Unstable Wood? Don’t Panic

My glued wood panels changed overnight. They mostly do. It might happen to you and at first you might panic, recut and reglue. Don’t!

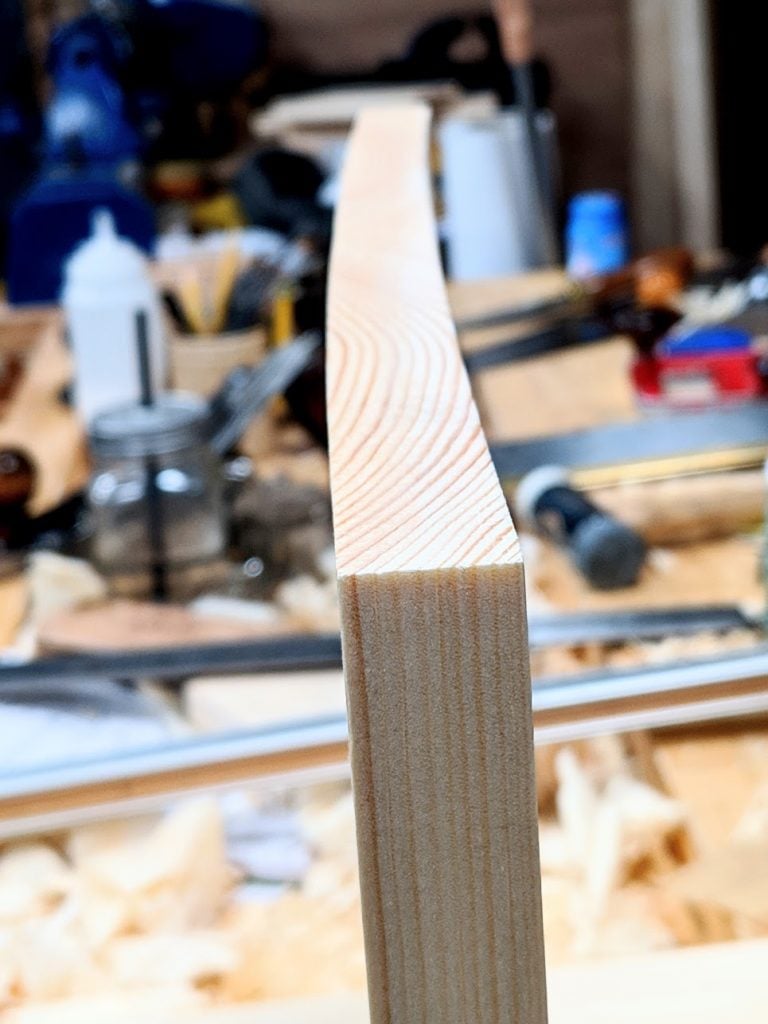

One thing I have learned through the years is that joints constrain wood and rarely does the wood have the power to resist the power of goo joinery. I had glued up my panels before I left for home last night. I had cut them to panel size and left them loose on the bench top. In the morning the topmost board had cup-curved with 1/4″ crown over the 15″ span.

The other boards beneath had remained flat and I knew full well this would happen. I did it on purpose so I could show you what happened.

I took the same board and flipped it over. Three hours later it was dead flat again.

Not only that, the same topmost board had shrunk over a sixteenth of an inch more than its counterpart cut adjacent from the same board. Leaving the board open to the atmosphere of my workshop the board had shrunk in its conditioning.

Leaving the board for the three hours both boards had shrunk to the same level. You can sticker your boards for a more even circulation of air but my preference is to stand or them out so all surfaces get the maximum exposure to the atmosphere. I do this over 24 hours and it works well for woods like pine.

Thanks Paul for this info. With my cold 43 Degree F and 70% humidity shop this happens to me. It is frustrating. My little floor heater raises the temp in my corner (primarily to warm my fingers) where I work but sometimes I think it just makes it not so good for my wood.

Paul you are a gem, really appreciate all your insights.

I share a similar problem, being confined to a corner of the garage with no climate control except a tiny space heater. Cheers to you for soldiering on!

You have the manners of a goat. No class mister, and no respect.

Glad to see there’s still a small corner of the internet where people insist on treating each other with civility.

Too small a corner, sadly.

I was wondering why a panel I glued up about a month ago hadn’t cupped as dramatically as I was expecting. I’d left it unclamped, but on end, in my garage. Still quite flat. For once I inadvertently did something RIGHT!

I removed the poor person. He can’t post now.

I knew that Steve was not making his comment without reason but you had removed the OP before I read Steve’s. Thank you for doing that, Paul. ‘Tis sad that there are those who are so insecure and troubled that they have to post boorish comments. We must not let them succeed.

Thanks for this very helpful posting.

I have just read the ungrammatical, ignorant, aggressive comment from the (perhaps appropriately-named) ‘Patchedupdemon’.

