Craftsman-style Rocking Chair Series Coming Soon

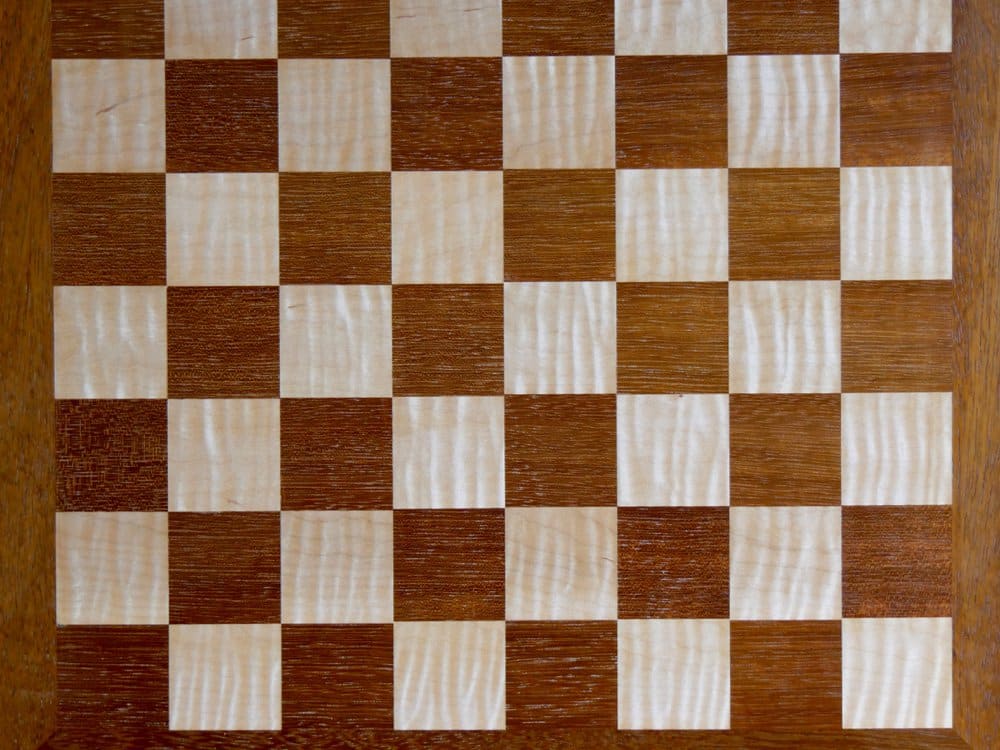

Since we made the beautiful chess board a few weeks ago we have progressed considerably and generated many more projects for you ongoing ‘apprenticing’.

Woodworkingmasterclasses.com has changed the way we reach out to woodworkers from when we could only impact on a local level to now reach all the way around the world. Whether you pay or take the free subscription, it’s all good stuff and I want you to learn everything I know to pass on. Whereas I will always enjoy one-on-one with people around my bench, woodworkingmasterclasses has proven to be a remarkable way to ensure people have 24/7 access to unencumbered teaching. If you get chance to look through our archived list of projects and the way we teach since we began filming, I think you will see that the expanse and quality of the projects caters to anyone and everyone no matter their skill levels or background.

Beyond that, yesterday I applied the final wax to a shellac finish on my rocking chair. Yes, it is the Craftsman-style and yes it will be the concurrent series taking us through to Christmas but we also have some Christmas projects as gifts and decoration for Christmas planned to intersperse up to the Christmas season.

I have enjoyed filming all the above projects but more than that are the emails and messages you send me. Life-changing is probably the number one statement people make. Next is downsizing the machine footprint in the workshop and then there is the acknowledgement that for most people their health and sense of wellbeing is markedly improved. I have known and experienced this throughout my woodworking life. Whereas only a few of you will actually go on to become full time woodworkers, that is not the goal of what we do. We just want people t have a better understanding of real woodworking and we’ve done it. From here on it’s all icing on the cake!

Excellent.

I’ve been making a version of this type of chairrecently I’ve and got to the dry-fitting stage by now, working it out as I go along, so I’ll be very keen to see what happens with Paul’s chair.

