I Sorby #3 Joins the Fold

My choice of hand plane is the Stanley (or Record, either way, or the Woden too) #4 for 95% of my tasks at the workbench this basic plane works best for me. New, old, no matter. I also use the Stanley #5 as a second if indeed I do feel the need for a longer plane. I don’t find any use for the longer planes I have and probably should have left them aside. I have little use for a wider one even though for three decades I combined the use of 4s with 4 1/2s and 5s with 5s with 5 1/2s. The makers name makes little difference to me at the end of the day one’s as good as the other and that includes what’s now called premium planes. Most are overweights and need a good slim down. Inevitably I get identical results from even the cheapest plane in the poorest condition within a few minutes.

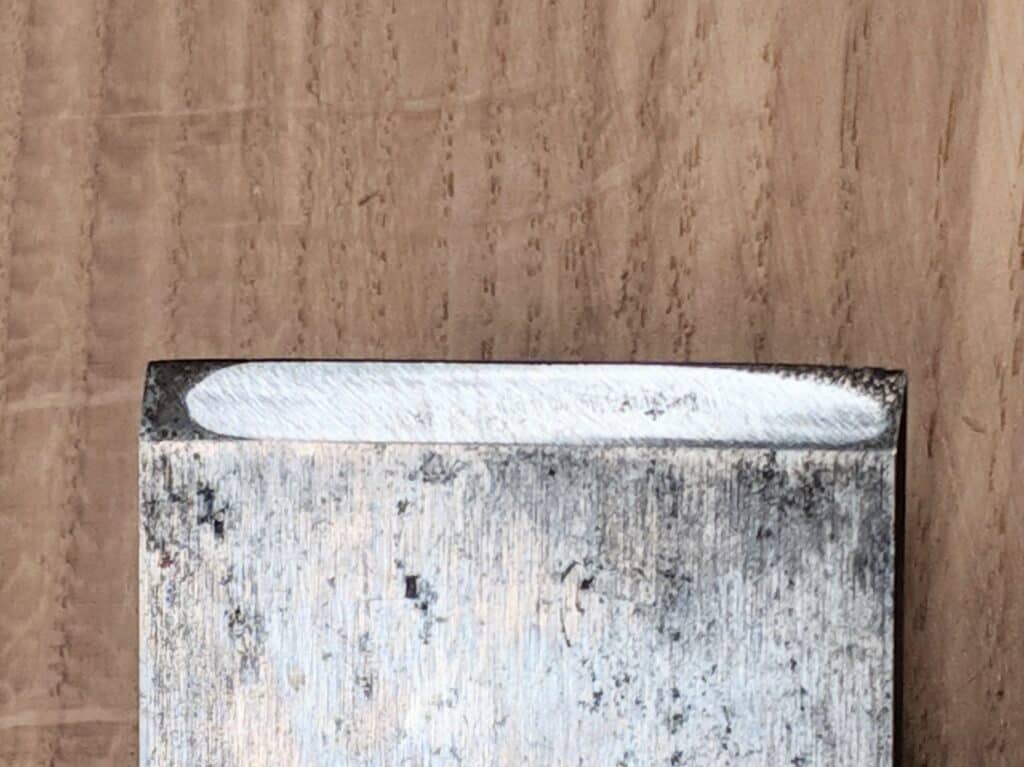

I did pick up a unique plane from the Bailey-pattern stable this past week, another rare find from an eBay seller. I tried to get it for less but the savvy seller knew what he had and rightly clung to his price. On my end I may have paid more than I should but truth is I had yet to see an I Sorby #3 anywhere before this one. It came just at the point when I thought I’d got the whole team of I Sorby planes from betwixt the two world wars. This one is in lovely condition and after sharpening and still some need to flatten the sole a bit I am happy to have it in my collection of I Sorby’s last gathering of planes. There is a good chance the series was not actually manufactured by I Sorby as such but by another company that bought them out or more likely just bought the name rights prior to the Second World War. Many tool makers were unable to continue and neighbouring tool makers bought them to increase their falling sales market. Though the plane is in good condition it was still a user in its day. The handle has user patination as does the rest of the plane. I enjoyed dissecting the carcass to find out whether the user was a full-time carpenter or not. He was.

