Spokeshave bevels on bevel-down spokeshaves

For more information on spokeshaves, see our beginner site Common Woodworking.

Muscle development in the hands

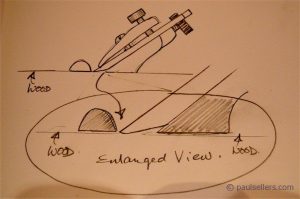

I meant to take pictures of a common problem with spokeshaves bedded at 40-45 degrees. This type includes almost all of the metal-cast models we know and love including Veritas and #151 models and more. People who tend to sharpen with micro bevels would best just sharpen a single bevel of 30-degrees. This gives an uncompromised edge with strength and sharpness equaling any micro bevel sharpening method because it delivers exactly the same physical cutting edge quality. I also recommend a honing guide for this because the short blade length plays havoc on untrained hands that have not yet developed hand and finger muscle and the resultant strength you get when development is achieved. Using a honing guide does give you the training that will reflect in the development of these key areas. To use a honing guide requires a additional extender to house the iron in as the iron itself is not long enough to hold in the guide and extend long enough to reach the stone for grinding.

My reasons for suggesting this is not reversing people from adopting the freehand methods I prefer, but resolving practical issues. Because new woodworkers do lack the strengths I speak of in their early development, they (my students all have this problem) they tend to lift the iron and deliver the wrong presentation angle to the sharpening plates. This then results in a sharper camber than with plane irons and when the iron is replaced in the body of the spokeshave, the over belly prevents the very cutting edge from reaching the wood and we end up with burnished wood not shaved wood and shavings. In some cases, the cutting edge lies compromised behind the fore aspect of the plane’s sole altogether and so it cannot possibly cut at all. Eventually of course you will want to freehand because of the slowness of loading the iron and setting it in the guide and all that that requires. By then you will have the right finger muscle for both strength and accuracy.

Cutting iron depth setting

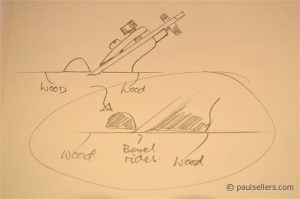

Another issue not readily seen and known is pushing the iron out too much beyond the throat and the face of the sole. This can of course develop shavings too thick and heavy for the spokeshaves and the throat opening.

I use a honing ‘guide’ with small blades like this, but it’s just a piece of 2×1″ with a saw kerf to hold the blade. It works really well and you can press down hard and also do the rounded bevel with no problem.

It just need to fit loosely, the downward pressure holds it firmly in place.

It’s a very accurate method too 🙂