Shaping the rockers was a bit tricky…..

Paul,

I stumbled on to your teachings about a year ago shortly after I started woodworking. I was building my first workbench and around here everybody was chanting Roubo, hard maple, walnut… yada, yada, yada. I wanted a bench that I could work on, not one that I could eat off of. Your workbench series on youtube sent me in the right direction and I have not looked back. My machines now begin to look like large expensive noise makers. I have totally enveloped myself in hand tools, lost a few pounds in the process and have built some nice pieces. My dovetails are still a “work in progress” but I will never cut one with a router. I enjoy the piece and quite in my workshop during the creative process and absolutely love using tools that past generations use. Picking them up from flea-markets, whether it be planes, saws, chisels, screwdrivers or files and cleaning them up, bringing them back to life, and using them is not only self gratifying but also empowering. You have taught me more that I ever thought possible through woodworking masterclasses and truly appreciate the effort and energy you must put into this. I only wish that I started my woodworking when you were still in the states, I would have came to one of your classes.

I cant wait for the rocking chair build. Mother has an empty corner in her living room that it will look great in come Christmas.

Best regards,

John

just try not to get sawdust in that hi-tech photo equipment!

When I first started with digital cameras I was indeed worried about this, but then I realised that the equipment was outdated before faults could ever occur from dust. My first camera cost me $1,200 for Nikon Coolpix 5700 which was about a 5 mp camera. My first 1GB memory card cost me $1,100. How things have changed.

I’m still paying off mine

Thanks Paul. I’ve been watching all of your videos over the past year as I’ve moved from wanting to do woodworking to actually doing it. Finding you online was perfect timing. I had finished remodeling my garage and was planning to fill it full of machines. Then, I came across you and one other person online and completely changed the direction I was headed. I am not one who willy nilly changes their mind but what I saw and felt with the wood working by hand was too profound to ignor. Having watched all of your videos in a compressed timeframe has shown me that you have really also improved your skill at capturing it on film. The early videos were good but now things are much better lit and the sound quality is excellent. I have enjoyed seeing this get better almost as much as I have enjoyed the woodworking. Mostly it shows me you are stretching and learning as you push into online.

One question about the rocking chair (I know it’s not out for a while on the MC series), what changes would you make if you were looking to have these as outdoor furniture that is more exposed to the elements? I am in need for some outdoor leisure furniture and I could see a pair of chairs to be something my wife and I would really enjoy.

Paul, I have often wondered: When it is not a table, what is it? 🙂

Really like your new studio space… excellent light and acoustics for videos. Good move (from castle).

This is off topic but I was wondering if your planning any classes in the U.S. In the near future. Thank you Thom

Are you going to show us how to make the rocking chair from one slab / piece of wood? Or are you going to have dimensioned pieces already cut to size? I think it would be most beneficial to show how you go from say one 8/4 piece of wood to finished product. Thanks.

Bit hard now that it’s made. Not sure what you are asking for here. If most of the components are made from 1″ (4/4 USA) rough-sawn material I wouldn’t use 2″ (8/4 USA) rough-sawn? What we did in this video, to help people see that I actually made the whole chair with hand tools and didn’t switch to machines elsewhere off camera, or have someone else do the work, which doesn’t happen either, is we time-lapsed the whole to cover the repetitive sections. Oh, and I did ripcut 2″ rough-sawn for the sections requiring thick stock, such as the rockers, legs and back support rails. I also ripcut the square spindles for the back from a wide board. I think this will answer your query, Wayne.

Paul, thank you so much for taking the time to reply. I have wanted to see this rocking chair project on video for some time now. I even have the back issues of the woodwork magazine that you did the write-up for this chair back in 2004-2005. One thing that I wondered was how you got the rockers, legs and back support rails, if you didn’t use 8/4 stock. But you answered my question with your reply.

I guess a better description of my question would be how you layout for the larger pieces so that there is minimal waste. Your dining chair project looks similar to this rocking chair, so I will re-watch those videos as well. Thanks again!