Not only does he have no manners, but he evidently has no imagination and fails to realise that this is a site of interest to woodworkers of all standards, from the absolute beginner to the professional. You have only to follow the woodworking pages of one of the Facebook sites to realise how often the cry for help goes up, along the lines of, ‘I glued up my table-top, fixed on the breadboard ends with screws and lots of glue, and now it’s all split!’ thus proving that there are very many out there who have no idea at all of the basic practicalities. That is why they are there; they need help.

Maybe Patchedupdemon had a bad night on the booze, or some other reason to be so unpleasant, but I hope the rest of us don’t have to put up with this kind of foul-mouthed nonsense again.

I removed it. He can’t post again.

Hi Paul……well done

Can I please ask why in all the three samples you have grain in same direction.

This was covered once by Phil but I have been told In the past that grain in multiple pieces should be in opposite directions to give equal and opposite forces, yours is proof to the opposite?

I hope you can reply……thank you for all you do for us.

Regards John

Yes, in this case the whole will shrink (or expand) in the same direction with no contrariness or conflict. Had I had the sides with grain running in the direction of the long axis I would have built in a serious probability that the top and bottom would crack somewhere at some time and especially if the top and bottom were insufficiently dry by even as little as 1-3% higher than say the 8% we might strive for as in furniture making. Shrinkage of the top and bottom would take place over a short period when moisture levels surrounding the piece drop. That results in cracks because the adjacent side pieces do not shrink discernibly in the length of the wood. In my piece `i will be using a trick to keep my drawers flush at the front and discussing other options as I build the drawers.

Wow Paul …what don’t you know??

I shall show your answer to mine and question below mine

(Oh it’s gone?? Was I seeing things??). As said will show your answer to my carpenter friend for further clarification.

Thanks…regards john

Sir,

I see from the on-end photo, that both pieces of wood that make up the panels are oriented so their rings cup in the same direction. I was wondering if you could talk more about that. Growing up, I was taught to alternate the ring directions on successive boards to reduce cupping. And I was also taught that that was a myth, and one’s primary concern should be matching the grain for the look you want, and not worry which way the rings cup. These two contrary bits of advice have left me with no advice at all. What’s the truth?

With regards,

C.

The most important element here is having the wood dried to a commensurate level to its final home when the piece is completed. Do this and you will keep any distortion to a minimum and you can orient your wood any which way you want. It is also true that wood is its most ‘elastic‘ when it’s at its newest. After a short time the wood settles. It still moves but by far less. Another consideration is the anchorage joints and glue bring to the whole. I hope that this can answer your question. Wood can be constrained but only in certain conditions. Floating panels within a mortise and tenoned frame will stay flat within the constraints of the grooves or rebates with stops affixed. Dovetailed sides will remain flat with the joint and glue holding same to the front. Alternating wood sections for lamination that has not be dried and seasoned down to a commensurate atmospheric moisture content (AMC) will simply result in a washboard effect rather than cupping. Cupping is much easier to constrain with turn buttons or other anchor points or indeed just glue and a housing dado than alternated boards that have washboarded. Focus on drying down to say 7-10% for minimal distortion.

Thanks for the information. As a follow-up question, approximately how long would you recommend allowing wood to dry out/settle before you begin working with it? Presumably this varies by species. Is there some general rule of thumb? Does it take longer with hard woods given their density over a softer species?

Paul, do you use a moisture meter? If so, what type and style (pin, contactless, etc.)?

I use a simple two pin meter made by Brennensthul. £18 and it works fine for me. All I need to know is what’s under 10% and what’s over 10%. Buying wood from a reputable supplier works well as most reputable suppliers are careful enough.

Paul, thanks for another practical/showcase of information.

However, the following part I don’t clearly understand:

“I took the same board and flipped it over. Three hours later it was dead flat again.”

Ok, I though understood why the jointed board cupped, i.e. you didn’t leave the individual boards long enough in your workshop to acclimatize enough, before gluing/joining them up.

However, why did the board go flat again by flipping it over? I though the damage has been done, so did the board straighten itself out due to gravitational pull by its own weight? If that is the case, can one add more weight if the board doesn’t go fully flat after a certain elapsed time period?

Reason for asking, this seems to have happened to some teak wood boards that I glued/jointed together, but it also cupped in the middle. So I am quite eager to see if I will get the same results by flipping it over.

Regards

Wood absorbs the greatest amount through the end grain but it also absorbs through the face at a lesser degree. When boards are stacked and left for a few hours the top board absorbs atmospheric moisture at a faster rate or indeed releases moisture at a faster rate depending on the atmospheric content. that being the case, and because the other boards are isolated from this by the top board, the top board has the greater movement. Flipping the board over mens the new upper side is absorbing (or releasing) and evening out the absorption into the fibres.

Hi Paul,

I’m sorry, but I didn’t understood something. You mentioned that “Wood absorbs the greatest amount through the end grain but it also absorbs through the face at a lesser degree”.

So, why is that on the last photo you stood the boards on the end grain, and not on the edge, since the edge absorbs less moisture?

