UK Bandsaw Blades With Teeth That Cut Beautifully

Over the past few years I have been getting used to British bandsaw blades because living in the US I wasn’t as familiar with them as I was say those sold by Highland Hardware of the brand name Wood Slicer.

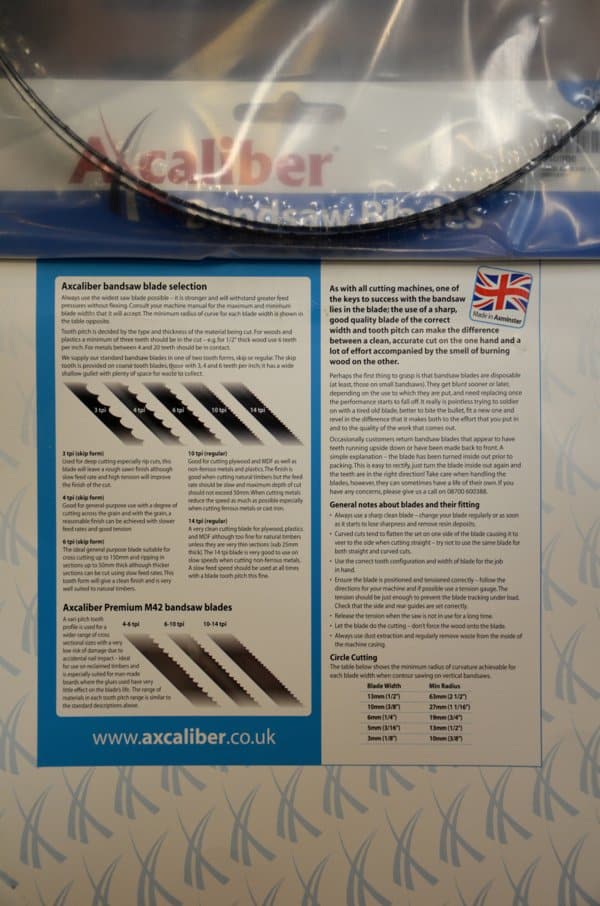

There are several makers out there around the UK but I think by far the best pound for pound blade is the Axcaliber range of blades.

I have been using their standard blade range as a general use blade and found it to have consistent hardness and good resistance to wear. A blade lasts me about a month or so but this will of course vary according the amount of use, the type of work and the material being cut. My band sawing needs are most likely less than most but I do require exactness in the cuts and expect consistency. It’s unlikely that I will switch to another maker now that I have found the quality I like.

Here are some of the package details for you to peruse. After I have tested out their M42 Premium blades for a few more weeks I will let you know what I think. Axminster have earned a high reputation for quality and customer care. One that indeed parallels Lee Valley Veritas in Canada.

I recall at the start of the year, you indicated that you were going to share some of your thoughts on bandsaws. Is that still in the works?

Paul, for years when my band saw blades got dull I just bought new. I now resharpen them by using a Dremmel tool and a cut off disk. I just touch the top of the tooth lightly with the tool and move on to the next tooth. Works really well for me. Not sure how many times I can do this. It takes me about 15 minutes to do a 105″ X 1/4″ X 8tpi blade. These are high quality Timberwolf brand blades. Do you resharpen your blades? What method do you use

If you touch the moving band saw with a carbounderum stone when you think it is blunt , this gives another life to the blade.

Here is a warning though. Whereas this can work, and if the blade is dulled already you might have nothing to lose, you can round the outer corners of the blade and not have the squared chisel teeth a bandsaw blade needs. In other words, it doesn’t necessarily work the way we might hope. Also, you personally must consider all of the safety issues surrounding your bandsaw, your abilities, your personal experience with bandsaws. Bandsaw blades are fairly inexpensive when you consider the amount of work they can produce.

I file the topof the teeth with a diamond file, sort as Paul does with the saws. A resharpened bandsaw may cutbeven beter than a brand new one. I use Starret Woodpeckers.

I think some people advocating running the bandsaw and using a sharpening plate or stones should be careful advising this as a solution to dull blades. This is dangerous and not in any way custom practice at all. I am not sure if this is what you are suggesting or whether you are just suggesting sharpening bandsaw blades with a diamond file, but I want to make sure we don’t give anyone the impression that sharpening a blade on a bandsaw whilst running is OK. In my view it is NOT!!!

I do mine with the machine off and unplugged. One tooth and at a time, takes some time but well worth the effort. The way I do it is fairly fast, but next time I might try Menegatti’s method using a diamond file.

I do sharpen on a saw vise!

I’m a little surprised, Paul, that you haven’t given Tuff Saws a try, given that they aren’t that far away from you there. Unless of course, Axminster are paying you something for this “puff”?

Best of luck to you.

A company I have used and found their blades to be top notch is “Tuffsaws.co.uk”, they will also make blades to your own requirements which might be handy for machines that use unusual sized blades.

I buy new blades.

I use my bandsaw for re sawing only its a 19″ 2 horse power, the problem I find is that I don’t get many re saws before I have to go out and buy a new blade even though the blade is still sharp. After complaining to the mob I buy them from they said the teeth lose their set and that’s just the way it is. The other issue I have with it is that I get a very loud screeching noise when ee sawing only. I’ve tried everything from rubbing paraffin on the blade to jojoba oil nothing stop that loud ear deafening noise.

Resawing is a common term used by woodworkers for what we commonly do which is simply sawing wood. The main difference seems to be that sawing wood through its thickest aspect is termed resawing but there again this is simply sawing and doesn’t really mean anything any different except that it identifies thick cuts from thin ones.

Using the bandsaw for thicker cuts obviates that deep cuts take more effort, energy and dulls the teeth many times faster. Also, cutting kiln dried and dry wood is much harder on the cutting points of the teeth; green wood takes less effort and the blades last much longer.

