Rasps and wood – two key ingredients

For more information on rasps, see our beginner site Common Woodworking.

On rasps for cabinet making

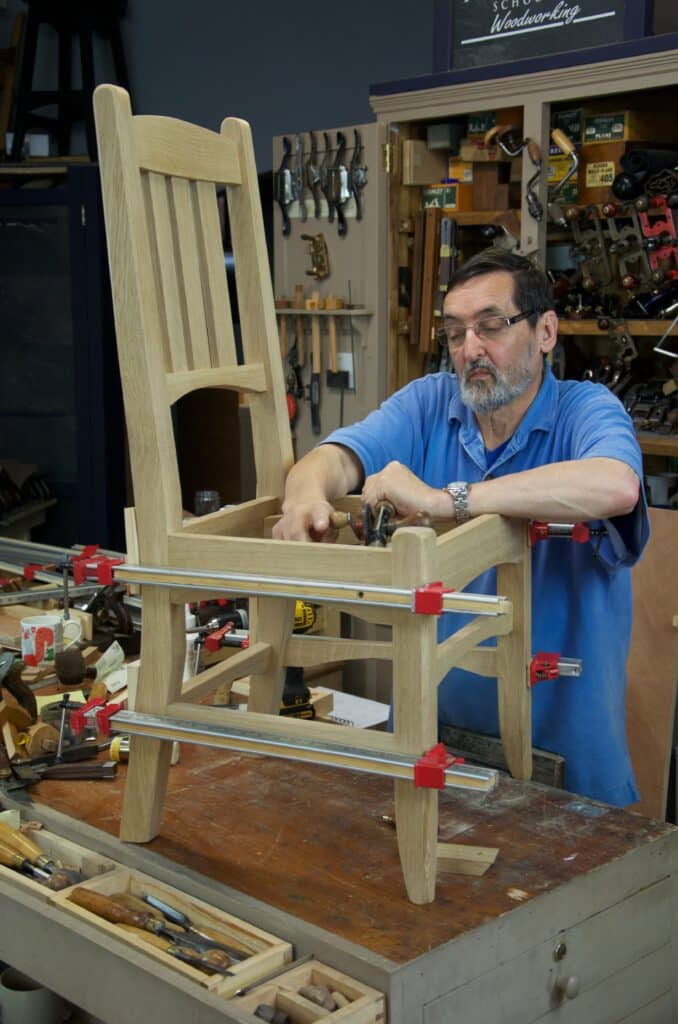

On many of my projects I use cabinet rasps and others for more detailed work because they remove stock fast and when well made surfaces shaped with them need only moderate refinement. I just finished off the latest video series on chairmaking where we make one of my designs in European what oak. To take care of some of the shaping I used a 10” cabinet maker’s rasp and used one that I have been using for the last couple of months or more. This leads me to a recommendation I am glad to make.

When I come across a tool that works well I like to pass on the information after I have used it, verified its quality and qualities and evaluated it for longevity. I have done that with expensive tools and less expensive ones equally, but don’t generally recommend tools that are low grade unless there is a reason. This usually occurs when I find a tool intended for another completely different purpose but can adapt or alter it for woodworking. A knife intended for cleaning the hooves of sheep can make a good hook knife for instance. And here’s is a knife originally intended for a foot knife to dress sheep and lambs feet but was adopted by UK electricians for peeling cables and is generally sold as an electrician’s knife now. This knife is the best pocket knife for me and I also use it as a layout knife and have had one of these in my pocket for a decade or more now. The blade is strong and thin, it takes and holds a good edge and it’s super strong. Yes, the Stanley folding pocket knife is still the ultimate knifewall knife I use at the bench, but this is a close knife to carry around. I choose less expensive tools over expensive ones if they seem to be a tool that offers a working tool of lasting quality.