Thank you for all of these valuable explanations.

I’d guess because it exposes both faces and the bottom edge is negligible..?

They were too long to stand on those facers. What I can’t show in photos is switching them end for end periodically.

Ah! And may I ask how often did you switch them, and how did you realize when to stop switching?

Maybe every half day?

Thank you Paul, will keep this in mind for future projects.

Perfect timing on this post. I just glued up some boards to make a sofa server and the next day they had cupped slightly. It had me questioning my eyes or my sanity. Thanks for keeping me sane.

Thanks to everyone who’s posted questions here. I’ve learned a great deal reading the posts and Paul’s answers. Thank you, Paul for sharing your knowledge with us all.

I live in Colorado where the humidity is quite low but, my workshop is my garage. The garage is not continuously heated and when I work out there I heat the garage with a propane heater. So, the temperature fluctuates a great deal and I imagine the humidity also to some degree.

Does temperature affect cupping and/or washboarding of the wood and are the affects as dramatic as one might expect from changes in humidity?

Thank you kindly.

Ed

Hi Ed,

I was always under the impression that any gas flame heating (e.g. propane) produces quite a bit of water vapour. I’m not sure how much but it might be worth monitoring the garage space humidity with a budget hygrometer and seeing if the humidity goes up once you use the propane heating. I think indirect heating via hot water radiators (gas or oil fired boiler outside of the garage/workshop) or direct electric heating either by electric convector, electric radiating (infrared) or electric blower heating would guarantee that you are not adding to the work space humidity. Just my thoughts.

Regards

One of the by products of burning propane is water or moisture. It’s possible that you may be greatly affecting the humidity of your shop with the propane heater, obviously depending upon installation, venting, etc.

Hello Paul and Happy Belated Birthday!

Before I ask my question please allow me to say Thank You…

I am impressed with your skill and Knowledge… but more so I am wholly impressed with the Man. The man is very impressive.

If I am listening correctly… It is vital to be patient… that even before one goes to work to dimension a rough piece of wood, it is important to allow that wood to acclimate, dry and find it’s final shape.

Paul, Is this correct?

Please adjust my thinking…. I’m very green and havent found my resting space yet.

SAVED $25.00

FROM THIS ARTICLE I BOUGHT NICE PIECE OF WHITE PINE 12×6 FOR DRAWER PROJECT AND AFTER 8 DAYS IN FLORIDA GARAGE SIDES WARPED UP 1 inch will go and flip over lay flat with small weight atop –

THANKS PAUL

Quite good information. Obvious when you think about it, but not something that would occur to most instantly. You really do know some stuff, and I greatly appreciate that you share it.

On the same day, glued up two padauk boards for one panel, glued up two pine boards for a second panel, left two remaining pine boards unglued. All laid flat on the workbench.

Only the glued up pine board cupped, the other two remained flat. What gives?

Thanks.

For those of you making a project using strip glued hardwood panels (perish the thought, but sometimes it’s simply the economically viable alternative), Paul’s information is vital. Since the boards usually come covered in plastic film things get real interesting when you take the film off.

Before making a chest of drawers out of panels I had to leave them standing on edge in the house for a fortnight and then lay them flat and monitor the cupping closely – turning them over as they went off over and over again. After a while the boards stabilised enough and I could bring out what was needed to the workshop piece by piece and bring it back in for storage. A bit of a hassle, but the project was worth the effort.

I did a little experiment a few months back with cupped pine boards. In the past I have straightened cupped plywood by moistening the concave side and heating the convex side. Thin plywood in particular can cup very fast and it can also uncup very fast! Some folk talk about putting it on damp grass in the sun, concave side down, to decup it. So I thought I would try it with pine boards. I scanned the internet and got a number of what seemed authoritative claims such as (a) can’t be done, (b) can be done but often fails (c) can be done easily, (d) if it can be done, moisten the convex side and heat the concave side. (e) if it can be done, moisten the concave side and heat the convex side. Well, that covered most of the possibilities (except for Paul’s — just flip the warped board and wait a while). Any way, I cut sections from a 10″ pine board, lay them all flat, and waited till they cupped (a lot) overnight. I then moistened one side, placed that side down, and heated the other with a radiant heater which hangs from the ceiling over my bench. The board with the concave side moistened and facing down, and the convex side facing up and heated, decupped pretty fast — in a few hours. I let it go for a while more and it began to cup in the other direction! Oh, in my experiments, once a board was decupped, it seemed to stay flat so long as I kept air circulating evenly around it, though that test only lasted a day since I used the nicely flattened boards!.

I noticed your last picture had a sliding {I call it that because I don’t know the proper name} dovetail penciled in. I have been very curious how you do that with hand tools. It would be a good subject for one of your instructional videos unless you have already done one. You’ve done so many and Itry to get to all of them.

Yes, we have several projects filmed with the use of sliding dovetails in them. A coat rail, foot stool and so on.