The screeching can be a bearing out of balance, misaligned even fractionally or of course damaged badly. Then you have harmonic screams that come from the frame of the whole bandsaw or all of the interconnected parts under pressure from tensioning the blade to the wheels.

Originally I had a 2″ wide 3tpi blade installed for slabs that blade was hard to install but they said it would be fine. The screaching started after I cut a few slabs and hasn’t stopped since, also this screaching only occurs when I resaw to get thinner planks but not on any other cut like ripping or curves. Also I find it odd in order to get the correct tension I always end up turning the tension wheel to it’s maxium capacity.

I’ll get atech to have a look at it I sincerely hope it’s not what you’ve said this could set me back quite a bit.

Bearings are really easy to change out. Usually a few minutes. There are large bearings on both top and bottom wheels and they have universal numbers on them and cost only a few pounds each. Check these by spinning the wheels with the pressure on. Newer bandsaw models in the UK may have an electric motor break on the motor which may or may not be released when the machine is off and so could stop the spin to feel or hear if something may be off. Other bearings are in the motor itself, around the drive shaft. So listen there. The last bearings surround the guides usually. Sometimes two either side of the blade; two above and two below the table. There may be a third, one top and one below the table, which are thrust bearings behind the blade. These are there to hit the back of the blade as it rotates. try spinning all four or six bearings freehand with the finger tips but think safety too. Even a hand driven blade in a bandsaw can have enough momentum not to stop when fingers are near. Also take a look at the bearings as the blade is running under power. Sound says a lot when it comes to a machine.

Not much I can today but tomorrow I will have an in depth look so far I have spun the wheels and there is a metal like screeching noise coming from both wheels but strangley when turned on that noise dissapears, however the guide bearings are not touching the blade all except for one are stiff and do not spin freely. If I do need to change the bearing in the wheels alignment will be a problem as I have never done any of this before.

I’ve only recently had the opportunity to use a bandsaw after acquiring an old DIY type 3 wheeled model for very little money. I sourced some blades from Tuff saws in the UK and found them to be very good with great advice and quick delivery.

Paul good news the bearings are fine, there is some rust on them and on all my blades but they are fine. The reason they weren’t spinning freely is because is inched them tightly down, not knowingly I was adjusting the gap loosening and tightening the wrong screws. However the screech isn’t there when I took the blade off and ran the machine it was running smoothly. I was watching a video on youtube it’s the only one that goes into some detail as to why they screech and it all comes down to the set he explains, it would be great if you watched it so I could get your feedback on this. I don’t regularly use my bandsaw and I do clean it up thoroughly after use as I’m in the habit of doing this with all my tools. I have learned quite a bit from you in this short post and now I know what to look out for but like all machines you get to know your tools and you become accustomed to their sound and operation and when something is up however small you pick it up fairly quickly. I just wanted to add the re saw marks left were ridges on the timber much like as he explains in his video. He further explains there is a small remedy by varying the set but not a complete remedy.

I found the solution to my screeching problem, it wasn’t the machine at all the culprit was the blade. I installed a new blade with different configuration as suggested in the FWW mag. a 1/2″ 3tpi skip tooth. Now the bandsaw runs smoothly and quietly so quite that when I was resawing I could clearly hear the birds chirping in the background and to top it off the cut was clean so clean in fact that the saw tooth marks left behind were about 1/32″ deep which minimises my planing time.

Thanks for this Salko. Makes me want to experiment with better blades. I often get screeching and just thought it was normal. I have the bearings all tuned up and set nicely. It does a pretty good job resawing but I’m always looking to improve results and get the most out of my generic chinese machine.

Anyone recommend a good skip tooth blade available in Australia?

I am from Australia I live in Queensland on the Gold Coast, the blade I’m now using is nothing fancy just a typical carbon blade but the 3tpi and half inch skip tooth is what’s made the difference. I bought it from Austec Sharpening Services in Nerang. Order from them and you won’t look back. You must order a minimum of 3 I can’t remember what it cost me some where between $60 and 70.

Thanks. I may have ordered from them last time, it did come from up north somewhere but it wasn’t a skip tooth so I might give that a shot next time I order. Wish I was up there right now. Been freezing cold down here at night at the moment. I’m just over 2hrs drive from Melbourne, Gipplsland, toward the East coast but inland. Was too hot in summer but now I just want winter to end. Good to hear from another Aussie following Paul’s blog.

Yes it is good to hear from a fellow country men I was beginning to think that we are a dormant society. I know where Gippsland is that is very beautiful up there I have an aunt who lives In Moe who recently moved there from Yallourn North if I spelt that correctly. Houses were very cheap there 15 years ago you could of bought a gorgeous home for 50k. I like Gippsland very much it’s very country hillbilly and great fishing as well.

You have to order a skip tooth but you don’t need to order from them just go local

Yea. I moved out here to get an affordable house 5 years ago. Can’t afford to live in the suburbs where I grew up. Great lifestyle change and been working with handtools more and more in my everyday work so its nice and laid back compared to the rat race I lived in before. Some of the locals can be a bit rough around the edges. Just wish I was twenty years earlier. This area was known for its timber industry and once grew the tallest hardwood trees in the world. Just gotta watch out for bushfires. Had to evacuate twice last summer. I don’t know what I’d do if I lost my workshop full of tools.

Yes bush fires are notrious in Australia I know they are a bit rugged but the beauty of the hills is you don’t have to associate with anyone there is a bit of distance between yourself and your neighbour. As for tools we all love to show off our tools to anyone that comes around but maybe we should limit that to our closest and trustworthy and keep those with sticky fingers in the dark and on the dole.