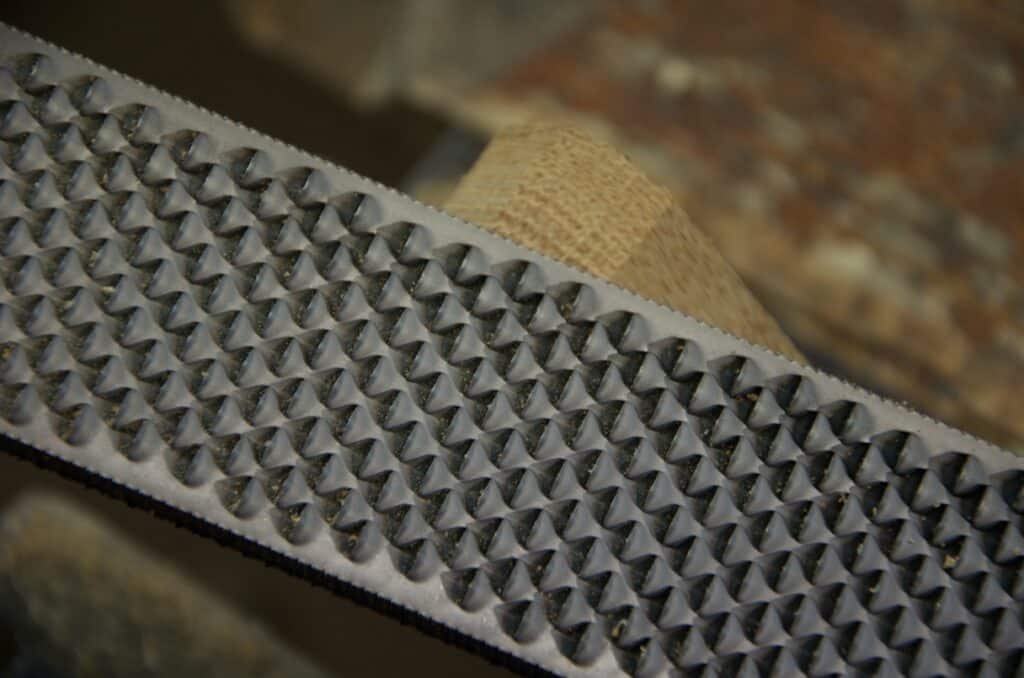

On then to a new favourite rasp that works wonderfully even though it’s not hand stitched. This rasp is from Tome Feteira in Portugal who gladly ship worldwide to almost all countries and they will ship just one item. Personally I might consider three or four different stitches from coarser to fine. I think one of these will indeed last you years of use going off my use of it so far. The hand cut 2455-250 #2 and #3 cuts work well, but you might want the coarser #1 for fast removal of material.

What I look for in a rasp is no different than most tools. I generally use a few rasps including the more expensive Liogier, Auriou and others, but this rasp is very inexpensive and it cuts so very nicely, removes stock fast and it holds up to all of the woods I have used it on, which includes rosewood and ebony, all the domestic hardwoods you can think of and then the hard knots you get in spruces and all the pines too.

Different stitches, sizes and so on, #1, #2 and #3 determine smoothness, so grading and grade choices becomes best suited to task. #3 is the smoothest. I picked this as a favourite from the ones I ordered. It’s one that compares with others made for over a £90 and gives me excellent results for under £20.

On wood supplies for the next two projects

Some of you started on our latest online broadcast through woodworkingmasterclasses last week or so. It’s the cherry Shaker sliding dovetail seat/stool/bench and in the UK you’ve asked where to get cherry from and I want reiterate the service offered by Scawton sawmills. They will ship any wood in any quantity to any destination and their prices are some of the best I have found. Scawton provide several European hardwoods like oak, ash, cherry, walnut and others. Order a specific wood type or do as I did and order a few board (square) feet of each. The cherry I bought was nice to work ,with the typical pleasant character cherry has as a hardwood. I’m hoping you are enjoying this series and learning the sliding dovetail at the same time.

The oak chair I made this week (above) for the next series was top notch too. I bought some lovely 8/4 (2”), from Scawton sawmill, that came to me at 2 1/4” (56mm) for leg material and book matching and that gave me the legs and back support rails for this chair. The 4/4 (1”) was sequentially cut and gave me a good selection. I am not saying that that will be the norm for sending out but I did end up with consistent colour as the boards I used came from the same tree.

Of course I enjoy making all of the projects for woodworking masterclasses, partly because I love training and teaching people and outreaching the globe with a new message that gives more meaning to my work than almost anything I’ve done so far, but also because I’m a maker. I also want to counter this present culture of naysayers who say you cannot make your living from working wood and be a furniture maker or any other woodworking trade. I would say that it’s all the ore viable if you are a hand tool woodworker as part of your skill sets. Most of these guys advising that you can’t probably never did or couldn’t make a living and so they say you can’t either, but it’s not at all true. I believe a small company of crafting artisans, three or more perhaps, can share their abilities and skills and be a viable entity if they learn what we are teaching. Most of my life has been spent working alongside people I have trained and most of them are woodworkers with guts and we had plenty of work, months ahead, and at one time 2 1/2 years ahead.

