mention here that it’s not adequate for doing tenon shoulders. Well, you say that of 12 PPI and then suggest 15-16 for shoulders / dovetails. You did mention the 15-16 as opposed to having two saws, so I was hoping that would work.

Basically I’m trying to determine the minimalist set of saws that will work so my start-up budget can remain smaller.

I have a panel saw D-8 that needs re-toothed, and hopefully my big box store one will get me through the workbench so I can try that, and I should then be good there from what I understand.

But now I need a back saw.

Or perhaps one needs two minimally – a 12-13 for general work and cheeks, and a 15-16 for shoulders and dovetails?

You specifically asked what would be good for tenon cheeks and so I answered to that end. There really is no one-size-fits-all back saw. Any dovetail saw will crosscut shoulder lines and if budget is truly the issue then A ZONA 24tpi will cut your dovetails and your shoulders for under $10 US or £10 UK and can be replaced as needed. Usually a saw like this lasts a couple of years or more. I don’t really care about the saw length, but for tenon cheeks, especially in hardwoods like oak, ash, cherry and walnut for instance, I prefer the heavier weight and length of the longer saw. A 10″ will work but what cuts a lot of tenon cheek will cut a little tenon cheek within reason.

Sorry for the confusion. I was trying to ask the one-size-fits-all question.

Let me pose this another way.

Given the versatility of hand tools and removing the desire to cut dovetails for now, if a novice were to get only one back saw — either a lower TPI, longer back saw or a higher TPI, shorter back saw — and get the other one in a year or two, which would you suggest, and how would you shore up what the tool would not be good at in the interim?

For example, get the higher TPI for shoulder lines and rely on chisel split for cheeks? Or use a higher TPI on both — it’ll work for smaller tenons, even if not ideal? Following the WWMC projects, not much involves large tenons I don’t think. Some other idea?

Or is it truly a minimum requirement to have two back saws in your arsenal?

I’m fine either way from a budget perspective, just curious what the minimal tool set might look like and how a lack in this scenario might be overcome by the versatility of hand tools.

Hopefully I am making sense here.

Personally I would go for a 12″ 13tpi tenon in a rip cut and then look for a a smaller saw. The zona is an excellent shoulder-cutting saw until you get a resharpenable one. Any tenon needs a decent quick-cutting saw.

Good to know.

I have been avoiding the Gent’s type saws as I hadn’t seen you use them much in the videos and it looked like the pistol handles would be easier for me to learn how to use and keep control and keep it straight.

I’m probably completely wrong there though.

I’ve recently read a few articles wherein you’ve indicated they are superior in small joinery work.

And even one in which you called out some cheaper 15-16 TPI/PPI (various Thomas Flinn) as good, inexpensive and resharpenable. So the ZONA may not actually be needed here — the Crown or PAX or “Greaves” or whatever else Flinn is putting out there.

It seems most of them have no taper in the blade, but maybe that’s no big deal.

This may be off topic or different blog entirely, but what makes the turned handle better than the pistol handle for our joinery work? The ability to use pointer finger and/or thumb to supply downward pressure?

I’m thinking of picking up a Crown — another blog you wrote points out you had to fix a small bend in the blade and give the teeth 1 pass with a file, but that’s no big deal. Seems like a cheap resharpenable tool that may be able to tackle shoulders and dovetails too if I can get used to the turned handle bit?

Tapers are a new issue and have no real value. They can end up tapered after decades of use because the toe end does wear down more quickly because it’s used more than the heel end. It wasn’t really an intentional design. Perhaps a little gimmicky perchance?

So much gimmicks these days. I finally figured out planes, saws are my new thing to try and figure out until it’s Spring and I can get back in my shop. I would not have so many questions if there’s wasn’t so much misinformation and such out there about hand tools. I’m sure there’s a few woodworkers out there but I’m afraid to go anywhere else but here without learning more as I would likely get led down some very wrong path. I will keep trying. I’m interested in the gent’s saw’s turned handle benefits over the traditional western pistol handles now. Thanks for all the help. I’m amazed at how active and fast you are able to respond on these things, and Joseph as well here and at WWMC.

The second thing I’m not sure about is the quality of the Crown and PAX saws. There seems to be no taper at all???

Hi, I’m a newbie in woodworking and I found your blog yesterday. It’s so helpful especially for me and I just want to thank you for sharing wonderful info.

I have a couple Veritas saw for dovetails. Eventually, as my world shrinks around me, Zona saws can be added.

But, my grandfather, “Zada” Polaski, left two backsaws, (Brand: “Warranted”, of course). One’s teeth were so bad, I filed that side flat ready for new toothing. The other’s teeth are much more easily restore to a crosscut configuration.

They are both fairly heavy plate (0.02 to 0.03 inches thick). Both blades 12″ long. But they make up a pair to my eye, and I’d like to work them to be complementary.

Would it be reasonable to file one rip at 12 tpi and one crosscut at a somewhat higher number of teeth per inch. Working with American Red Oak for radiator covers (1×3″, 1×4″ corners 3×3″), would the pair of them cut tenons well working together.

I’d be able to pass them on as a matched, complementary set.

Might you refined this plan in any way?

I will get back soon Jeff. Tied up with a class right now.

Dear Mister Sellers,

could you tell me what are the thickness of the blade of the saws you use? I have got a couple of english saws which are very good but all of them are quite thick compare to japanese ones ; none of them are under 0.5 mm thick. Is there a particular brand famous for thin blades among the western maker?

Thank you for your answer.

Dear Paul,

I would like to buy a set of saws that would cover up all (or at least 90%) of my joinery saw needs. Considering my budget, I would have two options:

1.) Pax saws

Two tenon saws (rip and crosscut) 30 cm long, 13 tpi each, plus a Pax dowetail saw, 20 cm long 20 tpi. I think that the two tenon saws would cover up most of the tenons and dovetails I would have to cut. The dovetail saw would cover up dovetails in thinner stock, plus other finer tasks.

2.) Veritas saws

Standard dovetail saw 14tpi, small crosscut saw 16 tpi, cross and ripcut carcass saws 14, and 12 tpi. The carcass saws are thought for cutting tenons as well as crosscutting somewhat larger stock. The standard dovetail saw plus the small crosscut saw are thought for dovetails plus other small joinery and fine tasks.

Which of the two sets would you consider as one that covers up nearly all your joinery needs?

Many thanks!!

Denes

Not that I’m advocating for you to get into the business, but you could probably make a small fortune (maybe even a big fortune) by selling your own line of fine ww tools. That would also likely in some people’s minds compromise your integrity if any of the tools didn’t live up to some people’s ridiculous expectations, but the grand fortune is probably just waiting to be had by Sellers Toolworks..

Yeah, I know. You’ve probably already been approached numerous times about this very notion and may have already crunched the numbers and called it off. I have lots of hair brained schemes. 😉

I am new to wood world. I just wanted to thank you for your amazing lessons on youtube. They are so helpful and interesting at the same. Watching your lessons always have a place in my free time. … there is an autenticity to what you share with audience that transmits a sense of peace–along with knowledge and experience about. I really feel so.

Thank you Paul! Best wishes!