My plane has the usual kick of a #3. The mechanisms work smoothly and respond like a well-trained sheepdog and that only comes from a well used plane where the rough edges have been worn off and greased by human hands. I was surprised that the sole hadn’t been truly flattened because it was actually twisted which means it would be impossible to true up any surface without creating an exact opposite twist. It’ll flatten easy enough when I get a few minutes. I may ask Hannah to do it as she is very good at things that require finessing.

There is no current rust but a little evidence of patination from rust sometime in the past. No pitting though.

I don’t know about the parts interchangeability of the various generations of Stanley planes but I just bought a very nice type 18 no. 4 plane from Jim Bode for $69. I don’t have the patience for eBay but when I do look it seems like people might be parting out planes to try to get more money than the total would be.

In regards to large planes, I bought a no. 8 at a junk store about 20 years ago. I don’t remember what I paid for it but considering my means at the time it couldn’t have been much. I bought it on a whim because I had never seen such a beast. I don’t think it’s necessary to have but I sure do think it’s fun to lean into that jewel and run it down the edge of a board.

Hello Paul,

Are you asking specifically for a US-made no 4? If not, I have UK-made one with a corrugated sole that you are welcome to have.

I bought the plane from a local (studio) cabinet-maker about 8 years ago when he was switching to all-wood (Krenov-type) planes. Though it is probably from the mid-1960′ and has phenolic/plastic handles, it has always given prima performance from whisper-thin to hogging as a scrub plane. I have never experienced this plane as inferior in quality in either castings or fit. I have since switched to Japanese kanna myself (for no other reason than that their quirks and temper seem to agree with me) — so for the last 3-4 years the plane has been relegated to jobbing – removing paint from and fitting windows and doors. So it does have some scratches to the sole. On the plus side, it has been a jobber all its life so there are no deep rust pockets etc.

I can find it and take some pictures during this weekend, if it has any interest. I just need to know where to send them.

You are more than welcome to have the plane for this project and spares — I would rather do that than sell it.

One thought, though, wouldn’t a skilled welder be able to weld together the crack in the original sole?

Let me know if this corrugated UK-made #4 sole has any interest.

Kind regards,

Henrik Lützen,

Copenhagen, Denmark

Paul, you mention that the quality of the planes are equal with respect to Sorby, Record, etc.

Sorry that I digress from your sharing about completing your collection of planes.

I’ve a 35 year old Record 04-1/2 that’s a challenge to set. Especially the frog,

It seems that the frog is ‘too low’ and the blade is not ‘resting on the frog.

Any suggestions of how to remedy the situation?

Cheers

I’ve worked with a lot of very skilled welders and have done a little bit of welding myself. You can not repair a crack like that in cast iron. The heat from the process will distort the tool by warping it and making the material around it brittle. In fact you would have to get the tool red hot just to try and repair it. I always try and make sure I use my planes over rubber mats or wood floors, concrete is not very forgiving.

Paul

I don’t have a #4 body or I would definitely send it to you. You may want to try New Hampshire Plane Parts. The have a very nice ebay store.

Agreed on NH Plane Parts. Very good chance they would have what you need. They also have another web-site, thevintagetoolshoppe.com. They are a true mom and pop operation. I am fortunate to live less than an hour from their storefront here in NH (USA) and I get my hand tools from them.

In reply to Tom…..maybe Tom should talk to Dave Bardin, of Chisel & Forge….as he actually repair that same sort of crack in the side of my Millers Falls No.14 Jack plane, and posted a “how-to” video of the process…..Dave used a Silver Braze rod, the torch had a No.1 tip on it.

The key is not only a pre-heat, but also a SLOW cool down….might be worth a look at that video.

Been in use ever since.

Another size plane Paul may want to check out…would be what Stanley called a No. 5-1/4 Junior Jack. Same width as a #3, yet not quite as long as a #5.

Paul,

I have several Stanley No. 4 planes. If you are asking for a donation, I’m happy to oblige.

“The makers name makes little difference to me”

I get your point, but different makers sometimes use different thread for the depth-adjustment knob; Stanley uses left-hand thread, where turning the knob clockwise (when viewed from behind) will increase the depth of cut. But a Dutch brand, Nooitgedagt (lit. “Who’d have thought”/”Never would have thought” – yes, we have some peculiar family names), which is still pretty common over here despite being out-of-business (1865-2010ish), uses normal right-hand thread for the depth-adjustment knob. I also recall handling an older Indian #4 plane at a thrift store (can’t recall the exact brand) that used RH thread for the depth adjustment. It was otherwise in ok condition but I didn’t buy it because of the reverse depth-adjustment.