So, anyway, here I am still making, still teaching and of course sharing my life with friends I work with and friends beyond anything I ever expected around the world.

Paul, your comments about rasps are timely. I’ve just signed on for the Masterclasses, and from the confusion of where to start, I saw a lot of people around me using less-than-great walking canes. Poor handle ergonomics, wrong size, or just plain unattractive considering the stellar qualities of some of my neighbors. Clearly, I need two things: (1) wood to rip to size -our standard lumber here in the US is 3/4″ unless it’s special request, and (2) rasps to shape the handle, if not also the shaft of the cane.

Your video shows you using NAREX rasps. They are available here now at reasonable prices, and I’d appreciate your evaluation of them as users. I can see myself buying one rasp for finishing work, but do the NAREX rasps hold up to the work? Please note they have recently released a new set of rasps “with Fine Cut”, with a roughness of 22 cm2, compared to their former cm2 range of 10, 12, 16 and 20 cm2 (whatever cm2 means).

To focus the question, considering potential shipping costs from the very lovely country of Portugal (been there, drank their wonderful wine), would the NAREX rasps “cut the mustard”?

I must say I was disappointed with the Narex rasp I tried. It seemed stamped out and difficult to direct as I like. I’m not going to recommend it as one I would buy but am willing to try more of them to see how they work beyond the single one I used.

Thank you for your very prompt feedback. Taking a look at the clock, I’ll pull my seniority in years and comment that you are up working a bit late, laddie.

I’ll contact Portugal. On Monday.

Where did you order yours from Paul? I see nothing on the site that lets you do so.

Thanks

I went to the contact us and used the sales@tomefeteira email. They got right back to me and I ordered that way. It was superfast.

Just hope they have some extra staff to cope with the ‘Sellers’ effect. 🙂

The stack of “Cherry” boards sure looks different than the Cherry we use in “the States”. Your boards are way more lighter in color, than American Cherry. Any comments?

I couldn’t really see any difference except maybe US cherry larger and less figured. Of course it’s light to start with and darkens over a few months.

Freshly cut cherry is frequently very light in color, almost white sometimes with a tinge of pink. Exposure to UV light is what darkens it.

Have you tried any of their saw files? Thought it might be worth asking before I placed an order.

I have been testing them out and so far they have been good. I want to test them for longer and number of saws per file yield I get but the ones I’ve used so far, alongside their flat 10″ and 12″ single cut files have been great. In a few weeks I will give my results ‘officially’.

Could you give us the name of the Electrician’s Knife you mentioned in the post above? Thanks.

It’s a “Lamb’s foot” by C.K here in the UK somewhere. I am not endorsing all of their products or indeed anyothers but the knife is a great knife and I love it. Here is one of two or three types the sell. And you can get it viaAmazon too.

Could you give any indication as to the price range. I don’t really know what to expect from a rasp. All I got are these cheap coarse ones I bought at a local big box store and they’re not much to write home about. I prefer to not use them.

Nevermind, I saw now you did mention a price level, sorry about that.

Saw files are very reasonably priced though.

I use a Victorinox Floral knife or Grafting knife for marking out and find it very good. It’s not as pointed as the Lambs Foot knife and I strip wire using the v-notch on the handle side regularly (same as bark stripping). Electricians knives can be over priced.

The rasps look good, I use milled files or millenicuts for work also so I used them on woodwork projects. They’re good depending on grain direction but haven’t done much “rasping” so far….

Thank you Paul

Unrelated question but I’d just like to ask how many cubic feet of wood is in that picture? As I haven’t purchased wood by cubic foot before I find it quite difficult to visualise how much I will receive.

Thanks

If i remember rightly I ordered 15 cubic feet 176 square feet at 1″ thick.

I read your blog every day and this is another great post. However, the file size of the images has been so large lately that the posts are hard to read on any device other than a PC with a dedicated internet connection. There are multiple 10MB images in this post. Here is a good article on image sizes for blog posts: https://om4.com.au/client/preparing-image-files-before-uploading-with-wordpress/

We have always resized for the blog and so automatically sized with no problems but i looked and found the problem so thanks for pointing out what wasn’t showing my end. I fixed the last post at least.

Hi Master Paul Sellers.

