Christmas!

At Christmas time we tend to escape from going to work as a sort of midwinter respite period of recovery from all the world has thrown at us. It can be a sort of long weekend of sorts, where we extend the usual weekly breaks to spend extra time with family and friends in a festive mood. Gift giving and sharing simple things we do together loads our minds with the memories that mean something to us – so we can recall them at will in the years ahead – memories for warming ourselves as we might hands held up to the glow of a log fire. In my world I remember all the Christmases with great fondness all the way back to my childhood; a time when presents were scarce but richer foods and love were heartening, warm and plentiful.

Those were of course simpler times and that is not just my imagination. What I have learned through my seven decades of life is never to allow myself to fall into self pitying. That way we recall those beautiful small things that somehow meant so much. One of my ultra-fond memories is my mum breaking up peanut brittle sheets into small pieces as we all sat around the open coal fire watching a film on a black and white TV. Why would something like that make me glow? Mostly it was the 6 kids and mum and dad enjoying and sharing each other’s companionship. A jigsaw puzzle or a game or two was all we really needed. Monopoly, snakes and ladders, drafts. Nothing complicated more than a 500 piece jigsaw puzzle.

Of course beyond the four walls we enjoyed snow-filled streets and sledging on home made sleds, making icy-black and treacherous slides along the pavements (sidewalks USA) and of course building snowmen with coal chunks for eyes and a carrot nose. Walks in the woods were always magically silenced by the padding of snow layers on the branches and the woodland floor. The world seemed so hushed even though cars were really quite few in the 1950s. Lakes and ponds froze over and icicles stopped the gutters from leaking with long stalactite spears hanging from the joint lines. What I have always enjoyed as a makerman the most (and still do given half the chance) is sneaking away into the quiet of an hour or two to be by my workbench making. When my boys were little they came with me and made something for either each other or especially their mum. She still owns a dozen or so spatulas or spoons and then too cutting boards or bowls carved with a gouge. These priceless jewels are pulled out every so often where she sits and stares at them for a few minutes, deep in thought. They moved on to finer work in dovetailed boxes, but we never despise the day of small things.

Mostly for me it’s more a clear, clean and put up; reflection becomes automatic as I replace assorted wood to the sorted racks and glance over the finished pieces I’ve made through the year. Do I miss making pieces for others? I do indeed, but I’m unlikely at my time now that I will return to making a piece and selling it to make my living from as a commission or spec’ piece. In many ways I am making as much as I ever did and more except now it’s not in the same quantities. My work has become more important than ever because of my age. It’s good though, very good, because not only do I get to continue making, I also get to involve others through my teaching and training and then too those I work with are quietly working in the background to teach and train too. Over the past two years I have worked alongside Izzy who has been so diligent to set up our Common Woodworking website at commonwoodworking.com. Over that time the site has become populated with all kinds of information to steer visitors in their opening steps along the right path to developing skill. Izzy’s background was not woodworking at all, or it wasn’t, and that is what we really wanted and needed. We needed someone to follow the same path our viewers and readers would follow and Izzy has done just that, she’s followed the same path anyone following commonwoodworkingcom. does in that she too builds each of the pieces, buys the actual tools and trials them, writes the output and the instructions and keeps everything sharp and focussed, be that that the tools she uses or the content on the website. She follows all of the videos and instructions as she does so and so makes certain that all the content is indeed instructional and all the buttons and links work.

The workshop is the heart of what we all ultimately revolve around. The quantity of and tool type I use I try as best I can to keep to a minimum. But then others ultimately creep in from time to time. Perhaps an additional plane, a 4 1/2 maybe, seems to pop up from nowhere, and then the questions from viewers pops up asking, “Why?” My reflections insist that keeping less simplifies more. It removes the misconception that everyone needs more tools. That’s not true for all at all. In more wealthy countries I saw men at shows wearing T shirts that said things like, “He who dies with the most tools wins.” Not too PC any more and to some this seems humorous. To me it’s more silly. To me it speaks of little boys in play whereas for me tools, the workbench, the workshop have always been where `i worked to earn my living. More a sober place without lacking humour though. No it can be consumerism spilling it’s guts out, with little thought that the rest of the big wide world might never own even a very small part of what they have. As an example, here in Britain 200 #4 planes can be had for under £30 most days. So more tools is not best at all in reality. I know that is not accepted by some but, no matter, I find it much less confusing in the workshop to mainly have what I use in the day to day.

