Poor-man’s Saw Tooth Setter (tutorial and video)

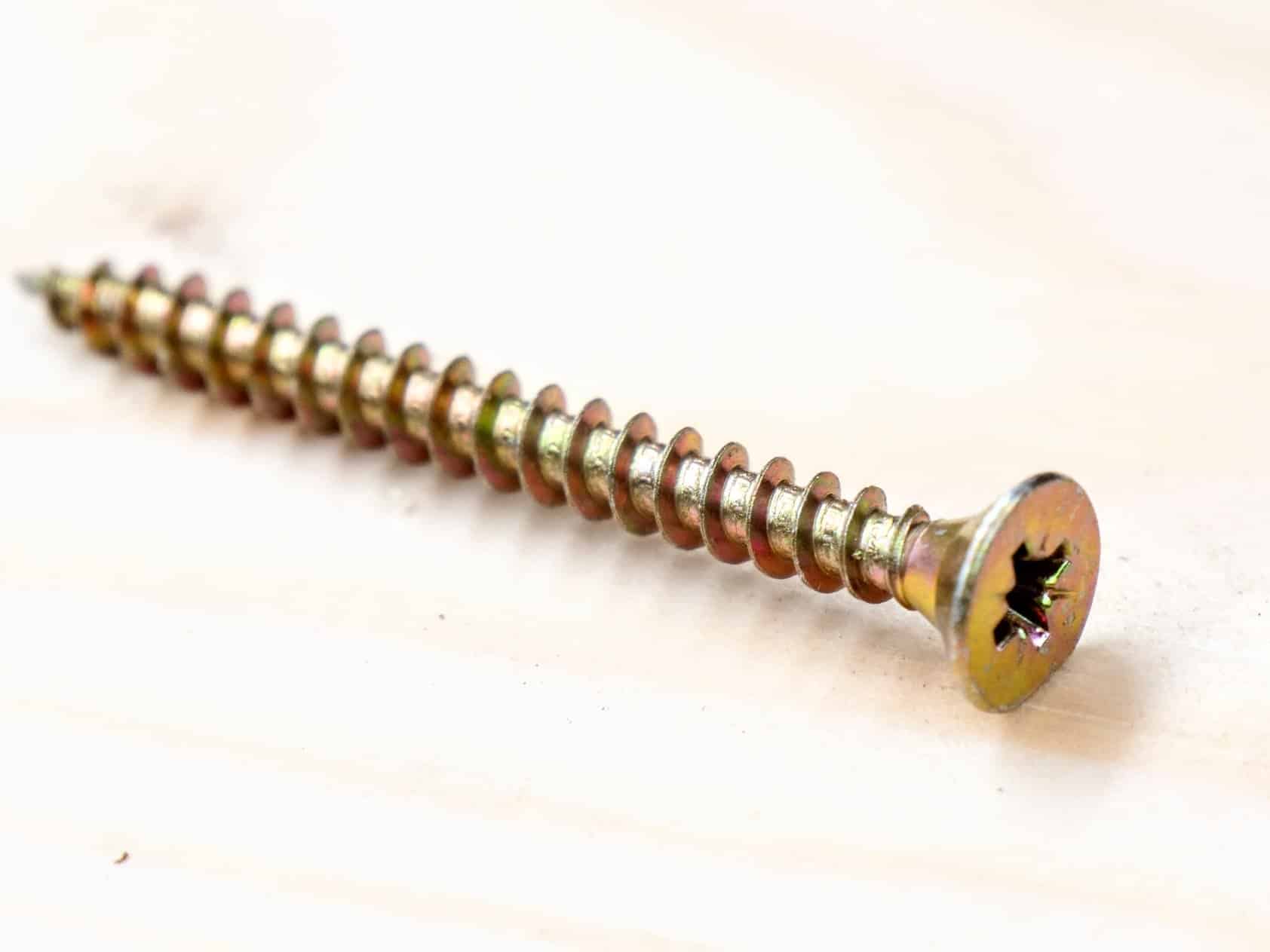

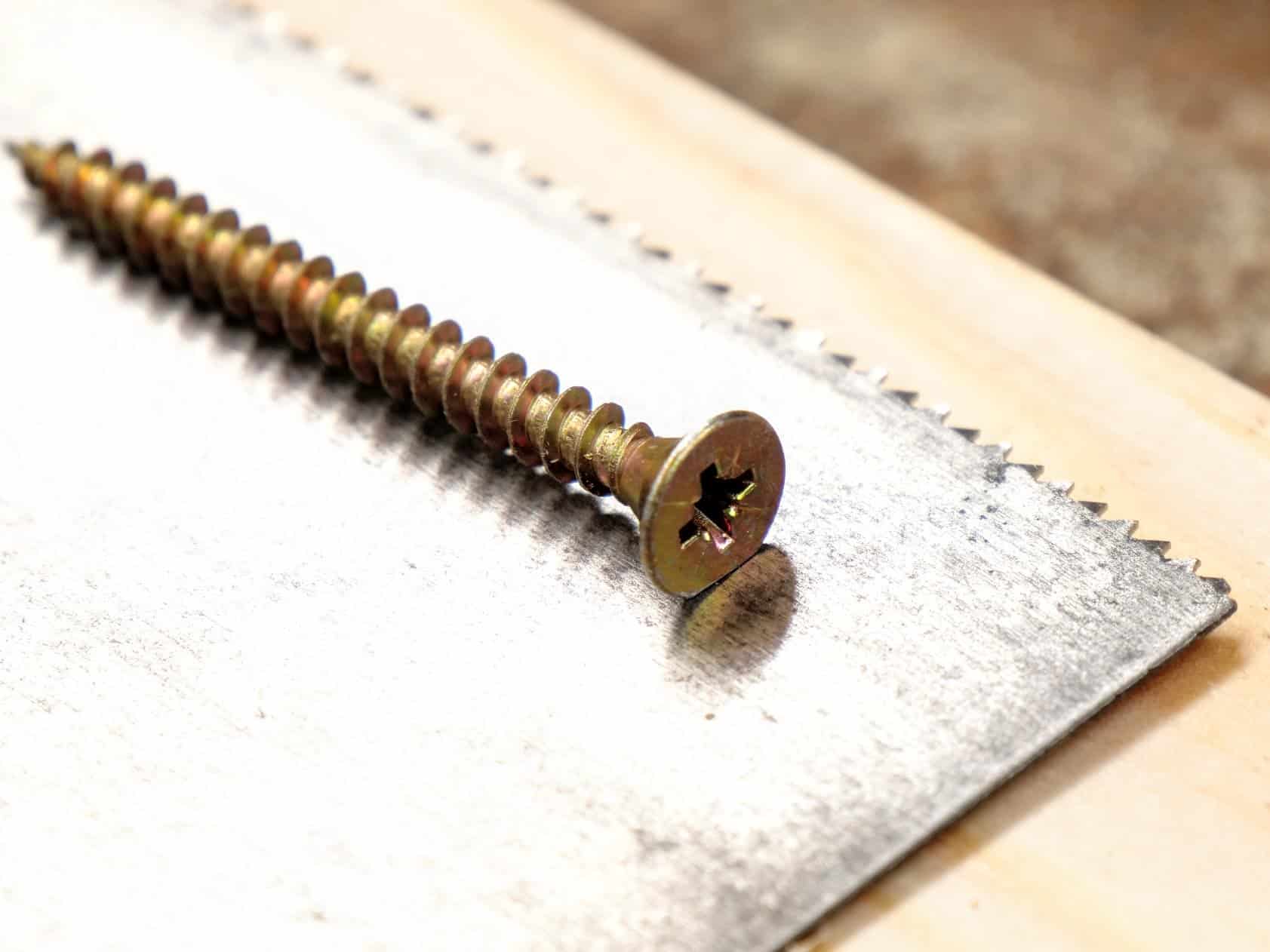

In a fix recently a small toothed dovetail saw needed setting before I could use it and I had no access to the usual nail punch (set USA) I use. I looked high and low for an alternative possibility but found nothing remotely suitable until I found a 2″ long wood screw.

Perhaps, I thought to myself, I could use this punch-like on the side of the teeth as I do normally on smaller teeth like these, but with the first couple of attempts the point glanced off the teeth without setting anything but my own teeth on edge.

OK. if you’ve read the blog you’re entitled to watch a very brief video on how it works here:

That’s brilliantly simple. I’ve heard of saw sharpeners of a past era setting saws without a saw set, but never seen it done. How was it done?

Oh just discovered Paul’s video on masterclasses showing the hammer and punch method for saw setting. Question answered.

This is a great idea. I don’t have a saw set yet but I have a bunch of screws. Looks like one is going to be made into a saw set and go into my “poor man’s” drawer with all the other tools ive learned to make from you. 🙂

Is this garage workshop? Can we have a tour? 🙂 you mentioned in some blog while a go about saving floor space… Anyway, thanx for all…

I love simplicity,Paul. Thxxxxx a lot.

I will try this! I been having trouble setting a 16pt saw. Thanks!

Other people sell things on their blogs; Mr. Sellers teaches us to think and work through issues without quitting. Thank you so much, Paul!