Cutting Out Your Wood

The wood I bought from my friend George is stacked outside the garage workshop in a pile and I have started to work it down to sizeable proportions. Cutting into it I have chestnut, elm and beech slabbed into 1 1/2″, 2″, 3″ and 4″. Before I take it down to working sizes I must decide what size will suit what component size, what components will suit what project and then what wood matches the envisaged project. I calculate that of the dozens of pieces needed to furnish my house the wood I currently have in stock will make about 15-20. The wood I bought had been stored outside under cover and without the ends having been sealed. It all still has the wane and the bark on but the bark is loose and falling off.

Mostly that means that beetles will have laid their eggs in the bark and the grub will find its food in the sapwood just under the cambium. In such cases the grubs bore up and down the narrow band to find the nutrition it needs to survive. Often they will take a detour into heartwood but not too deeply. Two tasks are ahead of me now to ensure minimal damage takes place straight off. Firstly I must decide if wane stays or goes. This can depend on a couple of things – one, whether the beetle work is character-giving or ugly, two, will I want waney edges on the specific piece. Another factor becomes evident with roughsawn wood that has aged over a few years and that is the bark and sapwood starts to disintegrate and becomes punky. This then absorbs and retains moisture which then discolours the heartwood and can lead to further rotting and decomposition. More decisions!

Fifty percent of my wood is already in excellent condition and ready to go as I have had some of it in since 2011. Ideally that’s the way to go but of course that is not always possible for most of us. A moisture meter is a handy and inexpensive piece of equipment. You don’t need an expensive one. Wood you have had in and in good storage conditions needs no more testing than just being in dry conditions with circulating air. Buying in wood is better either moisture tested or kept for a number of months. We can’t always do that so the moisture meter comes in then to make sure. Of course this is only important in areas where shrinkage affects the whole. Places where opposing components will not shrink at the same rate or where there are mitres and such. Breadboard ends is a good example as is wide picture framing.

Wane is not particularly attractive in large quantities but when carefully chosen it can make a distinctive alternative. I certainly would not want all table tops to have waney edges and calling it “live edge” doesn’t alter the intrusion if it’s not desired. In my world, ‘live edge‘ and ‘character‘ this or that often translates into lack of imagination, not always though.

Just that I often see these lazy descriptions placed on slovenly work. I have seen it successfully used by many makers to really enhance spaces that can actually be difficult with more traditional pieces. I have also seen it overwhelm small spaces and conflict with what exists. I would use it carefully and enjoy it in the write places but not necessarily in large quantities.

There are some really nice accent pieces that lend themselves to large areas like entryways and offices, large lounges and such. Places where they nor the room overwhelm. I’ll be looking into this more when I build the pieces for the house. The rooms are not big, but having the wood drying is inspiring and we will see what transpires.

Paul –

Just curious…with so much rough sawn wood, will you initially dimension by hand or machine?

Thanks.

Eric

It’s a combination of handsaw, bandsaw and hand planing.

Paul,

You mention 15-20 pieces out of the wood you have on hand. As you build pieces for the new house, will you be showing how you optimize the use of your unmilled lumber when laying out rough cuts?

I feel as is if I am wasting wood when rough cutting (oversizing my rough cuts), but it seems, probably due to my skill level, that this is necessary when milling all the wood by hand. I am hoping I can get a sense if I am being as conservative as I can be when cutting up unmilled lumber or if I need to improve in this area.

It is a difficult one because people are as time strapped as I am. Economy of time is important so taking wood even from roughsawn boards to bench quality and milled is quite an extravagance. But I may pull together a video on how I work that would show my general considerations for reduction which could be applied to all wood.

I’ll keep an eye out for it.

That would be a most useful video. I do hope you find the time to do it!

I think this will be a popular video!

WOW Paul that lot will sort the boys from the men, next thing we will see you digging for a saw pit!! Fantastic stuff

Do I see some in your lovely warm workshop?? Those wormy blighters will be jumping out and attacking in secret corners like a jack in the box, with a new spring. Will love following this one…..thanks john

