A Clamp in Time

For more information on sash clamps, see our beginner site Common Woodworking.

I grew up with cramps, the steel type and not stomach cramps, but cramps they were. When I was 15 the cramps we used, mostly Record and Woden, were sash and ‘T’ bar cramps and in my view worked to a level of perfection for that era and, until I began using alluminium ones, they seemed just fine. I suppose at first I had a sort of loyalty to the ones I used. Today that has changed. Most likely I wouldn’t use them for general work but I do keep ‘T’ bars around for heavier joinery and such.

Through the years you have seen me use mostly extruded alluminium sash cramps that are now named under the Americanism clamps. For the sake of universalism I now use the term clamps too. I am not sure which of the two terms seems the most accurately appropriate––the one most familiar or the one most common. I own about 50 clamps because of the school. It’s nice to have access to so many, but it seems we use them mostly to speed things up for different reasons.

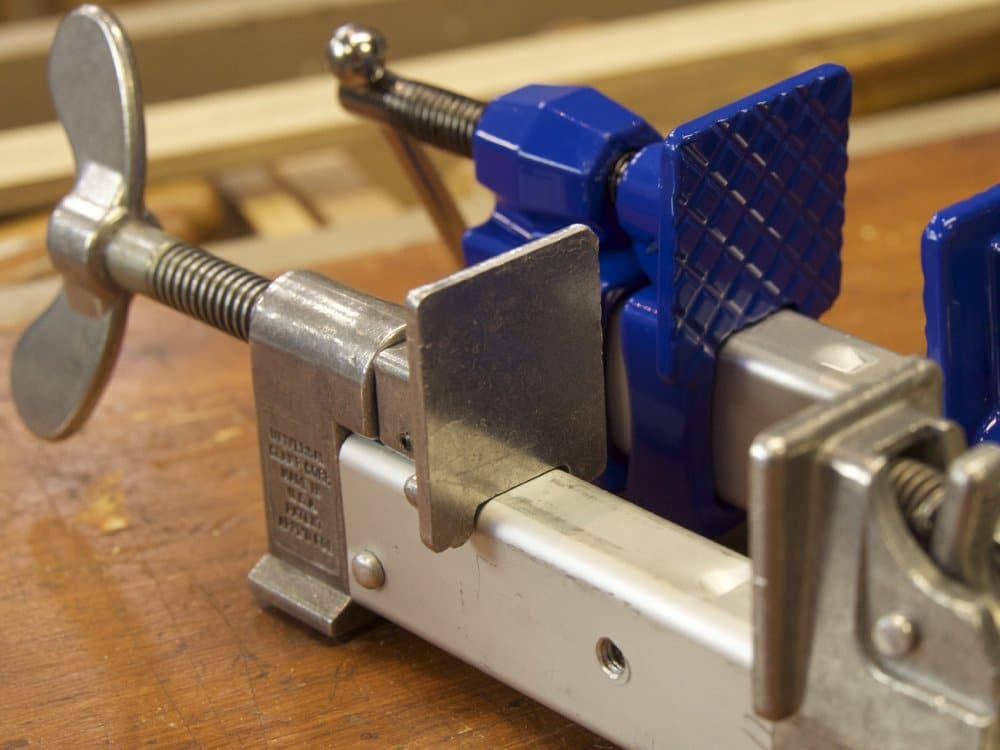

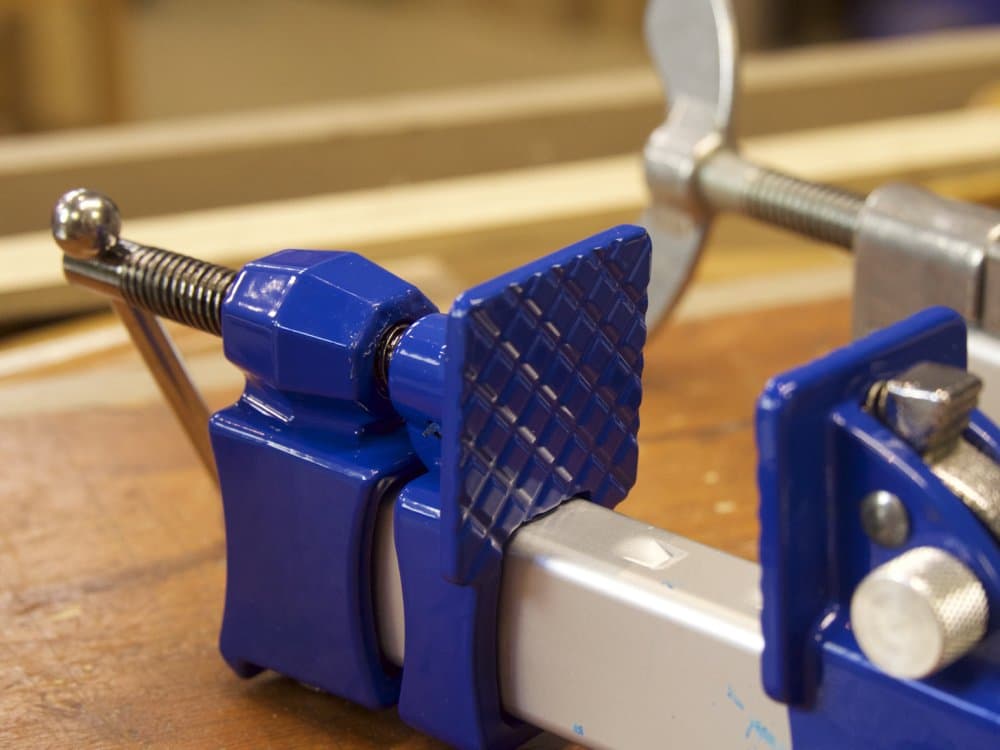

and they arrived with a couple of bench holdfasts that I also wanted to put through their paces. I was impressed as soon as I picked the Fine Tool Juuma clamps up as they were so nicely made from thick extruded aluminium with clamp heads and slides that really matched the beam’s strength in every way. I think that these are indeed lifetime clamps. Here you can see the various component parts and they are as I said arriving in Europe at just the right time because good lightweight clamps can be hard to come by at the right price.

I didn’t retrofit the beams as yet as I did with the cheaper versions as they didn’t really seem to need it technically but I plan to as I like the feel all the more. I did add the wooden pads though as the direct transfer of solid pressure through the wood seems more positive than the softer pads that come with the wood. This week I have three other new products for woodworking that I like. A solidly made bench holdfast, a new bench knife for knifewalls and additionally another video we made for making hand made cam clamps for about £1 a piece.

I’ve built my own clamps, the big bar clamp types. It was by far the cheapest option and the internet is full of designs. Pine, plywood and threaded rods basically. I think they work almost as well as a store bought one, I cannot say for sure as I have never owned or used a commercially bought bar-clamp. I only have the small ones.

There’s something about me and clamps, I just don’t want to spend money on them, it easily turns into huge sums.

Tell me it isn’t so Paul. You’ve found a replacement for the Stanley knife? I bought one about a month ago after trying several types and the Stanley is the best by far.

Another thing I wish you could do was put links to these tools you mention.

