Making the wall clock 6

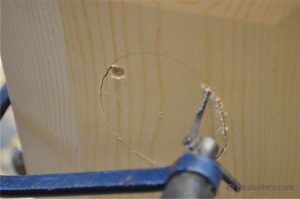

With the panel completed and in situ, I mark the centre of the hole. I take care to mark the hole at the top and not the bottom of the panel and this is important if you have selected grain for a particular aspect presentation. Establishing the distance between the two sides, I split the distance and this gives me the vertical centre-line . This then establishes the distance from the underside of the top crossrail. The two crossed lines mark the centre of the hole. Your hole size depends on the insert size of your chosen timepiece.

If you approve the position, cut out the hole.

Once you have cut the hole, you may need to file the hole to smooth out undulation left by the saw cut.

You should check that the insert fits before glue up in case adjustment is needed.