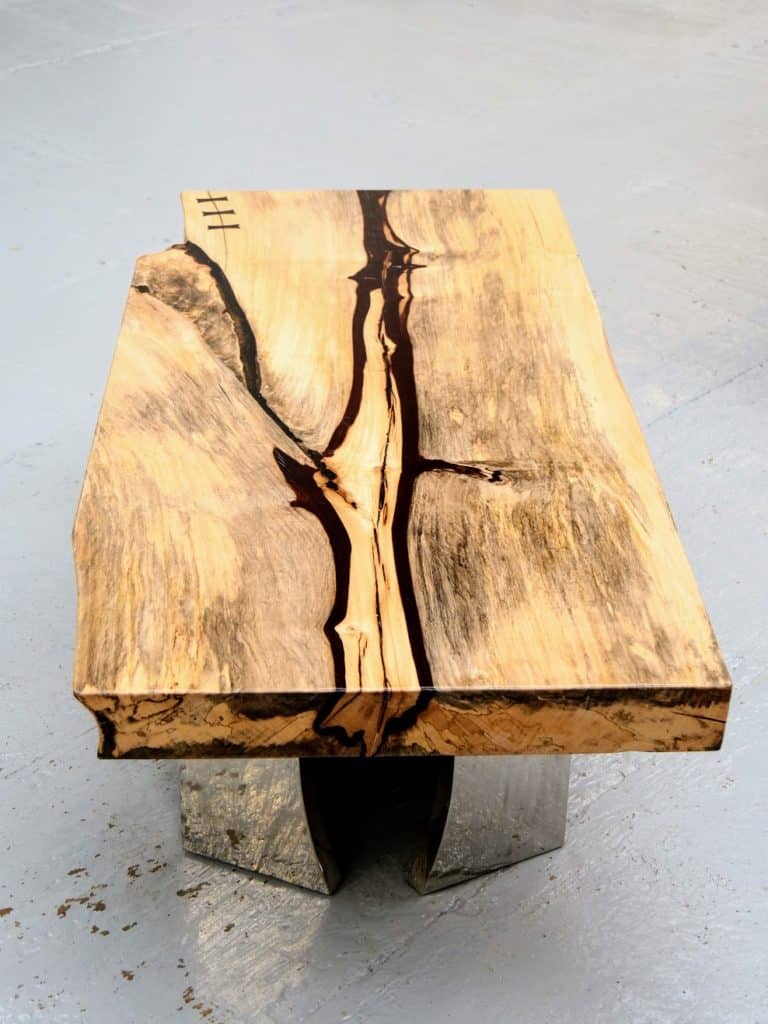

I’ve never liked the infill acrylic too much, on the perimeter it looks good as shown tho.

It’s not my choice but this artists is a truly creative artisan and I like the levels he goes to in his individualistic pursuit of both art and craft in a combined form. He’s also a neat person to know too.

I was splitting hickory for fire wood when on the underside of the bark I found the most fascinating traces made by the wood beetle worm: https://scontent-iad3-1.xx.fbcdn.net/v/t1.0-9/s960x960/67404306_10156997478901549_8362353998790918144_o.jpg?_nc_cat=102&_nc_ohc=02R-JZpuL9EAQlQcah4-FPRRzkolW7JbSLNK35rLtRmdCIFonh_xNRL0w&_nc_ht=scontent-iad3-1.xx&oh=f1d84036b8b96672af77bcdd304d7f33&oe=5E868872

That is indeed nice.

Hello Paul,

I have some oak that was harvested locally and the ends weren’t sealed before it was stacked. There is cracking 6 inches in on some of the boards and I suppose this will have to be sacrificed. I was told that dipping the end in molten paraffin wax is a good sealant during drying but wondered what you recommend ?

Paint will work fine. Paraffin wax too but that’s not the most convenient to get hold of. Use either acrylic or oil-based paint.

In the United States paraffin wax is found in the cooking aisle of the grocery store because it is sometimes used when preserving food in mason jars. The box is often 3x3x6 inches.

Paint works fine. Just as well. The rest of the world won’t find it in the cooking aisle.

I like that you mentioned “live edge”. We see that term used as we used to say “rustic”. So many times we have allowed ourselves to call work a popular catch phrase to hide the fact that we may have not spent the time we probably should have on a piece. It turned out a little sloppy? Oh, that’s rustic.

I’m curious. Is that a doll house with a miniature stool and table sitting on the banana box?

It is indeed, well spotted. For my youngest granddaughter in a few months, when she is older. She’s just one now.

Wonderful gift! Many blessings to you and yours.

A wonderful gift! Many blessings to you and yours. Thank you for all you do.

Hi Paul…Using a moisture meter what percentage of moisture is optimum for woodworking?

USE MIRRORS PIC HERE placeholder was not removed when photos were added to the article, it seems