Every time you mention Portugal I feel proud to be Portuguese. Thanks(Obrigado)…

And so you should be proud of your heritage and what Portugal offers to today’s world. One day I will come to Portugal for a rest.

I wonder what the shoe rasp is like? Could be handy in the toolbox. Takes up less room on the bench and you get two rasps in one from what I can tell. I’ve been looking for one like that so I might give it a go along with a half round #2. Thanks Paul. Have been waiting to purchase some good rasps.

Here’s another source of rasps, a company that sells guitar making tools and parts. I bought a couple of them and am quite happy with the way they cut. Unfortunately I can’t compare them to the some of the other manufacturers (like Narex or some of the premium brands) since I have not tried those.

The prices are quite reasonable as you can see from their website.

Here’s the link: http://www.stewmac.com/Luthier_Tools/Types_of_Tools/Files/Dragon_Hand-cut_Rasp.html

It’s much better now. Thanks Paul!

Paul, When I use files, especially on end grain, I get beautiful polished wood, but with rasps, I often end up with the desired shape, but it will be furry or even grooved. There is something I don’t understand about rasps interacting with grain or about the progression of work when shaping with rasps, that keeps me from getting what I want without a lot of sanding at times. Any thoughts? Do you need to work through multiple rasps? I’m using good rasps, so that’s not the issue.

The coarseness does make a difference but for a finer level we do rely on finer stitching. I also think that there are techniques to using rasps that take the rasp in a stoke one direction you get grooves, and, counter the path of leat resistance and you get a smooth surface. Feeling for this is what makes a difference. I have three r four rasps by different makers that work well but have been pleased with Tome Feteira rasp, even their big 12″ horse rasps that look quite big and brutal give a good and level surface in end-grain oak very nicely and very quickly too.

I just got confirmation from Tome Feteira that the rasp in question is the one sold here: http://www.traditionalwoodworker.com/8-Patternmakers-Cabinet-Rasp-5-Hand-Cut-in-Portugal/productinfo/820-1510/

I hope that I am not overstepping any boundaries by posting the link.

Wayne, Tome Feteira does retail out through Traditional Woodworker. I’d spring for a set of three, but I’ll wait until there’s a more pressing need. US$220 plus shipping is a bit of a whack. I hope those who do use them share feedback with us.

Personally, I’m going to work for a while with admittedly cheaper rasps on hand, and old edged planes and spokeshaves that I’m rehabbing now. I have a feeling that this early in my experience I might learn more that way. In a pinch, I can always fall back on carving tools.

I just picked up some beautiful scrapers from tgiag.com, which would be “Two Guys in a Garage”. They are selling (1095 blued steel) scrapers quite reasonably, and there’s another inexpensive opportunity to learn.

I could wish for a tour of the Tome Feteira factory, where they might greet me at the door with a nice bottle of Port wine in hand.

To clear up pricing here. The traditional woodworker prices are higher than buying direct from Tome Feteira because they have to make a mark up for profit. I hadn’t envisioned people going through a catalog company as TF are happy to deal directly with customers as well as wholesale. Buying directly from them the 10″ cabinet rasp 2nd cut (2455250) should cost you is 38 euros and the 8″ is 28 euros, so $40 and $30 respectively plus tax and shipping. Vat is 23% so $6-8. Shipping I don’t know but perhaps $10. That will make these rasps around $46 – $58 respectively as apposed to US catalog price of $80 and $99 respectively plus TW’s shipping, which will make it twice the price.

Paul, I sent you my contact information via your site’s “Talk to Paul” contact form. Tome Feteira have been very helpful and gracious. I simply asked the question the wrong way. Traditional Woodworking of course has to make a profit, and they have been diligent in that.

Golly, this is a self-fulling hobby for me, but every once in a while the retired businessman peeks out and shows his teeth. 😉

I’m making some cane blanks now, and with five weeks in Maine coming up (“Where life is as it should be”) I’m looking forward to trying out some work-arounds. That is what we are about, I believe.

Paul, I have tried to buy directly from Tome. Maybe they deal directly with you because you are in the UK, but they would not give me prices or instructions for direct buying. They kept referring me to the USA distributors.

Wayne, that has also been my experience. They referred me to (1) a US distributor in the sales channel and (2) Traditional Woodworker. It may very well be that they are obligated by sale contracts to go through these channels, at least in the US. To be honest, if I were an import or wholesale representative, I wouldn’t take on a manufacturing client that kept undercutting my pricing agreements by dealing directly with the public.