I’ve found it annoying to have a mixture of planes with LH and RH threads, so despite having a few pretty nice (and cheap or even free) planes, I don’t use them because of that RH thread. It’s either all RH or all LH for me. And since my first plane was a Stanley #4 with LH thread, that’s what I’ve got used to and will stick to.

Bit sorry to hear (again) that you don’t see much use for a #7. It’s the plane I enjoy working with the most (that and the wooden router) because of the ease with which it produces perfectly straight edges. But yes, it gets used much less than my #4. Perhaps I’d use a #5 for that instead of the #7, but I haven’t found a single #5 over the past three years. In fact, I was thinking of making my own foreplane using the above mentioned Indian #4 plane’s frog to make a wooden #5, as shown in one of your blogposts, until I noticed the reverse depth-adjustment in the Indian plane. Still looking for a good donor frog to craft my own wooden foreplane #5.

As to the plane of your friend, welding cast iron is possible but not easy due to the brittleness and thermal stresses occurring during the cooling down. The preferred method to repair cast iron is brazing, which is much easier and yields a pretty strong and ductile repair. Any moderately equipped welding shop with oxy-acetylene capability should be able to repair the sole. I have one brazed plane (incidentally, a #3 too) that works just fine and only the different colour of the brazing shows that it has been repaired. I bought it in the repaired condition. I consider the gold-coloured repair a battle scar. I’m sure you and your friend know of the possibility of repairing the sole so I assume you have a good reason for wanting a ‘new’ sole. All my Stanley planes are ‘made in England’, except for a #4 1/2. The frog-seats look very different on mine. Otherwise I’d gladly send you the sole as small token of gratitude for all you do.

Hi Paul,

Just a reminder that you need to be sure that the body is a match with your frog. That plane seems to be a type 15. A body from a type 10 thru 15 will work.

Paul

That is a very nice 1929-30 Type 14 plane. I have a corrugated body that will match everything. It has some patina, no pitting, perhaps 85% japanning, and a good mouth. Whoever restored the broken plane will be able to make this one look the same. $5 plus shipping from Maryland.

Ed

John

I did not see your reply before I made mine. You are right in that the body is a type 15. I thought type 14 because the first thing I noticed was the non-nickeled lever cap with the straight hole. The lever cap with the straight hole was not nickel plated until the 15. The common type studies do not mention this. It must be a replaced lever cap, or from a transitional period between the two types. At any rate, my body is the same as the subject plane.

Ed

I saw your plea in the last line of your post, Paul, and though I do own 2 #5’s (though no #4’s) I can’t really bear to part with either one of them (since one I use, and one is on permanent loan to my students), but I do have a possible source for you (although apparently he doesn’t have any at the moment), and that would be Sandy at Sandy’s Tools, reachable at http://www.sydnassloot.com/ or more directly at [email protected]. I can testify that his prices are reasonable (bought my student’s plane for $38 including USPS shipping), and he doesn’t lie or even ‘stretch’ the truth one single bit. In short, he’s the ideal online tool seller. Hope this helps your friend out, somehow.

I have been thinking about picking up a #3. Did you purchase this solely for its collectors value or do you intend to use it ? For box making and small projects, my 4 1/2 is a little too cumbersome so I’m curious how the 3 performs. Thanks for any insight.

I do lover the number 3 planes and use a Stanley on a regular basis. I have the new Sorby set up to use and will have no hesitation to use it as I need, butI also try to use what people can get their hands on so I am careful not to create something exclusive.

I love using a number 3, but also find a 4 or 4 1/2 to work fine for small boxes.

Harry Moos writing in FWW about 20 years ago if I recall:

“Just a few more strokes on the oilstone and the blade is finished. I look at its edge against the light and there is no reflection. I reassemble the plane and run it over a long piece of pine. The first shaving is too thick. Another adjustment, and then a paper-thin shaving curls away down the length of the board. I make another half-dozen passes before I blow away the bits of wood clinging to the blade, wipe away the fingerprints with an oily cloth, and place the plane on the shelf that I have reserved for it. This once dirty, dull, and rusted piece of iron from a flea market has become a polished, sharpened beauty, ready to take its place among my other old tools. At times like this, I honestly don’t know if I love the tools because they enable me to work wood, of if I work with wood because it gives me a good reason to collect these fine old tools.”

Pretty much sums up my approach to woodworking

By the way, Paul, did you see my offer of a plane body last week?