By the way, I updated my subscription to the monthly payment one and I haven’t watched very little TV since. You’re definetly more interesting.

Peter

No. It doesn’t replace it but it will run nicely alongside it.

Unfortunately for woodworkers in New Zealand there is very little choice as to what type of clamp we can get, mostly steel sash or tee bar clamps. I have only occasionally seen or used the alloy clamps you show and that was many moons ago. New Record sash clamps (600 mm) start at around $50 each and second hand clamps on Trade Me are not much cheaper and are often in very used condition making it quite expensive to build up a collection. I have half a dozen 1200 long tee bar clamps, made in India, which were relatively cheap at $30 each. These work OK but for one short coming; the thread isn’t long enough to reach the next adjustment hole, but drilling 10 mm holes in between made them usable. Clamps are an item you can never have enough of in the workshop, there will always be that one job that will require at least one more.

Clamps are way too pricey, I have a some dirty old CLS that I took out a skip and this bit nicked from a 1960’s popular mechanics, sorry for the long URL.

https://books.google.co.uk/books?id=CNwDAAAAMBAJ&lpg=PA202&dq=shopmade+clamp&lr=&num=20&as_brr=1&pg=PA202&redir_esc=y#v=onepage&q=shopmade%20clamp&f=false

column clamps made my last glue up a dream, no lateral movement at all because it was designed to just fit, saved floorspace having it all sitting on end, gravity is acting completely in your favour rather than trying to pull your boards apart.

As a massive cheapskate and rank amateur it would take a lot to convert me to real clamps, who knows maybe I’ll find some reasonably priced at a car boot sale.

Thanks for the heads up on the home made cam clamps. Just what I’ve been waiting for! The new aluminium sash cramps you bought look very interesting at the moving jaw end, a different design to the standard cheap ones. One of mine broke there when it was dropped, and although it still works the spring no longer functions and it has to be set by hand. It also slips off the end at any opportunity (easily fixed I suppose) or adjusts itself at random.

Just as an aside, I fitted all my clamps/cramps with pads cut from 1/8″ cork floor tiles, and so far I’m very happy with them. Just soft enough to not mark, and thin enough not to take away from the pressure function.

Thanks Paul, I’m looking forward to the cam clamps project update.

They are very useful in the shop without having to spend a fortune on clamps.

Thank you Paul for your wonderful lessons. I have found the aluminum bar clamps a huge help when working alone on larger projects. In the USA, the price differential for the high quality clamps was such that I spent a bit more and got the really good ones. While the butterfly handle is a negative for you, I have found that they help me when the glueup gets messy. The closely spaced detents allow a fast tightening of this clamp…more so than if a Tommy bar was present.