Exceptions are possible. For instance, vintners in France deal through import/export agents, but they have the right to either gift or sell their wine directly to consumers who have travelled to France to visit the winery and vineyards. I have had fond experience of that, but in several instances, it was limited to people in the business. I remember one occasion in which I had to represent myself as a wine consultant, and have a coughing fit whenever I was asked a question I knew nothing about.

No “In Vino Veritas” that day, but the wine was good.

Paul has a real set of lifelong credentials that puts him in a whole different category.

It would be very interesting with a comparison between the Tome Feteira hand-cut rasps, and those from Auriou.

I haven’t used a hand-cut rasp my self, but I have heard that the small irregularities in a hand cut makes for a smooth surface with a minimum of grooves, compared with a machine cut rasp where all the small cuts line up perfectly. Sound plausible anyway. And it makes me wonder why they don’t set up the machines to cut the rasp pattern a little randomly – should be fairly easy to do.

I found both makes to be good and the Tome is indeed much less costly. I did buy in a couple of Narex rasps and did not feel they offered a quality rasp in what I bought so I would not recommend these.

Whoops. Lost the entry. Long story short, I found old rasps that gave hand cut results, and used craftmanship that I picked up along the way to mitigate the shortcomings in machine productions. Body stance, arm angle, and a twist of the wrist.

Is Narex the producer of a bad rasp, a disappointing rasp, or a mediocre rasp — which by definition is average, which is what I myself am, so no big problem to get along.

Hi Paul,

I emailed Tome Feteira, and they’re also willing to ship the items by registered package which is much cheaper than DHL for shipping to Asia. I then tried to order 2455250 #1, 2 and 3 but they told me that 2455250 the hand cut cabinet rasp only comes with one type of cut. Will ask them for more information.

Keep an eye on eBay. A lot of Tome Fetiera files are up for sale, and a few rasps from time to time. Please do let us know what your results for the cabinet rasp are.

I’ve bought a few on eBay and won’t buy more until I actually get the work done (smile).

Cheers mate. Got the latest catalogue from Tome Feteira.

There’s no #1 for 210 cabinet rasp as well.

So I ordered 2051250, 2102250 and 2103250 straight from Tome Feteira to get #1, 2 and 3, and the shipping fee is so much cheaper than the ones on eBay. (Shipping to Taiwan in my case)

Since a #5 rasp is so fine, I can just use a fine file to do the smoothing, is that right?

Could you update this thread with a few other options perhaps?

I’m doing (for the first time) a little Gothic pierced tracery on a cabinet. I noticed that another person had done some and suggested using a cabinet maker’s rasp on the hollowed curve before the open area. In something small (these details would only be about 5″ tall and 3″ wide total) would a riffler be a better idea? Thanks.

Rifflers work well if well made. Pick Liogier or Auriou.

Just to add a note here I’m from Portugal and from the city where Tome Feteira factory is, I contacted them via the same email (in Portuguese) and offered to go get it to the factory and they told me they only sell in packages of 12 or at the very minimum 6 so they might have changed the rules a bit since you last posted this. Shame, I really wanted their files and rasps..Finding bahco products manufactured here is not easy task also

I just bought a cabinet and half-round rasp in cut 3 from tome feteira. I emailed them directly and was emailed back by Rowland tools in the UK for the order. So I guess indeed they changed the ordering process for single items. I got the rasps in about 3 weeks, but unfortunately they weren’t sharp at all. 🙁 has anyone else experienced this?

I have had them in vinegar for tree days and now the flat sides are sharp but not as good as I would like them to be. I’ll give them another two days in vinegar.

What I have found so far is that the rake angle and teeth width of a rasp determine the smoothness of cut, combined with the randomness of the teeth placement. I’m using the rasps on medium hardwoods. The teeth of the rasps seem a bit too wide, certainly much wider than the hand stitched rasps I use.

I wonder how they compare to Bahco rasps. Bahco is more readily available it seems. Considering they make the best files, I would imagine they should make good rasps too. And being also Portuguese as T. Feteira, I guess the apple doesn’t fall far from the tree. Can anyone offer thoughts on their comparison?

Bahco rasps would be ok for perhaps coarse work but they do not compare to Auriou or Logier. No where near. Maybe one hundredth the quality. Expensive rasps are well worth the money in my view.

This I would imagine. But I was actually thinking Bahco compared to T. Feteira?

I felt that the Feteira rasp worked a lot better than the Bahco.

Thank you Paul!