Saw Sharpening video – My Micro-bevel Method Works Great

For more information on saws, see our beginner site Common Woodworking.

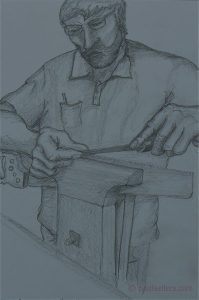

I don’t really read blogs and forums much because it would mean I couldn’t write the things I feel important to pass on. I wanted to help people establish a simple method of sharpening that works very effectively, efficiently and yet does not compromise cut quality. It follows the pattern we use for ripcut sharpening but has a progressive tooth pattern that goes from passive or neutral to a more aggressive presentation of the tooth to the wood. The end result is that in a few minutes your saw is sharp and you can use the same configuration on almost any of your saws from 6″ gents to 22″ panel saws. After that, on large handsaws, you can still use the same pattern of sharpening or you can sharpen rip or fleam cut according to task.

Here is the method we taught through our woodworkingmasterclasses videos in our online broadcast some months back. We have other methods we will expand into as time permits but you will most likely stay with this one. It’s the method I use for all saw makes and types including Disston, Atkins, Veritas, Lie Nielsen, Spear and Jackson, Tyzack, Thomas Flynn, Pax, Crown, Garlick and many others.

I hope that you enjoy my method.

Paul,

How do you go about handling badly misshapen teeth on old saws? I just picked up a saw recently and some of the teeth were in such poor condition I had to start over by filing all the teeth off and now I am in the process of filing the teeth back in. How would you go about this process?

Erik

Misshapen and distorted teeth is another story and what we teach in this video is designed to present a method that works for people to have a cross and ripcut in one saw which has been the way for centuries of woodworking. Small toothed saws with progressive teeth patterns changing the rake and strengthening the back of the teeth with a bevel gives us a saw filing method that is simple and effective and, better than even that, doable.

Restoring a saw and redefining teeth on the other hand is not a so practical in the opening stages of learing to get the rhythm and precision right. It takes hundreds of sharpenings to gain accuracy, competence and confidence and you have to start with a good saw of your own or practice on some other saws that you can get the feel on.

So, the purpose of the DVD is to get everyone started and not feel intimidated to do what is essentially a simple task. It’s about development and personal growth. We will be covering the types of saws you speak of some time in the future. Filing off teeth and then freehand recutting and filing new teeth is not generally a good starting point for the novice. We want to get people started and the best place to do that is gradually from a good saw.

Hi Paul,

The back bevel idea is just brilliant! It makes a lot of sense to me.

Also, this is a great demonstration of saw filing technique for me, a total newbie!

I do have a somewhat related question. A while ago, you had blogged about some saws being a kit rather than a finished saw. I went ahead and bought a Crown 10 inch dovetail saw with a brass back. It seems quite good to me but I don’t think it cuts well enough. I am going to hammer it the way you showed to take out some of the set and see if it performs better. Now, the question is, should I refile it to reduce the 16TPI to something less, say 11?

Thanks!

Once you take out some of the set it will cut about twice as well. Crown saws are made by Thomas Flinn in Sheffield and they make saws of different degrees of quality but the same steel, hand le and brass back is used for all of their saws it seems. The teeth are or were always overset.

16TPI is a good number and not 11 for a Dovetail saw. It will be fine and may neeed touching up with light filing.

Great Video Paul What was the file you used for putting the micro bevel on It looked like it was plastic backed?

It was an EZELap medium diamond file.

Well I tried this with an older Stanley saw and I had good success, it wasn’t quite as bad as sawing with a butter knife but it was pretty bad so I suspect almost anything would have improved it. Using your method changed the tooth shape dramatically, so I was a little hesitant – I will not be hesitant next time. Thanks, the video made all the difference.

Dear Paul,

I would first of all like to say a big thank you for all the information you have been genelously offering to anyone/everyone who came across some issue in woodworking.

I am an absolute beginner in woodworking who just happened to be interested in making something of wood. I have never had a physical contact with any woodwork professionals, e.g. cabinet maker, not even a carpenter. Nobody around me is familiar with hand tools. My only resource to seek for help is a variety of YouTube videos including yours. It took me almost 1 year to make my first chisels work, i.e. to the extent that they cut a piece of paper effortlessly, following your sharpening method.

I now have a new challenge: sharpening and setting a saw. In your video ‘How to Sharpen a Woodworking Handsaw’, you use a pink tool to create a ‘micro-bevel’ on the teeth. What is it? It looks a very fine (say, 1,000+ grit) nail polisher to me…

I would be grateful if you could clarify this.

Many thanks and kind regards,

Hello, forgive me for jumping in, but here is a product link for the item in question. Available from a number of online stores etc.

http://eze-lap.com/woodworking_shop_machine_use/hone-stone/

Medium grit i think is what was specified.

Hi Brian,

Many thanks for the info. I think you’re right and it wasn’t ‘pink’, but purple!

Best wishes.

Hellow, Thanks for teaching me how to sharpen saws! I have been learning alot from your vidoes.

I am using nicholas files and they seam to cut eqally well in both directions. I have ordered some Grobet files following your recomendation.

I was wondering why you only use the file in one direction?

Thanks David

Files only cut on the forward stroke generally. There may be a residual amount of abrasiveness, and its highly likely what you consider filings from reverse cutting is just swarf from the teeth of the file as you pull the file backwards, but withdrawing the file in a reverse-cut actually damages the cutting edges of the file because there is no support behind the edge to back it up.