Today worked well

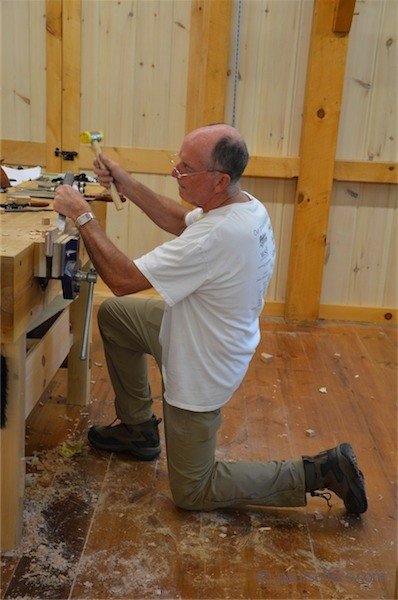

The class is going really well. Tomorrow many of the tables will be ready for assembly and on Saturday they should be done. I am writing up my findings on bench heights and at the same time quizzing them as to how they feel. I think you will be amazed at the findings.

Other things that I taught today was how to use cock bead and what the primary reasons that furniture makers used this detail in their work. I installed cockbead to my tool chest drawers using only a coupe of tools.