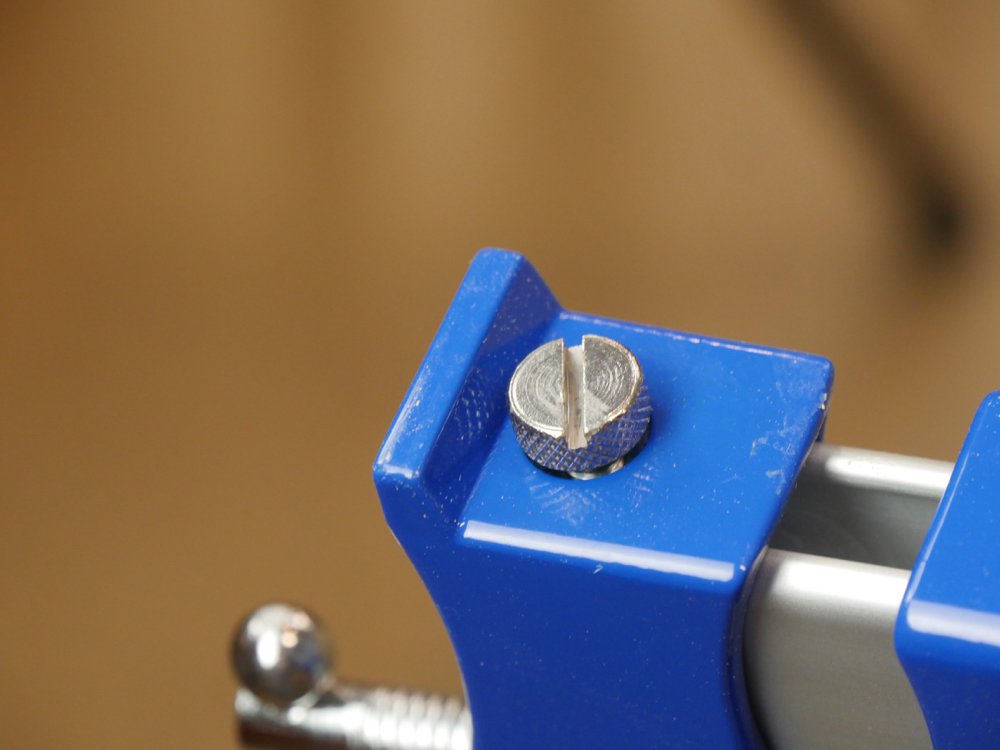

I’d be interested in how you glued the ply pads to the clamp heads Paul, in particular how you got a solid bond onto a raised checkered surface. Did you remove the paint on the raised edges so that you actually bonded to metal and not paint? Thanks.

Scott

I left everything as is and used double sided mounting tape.

Looking at the sixth picture, it looks like the head can be removed. Can you put it at the other end to make a pusher cramp?

Sylvain

Dear all,

The ‘butterfly’ ones from Dubuque Clamp Works can be fitted with an add-on for clamping corners. Two of these devices help me a lot, as I’m not always ‘dead square’ with my frames and boxes.

According to Oxford English Dictionary (23 wonderful books on the world’s most difficult language) there’s no difference between the nouns clamp or cramp when referencing woodworking.

Sven-Olof

Is it by chance a knife that is more readily available in the US?

I made some threaded rod clamps using aluminium bar with a timber lining rather than wood blocks – had all of the materials so price was free. Work well and produce pressure from both sides. Also bought cheap Tbar, steel bar and aluminium clamps – only one of each. Each had a disadvantage, but then they where the cheapest I could buy. Of the 3 I favour the single steel bar one.

HI Paul, would you know when the video on can clamps is going to be out ? I can’t find them here in the Philippines and I need to build few of these ! All the best and Merry Xmas to you and family. Daniel (ICRC)

So far I have been happy with the Harbor Freight aluminum clamps I bought for my bench build 3 years ago and have held up well. I have several of the “heavy Bessie ” clamps which are great but they are a lot heavier also.

Steve

Hi NZ Pete. Also in NZ, I share your pain with regard to tools. For Paul’s bench build I needed sash clamps and got a couple of old Wodens off Trd me, but as you say they fetch a good price and need a bit of work removing old glue etc. I got a few more from The Toolshed, which were cheapish and are actually very solid and good – the store manager told me they are from the same Chinese factory as the well known blue ones. That being said, I do think we get some Trd me good deals on old woodwork tools, and I’ve certainly got good value vintage Stanley planes compared to the famous UK auction site (spend a bit of time in UK too). I’m yet to use my new bench, and am hoping that the NZ Radiata pine won’t be too soft…

+1 for the Juuma clamps. I bought a couple about 1½ years ago. Very fine quality, easy to adjust and a good design on the important details. At this price, I don’t need to bother with fittings and pipes. The aluminium stock makes them lightweight, but they are still plenty strong and durable for their intended use.

I use mine both when glueing up largish frame work, such as doors and windows, where I just need to align everything and keep it steady. And I use them with some battens as clamping cauls for glueing smaller table tops and panels, sometimes adding a couple of pinch dogs (like Paul’s) to the ends.

I use hide glue and just need to let it set before standing it up against something. With these, it’s very simple to remove the glued-up piece without disturbing it too much.

Where is the video about making cam clamps? I have looked every place on your members website and can not find it. Is it on YouTube? HELP!

We will announce it when the editing us done. I only posted that I had spent some time filming the video. Not sure of release dates yet.