By that I mean I really don’t use moulding planes and panel raising planes too much as indeed I would most like never use a power router with the ultimate plethora of moulding bits to mould the edges of my furniture. Why? Well, they don’t even produce the bits with shapes I like and the ones I do like can be completed without special planes. Also, I really never liked power routers. I don’t like the mess they make, the dust they cause, the noise, the moulds they make or much of anything else about them. They’re highly invasive on every front including to my neighbours. But if others add moulds to their bookcases or rout out their housing dadoes with them I have no problem with that. You will never see me set up a machine router to cut dovetails nor use one for the housing dadoes. This too keeps things simple. Now what you may well see, possibly, is me using the bandsaw. It’s quiet, versatile and relatively safe when used properly. You might also see me use a belt sand sander and a random orbit sander. Now there’s a surprise!. I don’t use them much but they’re very efficient in creating a good surface for finishing.

So where do I draw the line for using this or that machine and related equipment? It’s really quite simple. At least it is for me. Generally, the bandsaw rips and crosscuts anything and everything whereas the tablesaw limits itself by its depth of cut and it’s inflexibility in linear cuts. This places the bandsaw at a higher level for me; I can rip through say six inch or thicker stock on a single machine and that cut can be straight or curved. Whereas crosscutting is limited by the depth of throat, I have learned to work around this in different ways not the least of which is by simply crosscutting an extra inch in length by handsaw and then crosscutting to exactness later, when the wood is dimensioned and planed, on the bandsaw. Extra width cuts are more rare than normal and with 99% of my rip cuts being well under 15″ and mostly less than 3-4″ it works perfectly well in the everyday of life. The alternative tablesaw of course offers several other options such as dadoing and grooving, perfectly parallel ripcuts and more. The problem I have is that whereas the work is skilless and easier, it especially neglects my physical workout ploughing, sawing and chopping and such. Quantifying this is nigh on impossible, but I do feel the incredible benefits of exercising in this particular way. And for someone who would never use a gym because of the ‘boredom effect’ as well as non profitable time constraints, hand work of this sort fits all the criteria. Why fix what’s not broke? Oh, and the tablesaw does take a massive footprint when fully set up. If I spin my bandsaw around (it’s on wheels) I can use the long length of the workbench for an infeed or outfeed table and a side support too.

Mortising keeps my upper body and especially shoulder muscles in particularly good shape. Believe it or not, it also improves breathing, posture and much more. Visiting a chiropractor for a couple of sessions to help with a stiff neck from a bike related need, the one thing he commented on was the upper body areas he was working on. “I don’t get to work on many 69 year olds that are in your condition, Paul. Is this from just woodworking? Now I am not saying I will never own another mortise machine being as I recently got rid of one because I had no need of it and I had not used it in ten years. I can see how in my growing older a mortiser might one day be more a necessity than a preferable piece of equipment, that’s all.

Funnily enough I do own a small a compact tablesaw and a chopsaw. The kinds you see on job sites. I don’t use them often, maybe once a year or so, maybe less too. I used to use full sized machines for prepping stock for my classes, where it was nothing to have to dimension 500 pieces ready for the classes. I use the small versions I have now mainly for my garden carpentry, house carpentry and such. I set them up outside for that sort of work; shed building and such. I still use predominantly handsaws, just for repeat cuts say for long rips and such, they save me time and there is little that grates more on us woodworkers than ripping OSB with a handsaw and worse still chip (particle USA) board and such.

So I end my year dwelling on such things knowing that they will be important for others too. Everything is about finding the balance that works for the individual rather than everyone. If you have arthritis, chopping mortises can be far too painful. If you have but an hour to spare, ripping down four inch thick elm with a 24″ handsaw is surely prohibitive. But if you go to the gym just to work on your pectorals, I think you will find hand sawing and chopping an amazingly productive alternative.

Happy Holidays and upcoming birthday!

I like this post. Someone in my semi-circle once said “He who dies with the most toys wins.” At 62 he probably owns the largest Lego set ever sold at retail. Or built one twice as big. And I think he meant “everything”, not toys, and that’s fine for him I guess. No bother though.

I personally own too many tools, especially hand tools – meaning that while most of my work is mostly hand tools now, I only use a small fraction, and boy is my workshop messy!

I am handing down a few of the more useful ones I don’t use to my 8 and 12 year old. I am boxing the others up and placing them into a tall corner until the next yard sale or until I find a use.

Then I will have just what I need on the wall, along with a few hand saws saved back for scrapers (or maybe a hand made scraper plane?) and to practice restoration. And a clean shop. And the peaceful mind that goes along with it.

I wish I could do this for a living. By the way, the leg thing I may have alluded to a while back in another post? The foot amputation went extremely well (it was a good thing), and I looking forward to getting back to the shop in a couple of months or three and making things happen!

Cheers!

