Making a Curve-soled Plane – Here it Comes!

Everyone needs a curve-soled plane at some time

It’s not often most woodworkers have need for a contoured seat or a hollowed bowl but if and when they do the reality of sculpting a smooth and prefect surface can present unquestionable doubt. The hollow defies flat planes, that’s obvious, and even compass planes curved in a single arc cannot help much if the hollow is truly dished. A curved plane sole curves in both directions, enabling the plane to work in more a scalloping, hollowing action. Thus any surface in any wood to any contoured area can be brought to superbly refined levels of workmanship. Only one or two steps remain before the finish richens the grain and polish is perfected by years of use by the new owners or owners.

Many hand tools make good seats and indeed many have been developed to both rough carve and finesse the hollowed bottom shape to a chair. Scorps and inshaves, travishers, curved spokeshaves, gouges, and scrapers all spring to mind and these tools all readily remove the wood to accommodate man’s posterior in comfort, but these tools come at a price that to many if not most can be prohibitive. Buying one of each will cost you around £400. On the other hand, few tools match that of the plane we are about to walk you through here and whereas all of the tools mentioned are extremely valuable to any artisan carving a chair seat or a dough bowl, the price for making one of these is about two hours work and less than £3 in materials. Give it a try. You will not regret it. If you want to wait, we also have a video coming and it will be free to any and all who own a free subscription to woodworkingmasterclasses.com

Any wooden-bodied plane can be readily made in about two hours from just about any wood ranging from spruce to oak and rosewood to laburnum. Some woods are stable and some not. Some hard and durable and some not. All woods fall anywhere in between. The choices are not as wide as it may seem, but don’t let experimentations stop you and if you need only one plane to perform one objective in a project, use any wood you have to hand. Most seats can be refined to contour in an hour after rough carving.

The traditional wood for planes is beech. Beech has all of the ingredients for a good and serviceable plane. I like other woods and especially woods like maple – hard maple – curly maple. Hard maple is a durable, dense-grained hardwood readily available in the USA, available less so in the UK. The thing that the two woods, beech and maple, have in common is that they have consistent grain density throughout the growth rings. In other words there is no hard and soft aspect to them. The hardness is uniform throughout and so they wear evenly. In the case of the plane I am making here I took my block from some very dense-grained Indian Laurel by slabbing off the sides on the bandsaw. You could do the same if you have dry wood as I have. If not, you can use any wood including a yellow pine two-by-four.

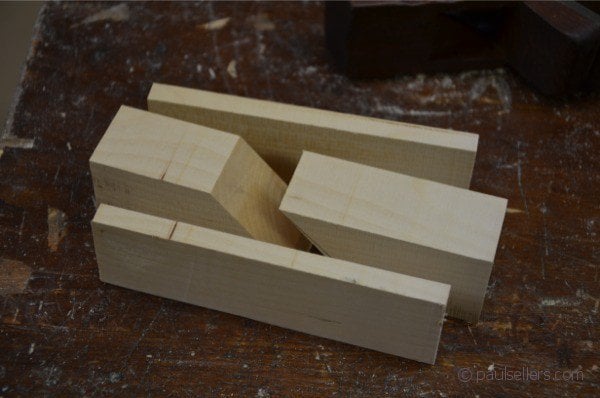

To make this radius plane you will need a block of wood 2″ by 2″ by 5″ long or pieces as follows: 2 @ 3/8″ by 2″ by 5″ long and 1 1/8″ by 5″ long. The plane is scaleable for larger and smaller versions and of course just about any radius can be made, in which case you will have to scale your wood accordingly. Use a harder wood if you plan on using them extensively. make sizes fit for purpose and develop others using the simple principles outlined in this short series. The iron measures 1/8″ by 1 1/8″ by 3 1/2″ and is made from O1 steel flatstock and you can buy it from MSC in the US and here in the UK eBay store I use. Cost is around £15 for a plate that will make about 6 plane irons.

Note: The version made on Woodworking Masterclasses requires a 1 1/2″ wide blade.

The tools you will need are:

Square

Plane

Chisels

Knife

Small hand router (optional)

Spokeshave

Marking gauge

Rasp

Tenon saw

Handsaw

See you soon!

Hi Paul & others!

Really looking forward to the stool build!

Just out of interest, would this sort of (curved in both directions) plane also be known as a Cooper’s stoup plane / clearing out plane by any chance? Or is that something completely different?

Reason I ask is that I stumbled across an old (and very detailed) Marples tools catalogue from 1938 on the web the other day (here: http://www.toolemera.com/bkpdf/MarplesCat1938.pdf ) and on page 116 of the PDF (Cooper’s tools – planes) it seems to have a plane that resembles a compass plane but is definitely curved in both directions (and besides, they’ve got compass planes listed in another part of the catalogue).

Just wondering!

Best Regards

Dave

Exactly like that.

Hi Paul, Many thanks for clearing that up! I didn’t want to assume – not that I have a stoup plane to use for this project, and they seem pretty rare, so I’ll be making one anyway! 🙂

Just also wanted to express my appreciation for your high quality, well-thought through blog posts (with dimensions, detailed close-up photos, links to suppliers, list of equipment). Just wanted to say it’s really appreciated when you’re so busy making videos and teaching and everything else you’re always doing!

I love looking though catalogues. I wonder what many of the tools do, especially the really specialised ones.

My 77 year old father-in-law – an engineer (blue collar i.e. manual worker) by trade – points out that tools are specialised and fettled perfectly for productivity. That way the Lords got more out of their indentured works, not more leisure time for their workers.

Jack

It is easier than making them from solid wood blocks because you need added tools to do this. In this we use common woodworking tools and that makes it doable for everyone.

Hi Paul,

Travishers are not that expensive, Windsor Workshops sell them, and you can buy Ben Orford blades only at Bristol Design. I am intested in the plane project, and have two old record no 4 blades, I suppose I could grind one to fit the plane. From what I see of the photos, the design is brilliant. I am glad you exist and are prepared to put in all this work!

I think that is true. I don’t think any of them are particularly expensive ,but if you plan on making one stool only they become so because they are specialised and have little use beyond chairmaking. The shop-made planes do a very good job for under a fiver in dollars or pounds and that’s why I pursued this path instead.

Thanks for your supportive comments. I really appreciate it.

Best for now,

Paul

How do you go about cutting down the steel flatstock into the needed length?

(Besides a hand sized power drill, I have 0 power tools)

Thanks,

Nic

A 12″ hacksaw will do it easily enough. 5 minutes or so.

Hi Paul,

Is there an option to buy an already made iron (cut to measures and edge) somewhere?

Not really but you could find a tool maker who would likely size one up once you make the plane body.

Try Hock Tools in California

They are so simple and easy to make and so inexpensive to make your own. I would never recommend that route if you’re making your own tools!

Hey Paul

Thanks for the great work your doing in keeping hand toool wood working alive.

Would a curved plane made with a regular 2 1/8” Stanley blade work or would it require to much muscle to push?

No, it would work just fine, no different than a travisher really which is half as wide again.