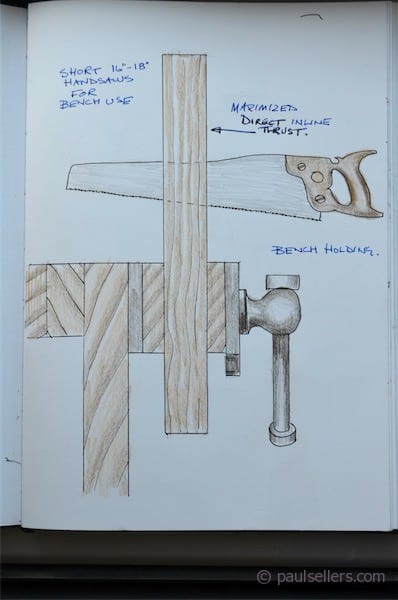

I would like to have a 16-18 inch saw like that in your sketch. Maybe with 11-12 teeth per inch. Seems to me like it would be very handy.

I have had no luck finding one, not even from the high end custom makers.

They are extremely rare. I have often wondered why no one makes a 16-18″ handsaw.

I found a Warranted Superior (generic) 16″ in an antique store for $2, still sharp. It has 8 TPI and I’ve since sharpened it. My wife has an old video on her phone of me sawing out my bench for a drawer using that saw — while sitting in a rocking chair that just happened to be right there at the right height in the right place at the right time. I used the rocking motion to work the saw. She thought it was hilarious.

Would it work to cut down a longer saw into a shorter one or will it change the geometry and dynamics of the saw?

I once heard it said ‘All tools with a cord eventually end up in the trash’. So true for power tools with parts that cannot be replaced or become too costly to justify repair. Power tools certainly have their place for the grunt, repetative or high volume work. For the smaller woodwork projects, there is nothing like building soley by hand putting sharpened hand tools to work and the satisfaction it brings.

I cut an old 26″ panel saw down to 18″.

2″ off at the toe. No discernable loss of ground taper, or flex.

6″ off at the heel. Handle situated before the back narrows.

Paul showed how to shorten a saw-blade when shortening his broken £5 backsaw.

Hi Paul. I thoroughly enjoy your episodes of using hand tools as a true craftsman. I have been doing woodworking for about 20 years but I still see myself as a novice. I have been watching some guitar luthiers build beautiful instruments and would like to give it a try myself. I am concerned about planing the top sound board by hand since the piece is so thin. Can you help me?

I have an 18″ hand saw although I have no idea who made it.You can vaguely make out ‘Gas St’ in a scroll on the blade but the rest is illegible. It has 7 PTS engraved on the heel (which is what it is). It was my dad’s and it’s a great saw.

Happy Holidays

Thank you, Mr. P. Sellers and team.

Thank you for the past years and those to come.

By the way! The fourth photograph is a wonder. Looks like Miss Izzy is on the move.

Oh, I didn’t forget: Happy birthday.

Paul, I hope you, your family, and team have a Merry Christmas and a joyous New year! Oh and Happy birthday on a few days!

Thank you for all the videos and postings!

Paul I truly enjoy and read most of what you write and show us Thanks for sharing and I hope that you and your family have a very Merry Christmas and a Prosperous New Year.

Paul, great Christmas to you and your family and everyone on the team, Merry Christmas to all of the blog !!!

My family and I recently moved to the country and I can say with some certainty it’s been a good move. My bench and tools are waiting to be unpacked and set up. I’ve been settling for a make shift bench in the backyard and find myself using the circular saw a lot, which I wouldn’t normally use, and few other power tools too. Sometimes I think I’d like a thicknesser, it would be nice but I’d become lazy to the process of dimensioning timber.

It’s hot here in Australia and for the time being that can be just as uninspiring as the cold. Good thing the ol’ limbs aren’t seizing up though.

Haven’t made any Xmas gifts this year and I should because I see far too much plastic being used and given, especially to children.

Thanks Paul for the projects you have given this year. I can’t wait to make the bookcase.

Enjoy Christmas everyone.

Paul thank you so much for all your valuable instruction. Have a very merry Christmas and a wonderful birthday.

Regards

Carole.

Paul, as one of the many around the world whom you have helped and instructed, I would like to thank you for providing such inspiring teaching through your videos and blogs. I thoroughly enjoy all you post, whether it’s techniques, tools, projects, photos of your work, or your memories of the past and thoughts about life.

A very happy and joyful Christmas to you, your family and your team.

A most Blessed Christmas and New Years to you and your family Paul and Happy Birthday also!!!

Paul, what an inspiration you are in so many ways . As a frustrated wood worker at present (due to an injury to left hand) , I look forward to your weekly inspiration blogs, enabling me to take a look at the world around me.

I wish you a happy 70th birthday, keep up your inspirational work

Martyn R Parrott

Happy Christmas to you and your family. Thank you again for your wonderful help in a fantastic approach of fine hand woodworking!

Matthieu

Merry Christmas to you and yours Paul. Thanks the gifts you have given us this year!. Looking forward to what’s to come in 2020.